WARNING!

This heater must be installed and serviced by trained gas installation and service personnel only!

Improper installation, adjustment, alteration, service, or maintenance can cause property damage,

injury or death. Read and understand the instructions thoroughly before installing or servicing

equipment.

CAUTION

WARNING!

NOTICE

Warning Symbols

Safety is the most important consideration during installation and maintenance of the infra-red heater. You will see the

following symbols and signal words when there is a hazard related to safety or property damage.

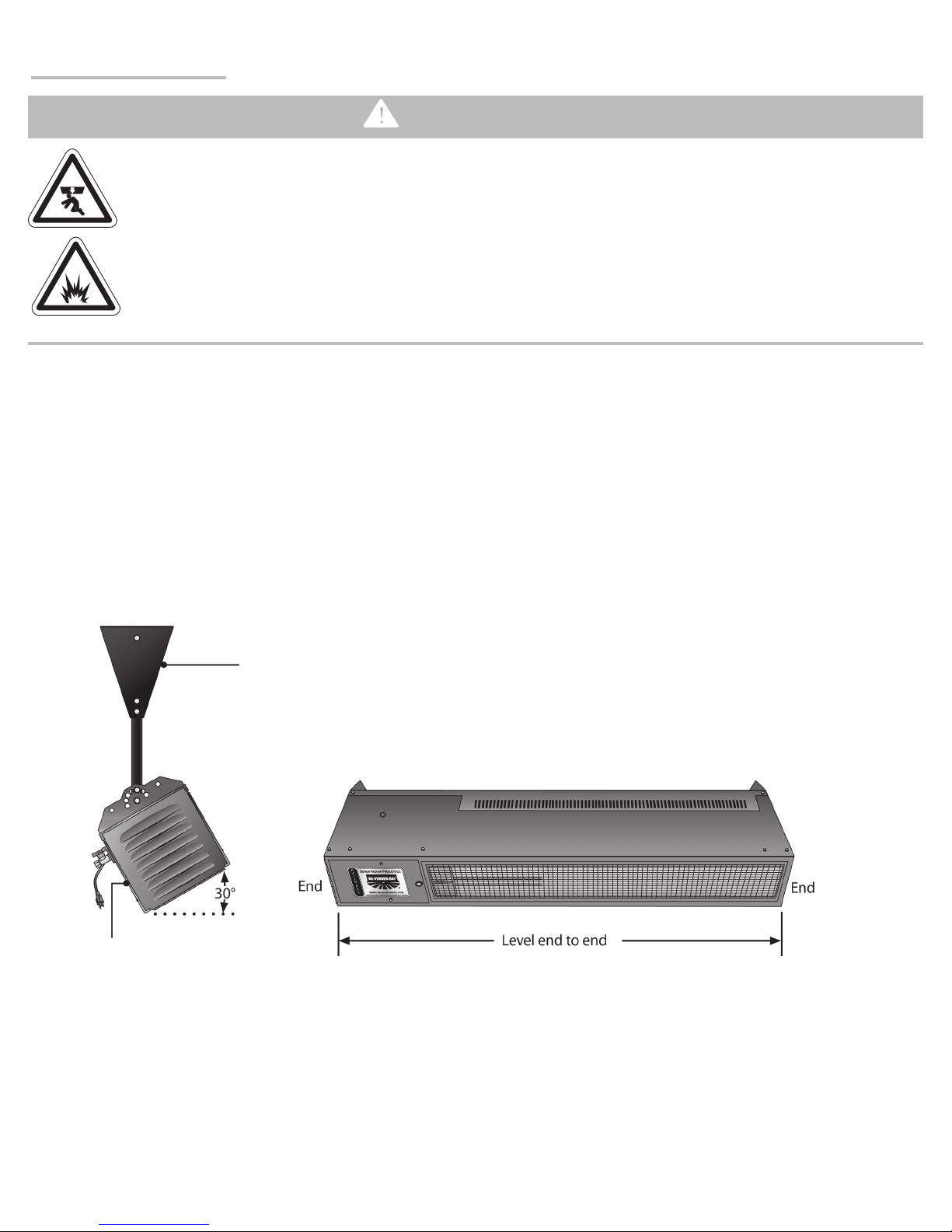

Application Considerations

• Infra-red heaters are designed and certied for use in industrial and commercial buildings such as outdoor restaurant

patios, warehouses, manufacturing plants, aircraft hangers and vehicle maintenance shops. For maximum safety, the

building must be evaluated for potential hazards before installing the heating system. A critical safety factor to consider

before installation is the clearances to combustibles.

• This heater may only be used in outdoor residential applications and is NOT approved for use in any indoor

residential application. This includes, but is not limited to, attached garages, living quarters, solarium, etc. Consult the

local re marshal and/or insurance provider if unsure of your application.

• The installation of this heater must conform with local building codes or, in the absence of local codes, with the current

CAN/CSA B149.1 and 2 and with the Canadian Electrical Code C22.1-latest edition.

• Check the CSA rating label on the heater to verify model number. Check and maintain the attached minimum

clearances to combustibles label and the proper gas to be used. Check all labels on the heater to verify proper

mounting.

• If an external electrical source is utilized, the heater must be electrically grounded in accordance with the Canadian

Electrical Code C22.1-latest edition.

• The installation of this heater in public garages must conform with the Canadian Electrical Code C22.1-latest edition

when an external source is utilized.

• In the installation for aircraft hangers, the heater must be installed at least 10 ft. (3 m) above upper wing surface and

engine enclosures of the highest aircraft which might be stored in the hanger. In areas adjoining to the aircraft storage

area, the heaters must be installed at least 8 ft. (2.4 m) above oor. The heater must be located in areas where they

will not be subject to contact by aircraft, cranes, moveable scaffolding or other objects.

• Under no circumstance is either the gas supply line or the electrical supply line to the heater to provide any assistance

in the suspension of the heater. The weight of the heater must be entirely suspended from a permanent part of the

building structure having adequate load characteristics.

1.0 Safety

1.0 Safety • Warning Symbols • Applications

Warning indicates a potentially hazardous situation

which, if not avoided, could result in death or injury.

Caution indicates a potentially hazardous situation

which, if not avoided, could result in minor or moderate

injury.

Notice indicates a potentially hazardous situation which,

if not avoided, could result in property damage.

3