Page 8 Supplement 29376

Series A6 andInstallationSupplement 29376

Series A6 &InstallationSupplement 29376

Series A6 Rear Pump Module Parts List

Item Qty. Description Part No. Part No.

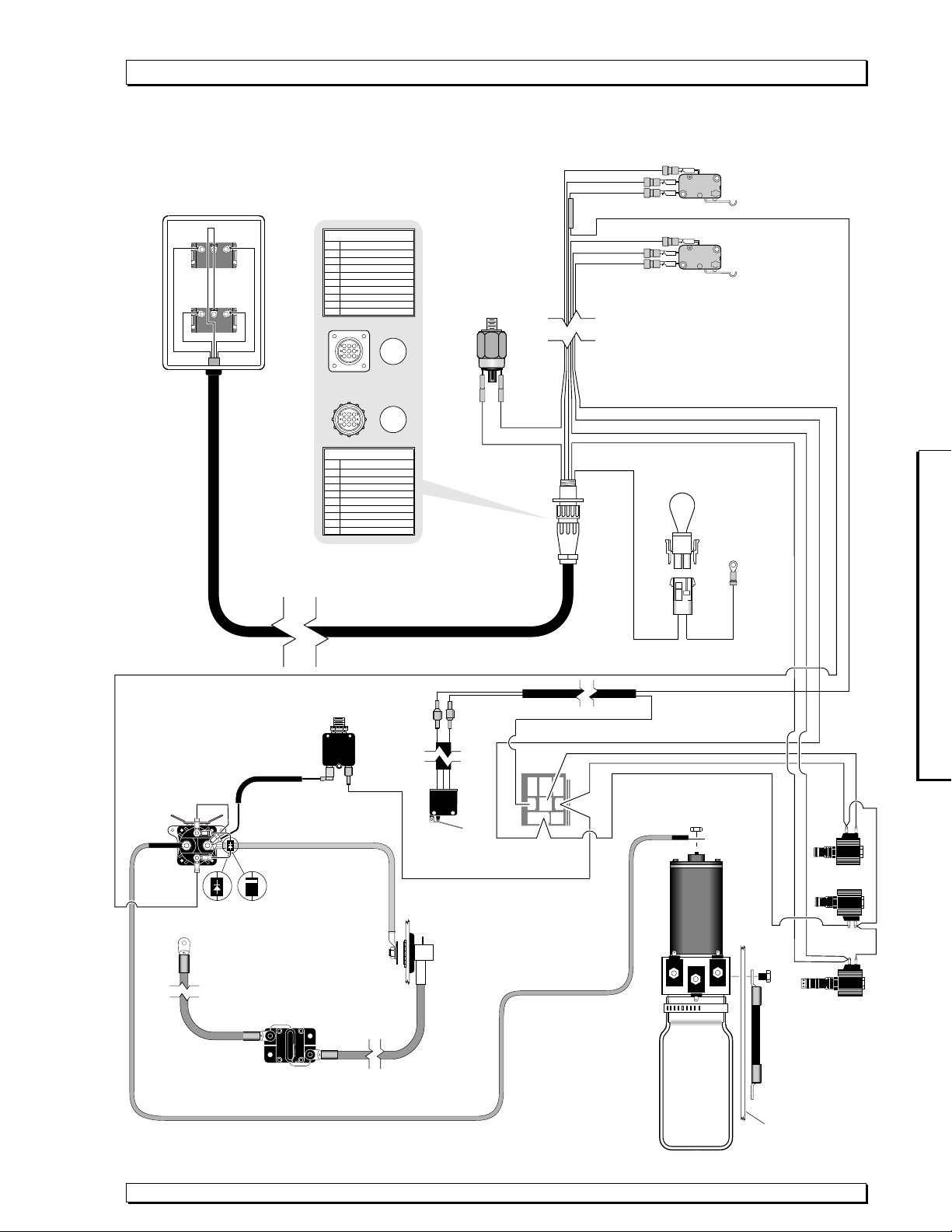

1 Pump Module (complete), 12 Volt, Rear 915R6516IBQD 915R6516IBQD

1 1 Pump Assembly (M268 with Reservoir/with Backup pump) Bridge, Prestolite 25597A12V-A6 25597A12V-A6

2 2 Fitting, 7/16”-20 O-Ring Male / 7/16”-20 JIC 37°Male 24504 24504

3 1 Elbow, 7/16”-20 JIC 37°Female Swivel (1) / 7/16”-20 JIC 37°Male (2) 26579 26579

4 1 Switch, Pressure 26577 26577

5 1 Harness, Pressure Switch / Up - Fold Microswitch 25811A 25811A

61See Control Box Assembly and Harness Options ✘See note below

71See Control Box Assembly and Harness Options ✘See note below

8 1 Control Box, Bracket-mount (Items 9, 10 and 11) ✘See note below 16970A 16970A

9 1 Control Box (only) ✘See note below 16932 16932

10 1 Clip, Bracket-mount ✘See note below 16933 16933

11 3 Screw, #6-20 x 1-1/4", Pan Head, Phillips ✘See note below 16945 16945

12 1 Face Plate and Switch Assembly ✘See note below 17909A-05 17909A-05

13 1 Face Plate ✘See note below 16931-05 16931-05

14 1 Switch, S.P.D.T., Rocker (Unfold/Fold) - Orange ✘See note below 17332 17332

15 1 Switch, S.P.D.T., Rocker (Down/Up) - Red ✘See note below 16942 16942

16 4 Screw, #6-20 x 3/4", Pan Head, Phillips ✘See note below 24739 24739

17 1 Strain Relief (SR 7W-2) ✘See note below (7A, 7B and 7C only) 11352 11352

18 1 Cover, Switch Box 26798 26798

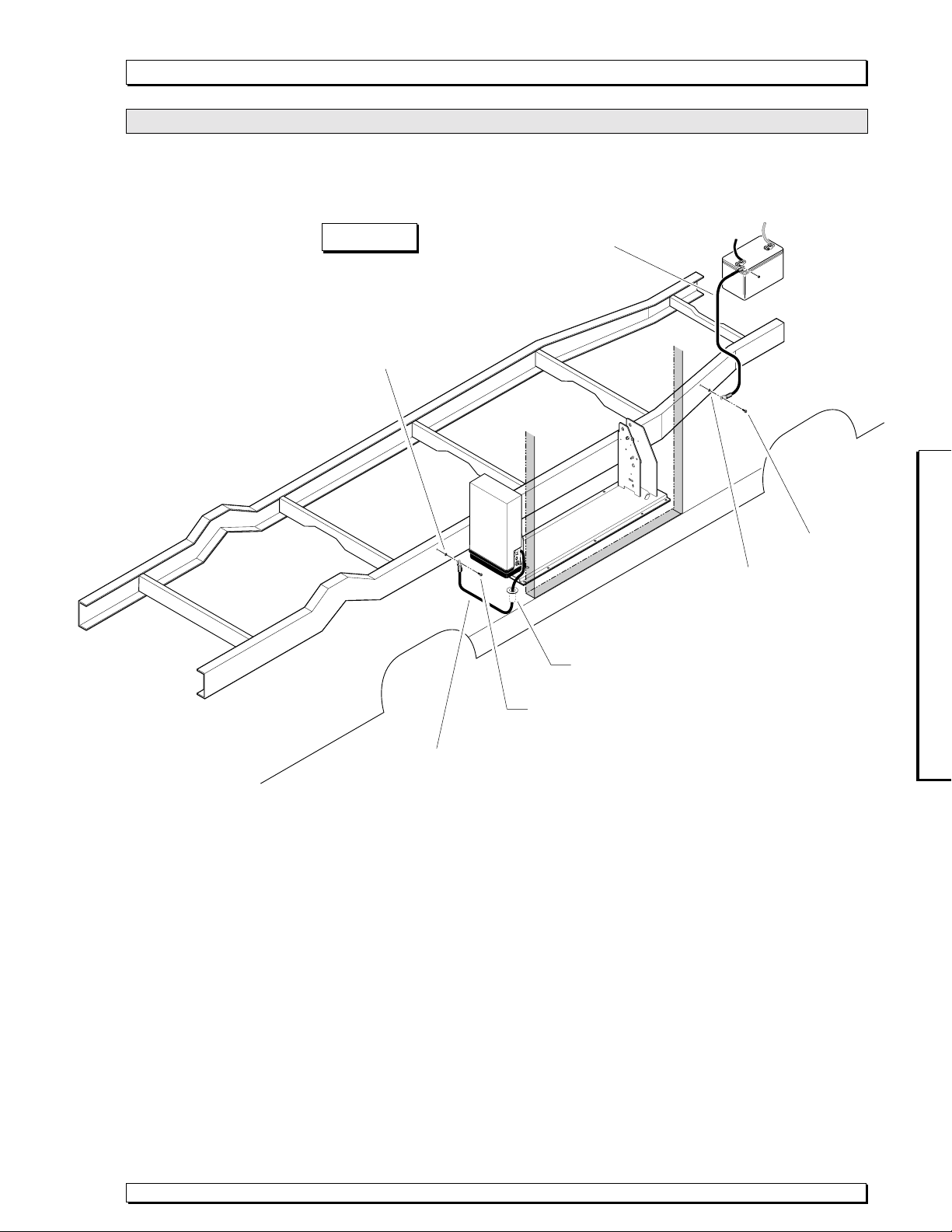

19 1 Plate, Backing / Mounting, Rear - Series A6 915R6501 915R6501

20 1 Harness, Pump Module ✘See note below 918R3914IBQD 915R3914IBQD

21 4 Snap Rivet, 1/8”, Nylon, Black 25759 25759

22 1 Jumper, Interlock ✘See note below 15708A 15708A

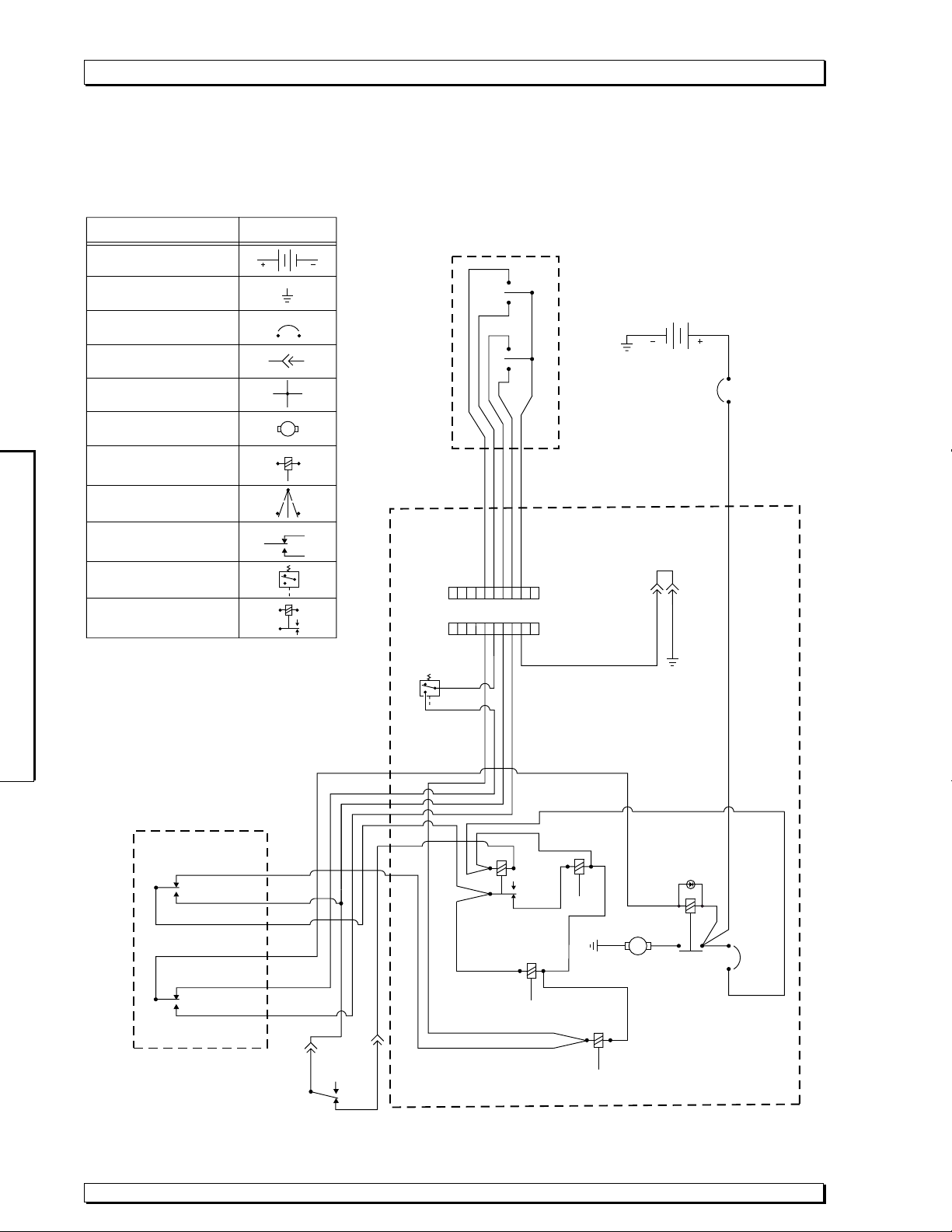

23 1 Relay, 30 Amp, S.P.D.T., 12 Volt ✘See note below 18087 18087

24 1 Pop Rivet, SD64BS, 3/16" ✘See note below 11513 11513

25 1 Washer, #10 Flat 11541 11541

26 2 Washer, 5/16” Flat 10063 10063

27 1 Cable, Ground - 36" ✘See note below 26161A 26161A

28 4 Bolt, 5/16”-18 x 1/2”, Nylock, Hex (3 shown) * See note below 10012 10012

29 1 Solenoid, Up - Prestolite Short / 100 Amp - 12V 28308 28308

30 1 Jumper, 16 Gauge 800-2000 800-2000

31 1 Diode Assembly, Up Solenoid 73906A 73906A

32 1 Power Cable, Millennium - Up Solenoid to Motor 29049 29049

33 1 Harness, Solenoid / Microswitch 25810A 25810A

34 1 Cable, Pump Module Hookup / Power 26082A-4 26082A-4

35 1 Harness, Up Solenoid / Circuit Breaker 25809A 25809A

36 1 Circuit Breaker, 5 Amp, Manual Reset 25736 25736

37 1 Stud, Power Feed 26084 26084

38 1 Cable, Lift Power, 37' with Loom ✘See note below 205-0712-37 205-0712-37

39 1 Rubber Boot, Red ✘See note below 82046 82046

40 1 Clip, Cable, 1/2”, Plastic ✘See note below 10092 10092

41 1 Snap Rivet, 3/16”, Nylon, Black ✘See note below 25973 25973

42 1 Clamp, Hose 17069 17069

L918, L918IB L919, L919IB

✘Indicates items available for replacement part purposes only. These items are not included with replacement pump

modules.

* Apply red #271 Thread Locker Loctite®to the three pump mounting bolts (item 28) if a blue nylon patch is not present

on the bolts when retrofitting an M268 pump assembly. Loctite®is available from The Braun Corporation under part

number 11522-1.

L915, L915IB L917, L917IB

Item Qty. Description Part No.

6A 1 Control Box Assembly (with Standard Quick Disconnect Harness) ✘See Note Below 900-0903AQD

6B 1 Control Box Assembly (with Armored Quick Disconnect Harness) ✘See Note Below 900-0903AQDA

6C 1 Control Box Assembly (with Coiled Quick Disconnect Harness) ✘See Note Below 900-0903AQDC

6D 1 Control Box Assembly (with 7' Long, 18 Ga., Quick Disconnect Harness) ✘See Note Below (not shown) 900-5903AQD

7A 1 Harness, Standard, Quick Disconnect (without control box)✘See Note Below 900-0902AQD

7B 1 Harness, Armored, Quick Disconnect (without control box)✘See Note Below 900-0902AQDA

7C 1 Harness, Coiled, Quick Disconnect (without control box)✘See Note Below 900-0902AQDC

7D 1 Harness, 7' Long, 18 Ga., Quick Disconnect (without control box)✘See Note Below (not shown) 900-5902AQD

Control Box Assembly and Harness Options

L916, L916IB