Bray 54 Series User manual

SERIES

PROXIMITY SENSORS

Installation Operation and Maintenance Manual

BRAY.COM THE HIGH PERFORMANCE COMPANY

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

1 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

TABLE OF CONTENTS

Definition of Terms

Introduction

Hazard-Free Use

Qualified Personnel

Pre-installed storage

Adjustment

Connections (Operation)

Sensor Part Numbers

Required Tools

Numbering

Operation Overview

Activators

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

2 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

DEFINITION OF TERMS

All information within this manual is relevant to the safe operation

and proper care of your Bray product Please understand the

following examples of information used throughout this manual

DANGER

Indicates a potentially hazardous situation which if not avoided

will result in death or serious injury

WARNING

Indicates a potentially hazardous situation which if not avoided

could result in death or serious injury

CAUTION

Indicates a potentially hazardous situation which if not avoided

could result in minor or moderate injury

NOTICE

Used without the safety alert symbol indicates a potential

situation which if not avoided may result in an undesirable result

or state including property damage

READ AND FOLLOW THESE INSTRUCTIONS CAREFULLY

SAVE THIS MANUAL FOR FUTURE USE

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

3 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

INTRODUCTION

All information within this manual is relevant to the safe operation

and proper care of your Bray product Please understand the

following examples of information used throughout this manual

The Series Proximity Sensor has been designed to provide

valve position indication utilizing various signal types Each of

these configurations will be covered in more detail on the pages

that follow

All Bray S Proximity Sensors utilize solid state switches

Although the solid state switch performs the same function as a

conventional mechanical switch there are dierences in the way

solid state switches operate

NOTICE

It is very important for the user to pay close attention to the

exact specifications of their sensor in order to avoid damaging

the unit

Solid state switches have current restrictions imposed by the

semi conducting materials used to form the sensor These

current limitations have to be accounted for during setup

Unlike mechanical switches which can normally handle several

amperes of current flowing through them solid state switches are

generally rated for half an ampere or less

NOTICE

The electrical characteristics of the S must be compatible with

the application

When working with the S several parameters must be

considered A few of which (with significant importance) are

listed here

> operating voltage

> maximum switching current

> output voltage drop

> residual current.

Using an S outside of these parameter limits can cause damage

to the unit and void factory warranty

Operating voltage is the amount of voltage necessary for the

sensor to operate The maximum switching current is the largest

amount of current that the sensor’s solid state electronics can

have flowing through them in the on-state (when the target is in

proximity of the sensor) During commissioning it is up to the

user to correctly apply the sensor to their control system in order

to limit the current flowing through the device All the necessary

information can be found in the technical manual

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

4 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

Introduction continued

Output voltage drop is defined as the amount of voltage that

will drop across the solid state switch This voltage drop will

often vary with the amount of current flowing through the sensor

and the load This drop in voltage becomes paramount when

connecting several proximity sensors in series each unit will have

a voltage drop across it – adding each subsequent drop and

subtracting from the supply voltage yields the resulting voltage

at the end of the series connection The user needs to ensure that

the supply voltage is large enough so that the resulting voltage

after all the drops is above the minimum operating voltage of

the last S in the series connection Sensors located a great

distance from the load require consideration as well as a general

rule every ft of wire will have a resistance of (see

electrical code references for the resistance value of specific wire

sizes) It is important for the customer to ensure that the distance

between the S and the control panel is not long enough to

cause the voltage drop to fall below the minimum operating

voltage of the sensor

Residual current is often referred to as leakage current In the

“o” state (target is NOT in proximity of the sensor) the sensor

draws a small amount of current in order to power the device’s

electronics This is necessary for the device to sense the target

at any point in time when the supply voltage is applied It is

important that this residual current is below the maximum o-

state current rating of the control system

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

5 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

HAZARD-FREE USE

This device left the factory in proper condition to be safely

installed and operated in a hazard-free manner The notes and

warnings in this document must be observed by the user if this

safe condition is to be maintained and hazard-free operation of

the device assured

Take all necessary precautions to prevent damage due to rough

handling impact or improper storage Do not use abrasive

compounds to clean or scrape its surfaces with any objects

Configuration and calibration procedures are described in this

document Proper configuration and calibration is required for

the safe operation of this product

The control system in which the unit is installed must have

proper safeguards to prevent injury to personnel or damage to

equipment should failure of system components occur

This document does not cover every detail about every version

of the product described It cannot take into account every

potential occurrence in installation operation maintenance and

use

If situations transpire that are not documented in sucient detail

please request the required information from the Bray Distributor

or Representative responsible for your area

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

6 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

QUALIFIED PERSONNEL

A qualified person in terms of this document is one who is

familiar with the installation commissioning and operation of the

product and who has appropriate qualifications such as

> Is trained in the operation and maintenance of pneumatic

pressure equipment and systems in accordance with

established safety practices.

> Is trained or authorized to energize, de-energize, ground, tag

and lock electrical circuits and equipment in accordance with

established safety practices.

> Is trained in the proper use and care of personal protective

equipment (PPE) in accordance with established safety

practices.

> Is trained in first aid.

> In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in the operation,

commissioning, and maintenance of equipment in hazardous

locations.

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

7 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

PRE-INSTALLED STORAGE

Bray Series Proximity Sensors are not weatherproof until

the unit is properly installed or all conduits and applicable port

connections are sealed o and prepared for storage The units

may be shipped with temporary covers to prevent foreign matter

from entering through the conduit openings however the user is

responsible for replacing with the proper sealing plugs to support

its NEMAIP ratings

To prevent condensation from forming inside the unit maintain

a near constant external temperature and store indoors in a well

ventilated clean dry room The temperature shall be between

F (C) and F (C) with a relative humidity less than

Store units away from vibration and direct sunlight exposure

and place units on a shelf or wooden pallet in order to protect

against dampness Keep units covered to protect against dust

and dirt if storing for long term placing the unit inside a plastic

sealed bag may be preferred

Bray cannot accept responsibility for deterioration caused on-site

once the cover is removed or due to improper storage

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

8 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

1

1

ADJUSTMENT

Adjusting the Activator

Adjustable activators are for customers that want the flexibility

to position their indication limits outside of the standard zero to

ninety degrees The three pieces of the adjustable activator can

be rotated in five degree increments To adjust follow the steps

below

1. Loosen the allen head bolt which holds the three pieces of the

activator on the pinion.

2. Rotate the relevant piece until the desired amount of travel is

achieved.

a Use the incremental degree marks on the activator for

reference

3. Ensure the yellow indicator is set to match the valve disc

position.

4. Tighten the allen head bolt.

Adjusting the High Visibility Activator

1. Remove the two activator cover bolts.

2. Remove activator cover by pulling up and away from the

actuator.

3. Loosen center allen head bolt holding the activator to the

pinion.

4. Rotate the relevant piece of the activator until the desired

amount of rotation is achieved.

a Insure that the open and close activator is visible when

the cover shield is installed

5. Re-tighten the center allen head bolt locking the activator to

the pinion.

6. Install the cover and mounting bolts.

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

9 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

S-connector

Y-connector

System side

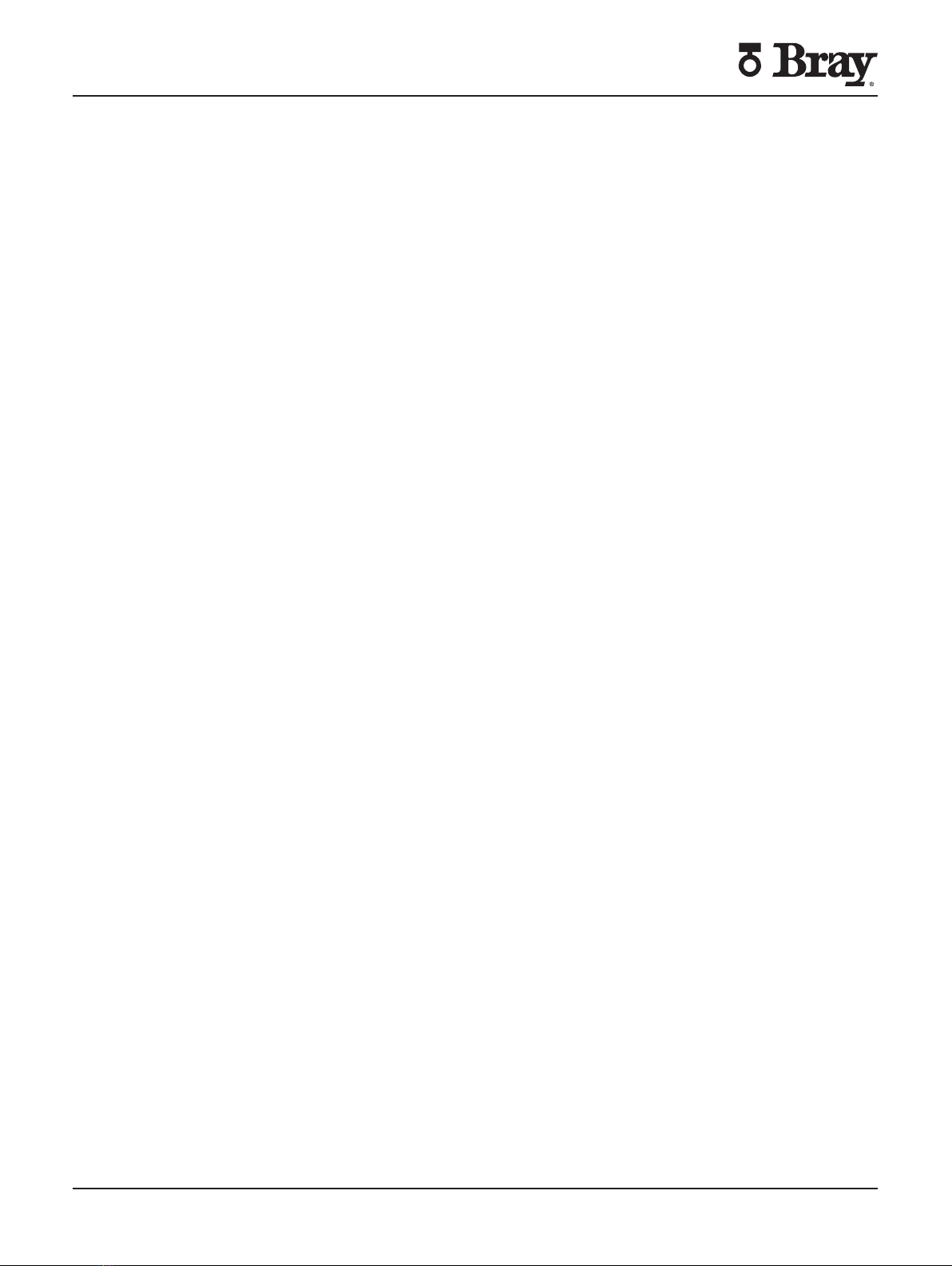

CONNECTIONS (OPERATION)

Bray oers three dierent connections to satisfy the customer’s

application requirements Each sensor’s pin connection is listed

in its respective technical manual Turn o all power and lockout

tag out service panel before installing or modifying any electrical

wiring

Sensor Only

Sensor connection supplies sensor power and signal output

Sensor and Solenoid (Shared)

Y-connectors are used to allow solenoid control on sensors

without dedicated solenoid outputs The system side line carries

both the sensor and solenoid power The system side line splits to

supply power and signal to sensor and solenoid

Sensor and Solenoid (Independent)

Bray also oers sensors with dedicated solenoid outputs In this

set up the sensor signal and solenoid power are transmitted on

the main system side line The solenoid is activated via power

supplied from the sensor through the S-connector S-connector

selection can be found in the sensor technical manual

Cable Gland Connections

M cable gland connections are found on the following sensors

-

-

-

- (included in Kit PN -xx)

In order to field-wire these models follow these guidelines

1. Take the sensor cover o. The cover should be kept on hand

for reference.

2. Wire the sensor as per the wiring diagram on the outside of

the sensor cover or technical specification sheet.

3. Close the cover and securely tighten cover screws

Range of wire size gauge acceptable

(single conductor per terminal)

General: 16 to 28AWG

Industrial: 14 to 22AWG

Hazardous: 14 to 22AWG

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

10 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

NOTICE

Cable glands used must be certified in accordance with the

application The temperature range of cable glands must

be selected according to application The degree of ingress

protection must not be reduced by cable glands

The cable gland connections must be properly sealed to maintain

the Ingress Protection rating of the S sensor Use a seal that

meet the requirements of the application

If the sensor is mounted on a vertical pipe it is recommended

that the sensor be positioned with the cable glands on the

bottom to prevent condensation from entering the sensor

through its conduits

In all cases the conduit should be positioned to prevent drainage

into the sensor

Ensure adequate drainage of wiring conduit to prevent water

contamination inside sensor

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

11 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

REQUIRED TOOLS

Hex key wrench

Hex key wrench

Hex key wrench

Screw Driver - Philips

Screw Driver - Flat

SENSOR PART NUMBERS

Bray Part Number Electrical Output

- DC -wire PNP

- Intrinsically Safe

- ACDC

- ASi-Interface Out

- Intrinsically Safe

- ASi-Interface Out

- DC -wire PNP

- DC -wire

- DC -wire

- DC w-wire PNP

-* DC Wire - Hazardous Location Out

*Included in kit PN54010-126XX536

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

12 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

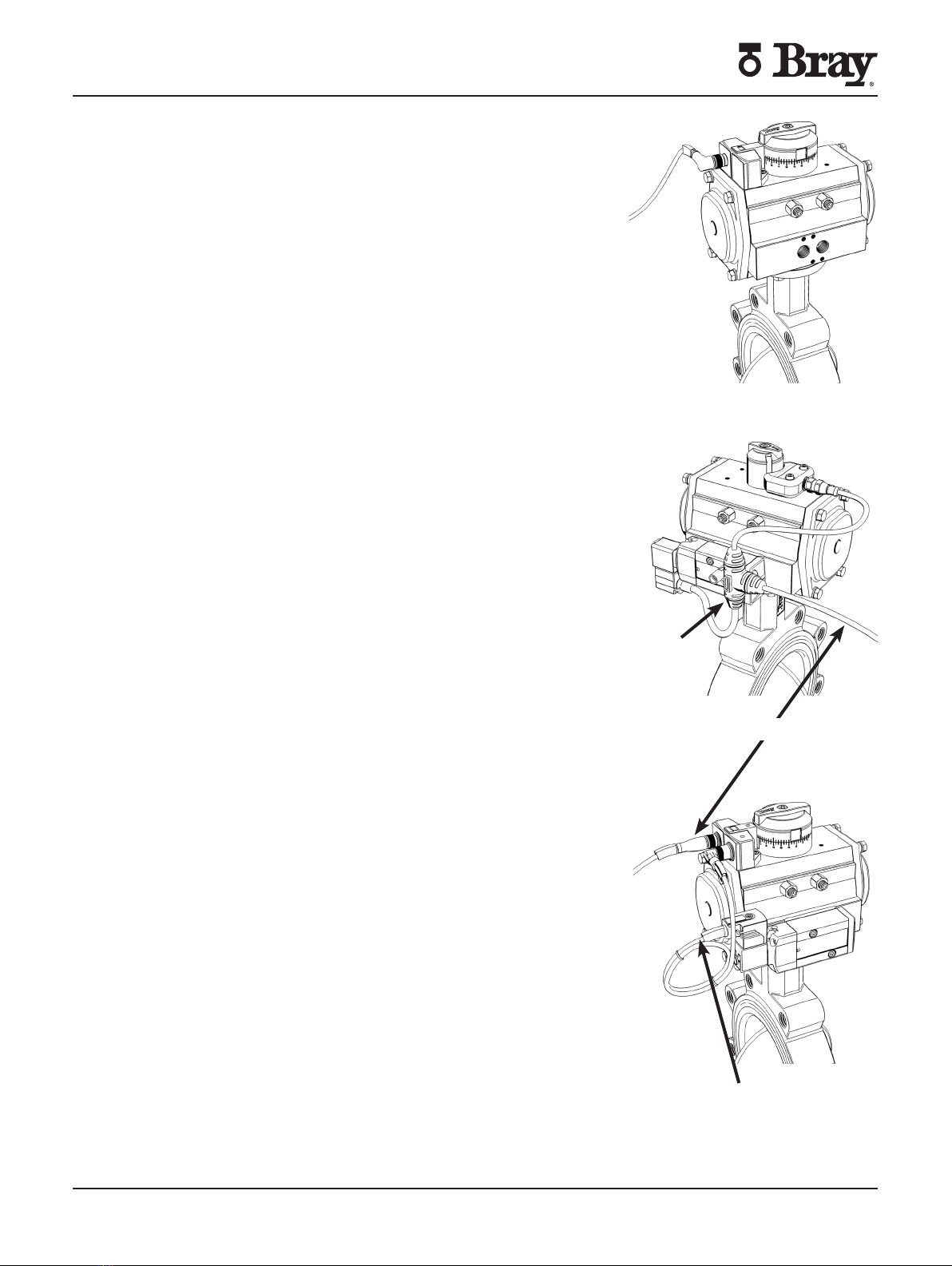

NUMBERING

Sensor Part Numbering

V

ersion

00: Plastic Base

01: Aluminum Base

Housing

0: Large Housing with Connector

1: Large Housing with Conduit Entry

2: Small Housing with Connector

3: Small Housing with Conduit Entry

4: Large Housing with Rd24 Connection

Electrical Output

1: DC 3 wire PNP

2: DC 2 wir

e Dual Function

3: Intrinsically Safe

4: AC/DC

5: AS-i

Activator Kit Numbering

Smallest

Actuator Size

For S92/93

0:

Imperial

5: Metric

A: Adjustable

B: Non-Adjustable

C: High Visibility

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

13 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Madein Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Made in Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

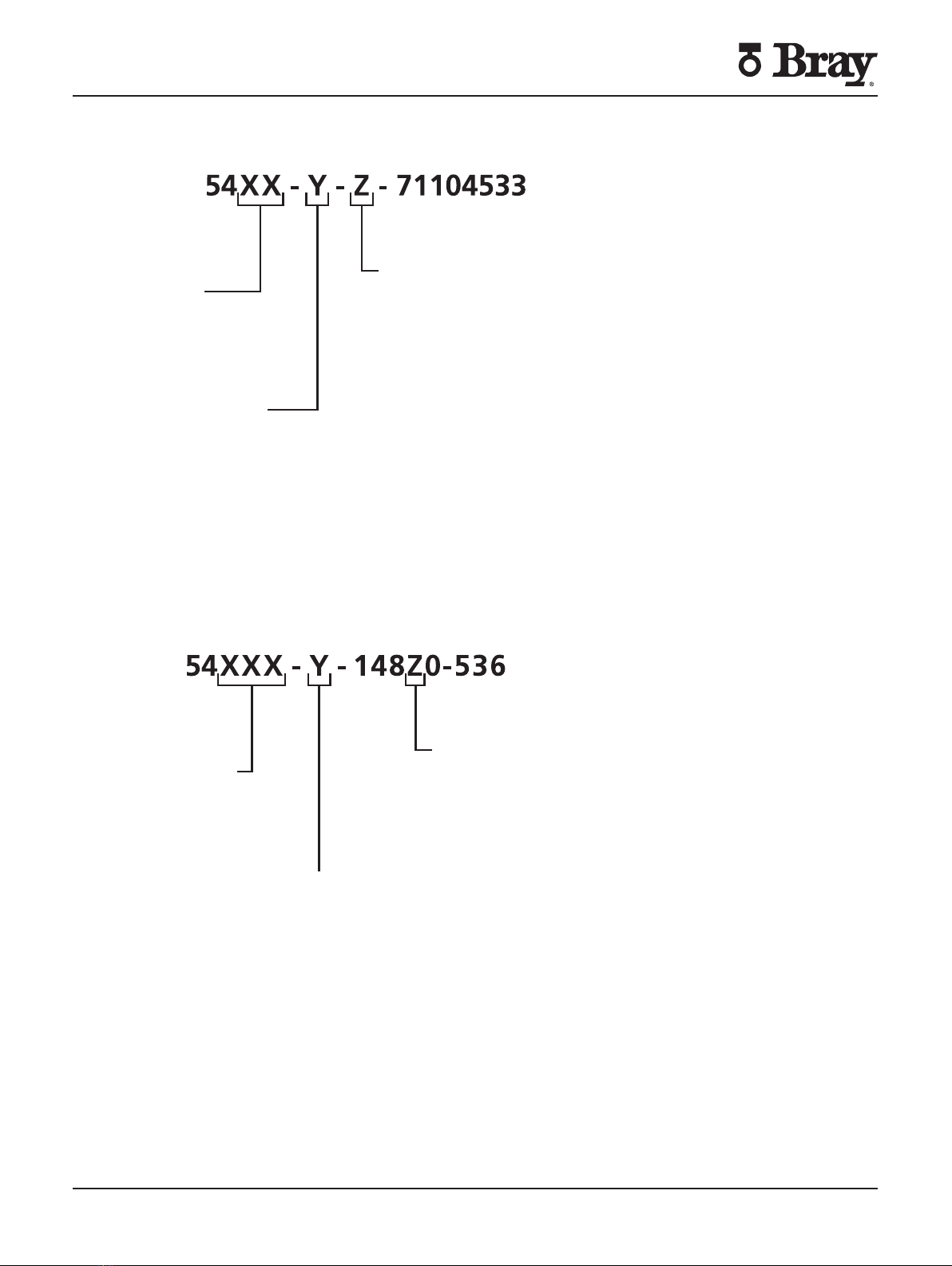

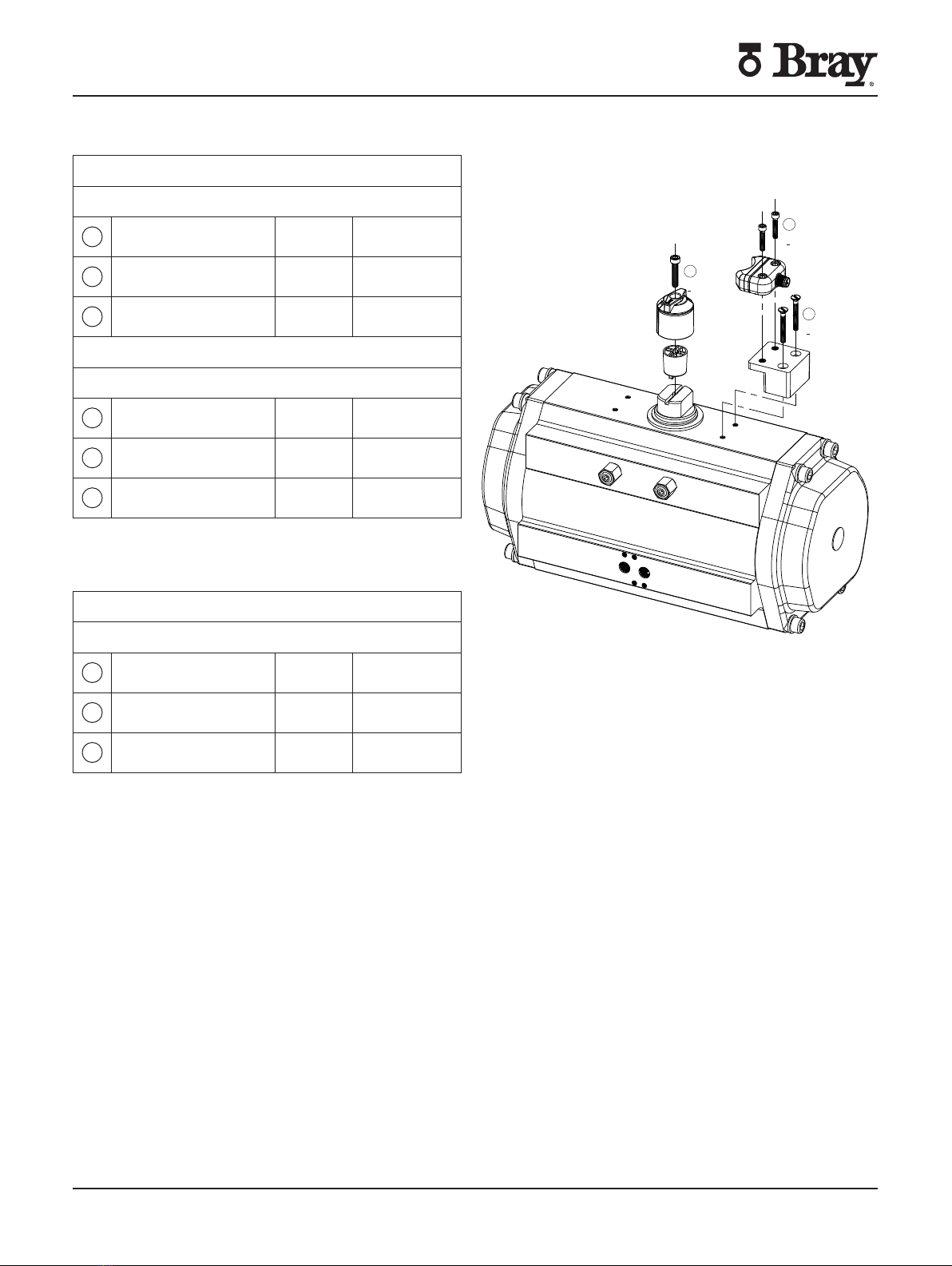

OPERATION OVERVIEW

Bray’s inductive sensors use a contactless indication system

designed to monitor the position of rotary devices An activator is

mounted onto the actuator center pinion As the valve is actuated

the open and close positions are measured by the rotation of the

activator The activator contains a metal insert that activates the

corresponding inductive switch in the sensor This activation is

relayed to the end user to validate valve position

Operations

Bray’s S Sensors contain two proximity switches in a

hermetically sealed housing Location of switches are designated

by a “” or roman numerals Iand II

Based on the position of the pinionactivator one of the metal

inserts on the activator will be directly in front of the switch

When the valve is open one of the metal inserts is directly in

front of the sensor This signals the end user of an open signal

and illuminates the corresponding LED When the valve is closed

the other metal insert activates the second switch This signals

the end user a closed signal and illuminates the second LED The

function of each switch can be selected by the end user This can

be done by adjusting the activator to match the actuator position

(see Section ) or by configuring the PLC All activators can

be configured to be used for clockwise or counter-clockwise

valve operation

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Made in Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Made in Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Made in Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Madein Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

R

IND.CONT.EQ.

57M3

12

540041-71104533

DC 3-Wire PNP + Out

10-30 V DC / 100 mA

II I

Madein Czech Republic

valve

PWR

4

L-

SII

V-

V+

V+

V-

3

2

1

5

6

4

3

5

I

II

II I

SI

L+

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

540022-71104533

5-30V DC / 100mA

DC 2-Wire PNP/NPN

3

4

L+

L-

L+

1

L-

I

II

2

I

II

I II

Made in Czech Republic

R

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

14 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

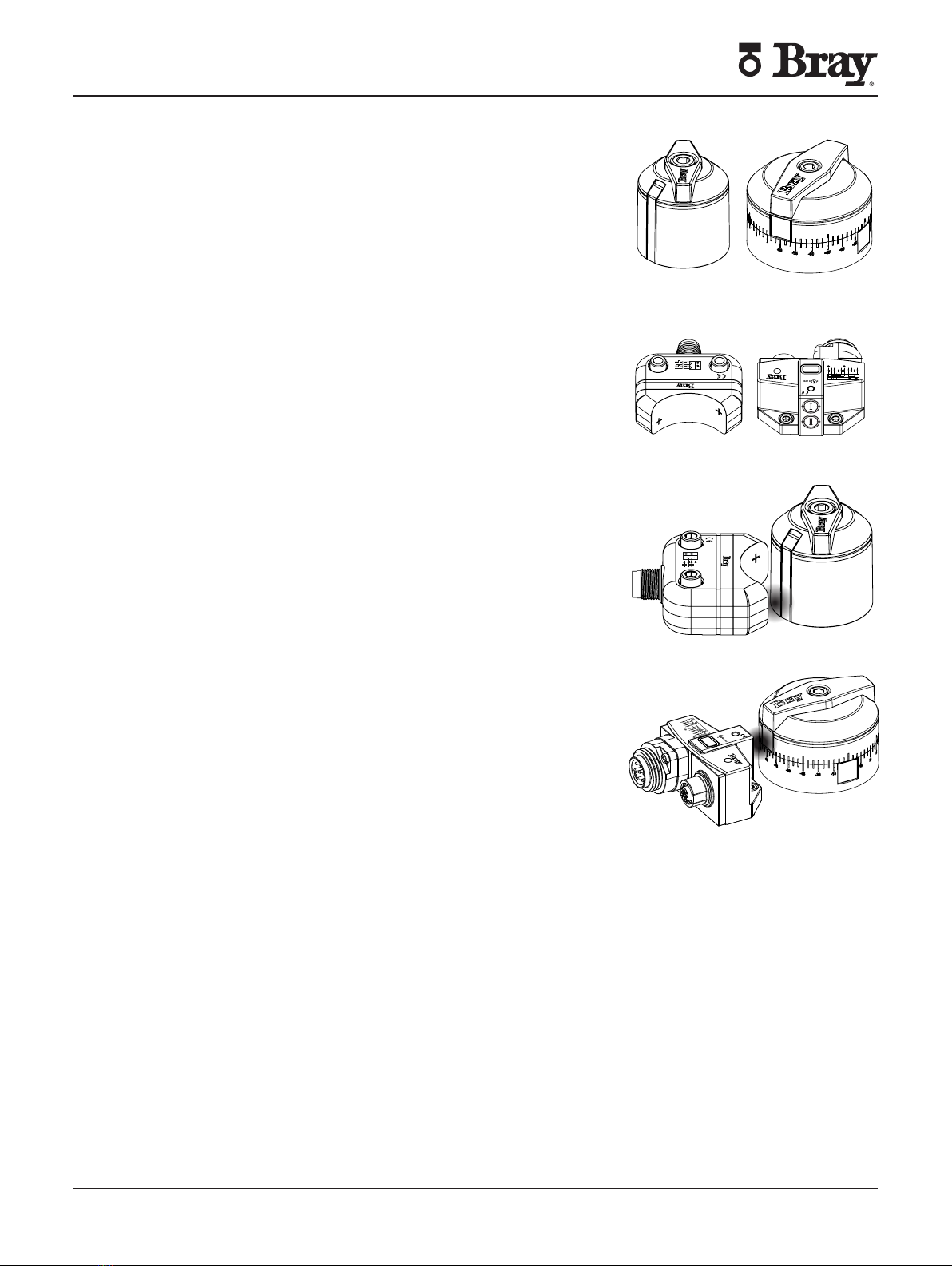

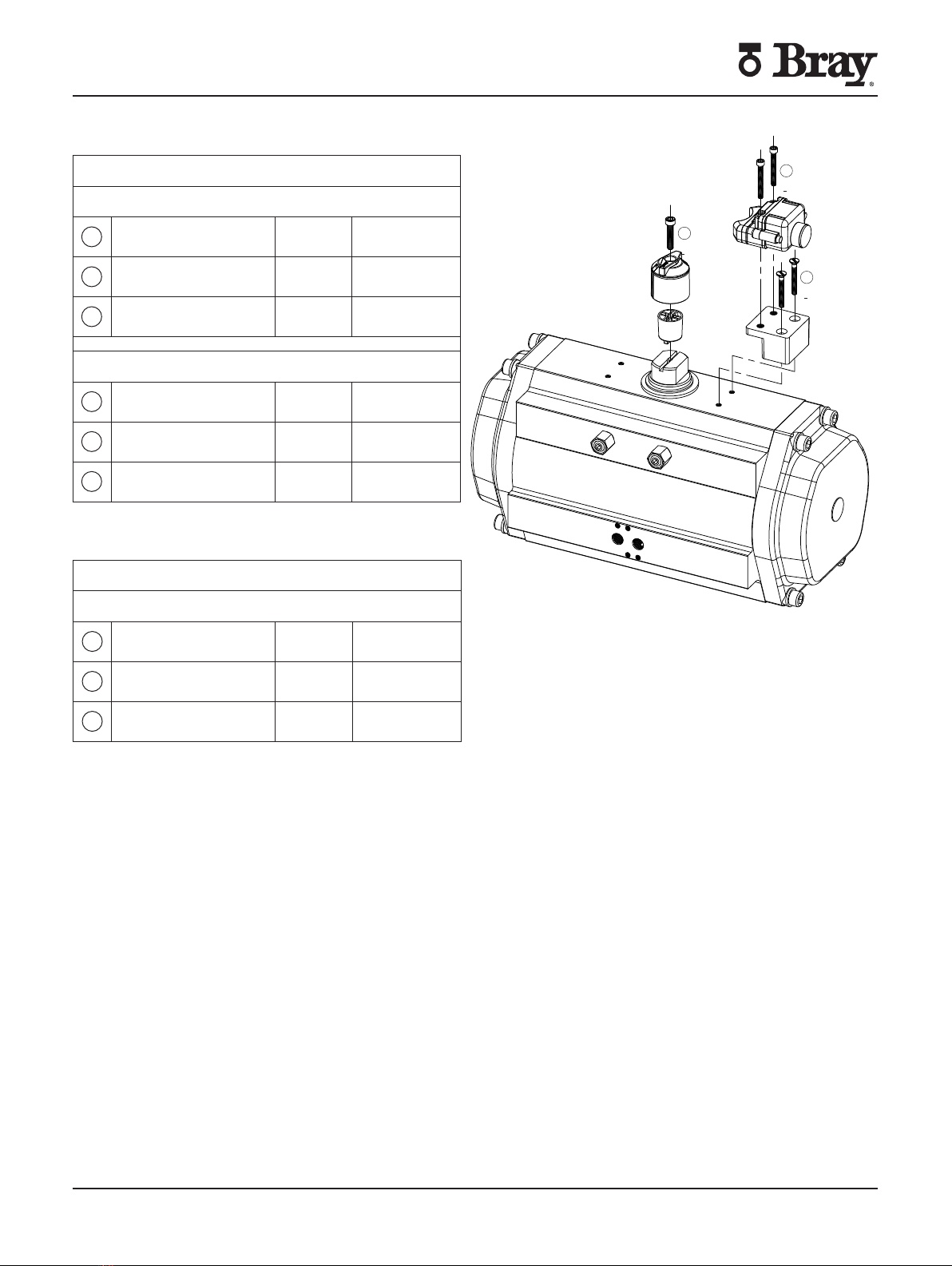

ACTIVATORS

All S sensors are oered with a dedicated activators

Configurations for installation vary based on the

application of the sensor and its mating components

Selection

Activator and sensor combinations reference the following

charts

Non Adjustable Activator

For Sensors PN -

-

-

Thread Type S Size Activator Kit PN

Imperial

- B-

- B-

Metric

- B-

- B-

Note The Series Scotch Yoke actuator will utilize activator

PN B-

Adjustable Activator

For Sensors PN - -

- -

- -

- -

Thread Type S Size Activator Kit PN

Imperial

- A-

- A-

Metric

- A-

- A-

Note The Series Scotch Yoke actuator will utilize

activator PN A-

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

15 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

High Visibility Activator

For Sensors PN

- -

- -

- -

- -

Thread Type S Size Activator Kit PN

Imperial

- C-

C-

C-

Metric

- C-

C-

- C-

Note The Series Scotch Yoke actuator will utilize

activator PN C-

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

16 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

Mounting

Mounting will vary based on the application in which it is

used All activators come with the necessary hardware for

sensor and activator mounting Hardware kits fit multiple

actuator sizes therefore some hardware may be left over

after installation

Size to - NAMUR x mm

Kit No B- Thread Type Imperial

Capscrew M mm Long

Capscrew - Long

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew M mm Long

Discard Unused Hardware

Non-Adjustable Activator - Rack and Pinion Actuator

Size to - NAMUR x mm

Kit No B- Thread Type Imperial

Capscrew M mm Long

Capscrew - Long

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew M mm Long

Discard Unused Hardware

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

17 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

Size - NAMUR x mm

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew - Long

Countersunk screw M mm Long

Discard Unused Hardware

Non-Adjustable Activator - Rack and Pinion Actuator Continued

Size to - NAMUR x mm

Kit No B- Thread Type Imperial

Capscrew M mm Long

Capscrew - Long

Countersunk screw - Long

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew - Long

Countersunk screw M mm Long

Discard Unused Hardware

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

18 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

Size to - NAMUR x mm

Kit No B- Thread Type Imperial

Capscrew M mm Long

Capscrew - Long

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew M mm Long

Discard Unused Hardware

Non-Adjustable Activator - Rack and Pinion Actuator Continued

Size to - NAMUR x mm

Kit No B- Thread Type Imperial

Capscrew M mm Long

Capscrew - Long

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew M mm Long

Discard Unused Hardware

SERIES 54 PROXIMITY SENSORS

Installation, Operation, and Maintenance Manual

19 of 28© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

Size - NAMUR x mm

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew - Long

Countersunk screw M mm Long

Discard Unused Hardware

Non-Adjustable Activator - Rack and Pinion Actuator Continued

Size to - NAMUR x mm

Kit No B- Thread Type Imperial

Capscrew M mm Long

Capscrew - Long

Countersunk screw - ” Long

Kit No B- Thread Type Metric

Capscrew M mm Long

Capscrew - Long

Countersunk screw M mm Long

Discard Unused Hardware

Other manuals for 54 Series

1

This manual suits for next models

4

Table of contents

Other Bray Accessories manuals