page 2

© Baxi Heating UK Ltd 2011

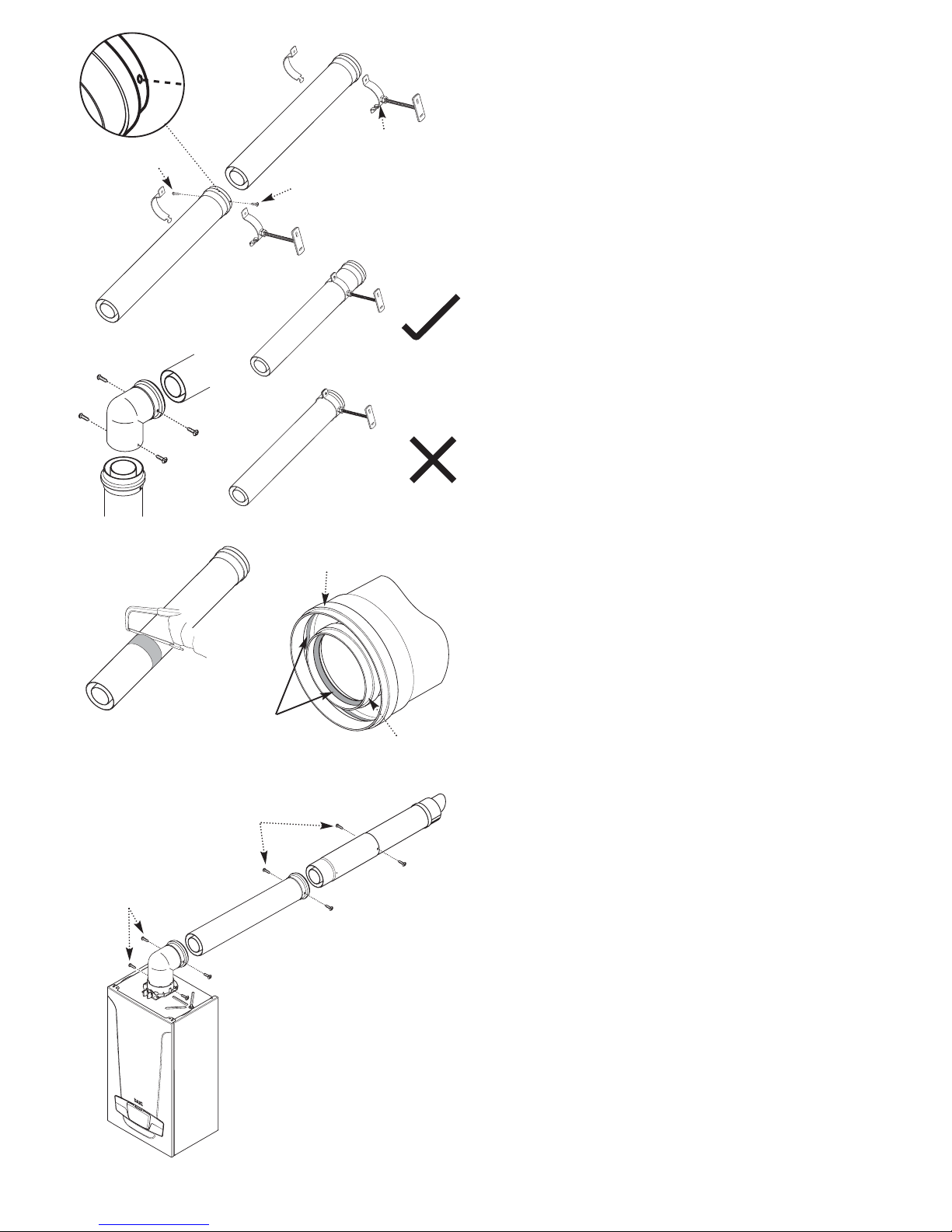

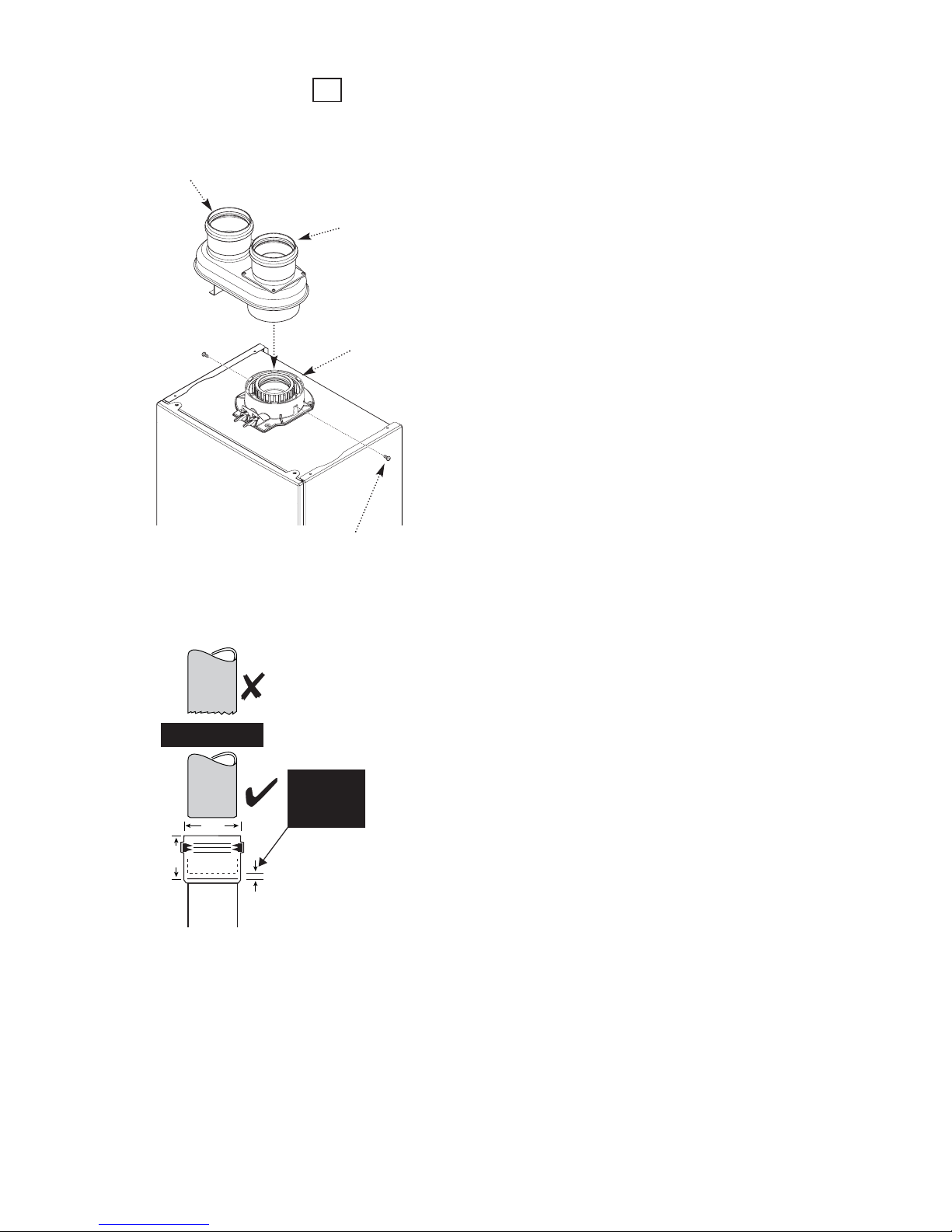

• Flue systems must be constructed using only components

approved for use with the appliance and installed in

accordance with BS 5440 Part 1, any manufacturers

instructions and Part J of the Building Regulations.

• In order to meet the requirements of the Gas Safety (Installation

& Use) Regulations, provision should be made such that all flue

joints and supports can be inspected.

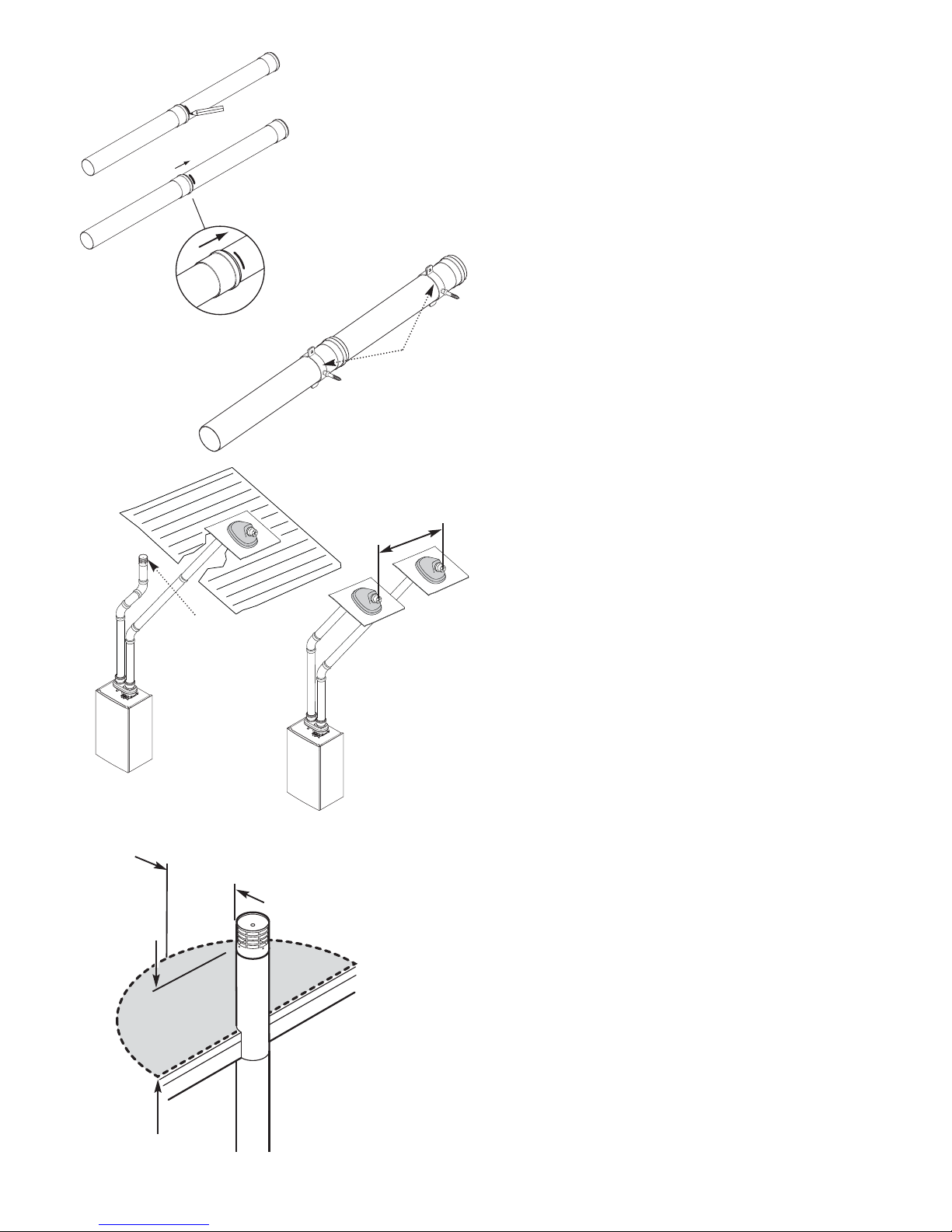

• The flue system should have a continuous fall back to the boiler

(1.5° to 3°) and be supported at least once every metre using

suitable support brackets (where shorter straight lengths are used,

for example between two bends, these should also be

supported).

• Ensure that the there are no ‘dips’ in the flue system.

• Consideration must be given to protect exposed parts of the

outlet duct where accidental touch may occur.

• All fittings should be correctly engaged and secured where

necessary. Expansion Gap details must be observed on twin

pipe 80/80 systems (Flue Group N).

• Flue extensions can be cut to length if necessary. The cut end

should be square and de-burred to prevent damage to seals when

assembling to a fitting.

• The MAXIMUM total equivalent length is given in the boiler

Installation & Servicing Instructions.

• If the flue system is to be fitted prior to the boiler, temporary

precautions must be taken to prevent rain entry into the room of

installation. Any precautionary measures must be removed prior

to fitting the boiler.

• It is the responsibility of the installer to ensure the integrity of

the flue & chimney system before commissioning the boiler.

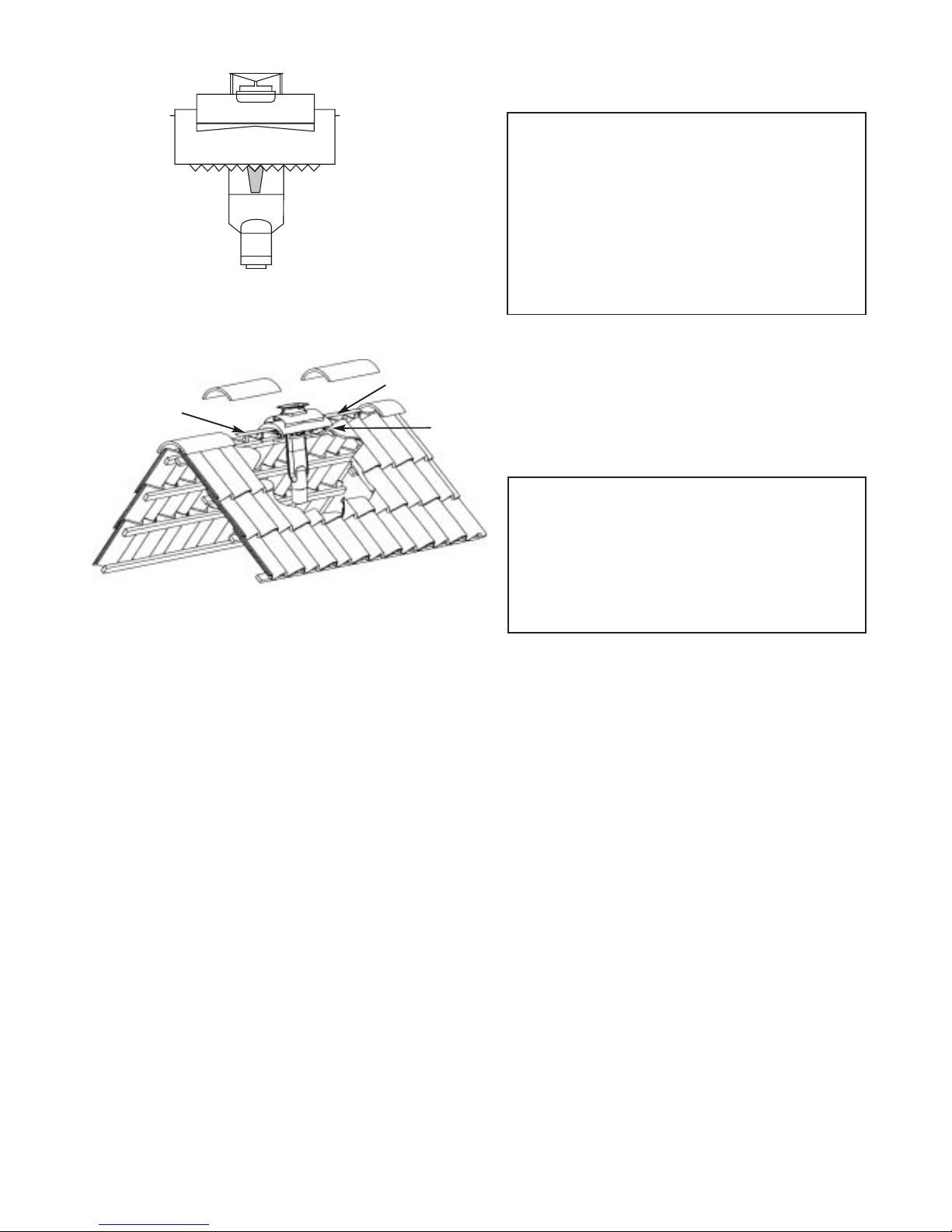

FLUE TERMINATIONS

It is important to protect building structures from the condensate

plume produced from the boiler exhaust duct flue terminal. This

should always be directed away, by using plume deflector or PDK

if necessary. Where PDK’s terminate under balconies it is

recommended to extend the terminal beyond the balcony.

TERMINAL GUARDS

• It is necessary to use a Terminal Guard where there exists the

risk of blockage and/or damage to the terminal or air intake of the

PDK, and also in instances where there is a risk of injury to people,

including the possibility of exposure to high temperatures.

• Any terminal that is less than 2 metres above finished floor or

ground level must be guarded. This also applies when terminals

are positioned above flat roofs and balconies to which there is

regular unimpeded access.

• A guard must not prevent correct & safe operation of the

appliance the terminal is connected to.

IMPORTANT NOTES

Please read before continuing with the flue installation !

CHIMNEYS & FLUES IN VOIDS

“Voids” includes ceiling & floor voids, purpose-built enclosures,

service risers, certain types of roof space and any other enclosure

that restricts access to the chimney.

The need to inspect applies to concentric and twin systems, and

both the air and flue ducts of the latter.

The requirement to inspect does not apply where a boiler is

mounted on the wall and the chimney system runs within the

building structure (e.g. direct from the rear of the boiler through

the wall to outside).

A proprietary liner containing a chimney system is also exempt,

providing there are no joints in this part of the system.

B.S. 5440-1, Gas Safety (Installation & Use) Regulations and any

Gas Safe Register Technical Bulletins must be consulted.

Chimney systems must not pass through other properties

because access may not always be available for inspection.

Access must be provided at strategic locations to allow

inspection to confirm:-

i) the system is continuous

ii) all joints are correctly assembled & sealed

iii) adequate support has been provided

iv) any “fall” or drain point required for condensation

has been provided

Inspection hatches must be permanent, be of sufficient size and

number, located such that no special equipment (e.g. an

endoscope) is required to perform inspection and have suitable

fire resistance.

Inspection hatches must comply with the following:-

i) all voids containing a concealed chimney system must

have at least one hatch

ii) hatches must be at least 300mm x 300mm

iii) no joint in the flue must further than 1.5m from the

edge of the nearest hatch

iv) hatches should, where possible, be located at

changes of direction in the flue

v) where iv) is not possible bends should fully visible

from both directions

As far as practicable hatches should be installed in non-habitable

areas such as cupboards and passageways.

A Gas Safe Registered engineer should always be consulted when

considering the positioning of inspection hatches.

The presence of other services and pipework may influence the

location of inspection hatches. In exceptional circumstances these

other services may have to be re-routed to allow suitable

positioning of a hatch.

Installation of any hatch shall not compromise the integrity and

safety of the property. If necessary consult Local Building

Regulations or Building Control Office for guidance. In all

instances the hatch manufacturers instructions should be

consulted and adhered to.

FIRESTOPS

Use of firestops may be required where the flue or chimney

passes between rooms or spaces. Any firestop or collar MUST

NOT prevent the linear expansion or contraction of the flue or

chimney

MAKING GOOD

Where the flue system passes through an external wall the joint

should ‘made good’ by use of suitable sealant or building

materials and the flue trims supplied if required.

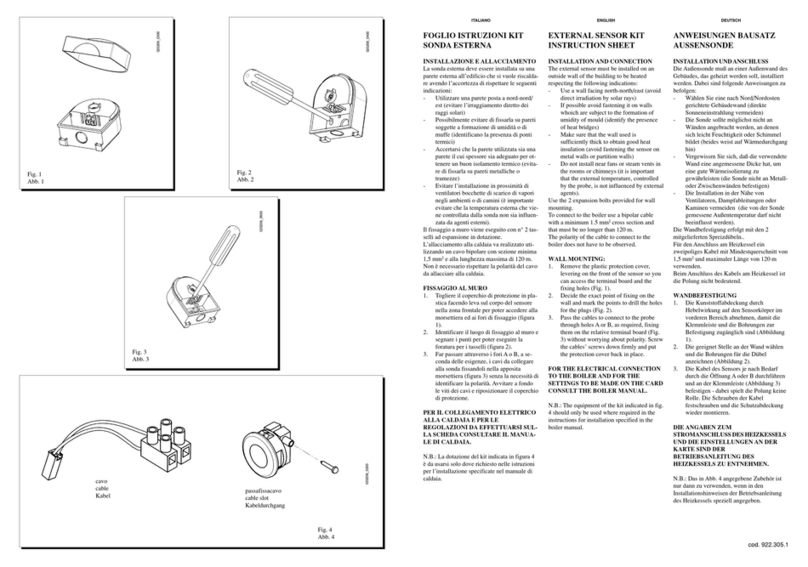

Terminal Guard

Part No. 720627901