Bray 6A series User manual

This document is not comprehensive and is intended to help first time users become familiar with the Bray SA

Electropneumatic Positioner For more detailed information the Installation Operation and Maintenance Manual

is available on the Bray website

SERIES A

ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

BRAY.COM THE HIGH PERFORMANCE COMPANY

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

2 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

TABLE OF CONTENTS

1.0 Mounting and Setup 3

2.0 Calibration 5

4.0 Positioner Optimization 10

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

3 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

1.0 MOUNTING AND SETUP

Step Place the mounting bracket on the

underside of the positioner Tighten the

mounting bolts and lock washers

Step Position the output shaft of the

positioner so that the flat () portion is

facing upwards

Step Insert the coupler over the output shaft

Ensure proper alignment of the coupler’s

set screw with the flat side of the shaft

before tightening the set screw

Step Position the yellow indicator on the base

of the coupler

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

4 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

MOUNTING AND SETUP (Continued)

Step Position the positioner on the actuator

and tighten the mounting screws

Step Insert the pneumatic fittings on the

positioner and actuator before inserting

tubing into the outputs of the positioner

to the inputs of the actuator

Note Supply air will be routed to Y in

the event of a signal loss (fail condition)

Single acting actuators release air from

Y upon loss of signal

For double-acting actuators make sure

Y is connected to the desired port for

fail position

Step Position the yellow ‘Transmission Ratio

Selector’ tab () in the position by

pushing it away from the labeled side of

the device

Step Adjust the yellow clutch wheel () on the

underside of the terminals using a mm

wide screwdriver to the position

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

5 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

2.0 CALIBRATION

Step Power on the unit with a to mA signal

Note Make sure signal does not order turn-

o during calibration process

Step Press the Menu Button

for seconds to enter into Configuration

mode

Step Once in Configuration mode parameter is

displayed in the bottom left hand corner of

the positioner screen Parameter allows

the user to select the type of actuator

being paired with the device

Step Use the Up Button to scroll through the

available options (in ascending order) until

you reach “turn” This option is for quarter

turn actuators

Note To scroll through parameters in

descending order hold down the

Menu Button while using the Down

Button to scroll through the parameters

until you find “turn”

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

6 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

CALIBRATION (continued)

Step Press the Menu Button once to

reach parameter Select

Step Press the Menu Button to scroll to

parameter

Note Parameter is skipped for quarter-

turn actuators

Step Hold down the Up Button until

calibration begins ( seconds) then

release The device will now progress

through “RUNS” completing a series

of checks For more information on the

calibration please refer to the product

manual

Note The calibration routine can take up

to minutes

Step a Note If an error is displayed on your

positioner during Run the lower

tolerance (down tolerance) of the

adjustment wheel has been exceeded

(If no errors are displayed skip ahead to

step )

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

7 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

CALIBRATION (continued)

Step b Adjust the gray friction clutch adjustment

wheel until the screen displays a in the

top right hand corner

If the clutch wheel is dicult to turn

ensure that

The yellow locking wheel under the

friction clutch adjustment wheel is not

locked (rotate right)

The friction clutch adjustment wheel

is not near the end of travel at either

the high or low end (If so rotate in the

opposite direction to allow enough

rotation to complete a successful

calibration)

Step c Once the down tolerance error has been

corrected the middle character of the

message line will change to an ‘O’

Step d To continue calibration press the

Up Button once and release

Step Upon successful completion of

calibration the status line will display

“FINISH”

Press the Menu Button once to exit

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

8 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

CALIBRATION (continued)

Step Step Press the Menu Button for

seconds The device will now be in

‘MANUAL’ mode

Step Step Use the or buttons to

manually close or open the valve to

ensure that the desired travel limits are

being attained

Step Step Toggle between Manual (“MAN”)

and ‘AUTO’ mode by pressing the

Menu Button

Step Step While in ‘AUTO’ mode test the

responsiveness of the device by varying

the command signal from mA to

mA

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

9 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

CALIBRATION (continued)

Step Upon completion of calibration insert

a mm wide screwdriver into the slot

located under the adjustment wheel and

turn the wheel left until you can feel that

it clicks in This helps prevent the clutch

wheel from slipping during actuation

To optimize performance the following measures can be applied if the positioner is too

responsive and does not reach end of travel smoothly

Step While in configuration mode scroll to

parameter (DEBA)

Step Increase the deadband to yield the

desired responsiveness by pressing the

Up Button

(Default is Bray recommended

value is to )

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

10 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

4.0 POSITIONER OPTIMIZATION

Step This is an example of screen with

increased deadband responsiveness

Step Use the Menu Button to scroll to

parameter (YCLS) This setting allows

users to assign a position where the A

will default to full open or close Select

‘uP do’ by pressing the Up Button

uP – Only Upper Limit (Full Open)

do – Only Lower limit (Tight Close)

uP do – Upper and Lower limits set

Step Use the Menu Button to scroll to

parameter (YCDO tight close)

Step Change the parameter value to the

desired lower limit for tight closing

Example If the positioner is at or

lower the actuator automatically goes to

full close

SERIES 6A ELECTROPNEUMATIC POSITIONER

QUICK START GUIDE

11 of 12© 2021 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

POSITIONER OPTIMIZATION (Continued)

Step Use the Menu Button to scroll to

parameter (YCUP full open)

Step Change the parameter to the desired

upper limit for full open

Example If the positioner is at or

higher the actuator provides full force

open

Step Exit Configuration mode by pressing the

Menu Button for seconds The

device will be in Manual Mode (“MAN’)

Press the Menu Button once to

leave the positioner in AUTO mode

THE HIGH PERFORMANCE COMPANY

HEADQUARTERS

Bray International, Inc.

13333 Westland East Blvd.

Houston, Texas 77041

Tel: +1.281.894.5454

All statements technical information and recommendations in this bulletin are for general

use only Consult Bray representatives or factory for the specific requirements and material

selection for your intended application The right to change or modify product design or

product without prior notice is reserved Patents issued and applied for worldwide

Bray® is a registered trademark of Bray International Inc

© BRAY INTERNATIONAL INC ALL RIGHTS RESERVED BRAYCOM

SINCE 1986, BRAY HAS PROVIDED FLOW CONTROL SOLUTIONS

FOR A VARIETY OF INDUSTRIES AROUND THE WORLD.

VISIT BRAY.COM TO LEARN MORE ABOUT

BRAY PRODUCTS AND LOCATIONS NEAR YOU.

ENSeries A Quick Start Guide

BRAY.COM

Other manuals for 6A series

3

Other Bray Valve Positioner manuals

Popular Valve Positioner manuals by other brands

ABB

ABB TZIDC manual

Samson

Samson TROVIS SAFE 3730 Series operating instructions

RTK

RTK RE3447 Series Installation and operating instructions

GF

GF SPC operating instructions

Samson

Samson Type 3766 Mounting and operating instructions

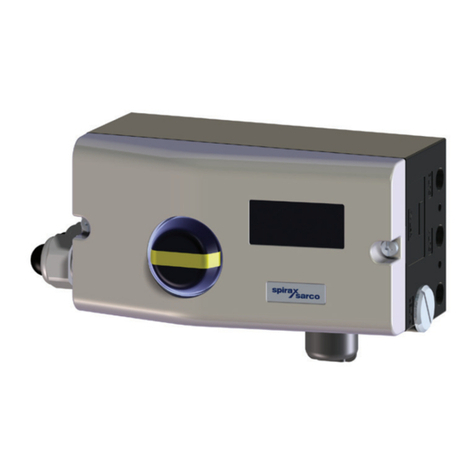

Spirax Sarco

Spirax Sarco SP7-10 Installation and maintenance instructions

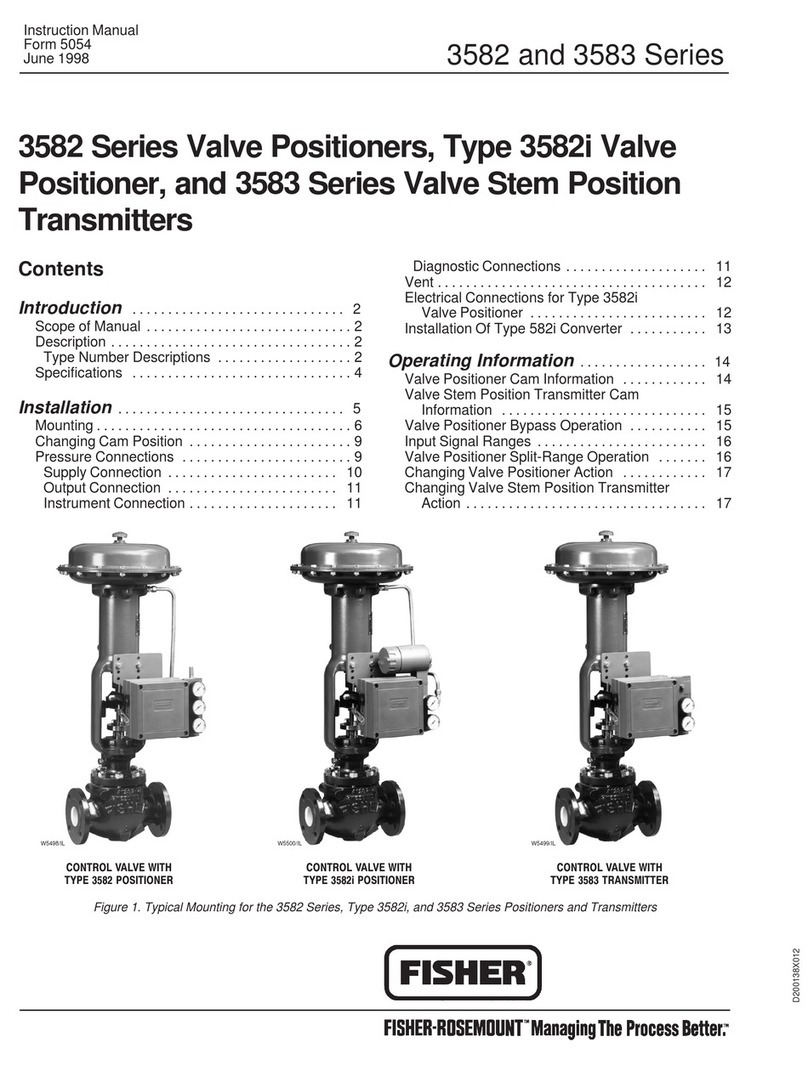

Fisher

Fisher 3582 instruction manual

Parker

Parker 404XE Series product manual

Lang

Lang LHT500 Assembly instruction

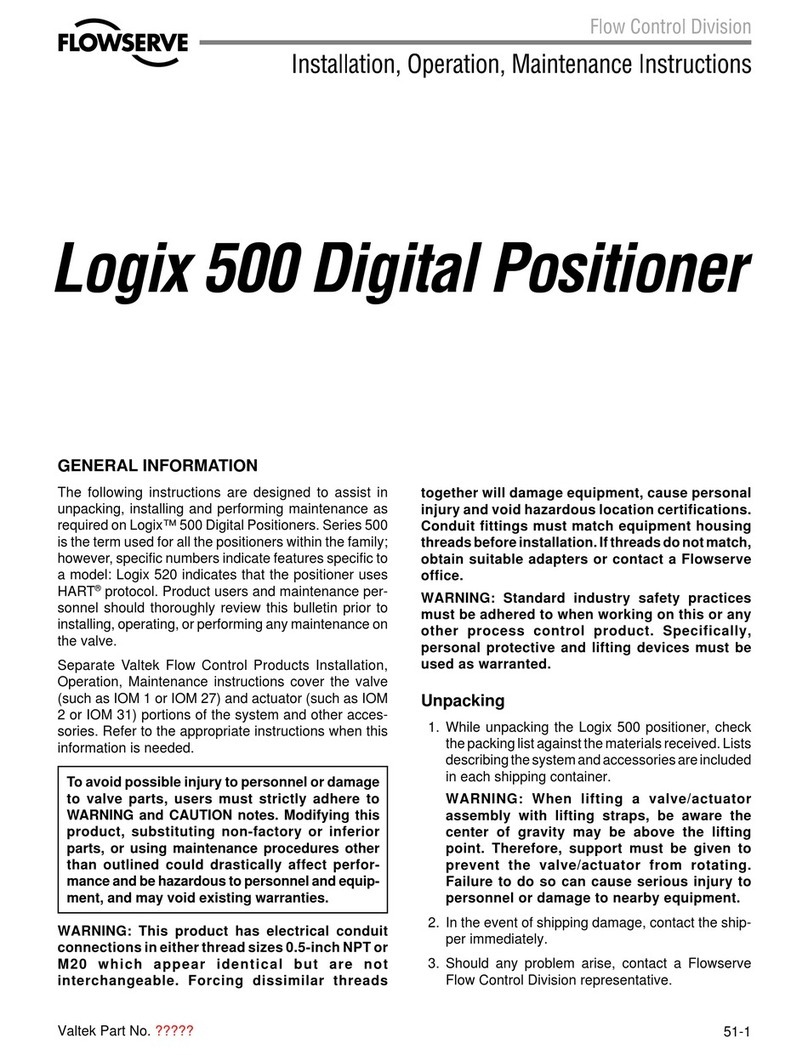

Flowserve

Flowserve Logix 500 Series Installation, operation & maintenance instructions

Samson

Samson 3725 series Mounting and operating instructions

tissin

tissin TS800 Series instruction manual