3582 and 3583 Series

2

Contents (cont’d)

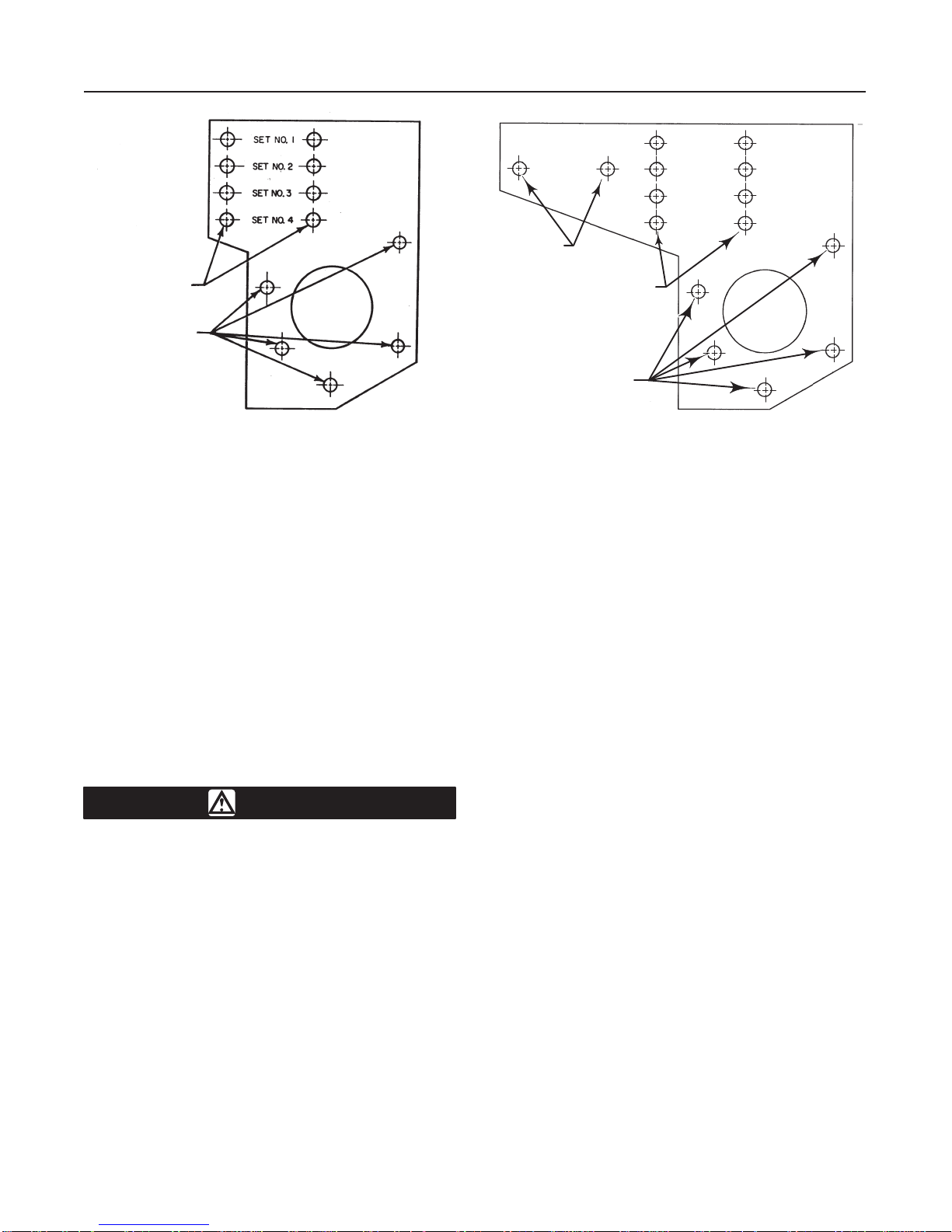

Calibration Of Valve Positioner Or Valve

Stem Position Transmitter

17. . . . . . . . . . . . .

Beam Alignment 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principle of Operation

19. . . . . . . . . . . . . . . . . .

3582 Series Valve Positioners 19. . . . . . . . . . . . . . .

Type 3582i Valve Positioner 20. . . . . . . . . . . . . . . . .

3583 Series Valve Stem Position Transmitters 20.

Maintenance

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Range Spring 22. . . . . . . . . . . . . . . . .

Replacing Gaskets 22. . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Nozzle O-Ring 22. . . . . . . . . . . . . . . .

Removing and Replacing the Relay 23. . . . . . . . . . .

Relay Maintenance 23. . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Flapper Pivot 24. . . . . . . . . . . . . . . . . .

Replacing the Type 582i Converter

Primary O-Ring and Filter 24. . . . . . . . . . . . . . . . .

Replacing the Type 582i Converter Housing

Cap O-Ring 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Type 582i Converter 24. . . . . . . . . . .

Reassembling the Type 582i Converter 25. . . . . . .

Parts Ordering

25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Kits

25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List

25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual includes installation, operation,

calibration, maintenance, and parts ordering informa-

tion for the 3582 Series pneumatic valve positioners,

the Type 3582i electro-pneumatic valve positioner,

and the 3583 Series pneumatic valve stem position

transmitters. Refer to separate instruction manuals for

information on the control valve, actuator, and acces-

sories.

Only personnel qualified through training or experience

should install, operate, or maintain the valve positioner

or valve stem position transmitter. If there are any

questions concerning the instructions in this manual,

contact your Fisher sales office or representative be-

fore proceeding.

Description

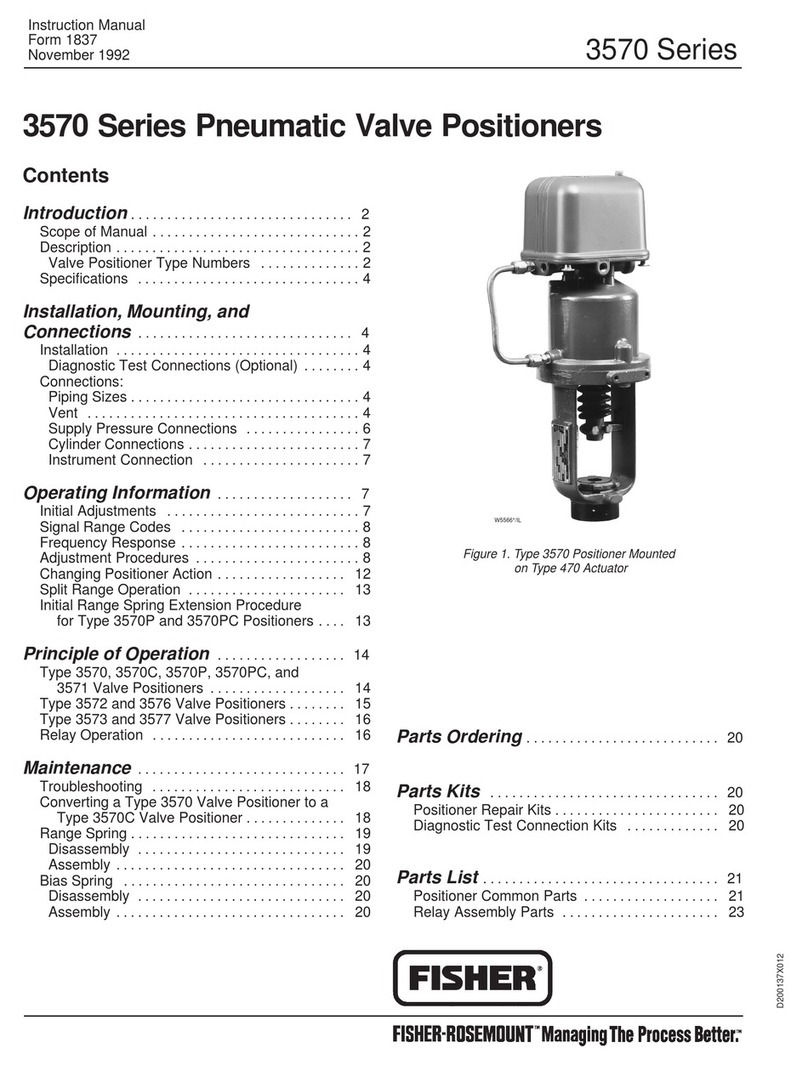

The 3582 Series pneumatic valve positioners and the

Type 3582i electro-pneumatic valve positioner shown

in figure 1 are used with diaphragm-actuated, sliding-

stem control valve assemblies. The pneumatic valve

positioners receive a pneumatic input signal from a

control device and modulate the supply pressure to

the control valve actuator. The positioner adjusts the

actuator supply pressure to maintain a valve stem

position proportional to the pneumatic input signal.

Type 3582NS positioners meet typical requirements of

the nuclear power industry. The Type 3582NS

construction includes materials that provide superior

performance at elevated temperature and radiation

levels. The O-rings are EPDM (ethylene propylene)

and the diaphragms are EPDM/Nomex. EPDM(1) dem-

onstrates superior temperature capability and shelf life

over nitrile. The Nomex diaphragm fabric demon-

strates improved strength retention at elevated tem-

perature and radiation conditions.

In addition, the Type 3582NS positioner is qualified

“commercial grade dedicated” under Fisher’s

10CFR50, Appendix B, quality assurance program.

These can be supplied as 10CFR21 items.

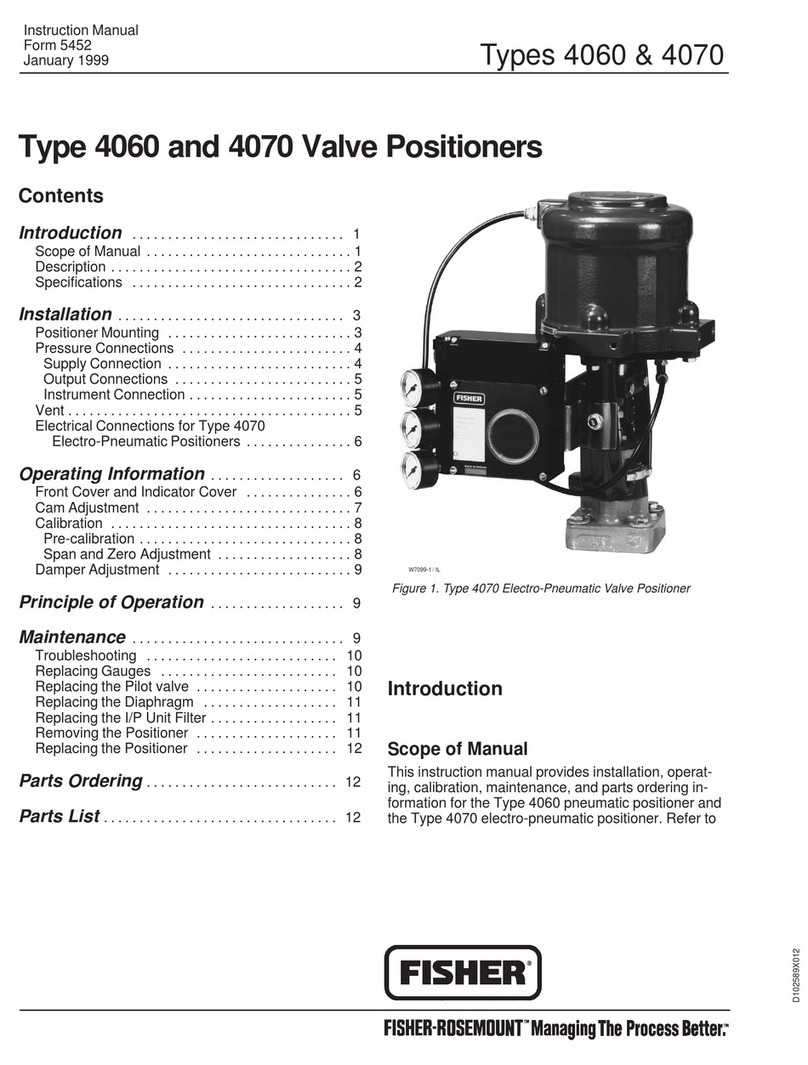

The Type 3582i is an electro-pneumatic valve position-

er, consisting of a Type 582i electro-pneumatic con-

verter installed on a Type 3582 pneumatic valve posi-

tioner. The Type 3582i valve positioner provides an

accurate valve stem position that is proportional to a

dc current input signal.

The Type 582i electro-pneumatic converter is a modu-

lar unit that can be installed at the factory or in the

field. However, do not plan to install a Type 582i con-

verter on an existing positioner until you contact your

Fisher sales office or representative for application

assistance.

The Type 582i converter receives the dc current input

signal and, through a nozzle/flapper arrangement, pro-

vides a proportional pneumatic output signal. This

pneumatic output signal provides the input signal to

the pneumatic valve positioner, eliminating the need

for a remote-mounted transducer.

The 3583 Series pneumatic valve stem position trans-

mitters are for use with sliding-stem diaphragm actua-

tors. These units provide an output signal that is di-

rectly proportional to the valve stem position.

Refer to the type number description for a detailed

explanation of type numbers.

Type Number Descriptions

The following descriptions provide specific information

on the different valve positioner or valve stem position

transmitter constructions. If the type number is not

known, refer to the nameplate on the positioner. For

the location of the nameplate, refer to key 25 in figure

21.

1. Use a clean, dry, oil-free air supply with instruments containing EPDM components.

EPDM is subject to degradation when exposed to petroleum-based lubricants.