Brecknell SBI-505 User manual

1

SBI-505 Indicator

User Instructions

AWT35-500827

Rev. A1

2

1.1 Contents

Introduction on page 3

Installation on page 5

Basic Operation on page 7

If you choose clr n, the indicator exits the accumulation mode without clearing

the total weight. If you choose clr y, the total weight is cleared and the indicator

exits accumulation mode. on page 10

Calibration and Parameter Setting on page 11

Output Format on page 19

Troubleshooting and Maintenance on page 22

3

1.2 Introduction

For safe operation please read and follow all safety information and

instructions.

This indicator is designed for basic weighing function. This includes:

lZero

lTare

lGross weight

lNet weight

lAccumulation

lPrinting

lAnimal weighing

Both kg and lb units of measure are available.

The default print format contains the following information:

lS.N. (serial number)

lGross weight

lNet weight

lTare weight

lDate

lTime

1.2.1 Options:

lPrinter

lRS232 serial interface or second display (remote)

WARNING: Settings, calibration, inspection and

maintenance should only be done by trained personnel.

WARNING: This indicator is a static sensitive device.

Remove power before making any electrical

connections. Do not touch any internal components.

Please take all anti-static precautions.

4

1.2.2 Specifications:

Accuracy class: 6000 e

Resolution display: 30, 000

ADC: 2,000,000

Zero stability error: TK 0< 0.1μV//K

Span stability error: TK spn< ± 6 ppm//K

Sensitivity (internal): 0. 3V /d input voltage -30 ~ 30μmV DC

Input voltage: 9-13.8 VDC: 0.3 amps (center terminal positive)

Excitation circuit: 5 VDC, 4 wire connection

maximum of 6 - 350Ω load cells

AC power adapter: AC100/240V: 50-60Hz, 1.6 amp

center positive 9 [email protected] amps

Maximum power source: 12VDC

Operation temperature: - 10 °C ~ + 40 °C

Operation humidity: ≤90%RH

Storage temperature: - 40 °C ~ + 70 °C

5

1.3 Installation

1.3.1 Power Supply Connection

The indicator is powered by an A/C adapter that plugs directly into the DC pin

at the bottom of the indicator. The indicator accepts 9 - 12 VDC center positive

adapter.

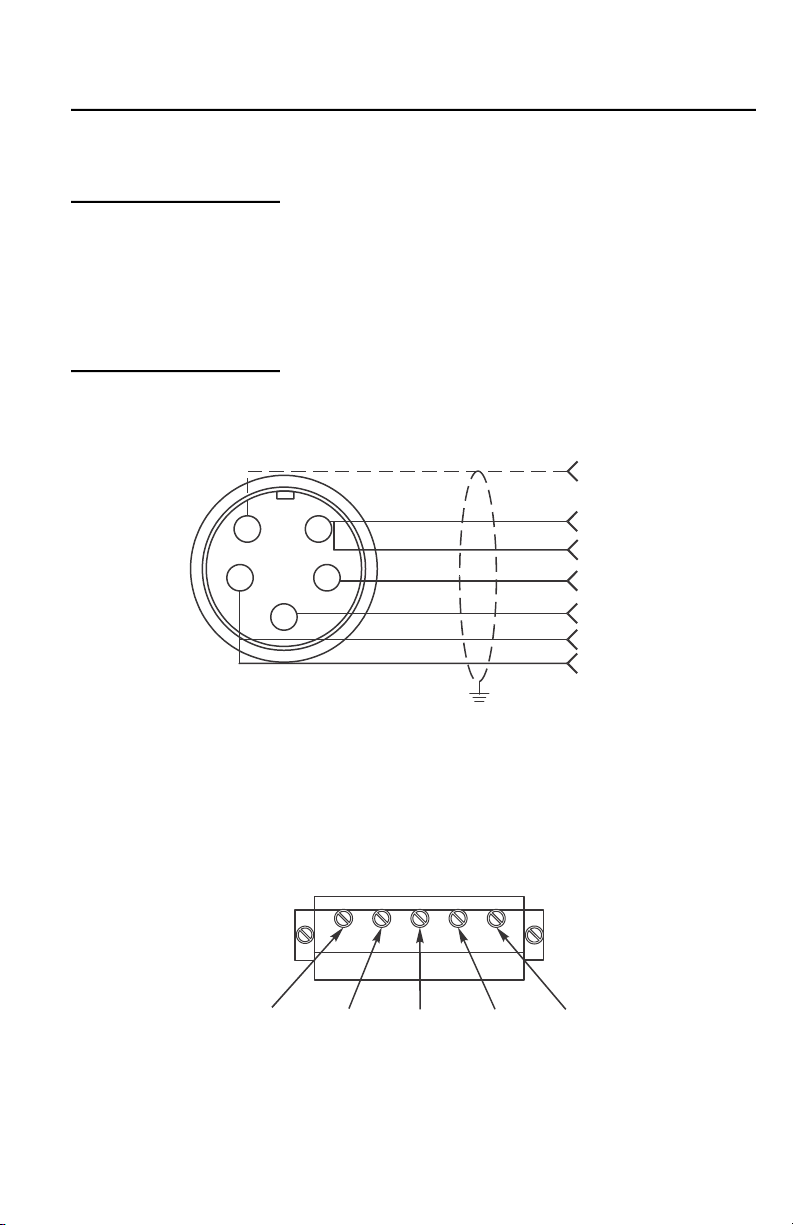

1.3.2 Connection of Loadcell and Indicator

The indicator can be connected up to 6 - 350Ω load cells. 4 wire or 6 wire

loadcells are acceptable.

Figure 1.1 Quick Disconnect

If using interface cable p/n AWT05-505848 (optional):

red = + exc., green = +sig, white = -sig, black = -exc.

Figure 1.2 PC Board Connection

51

42

3

HD

+Exc

+Sen

+Sig

-Sig

-Exc

-Sen

+SIG GND+EXC -EXC-SIG

6

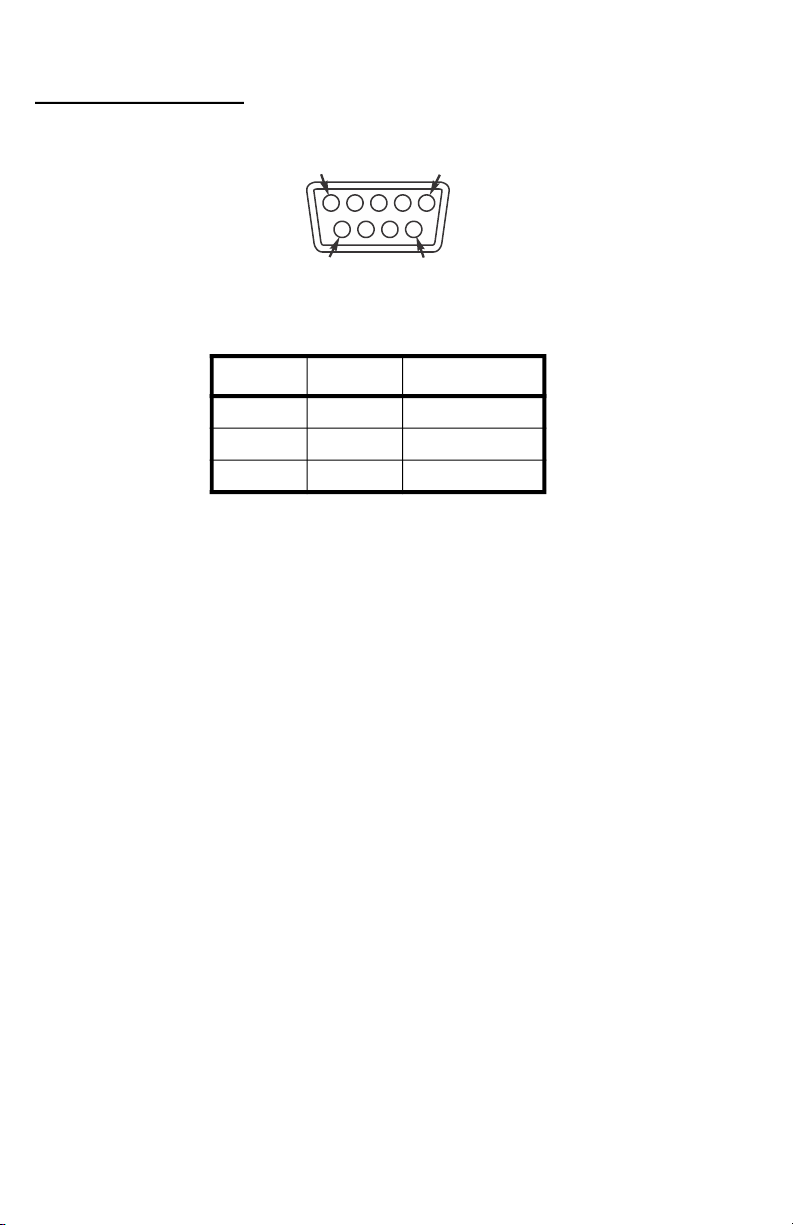

1.3.3 Communication interface

Below is the RS232 DB9 pin:

Pin assignments are shown below:

DB9 joint Definition Function

2 TXD Sending data

3 RXD Receiving data

5 GND Ground interface

1

9

99

5

7

1.4 Basic Operation

1.4.1 Power

Press and hold the ON/OFF key, shown below, for two seconds to power on or

off the indicator. After a self-test, normal weighing mode will be accessed.

1.4.2 Zero Operation

Initial Zero Setting During power up, if the weight on the scale is

within the initial zero tolerance, the indicator will

show zero automatically. The center of zero and

stable annunciators will be lit.

Pushbutton Zero When the scale is stable and not showing a

negative weight, you can zero the weight, within

tolerance, by pressing the Zero key, shown

below.

1.4.3 Tare Operation

When a gross weight is tared, the indicator will show the net weight. The Net

and Tare annunciators will light.

In tare mode, press the Tare key to clear the tare weight and the indicator will

show the gross weight.

1.4.4 Print

If the weight is stable, press the Print key to print the weight to a connected

printer.

ON

OFF

Zero

8

1.5 Counting Function

Follow these steps to count items of the same weight.

1.5.1 Getting a Piece Weight

1. While in the weighing mode, press the Zero key to clear weight from the

scale.

2. Load pre-counted sample pieces of (5, 10, 20, 50, 100, 200, or 500) on

the scale and press the Count key.

PCS 0 is displayed.

3. Using the Zero key, select from the quantity choices (5, 10, 20, 50,

100, 200, 500).

4. Press the Print key to select the displayed choice.

The quantity of items is shown.

5. Remove the sample pieces and zero the scale if necessary.

6. Load the items to be counted on the scale.

The quantity of items is shown.

7. Press the Count key to return to weighing mode.

If you want to weigh items with a different piece weight you must turn the unit

off and on again and then repeat steps 1 through 7.

9

1.6 Accumulation Operation

1. With 0 on the display, add the weight to the scale. Press the Total key

to enter the accumulation mode.

The Total annunciator turns on and the display shows n 001,

and then the display goes back to the loaded weight.

2. Unload the weight.

The display shows 0.

3. Load the second weight and press the Total key.

n 002 is displayed then the display goes back to the loaded

weight.

4. Repeat the previous steps for a maximum 999 times.

Viewing the Accumulation

1. To view the values during accumulation, press and hold Total and ON/

OFF keys.

nnn is displayed and then the total accumulated weight is

displayed. nnn is the number of accumulations included in the

total weight.

2. If the total weight is beyond the display capability, it will show the first

4 digits then the last 4 digits. For example, the first four digits are 0012

and the last 4 digits are 34.56, the actual weight is 1234.56.

Clearing the Accumulated Weight

Follow these steps to exit the accumulation function:

1. While the display shows the last 4 digits of the accumulated weight,

press and hold the Total key.

clr n is displayed. This prompt means Clear the accumulated

weight? - No.

2. Press Zero or Tare to toggle between clr n and clr y which means

Clear accumulated weight? - Yes.

10

3. When the desired choice is displayed, press the Print key to accept

that choice.

If you choose clr n, the indicator exits the accumulation mode

without clearing the total weight. If you choose clr y, the total

weight is cleared and the indicator exits accumulation mode.

11

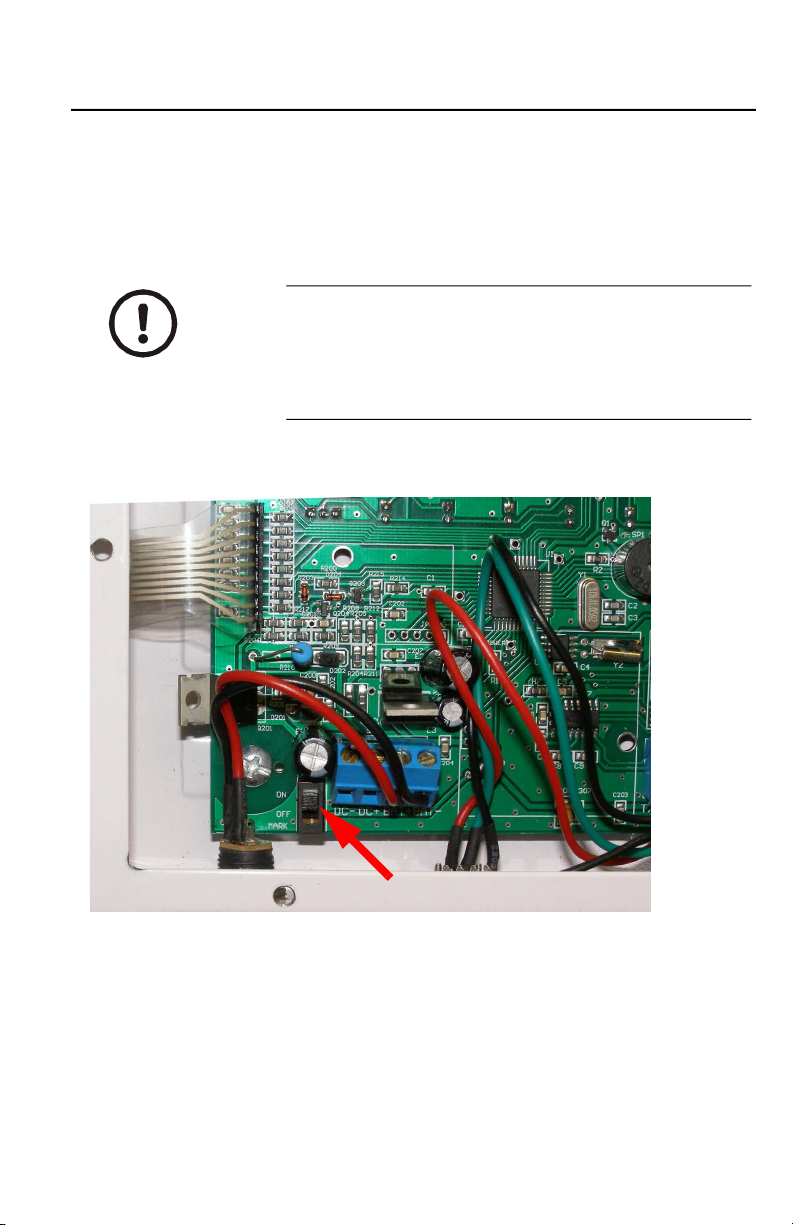

1.7 Calibration and Parameter Setting

The Parameter menu is divided into a calibration section and a parameter

configuration section. To enter the parameter part of the menu, follow step 1

below. To enter the calibration plus the parameter section, follow step 2 below.

You may need access to the Seal switch on the main board, shown in the photo

below.

1. For access to the parameter section only, the Seal switch must be in the

OFF position. Press and hold the Print and Total keys.

This accesses the menu section numbered C08-C39.

2. For access to both the calibration and parameter sections, the Seal

switch must be in the ON position. Press and hold the Print and Total

keys.

This accesses the complete menu numbered C01-C39.

CAUTION: If you break the official seal to open

the back of the indicator you may need to have

the indicator recertified by local weights and

measures officials. Open the back only if you are

sure it is correct to do so.

Seal switch

12

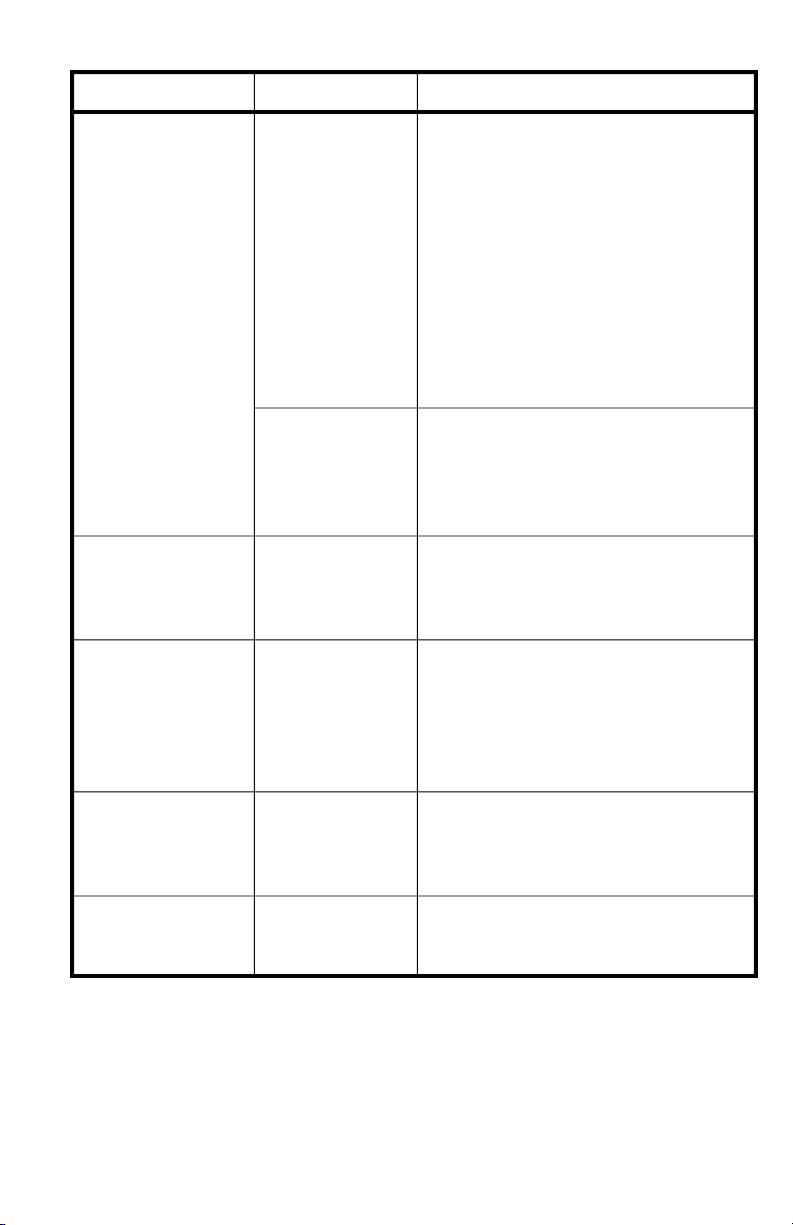

The table below shows the name and symbol of each front panel key and their

function while in the menu.

Be sure to return the seal switch to its original setting

once you are finished with calibration and

configuration.

Function Key Symbol

Enter Print

Increase Zero

Decrease Tare

Left kg/lb

Right Gross

Back Total

Exit Calibration Count

Power ON/OFF

13

1.7.1 Calibration Instructions

When initial installation or recalibration are necessary, locate the seal switch

and place it in the ON position.

Follow the calibration steps. Press and hold the Print and Total keys to access

the calibration menu. Below are the seven calibration parameters.

The SBI-505 requires a minimum of 10% of the

configured scale capacity in dead weight to calibrate

the indicator.

Step Method of Operation Display Remark

1[C01 ] After you enter calibration mode, it displays

[C01 ] (1 is blinking)

2

press

press or to toggle

choices

[C01 X] Calibration Weight option:

X=1=kg

X=2=lb

3

press

press

press or

[C02 ]

[C02 0]

[C02 2]

Set decimal position (2 is blinking)

Option: 0/1/2/3/4

Select decimal digit

example: two decimal places [C02 2]

4

press

press

press or

[C03 ]

[C03 1]

Set graduation (3 is blinking)

Option:1/2/5/10/20/50

Select required graduation

Example: graduation 5 = [C03 5]

5

press

press

press or /

[C04 ]

[XXXXXX]

Max capacity (4 is blinking)

Current setting shown (default 10000)

Example: max weighing 100kg = [0100.00]

6

press

press

press or

press

[C05 ]

[C05 0]

[C05 1]

[CAL 9]

[0000.00]

Zero calibration options (5 is blinking)

0=skip zero calibration (default)

1=zero calibration. Choose 1 and ensure

scale is empty, then press . Wait till

display counts down to [0.00] (example for

two decimal point). At 0 the zero calibration is

complete.

14

1.7.2 Reset Configuration Parameters to Defaults

To reset the indicator to its default configuration the Cal switch must be in the

"ON" position.

7

press

press

press or

press

press or /

press

[C06 ]

[C06 0]

[C06 1]

[SPAN ]

[0100.00]

[0800.00]

[CAL 9]

[0800.00]

[CAL End]

Span calibration options (6 is blinking)

0= No span calibration

1= Span calibration

Load weights on scales to 100% of capacity.

Suggest close to the max capacity, at least

10% of max.capacity. Suggested minimum

span weight is 10% of capacity.

Enter actual weight applied. Example shown

is 800.00. Press press and countdown

begins. CAL End is displayed then 0800.00

when cal is complete.

Press Count to exit calibration. Press Print to

proceed to Parameter C07.

Method of Operation Display Remark

press

press

press or

[C07 ]

[C07 0]

[C07 1]

Default parameters setting option

0=skip default parameters

1=restore default parameters

Note: after the above parameters setting is

finished, please do not select 1 to avoid losing

new setting of parameters.

Step Method of Operation Display Remark

15

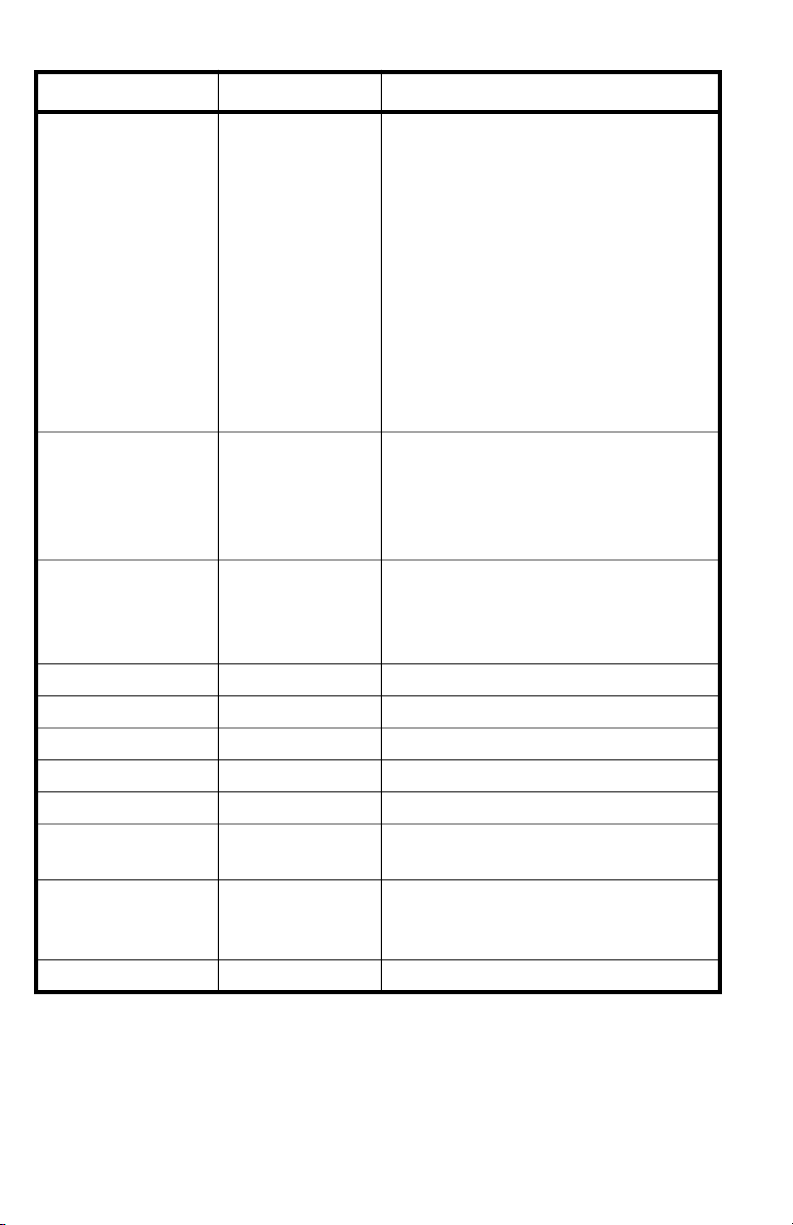

1.7.3 Application Function Parameters Setting

Chart

From step 1 on page 11, parameter C08 will be displayed. Press or to find

the parameter to be changed. See the table below for information on available

parameters.

Function Parameter Parameters Setting and Instruction

Key tone C08

Warning tone

Options: 0 = no key tone

1 = key tone

Automatic power off C09

Automatic power off

Option: 0= close auto power off

10= power off automatically if no

change within 10 minute.

30= power off automatically if no

change within 30 minute.

60= power off automatically if no

change within 60 minute.

Power saving setting C10

Power saving setting

LED Version ONLY:

Option: 0= continuous power on

3= power off if no scale or

keyboard activity within 3min.

5= power off if no scale or

keyboard activity within 5 min.

LCD Version:

0= power off backlight

1= backlight when the weight

changes or keyboard activity.

2= constant backlight

NA C11 = NA NA

Unit key C12

Kg/lb conversion

C12=0 kg only

C12=1 kg and lb both active

Upper/lower limit alarm

C13

Upper limit alarm

value Can be set to a value within the maximum

capacity limit

C14

Lower limit alarm

value

A/D Counts C15 Raw counts Enter C15 to check A/D counts

16

Date and time C16 Date set the date, from left to right: year/month/

day

C17 Time set the time from left to right: 24hour/min/sec

RS-232

Communication setting

C18

Serial interface data

strings

Output/Input options (Output Format on page

19):

0= Serial interface data output disable

1=Continuous transmit to remote display

2=Print key only

3=Command request method to a host

device. See Troubleshooting and

Maintenance on page 22

4= Indicator sends format continuously to a

computer.

5= Indicator sends format continuously to a

host device compatible with RD65 remote

display from Brecknell.

C19 Baud rate

Baud rate option:

0=1200/1=2400/2=4800/3=9600

Fixed 8,none & 1 stop bit

Zero range

C20

Manually zero range

Baud rate options:

0= Disable zero key

1=±1% max capacity

2=±2% max capacity

4=±4% max capacity

10=±10% max capacity

20=±20% max capacity

100=±100% max capacity

C21

Initial zero range

Option:

0= Disables initial zero setting on power up

1=±1% max capacity

2=±1% max capacity

5=±1% max capacity

10=±1% max capacity

20=±1% max capacity

Function Parameter Parameters Setting and Instruction

17

AZT - Automatic Zero

tracking

C22

Automatically zero

tracking range

Options:

0= Disable zero tracking

0.5=±0.5d

1.0=±1.0d

2.0=±2.0d

3.0=±3.0d

4.0=±4.0d

5.0=±5.0d

Note: 1. d = division

2. the zero tracking range cannot

bigger than manual zero range, see

C20.

C23

Automatically zero

tracking time

Options:

0= Disable zero tracking time

1= 1 second

2= 2 seconds

3= 3 seconds

Overload range C24

Overload range

Option:

00= close overload range

01d~99d

remark: d =division

Negative range

C25

Negative display

range

Option:

0=-9d

10=10% max. capacity

20=20% max. capacity

50=50% max. capacity

100=100% max. capacity

Stability C26

Stability time

Option:

0= quick

1= medium

2= slow

C27

Stability range

Option:

1= 1d 2=2d 5=5d 10=10d

D= division

Function Parameter Parameters Setting and Instruction

18

Digital filter

C28

Dynamic filter

Instruction: Dynamic

filter is collecting the

data filter before

loaded weight

stable. When loaded

weight easily

shaking (for

example animal),

you can set this filter

to make weight

display more stable

Option:

0= Disable dynamic filter

1=1 digital filter strength

2=2 digital filter strength

3=3 digital filter strength

4=4 digital filter strength

5=5 digital filter strength

6=6 digital filter strength

Note: Do not over filter. The bigger the

number, the more aggressive the filtering.

Try less than 3.

C29

Noise filter

Option:

0=Disable noise filter

1=1 digital filter strength

2=2 digital filter strength

3=3 digital filter strength

C30

Print time and date

C30=0 yy.mm.dd

C30=1 mm.dd.yy

C30=2 dd.mm.yy

C30=3 yy.mm.dd

NA C31 NA NA

NA C32 NA NA

NA C33 NA NA

NA C34 NA NA

NA C35 NA NA

Gravity of calibration

location C36 C36=9.7000~9.9999

Gravity of destination

Version No.

C37

C38

C37=9.7000~9.9999

NA C39 NA NA

Function Parameter Parameters Setting and Instruction

19

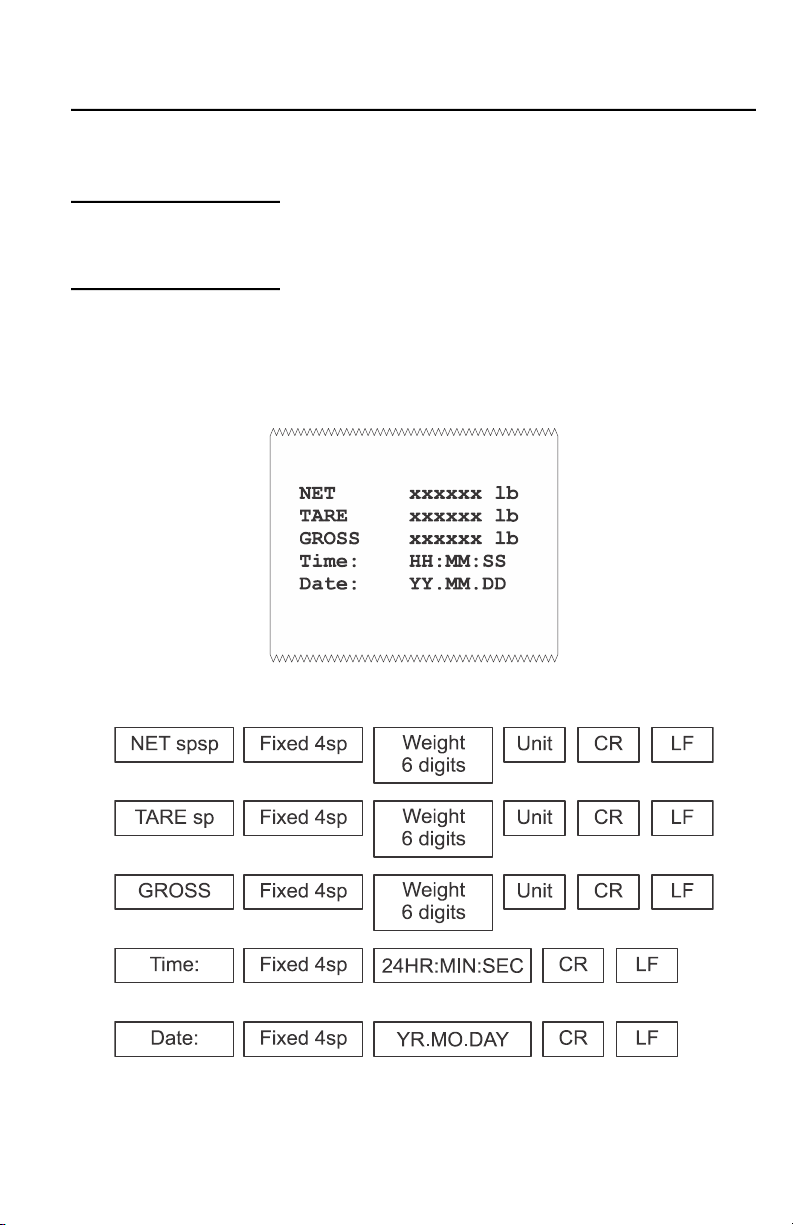

1.8 Output Format

1.8.1 Option 1 - Not Available

1.8.2 Option 2 - PRINT key only

By default, if you press the Print key while in net weighing mode, the following

format will be sent to a peripheral device. In gross mode the first two lines will

be left out of the format.

20

1.8.3 Option 3 - Host commands

When the indicator receives one of the commands shown in the table below,

the indicator responds with a corresponding format. An example for the R

command is shown below.

Command word and role as follows:

Example: R command receive data format

Print format for R command

NET XXXXXX(unit)

TARE XXXXXX(unit)

GROSS XXXXXX(unit)

Time: 24hr.mn.ss

Date: yy.mm.dd

ASCII

Command NAME Function

T TARE Save and clear tare

Z ZERO Zero gross weight

P PRINT Print the weight when stable

R G.W/N.W Read gross weight or net weight w/motion

C Kg/lb Kg/lb conversion

Start

Transmission

Polarity:

<SP> = Positive

“-” = Negative

Weight Data Space

Units:

lb = pound

kg = kilogram

Space

Gross/Net:

GR = Gross

NT = Net

Line

Feed

Carriage

Return

Fixed

Space

Other manuals for SBI-505

1

Table of contents

Other Brecknell Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Chauvin Arnoux

Chauvin Arnoux B102 user manual

Kimans

Kimans HYDRASONIC S8 user manual

SYCLOPE

SYCLOPE HYDRO'pH Installation, commissioning, maintenance and programming instructions

Teledyne Lecroy

Teledyne Lecroy USB Advisor T3 quick start

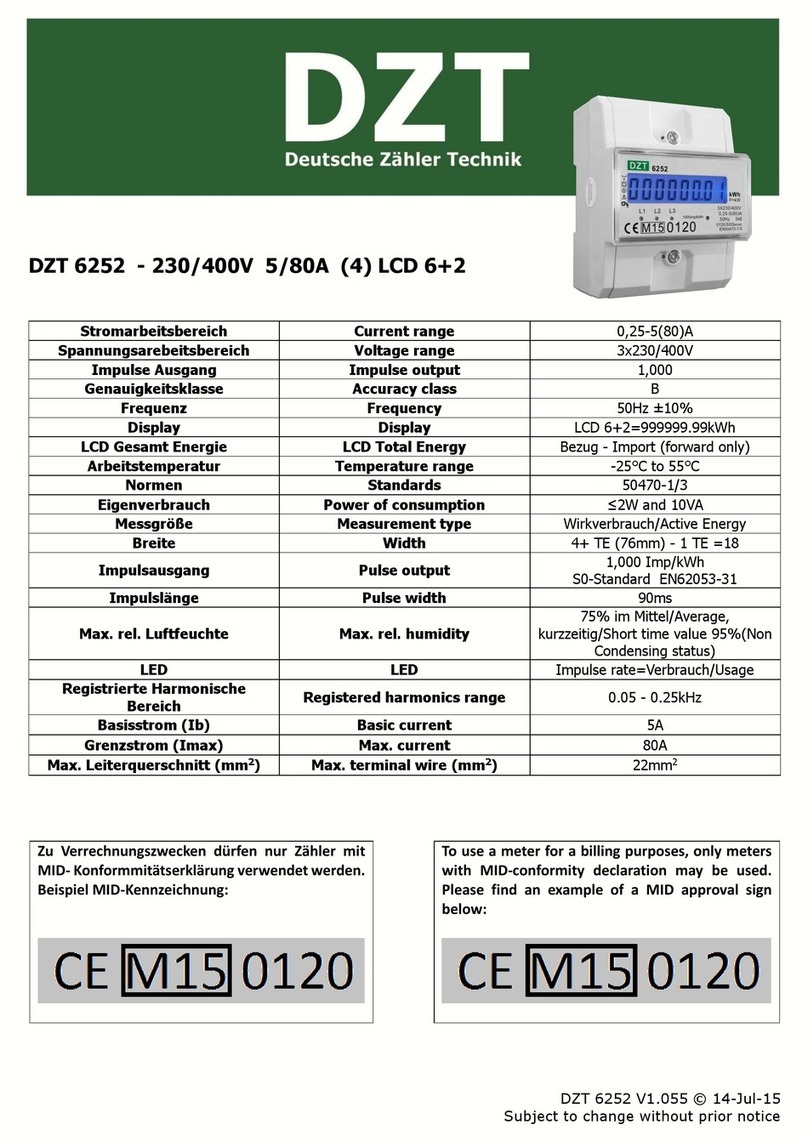

Inepro

Inepro DZT 6252 Short manual

PRAXSYM

PRAXSYM PM-6000 user manual