Breconcherry Andantex Cyclone User manual

Breconcherry Cleaning Technology

Orbital cleaner Cyclone, Twister, Typhoon, Tempest, Tornado,

Tornado 4

Operating instruction (Translation from the original language)

430BAL011762EN_2

COPYRIGHT

These Operating Instructions are the English translation of the original operating

instructions in the sense of the EU Machinery Directive. This document is

protected by copyright. All rights reserved. The document may not, in whole or in

part, be copied, reproduced, translated or reduced to an electronic medium of

machine-readable form without the express permission of Breconcherry.

LEGAL NOTICE

_

We kindly request that you answer a few short questions about these Operating

Instructions. Use the following QR code or link to access the questionnaire:

https://www.ntgt.de/ra/s.aspx?s=367112X57707125X58087

430BAL011762EN_2

2 28.05.2018

TABLE OF CONTENTS

1General Information 5

1.1 Information on the Document 5

1.1.1 Binding Character of These Operating Instructions 5

1.1.2 Notes on the Illustrations 5

1.1.3 Symbols and Highlighting 5

1.2 Manufacturer address 6

1.3 Contact 6

1.4 EC Declaration of Conformity for Partially Completed Machines 7

2Safety 8

2.1 Intended use 8

2.1.1 Requirements for operation 8

2.1.2 Improper operating conditions 8

2.2 Operator’s Duty of Care 8

2.3 Subsequent changes 9

2.4 General safety instructions and dangers 9

2.4.1 Principles for safe operation 9

2.4.2 Environmental Protection 10

2.5 Supplementary Regulations 10

2.6 Qualification of personnel 10

2.7 Safety equipment 12

2.7.1 Signage 12

2.8 Residual dangers 13

2.9 Danger zones 13

3Description 15

3.1 Design 15

3.2 Functional description 16

4Transport and storage 17

4.1 Storage conditions 17

4.2 Transport 17

4.2.1 Scope of supply 17

5Technical data 18

5.1 Identification 18

5.2 Cyclone: 18

5.3 Twister: 19

5.4 Typhoon 19

5.5 Tempest 19

5.6 Tornado 20

5.7 Tornado 4 20

5.8 Resistance of Sealing Materials 20

5.9 Tools 22

5.10 Weights 23

6Assembly and installation 24

6.1 Safety notes 24

6.2 Notes on installation 24

6.3 Installation 24

6.4 Removing 26

7Start-up 28

7.1 Safety notes 28

7.2 Commissioning 28

8Operation and control 29

8.1 Safety notes 29

8.2 Operating Conditions 29

9Maintenance 34

9.1 Safety notes 34

9.2 Maintenance intervals 35

9.3 Disassembly 35

9.3.1 Remove the lower body 35

9.3.2 Separation of the upper and lower body 40

9.3.3 Removal of the shaft bearing 40

430BAL011762EN_2

28.05.2018 3

9.3.4 Removal of individual parts from the upper body. 41

9.3.5 Disassembly of the planetary gear 43

9.4 Installation 45

9.4.1 Torque of the cleaner components 45

9.4.2 Installing the drive shaft assembly 46

9.4.3 Assemble the planetary gear 47

9.4.4 Planetary gear installation 48

9.4.5 Installation of the slide bearing 50

9.4.6 Installation of the bevel gear in the upper body 50

9.4.7 Installation of the retaining ring in the upper body 51

9.4.8 Installation of the shaft bushings in the lower body 52

9.4.9 Assembling of the upper and lower body 52

9.4.10 Mounting the nozzle carrier 54

9.4.11 Check the assembly 60

10 Alarms 62

10.1 Malfunctions and remedies 62

11 Decommissioning 63

11.1 Safety notes 63

11.2 Disposal 63

11.2.1 General notes 63

12 Appendix 64

12.1 Lists 64

12.1.1 Abbreviations and terms 64

430BAL011762EN_2

4 28.05.2018

1 General Information

1.1 Information on the Document

The present Operating Instructions are part of the user information for the

product. The Operating Instructions contain all the information you need to

transport, install, commission, operate and carry out maintenance for the product.

1.1.1 Binding Character of These Operating Instructions

These Operating Instructions contain the manufacturer's instructions to the

operator of the product and to all persons who work on or use the product

regarding the procedures to follow.

Carefully read these Operating Instructions before starting any work on or using

the product. Your personal safety and the safety of the product can only be

ensured if you act as described in the Operating Instructions.

Store the Operating Instructions in such a way that they are accessible to the

operator and the operating staff during the entire life cycle of the product. When

the location is changed or the product is sold make sure you also provide the

Operating Instructions.

1.1.2 Notes on the Illustrations

The illustrations in these Operating Instructions show the product in a simplified

form. The actual design of the product can differ from the illustration. For detailed

views and dimensions of the product please refer to the design documents.

1.1.3 Symbols and Highlighting

In these Operating Instructions, important information is highlighted by symbols

or special formatting. The following examples illustrate the most important types

of highlighting.

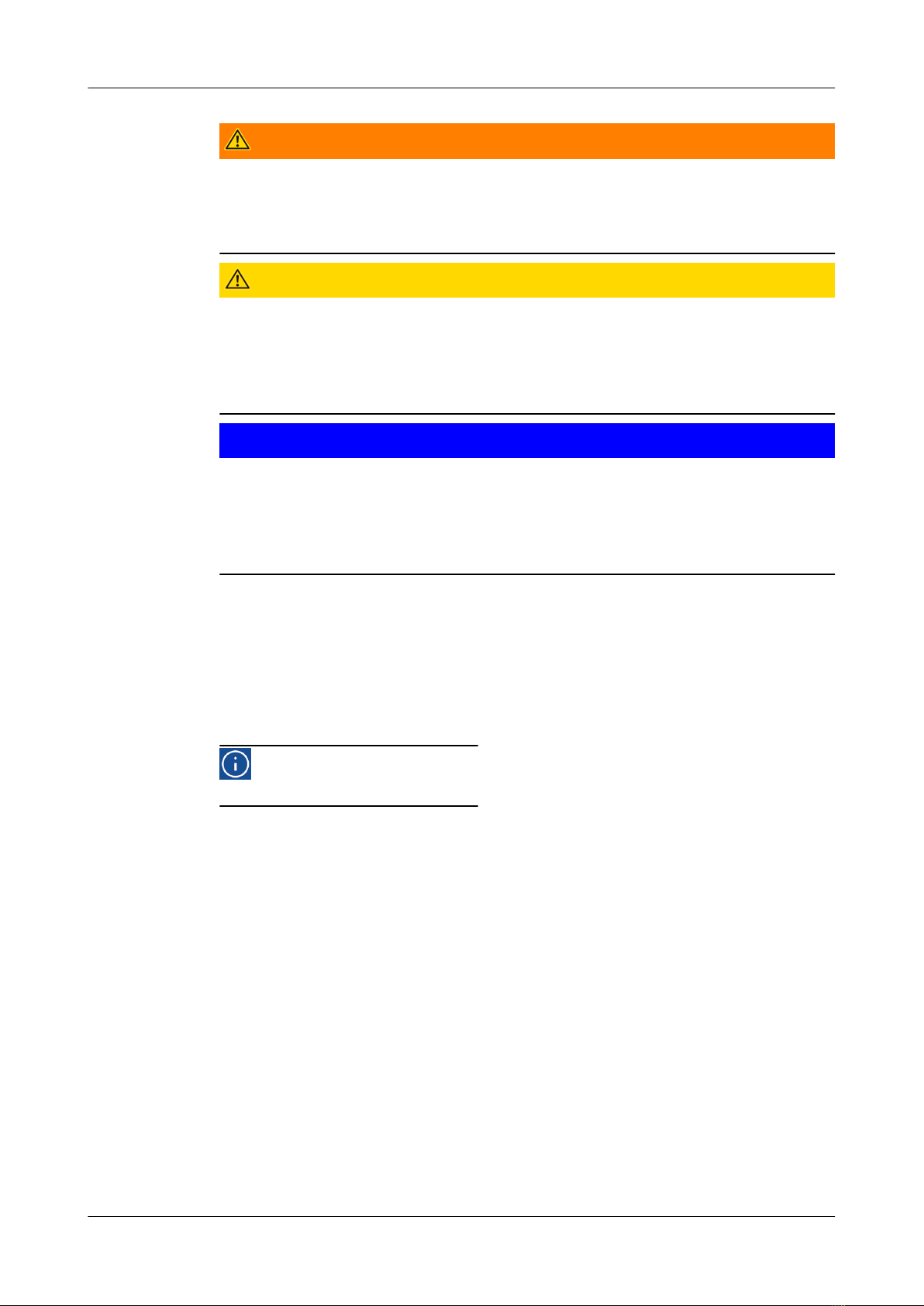

Danger

Warning: Fatal Injuries

Failure to observe the warning can result in serious damage to health, or

even death.

► The arrow identifies a precautionary measure you have to take to avoid

the hazard.

Warning: Explosions

Failure to observe the warning can result in severe explosions.

► The arrow identifies a precautionary measure you have to take to avoid

the hazard.

General Information

Information on the Document

430BAL011762EN_2

28.05.2018 5

Warning!

Warning: Serious Injuries

Failure to observe the warning can result in serious damage to health.

► The arrow identifies a precautionary measure you have to take to avoid

the hazard.

Caution!

Warning: Injuries

Failure to observe the warning can result in minor or moderate damage to

health.

► The arrow identifies a precautionary measure you have to take to avoid

the hazard.

Notice

Warning: Damage to Property

Failure to observe the warning can result in serious damage to the

component or in the vicinity of the component.

► The arrow identifies a precautionary measure you have to take to avoid

the hazard.

Carry out the following steps: = Start of a set of instructions.

1. First step in a sequence of operations.

2. Second step in a sequence of operations.

®Result of the previous operation.

®The operation is complete, the goal has been achieved.

Hint!

Further useful information.

1.2 Manufacturer address

1.3 Contact

Phone:+44 (0)1531 632476 Fax:

+44 (0)1531 633839

Mail: [email protected] Web:

http://www.breconcherry.com

General Information

Manufacturer address

430BAL011762EN_2

6 28.05.2018

Breconcherry Ltd

Westfalia House, Old Wolverton Road

Milton Keynes, MK12 5PY, United Kingdom

1.4 EC Declaration of Conformity for Partially Completed Machines

in accordance with the EC Machinery Directive 2006/42/EC, Annex II 1. A

Manufacturer:

Breconcherry Ltd

Westfalia House, Old Wolverton Road Milton

Keynes, MK12 5PY, United Kingdom

We declare under our sole responsibility that the partially completed machine

Designation:

Type:

Cyclone · Twister · Typhoon · Tempest ·

Tornado · Tornado 4 – TSG

Breconcherry Orbital cleaner

conforms with all the relevant provisions of this directive and the following directives:

Relevant EC directives: 2006/42/EC EC Machinery Directive

Applicable harmonized

standards, in particular:

DIN EN ISO 12100 Safety of Machines - General

design principles - Risk

assessment and risk reduction

Other applied standards and

technical specifications:

--

Remarks: We declare that the incomplete machine

identified here complies with the "Essential

Health and Safety Requirements" defined in

Annex I, section 1 and section 2.1. The

technical documentation is compiled in

accordance with Annex VII, part B. In response

to a reasoned request the relevant information

will be transmitted to the appropriate national

authorities.

Person authorised for compilation and

handover of technical documentation:

Person authorised to compile the technical file

for CE marking

Breconcherry Ltd

Westfalia House, Old Wolverton Road Milton

Keynes, MK12 5PY, United Kingdom

General Information

EC Declaration of Conformity for Partially Completed Machines

430BAL011762EN_2

28.05.2018 7

Milton Keynes, 2016-04-18

________________________________

Ilija Aprcovic

Managing Director

2 Safety

2.1 Intended use

The orbital cleaner Cyclone, Twister, Typhoon, Tempest and Tornado are

designed for the cleaning of tanks and containers. This cleaner are designed for

the installation and operation at any angle. Using the device for any other

purpose is considered contrary to its designated use.

Hint!

The manufacturer will not accept any liability for damage resulting

from any use of the cleaner which is not in accordance with its

designated use. The risk of such misuse lies entirely with the operator

of the facility.

2.1.1 Requirements for operation

The prerequisite for reliable and safe operation of the component is proper

transportation and storage as well as professional installation and assembly.

Operating the unit within the limits of its designated use also involves adhering to

the operating, inspection and maintenance instructions.

2.1.2 Improper operating conditions

The operational reliability of the cleaner cannot be ensured under improper

operating conditions. Therefore avoid improper operating conditions.

Operating the cleaner is not permitted if

•Persons or objects are in the danger zone.

•Safety devices are not working or were removed.

•Malfunctions have been detected on the cleaner.

•Damage has been detected on the cleaner.

•Maintenance intervals have been exceeded.

2.2 Operator’s Duty of Care

In your capacity as operator of the facility you bear a particular responsibility for

the proper and safe handling of the cleaner in your facility. Only use the cleaner

when it is in perfect condition to prevent danger to persons and property.

These Operating Instructions contain the information you and your staff need for

the safe and reliable operation during the entire service life of the cleaner. Be

sure to read these Operating Instructions carefully and ensure that the measures

described here are observed.

The operator's duty of care includes planning the necessary safety measures and

monitoring that these measures are observed. The following principles apply:

•Only allow qualified staff to work on the cleaner.

•The operating company must authorize personnel to carry out the relevant

tasks.

Safety

Intended use

430BAL011762EN_2

8 28.05.2018

•Working areas and the entire environment of the cleaner must be neat and

clean.

•Personnel must wear suitable work clothing and personal protective

equipment. As the operating company must ensure that work clothing and

personal protective equipment are used.

•Inform personnel regarding any properties of the product which might pose a

health risk and the preventative measures to be taken.

•Have a qualified first-aid representative on call during the operation. This

person must be able to initiate any necessary first-aid measures in case of an

emergency.

•Clearly define processes, lines of authority and responsibilities associated

with the cleaner. Everybody must know what to do in case of an emergency.

Instruct the staff in this respect at regular intervals.

•The signs relating to the cleaner must always be complete and legible. Check,

clean and replace the signs as necessary at regular intervals.

•Observe the Technical Data specified and the limits of use!

Hint!

Carry out regular checks. This way you can ensure that these

measures are actually observed.

2.3 Subsequent changes

You should never make any technical modifications to the cleaner. Otherwise you

will have to undergo a new conformity process in accordance with the EC

Machinery Directive on your own.

In general, only original spare parts supplied by Breconcherry should be

installed. This ensures the reliable and economical operation of the cleaner.

Using spare parts from third-party suppliers will invalidate any and all

warranty claims.

2.4 General safety instructions and dangers

The cleaner is operationally reliable. It was built according to state-of-the-art

science and technology.

Nevertheless, the cleaner can pose dangers, especially if

•the cleaner is not used in accordance with its intended use,

•the cleaner is not used correctly,

•the cleaner is operated under impermissible operating conditions.

2.4.1 Principles for safe operation

Dangerous situations during operation can be avoided by safety-conscious and

proactive behaviour of the personnel.

To ensure the safe operation of the cleaner the following principles apply:

Safety

Subsequent changes

430BAL011762EN_2

28.05.2018 9

•The Operating Instructions must be kept ready to hand and accessible for

everyone at the cleaner's place of use. They must be complete and in clearly

legible form.

•Only use the cleaner for its intended use.

•The cleaner must be functional and in good working order. Check the

condition of the cleaner before starting work and at regular intervals.

•Wear tight-fitting work clothing for all work on the cleaner.

•Ensure that nobody can get hurt on the parts of the cleaner.

•Immediately report any faults or noticeable changes on the cleaner to the

person responsible.

•Never touch the pipes and the cleaner when these components are hot! Avoid

opening the cleaner, unless the process units have been emptied and

depressurised.

•Observe the accident prevention regulations and all local regulations.

2.4.2 Environmental Protection

Harm to the environment can be avoided by safety-conscious and proactive

behaviour of the staff.

For environmental protection the following principles apply:

•Substances harmful to the environment must not be discharged into the

ground or the sewage system.

•Always observe the pertinent regulations relating to waste avoidance,

disposal and utilization.

•Substances harmful to the environment must be collected and stored in

suitable containers. Clearly mark the containers.

•Dispose of lubricants as hazardous waste.

2.5 Supplementary Regulations

In addition to the instructions in this documentation the following also has to be

observed:

•pertinent accident prevention regulations,

•generally accepted safety rules,

•national regulations applicable in the country of use,

•work and safety instructions applicable in the facility,

•installation and operating regulations for use in potentially explosive areas.

•For use in Ex-protected areas, special safety and operating instructions apply.

For this purpose, Breconcherry supplies a separate ATEX supplementary

operating manual, which must be observed.

2.6 Qualification of personnel

Safety

Supplementary Regulations

430BAL011762EN_2

10 28.05.2018

This section contains information about the qualifications that staff working on the

cleaner must have.

Operating and maintenance personnel must

•have the necessary qualification to carry out their tasks,

•be instructed with regard to possible dangers,

•know and observe the safety instructions given in the documentation.

Only allow qualified electricians to carry out work on the electrical equipment or

have a qualified electrician supervise the work.

Only allow specially trained personnel to carry out work on an explosion-

protected system. When working on explosion-protected equipment observe the

standards DIN EN 60079-14 for gases and DIN EN 50281-1-2 for dusts.

The following minimum qualifications are required:

•Vocational training as a skilled worker who can work on the cleaner

independently.

•Sufficient instruction to work on the cleaner under the supervision and

direction of a qualified specialist.

Each member of staff must meet the following requirements to be allowed to work

on the cleaner:

•Personal suitability for the respective task.

•Sufficient professional qualification for the respective task.

•Instructed with regard to the function of the cleaner.

•Instructed with regard to the operating sequences of the cleaner.

•Familiar with the safety devices and their function.

•Familiar with these Operating Instructions, especially with the safety

instructions and the information which is relevant for the task on hand.

•Familiar with the basic regulations with regard to occupational health and

safety and accident prevention.

For work to be carried out on the cleaner the following user groups are

distinguished:

Safety

Qualification of personnel

430BAL011762EN_2

28.05.2018 11

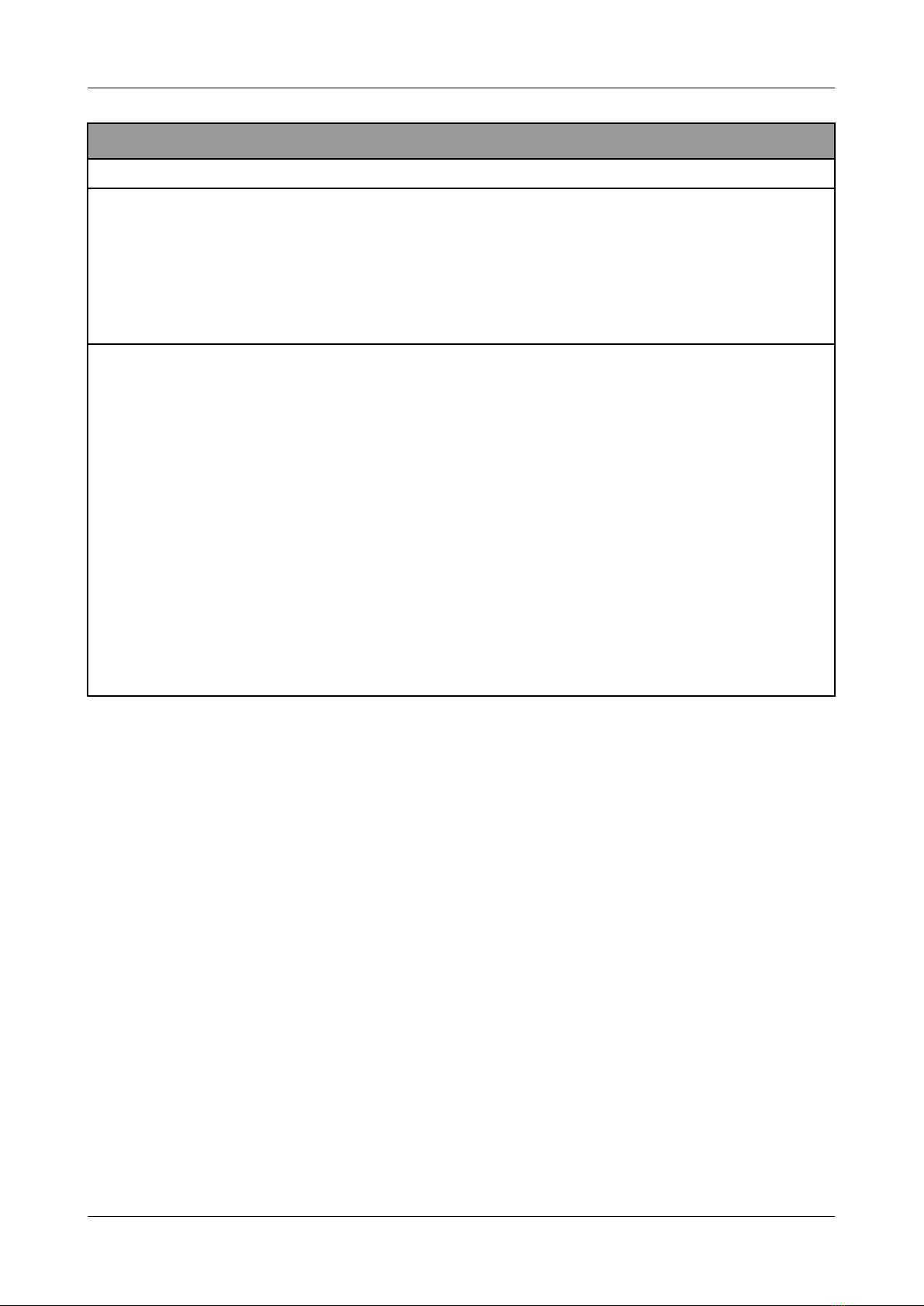

User groups

Staff Qualifications

Operating personnel Adequate instruction and sound knowledge in the following areas:

•Function of the cleaner

•Operating sequences of the cleaner

•What to do in case of an emergency

•Lines of authority and responsibilities with respect to the task

Maintenance personnel Adequate instruction as well as sound knowledge of the design

and function of the cleaner.

Sound knowledge in the following areas:

•Mechanical equipment

•Electrical equipment

•Pneumatic system

Authorization with regard to safety engineering standards to carry

out the following tasks:

•Setting devices into operation

•Earthing of devices

•Marking of devices

The relevant certificates of qualification must be submitted before

work can be carried out on ATEX certified machines.

2.7 Safety equipment

2.7.1 Signage

Dangerous points on the cleaner are indicated by warning signs, prohibition signs

and mandatory signs.

The signs and notes on the cleaner must always be legible. Any illegible signs

must be replaced immediately.

Safety

Safety equipment

430BAL011762EN_2

12 28.05.2018

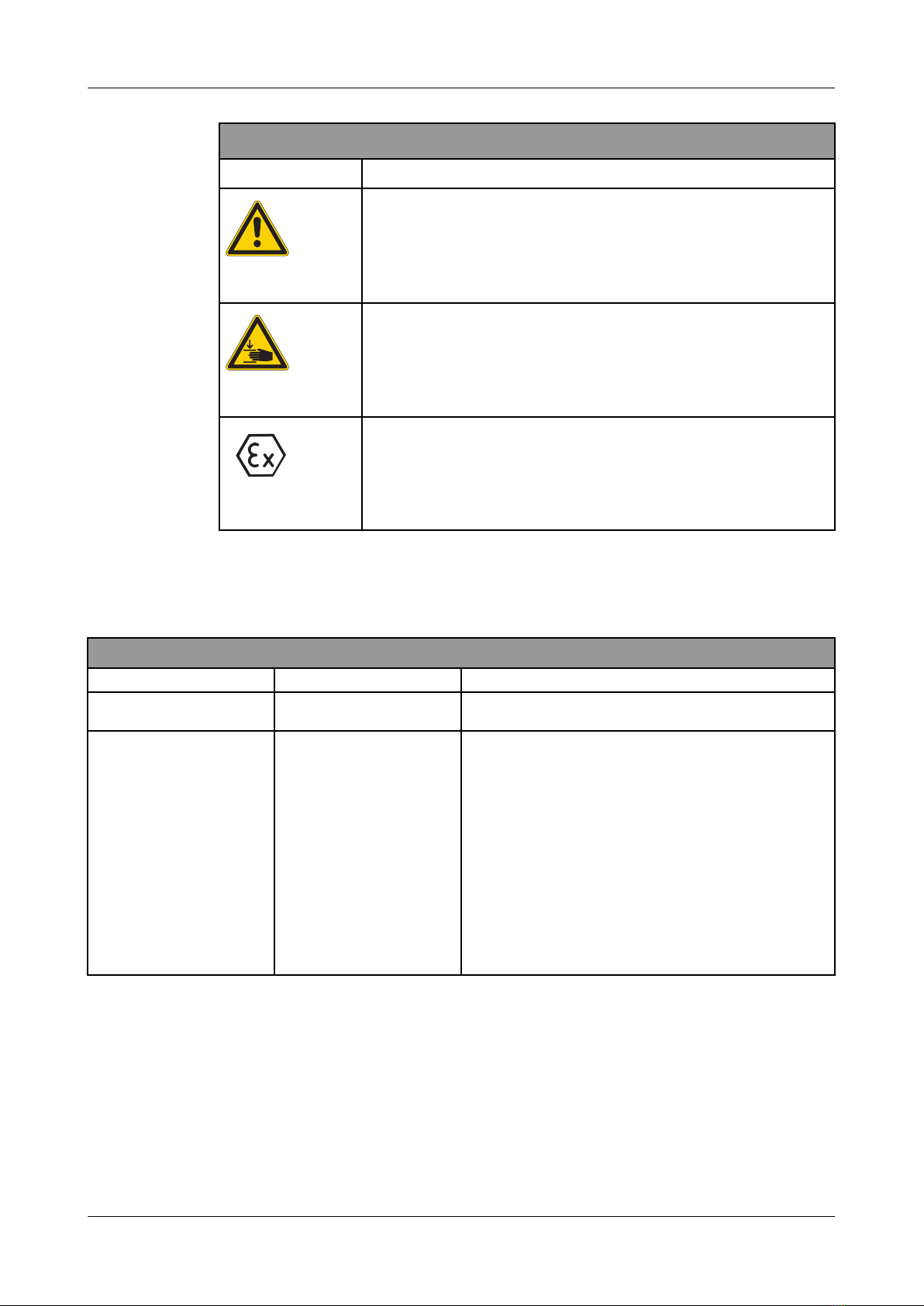

Signs on the cleaner

Sign Meaning

Fig.1

General hazard warning

Fig.2

Warning Crushing

Fig.3

Explosive atmosphere hazard warning

2.8 Residual dangers

Dangerous situations can be avoided by safety-conscious and proactive

behaviour of the personnel and by wearing personal protective equipment.

Residual dangers on the cleaner and measures

Danger Cause Measure

Danger to life Inadvertent switch-on of the

cleaner

Effectively disconnect all components, effectively prevent switch-

on.

Risk of injury Danger presented by moving or

sharp-edged parts

The operator must exercise caution and prudence.

For all work:

•Wear suitable work clothing.

•Never operate the machine if the cover panels are not

correctly fitted.

•Never open the cover panels during the operation.

•Never reach into openings.

As a precautionary measure, wear personal protective equipment

in the vicinity of the cleaner:

•Protective gloves

•Safety shoes

2.9 Danger zones

Transport, Installation

Do not set the cleaner down on the lower body. Store the cleaner in horizontal

position and secure it against rolling away to the side.

Commissioning

Please observe the following notes:

Safety

Residual dangers

430BAL011762EN_2

28.05.2018 13

•When installing the cleaner, secure it against tipping and twisting and secure

all fixing points correctly.

•Only set the cleaner into operation in closed vessels.

Operation

Please observe the following notes:

•Provide suitable protective measures to ensure that the cleaner cannot be set

into operation outside of the vessel.

•In the event of faults, stop all media supplies immediately.

•Check the installation situation to ensure that the cleaner is not in contact with

other parts and that rotation cannot be obstructed.

•Do not allow the maximum cleaning pressure and the maximum cleaning

temperature to be exceeded.

•Vessels, tanks and road tankers etc. must be grounded by suitable means.

Maintenance

Please observe the following notes:

•Close all media supply lines and ensure that no hot or aggressive media are

applied to or are in the cleaner.

•Never set the cleaner down on the lower body.

•Do not attempt to turn the nozzles by hand.

•Do not use the lower body as a tool contact point for installation or removal.

Safety

430BAL011762EN_2

14 28.05.2018

3 Description

3.1 Design

Fig.4: Sample orbital cleaner

Design

No. Designation

1 Upper body

2 Lower body

3 Nozzle carrier

4 Nozzle

5 Self-cleaning nozzle

6 Nozzle sleeve

Description

Design

430BAL011762EN_2

28.05.2018 15

3.2 Functional description

The principle of operation of the Orbital Cleaner is based on two horizontally and

vertically rotating axes, as shown in the following diagram.

Fig.5

•Hygienic design

•No ball bearings

•Slim, compact construction

•Intensive cleaning through directed streams

•Long service life

•Maintenance friendly

•Drive happens through the cleaning medium

•Low number of components (same spare parts for orbital cleaner Typhoon,

Tempest, Tornado)

Description

Functional description

430BAL011762EN_2

16 28.05.2018

4 Transport and storage

4.1 Storage conditions

Store the cleaner in a dry place and ensure it is not subjected to vibration and is

protected from external influence.

Storage temperature +5...+40 °C

4.2 Transport

For transport, the following principles apply:

•Only use suitable lifting gear and slings for transporting package units/

cleaners.

•Observe the pictograms on the package.

•Handle the cleaner with care to avoid damage caused by impact or careless

loading and unloading. The outside synthetic materials are susceptible to

breaking.

•Only allow qualified staff to transport the cleaner.

•Movable parts must be properly secured.

•Only use approved, fully functional load lifting devices and lifting accessories

which are suitable for the intended purpose. Observe the maximum load-

bearing capacities.

•Under no circumstances should anyone stand under a suspended load.

•Take care when transporting the cleaner. Do not grip sensitive parts of the

unit to lift or push the unit or to support yourself. Avoid putting the unit down

with a jerk.

•Do not set the orbital cleaner down on the lower housing. Store the orbital

cleaner in the horizontal position and secure the cleaner against rolling away

to the side.

4.2.1 Scope of supply

On receipt of the cleaner, check whether

•the details on the type plate correspond to the data in the order and delivery

documents,

•the equipment is complete and all components are in good order.

Transport and storage

Storage conditions

430BAL011762EN_2

28.05.2018 17

5 Technical data

5.1 Identification

The marking on the cleaner is used for the clear identification of the cleaner.

Hint!

Cleaners for use in explosive atmospheres (ATEX) have a different

marking, which is explained in the associated ATEX Operating

Instructions.

TY TSG 4.5 mm CPTTFE 1“BSP

4660-4969-117

SN 1435882-0010-001

Fig.6

The label contains the following characteristics:

Characteristics of the cleaner

Cleaner designation TSG 4.5 mm CPTFE 1"BSP

Part number 4660-4969-117

Serial number

1438612-0010-001

The serial number is composed of: Order

confirmation number - item number - serial

number.

5.2 Cyclone:

Technical specifications – Cyclone

Term Description

Standard materials Stainless steel, C-PTFE or PTFE

Standard connection Inner threads 3/4" BSP/NPT // 1"PinFix / 3/4"

BSPT / 3/4" NPS

Working temperature max. 95 °C (203 °F)

Ambient temperature max. 140 °C (284 °F), max. 30 min

Operational system pressure 4...10 bar (58...145 psi)

Tank opening min. Ø 77 mm (3 inch)

Nozzle specifications 360° spray pattern

Four nozzles with 3 mm / 4 mm bore

Technical data

Identification

430BAL011762EN_2

18 28.05.2018

5.3 Twister:

Technical specifications – Twister

Term Description

Standard materials Stainless steel, C-PTFE, PTFE

Standard connection Inner threads 3/4" BSP/NPT // 1"PinFix / 3/4"

BSPT / 3/4" NPS

Working temperature max. 95 °C (203 °F)

Ambient temperature max. 140 °C (284 °F), max. 30 min

Operational system pressure 4...10 bar (58...145 psi)

Tank opening min. Ø 100 mm (3.94 inch)

Nozzle specifications 360° spray pattern

Four nozzles with 3 mm / 4 mm bore

5.4 Typhoon

Technical specifications – Typhoon

Term Description

Standard materials Stainless steel, C-PTFE, PTFE

Standard connection Inner threads 1" BSP/NPT // 1"PinFix / 1"

BSPT / 1" NPS

Working temperature max. 95 °C (203 °F)

Ambient temperature max. 140 °C (284 °F), max. 30 min

Operational system pressure 4...10 bar (58...145 psi)

Tank opening min. Ø 130 mm (5.12 inch)

Nozzle specifications 360° spray pattern

Four nozzles with 3 mm / 4.5 mm / 6 mm bore

5.5 Tempest

Technical specifications – Tempest

Term Description

Standard materials Stainless steel, C-PTFE, PTFE

Standard connection Inner threads 1.5" BSP/NPT // 1.5"PinFix / 1.5"

BSPT / 1.5" NPS

Working temperature max. 95 °C (203 °F)

Ambient temperature max. 140 °C (284 °F), max. 30 min

Operational system pressure 4...10 bar (58...145 psi)

Technical data

Twister:

430BAL011762EN_2

28.05.2018 19

Technical specifications – Tempest

Term Description

Tank opening min. Ø 210 mm (8.27 inch)

Nozzle specifications 360° spray pattern

Four nozzles with 7 mm / 8 mm bore

5.6 Tornado

Technical specifications – Tornado

Term Description

Standard materials Stainless steel, C-PTFE, PTFE

Standard connection Inner thread: 1.5" BSP/NPT // 1.5"PinFix / 1.5"

BSPT / 1.5" NPS

Working temperature max. 95 °C (203 °F)

Ambient temperature max. 140 °C (284 °F), max. 30 min

Operational system pressure 4...10 bar (58...145 psi)

Tank opening min. Ø 220 mm (8.66 inch)

Nozzle specifications 360° spray pattern

Two nozzles with 11 mm bore

5.7 Tornado 4

Technical specifications – Tornado 4

Term Description

Standard materials Stainless steel, C-PTFE, PTFE

Standard connection Inner thread: 2" BSP/NPT // 2.5"PinFix / 2"

BSPT / 2" NPS

Working temperature max. 95 °C (203 °F)

Ambient temperature max. 140 °C (284 °F), max. 30 min

Operational system pressure 4...10 bar (58...145 psi)

Tank opening min. Ø 250 mm (9.84 inch)

Nozzle specifications 360° spray pattern

Four nozzles with 8 mm / 9 mm / 10 mm /

11 mm / 12 mm bore

5.8 Resistance of Sealing Materials

Technical data

Tornado

430BAL011762EN_2

20 28.05.2018

This manual suits for next models

5

Table of contents

Other Breconcherry Ultrasonic Jewelry Cleaner manuals

Popular Ultrasonic Jewelry Cleaner manuals by other brands

CIXI V-MART

CIXI V-MART VSC28A instruction manual

inventum

inventum RR410 instruction manual

Graymills

Graymills HANDI-KLEEN PL364 Operation and maintenance instructions

Wilson Electronics

Wilson Electronics 9506-2200 Operating instructions & service manual

Melissa

Melissa 631-102 user guide

Belanger

Belanger DuraBlaster owner's manual

Kärcher

Kärcher 1.084 Series manual

Nilfisk-Euroclean

Nilfisk-Euroclean Compact Patio operating instructions

Miele

Miele SEB 213 operating instructions

formlabs

formlabs Form Wash Installation and usage instructions

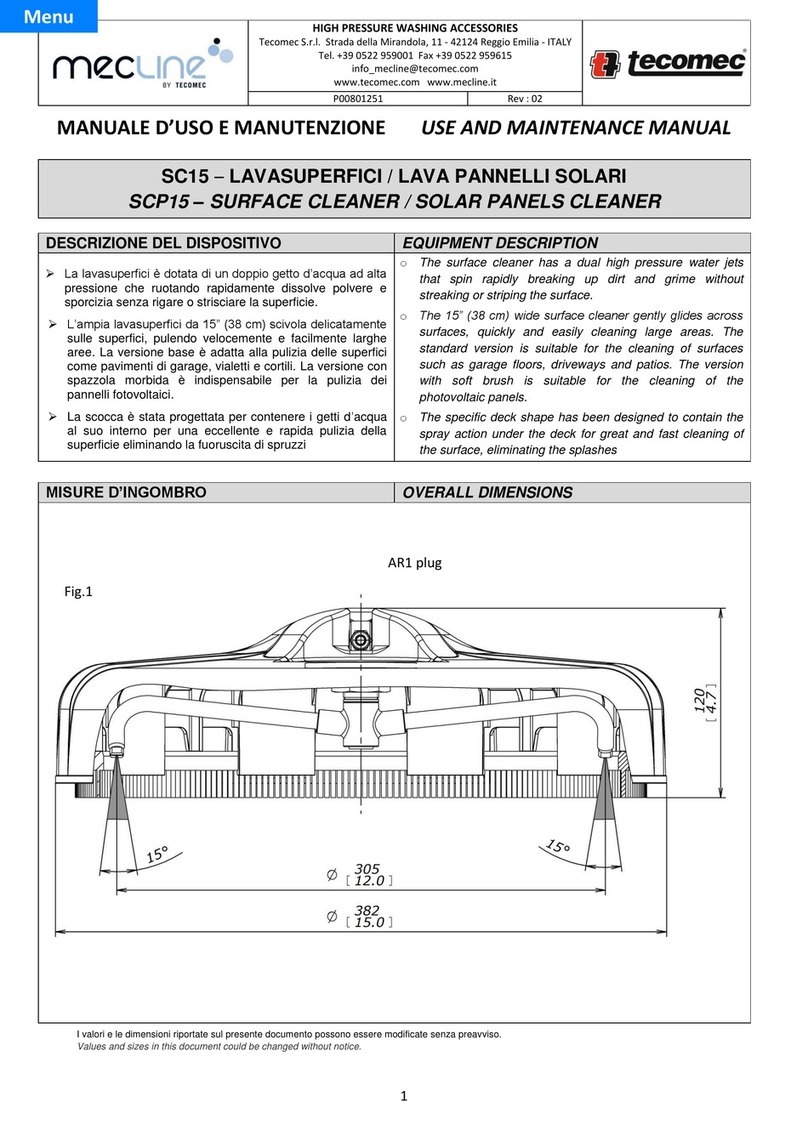

Tecomec

Tecomec Mecline SC15 Use and maintenance manual

Kränzle

Kränzle Round Cleaner UFO light operating manual