Breconcherry Planetary Gear Stainless Steel User manual

Breconcherry Cleaning Technology

Cleaner ATEX Version

Operating instruction (Translation from the original language)

430BAL011767EN_3

COPYRIGHT

These Operating Instructions are the English translation of the original operating

instructions in the sense of the EU Machinery Directive. This document is

protected by copyright. All rights reserved. The document may not, in whole or in

part, be copied, reproduced, translated or reduced to an electronic medium of

machine-readable form without the express permission of Breconcherry.

LEGAL NOTICE

_

We kindly request that you answer a few short questions about these Operating

Instructions. Use the following QR code or link to access the questionnaire:

https://www.ntgt.de/ra/s.aspx?s=367112X57707125X58087

430BAL011767EN_3

2 28.05.2018

TABLE OF CONTENTS

1 General Information 5

1.1 Information about this document 5

1.1.1 Binding Character of These Operating Instructions 5

1.1.2 Validity of the Instruction manual 5

1.2 Manufacturer address 5

1.3 Contact 5

1.4 Marking 6

2 Safety 8

2.1 Intended use 8

2.1.1 Requirements for operation 8

2.1.2 Improper operating conditions 8

2.2 Safety notes 8

2.3 Operating Conditions 10

2.3.1 Temperature 10

2.3.2 Pressure 11

2.3.3 Flow volume 11

3 Declaration of Conformity 14

4 Cleaning 15

4.1 The cleaning of the tanks in explosive atmospheres 15

4.1.1 Basics 15

4.1.2 Guidelines 15

4.2 Selection of the cleaning parameters according to TRGS 727:2016 16

4.2.1 Cleaning with water jets with pressures of up to 12 bar 16

4.2.2 Clean with solvents of low and medium conductivity from pressures up to 12 bar 16

5 Maintenance 17

5.1 Putting cleaner in the tank - mechanically generated sparks 17

5.2 Manhole cover 17

5.3 Electric functions 17

5.4 Grounding - electrical load 17

5.5 Filling the tanks 18

5.6 Inerting 18

5.7 Foreign material in the fluids. 18

5.8 Petroleum vehicles 18

5.9 Maintenance / servicing 18

5.9.1 Authorized personnel / OEM replacement parts 18

5.9.2 Maintenance 18

5.10 Flow and operational parameter monitoring for orbital cleaners 19

6 Additional information on cleaner selection 20

6.1 Possibilities of ATEX classification 20

6.1.1 Cleaner with its own potential ignition source 20

6.1.2 Additional restrictions on usable substances 21

6.2 Instructions for the operation of the cleaner 21

6.3 Explosion groups 21

6.4 Substance classification 21

7 Further information sources 22

8 Appendix 23

8.1 Lists 23

8.1.1 Abbreviations and terms 23

430BAL011767EN_3

28.05.2018 3

430BAL011767EN_3

4 28.05.2018

1 General Information

1.1 Information about this document

The present Operating Instructions are part of the user information for the

component.

1.1.1 Binding Character of These Operating Instructions

These Operating Instructions contain the manufacturer's instructions to the

operator of the product and to all persons who work on or use the product

regarding the procedures to follow.

Carefully read these Operating Instructions before starting any work on or using

the product. Your personal safety and the safety of the product can only be

ensured if you act as described in the Operating Instructions.

Store the Operating Instructions in such a way that they are accessible to the

operator and the operating staff during the entire life cycle of the product. When

the location is changed or the product is sold make sure you also provide the

Operating Instructions.

1.1.2 Validity of the Instruction manual

The instruction manual is valid exclusively for the cleaner marked with an ATEX

marking.

The approved cleaners are suitable for operation in potentially explosive

atmospheres, taking into account the relevant regulations and the manufacturer's

declaration or declaration of conformity.

Use in potentially explosive atmospheres must be specified when ordering, as the

ATEX cleaners are slightly modified and labelled.

Their conformity, and therefore, their suitability for the intended purpose with

regard to the safety of the product in which they are installed must be assessed

in the conformity assessment of the entire product.

The ATEX version of the cleaner may only be safely used in hazardous areas for

the intended area. This manual contains basic instructions for the use of the

cleaner in potentially explosive atmospheres. This document is a supplement to

the general standard operating instructions for the cleaner and is therefore to be

considered part of it. These additional operating instructions must be observed

before installation and commissioning. The operating instructions must always be

available at the cleaner/system site.

1.2 Manufacturer address

1.3 Contact

Phone:+44 (0)1531 632476

Fax: +44 (0)1531 633839

General Information

Information about this document

430BAL011767EN_3

28.05.2018 5

Breconcherry Ltd

Westfalia House, Old Wolverton Road

Milton Keynes, MK12 5PY, United Kingdom

Mail: [email protected] Web: http://

www.breconcherry.com

1.4 Marking

The orbital cleaners have a labelling on the lower rotating body. The following

data is available depending on the material being used.

Planetary gear stainless steel

Logo

Fig.1

Short Name I.e. Ty TSG 4.5mm CPTFE 1"BSP"

Comes from: Type, i.e. Ty, Variants, i.e., TSG, Nozzle bore, i.e. 4.5mm, Bearing

materials, i.e. C-PTFE, connections, i.e. 1"BSP

Material number / Year of Manufacture e.i. 4660-4969-117 YOC2018

Serial number i.e. SN 1435882-0010-001

ATEX labelling

Fig.2 Fig.3

II 1G Ex h IIC T3..T6 Ga

0°C ≤ Ta ≤ 140°C

Fig.4 Fig.5

II 1D Ex h IIIC T140 °C Da

0°C ≤ Ta ≤ 140°C

Certification number: TPS 18 ATEX 22040 001 X

Address Breconcherry Ltd

Westfalia House, Old Wolverton Road Milton

Keynes, MK12 5PY, United Kingdom

General Information

Marking

430BAL011767EN_3

6 28.05.2018

Planetary gear PEEK

Logo

Fig.6

Short Name i.e. Ty TSG 4.5mm CPTFE/PEEK 1"BSP"

Comes from: Type, i.e. Ty, Variants, i.e., TSG, Nozzle bore, i.e. 4.5mm, bearing

materials, i.e. C-PTFE, connections, i.e. PEEK. Connection, i.e. 1”BSP

Material number / Year of Manufacture e.i. 4660-4969-130 YOC2018

Serial number i.e. SN 1435883-0010-001

ATEX labelling

Fig.7 Fig.8

Typhoon, Tempest,

Tornado, Tornado 4:

II 1G Ex h IIB T3..T6 Ga

II 1D Ex h IIIC T140°C Da

0°C ≤ Ta ≤ 140°C

Fig.9 Fig.10

Cyclone, Twister:

II 1G Ex h IIC T3...T6 Ga

II 1D Ex h IIIC T140°C Da

0°C ≤ Ta ≤ 140°C

Certification number: TPS 18 ATEX 22040 001 X

Address

Fig.11

General Information

430BAL011767EN_3

28.05.2018 7

Breconcherry Ltd

Westfalia House, Old Wolverton Road Milton

Keynes, MK12 5PY, United Kingdom

2 Safety

2.1 Intended use

The cleaner is intended for the cleaning of tanks and vessels. This cleaner was

designed for the installation and operation at any angle. Using the device for any

other purpose is considered contrary to its designated use.

The cleaner is intended only for operation with supply of liquid medium. Exposure

to air, other gaseous media or steam is also not permitted, even for a short time.

Hint!

The manufacturer will not accept any liability for damage resulting

from any use of the cleaner which is not in accordance with its

designated use. The risk of such misuse lies entirely with the operator

of the facility.

2.1.1 Requirements for operation

The prerequisite for reliable and safe operation of the component is proper

transportation and storage as well as professional installation and assembly.

Operating the unit within the limits of its designated use also involves adhering to

the operating, inspection and maintenance instructions.

2.1.2 Improper operating conditions

The operational reliability of the cleaner cannot be ensured under improper

operating conditions. Therefore avoid improper operating conditions.

Operating the cleaner is not permitted if

•Persons or objects are in the danger zone.

•Safety devices are not working or were removed.

•Malfunctions have been detected on the cleaner.

•Damage has been detected on the cleaner.

•Maintenance intervals have been exceeded.

2.2 Safety notes

Please heed the following notes

•Conformity applies only to cleaners without electrical components.

•Before putting the cleaner into operation, make sure that nobody can be

endangered by the cleaner’s running.

•Never operate the cleaner outside the object to be cleaned.

•Rotating parts and spilled cleaning fluid can endanger people and cause

property damage.

•The cleaners may only be operated if cleaning fluid is supplied. For the orbital

cleaners, flow control with a time-delayed start-up must be ensured by the

operator (see chapter "Flow monitoring", section 5.10, page 20).

Safety

Intended use

430BAL011767EN_3

8 28.05.2018

•The cleaner must not be exposed to gas and vapour instead of liquid, not

even briefly when starting the cleaning process and emptying pipes. High

speeds and increased friction could cause damage and ignition hazards.

•The cleaners must be filled with cleaning fluid without pressure and then

started gently. Filling under pressure would amount to a short-term operation

with gas or vapour, which can lead to ignition hazards. A sudden start can

lead to damage and thus to an ignition source. Pressure surges are to be

avoided.

•In the event of malfunctions, shut down the cleaner (disconnect from the

power, air and fluids supplies) and secure it against further use. Defects are

to be rectified immediately.

•The maximum operating conditions must be observed and monitored (see

chapter "Operating conditions", section 2.3, page 10). There is a danger that

excessive charge formation may lead to increased wear and leaks (see

chapter "Selection of cleaning parameters", section 4.2, page 16).

•Observe the safety data sheets supplied by the detergent manufacturers. The

cleaner must only be operated with such cleaning detergents and used in

such mediums against which all materials used are sufficiently resistant. The

sealing materials must always be matched to the type and temperature of the

cleaning medium.

•During cleaning, liquids must be removed from the tank so that no

electrostatic charges build up in the liquid that could accumulate. During

cleaning, do not add any liquids in the container.

•At the start of tank or container cleaning, atmospheric conditions must be

present inside, see table "Conditions for starting tank cleaning" (Page 10).

•The cleaning medium must be removed after spraying and must not be

pumped through the cleaner again.

•The cleaner must be regularly checked for damage and function, taking into

account the operating conditions. Breconcherry recommends a visual

inspection at every cleaning process.

•Maintenance of the ATEX cleaner is mandatory after a maximum of 150

operating hours. Maintenance-free cleaners (usually rotating cleaners) must

be inspected after a maximum of 150 operating hours and after a maximum of

3 years or 2500 hours of operation. Depending on the operating conditions,

the operator must specify shorter maintenance intervals or inspection

intervals.

•The performed maintenance must be logged.

•The user must ensure a loss-proof lead connection into the tank. For this,

Breconcherry offers, among other things, suitable components and a

mounting system.

Safety

Safety notes

430BAL011767EN_3

28.05.2018 9

Conditions when starting the tank cleaning

Designation Size

Absolute pressure 0.8...1.1 bar

Ambient temperature See the instruction manual of the

cleaner

Operating temperature See the instruction manual of the

cleaner

Temperature in the tank See the instruction manual of the

cleaner

Acidity content Maximum of 21% by volume

Relative ambient humidity until saturation

2.3 Operating Conditions

The cleaner is driven by the cleaning liquid flowing through it at a suitable

pressure and flow rate. For effective operation, the cleaning fluid must be

supplied to the cleaner at the correct pressure, flow and temperature. The

requirements are specified in the tables below.

2.3.1 Temperature

The maximum surface temperature depends mainly on the operating conditions

and not on the device itself. Therefore, the device is characterized for a range of

temperature classes or a temperature range.

The temperature classes define ignition ranges, according to which combustible

gases and flammable liquids are classified according to their specific ignition

temperature. The ignition temperature of the media can be determined from

relevant tables, e.g. International Chemical Safety Cards (ICSC) http://

biade.itrust.de.

To comply with the required temperature class, the respective maximum

operating and ambient temperatures must be strictly observed and monitored:

The following table applies to Orbital Cleaner, Troll Ball, Turbo SSB, Sanitor, Turbodisc, Chemidisc and Sanidisc.

Temperature

class Maximum surface temperature Proper operating conditions

T3 ≤200 °C Operating and medium temperatures - maximum 95°C

Ambient temperature: maximum 140°C (minimum °C)

T4 ≤135 °C Operating and medium temperatures - maximum 95°C

Ambient temperature: maximum 100°C

T5 ≤100 °C Operating and medium temperatures - maximum 75°C

Ambient temperature: maximum 75 °C

T6 ≤85 °C Operating and medium temperatures - maximum 60 °C

Ambient temperature: maximum 60 °C

Safety

Operating Conditions

430BAL011767EN_3

10 28.05.2018

The following tables apply to the Torus and the Chemitorus

Temperature

class Maximum surface temperature Proper operating conditions

T5 ≤100 °C Operating and medium temperatures - maximum 65 °C

Ambient temperature: maximum 75 °C (minimum °C)

T6 ≤85 °C Operating and medium temperatures - maximum 60 °C

Ambient temperature: maximum 60 °C

2.3.2 Pressure

The proper operational pressures are given in the following tables. The specified

operating pressures must be observed and monitored.

Hint!

The specified pressure is the pressure at the cleaning head and not at

the pump.

Cleaner Operating pressure range

Orbital cleaner 4 – 10bar

Turbo SSB 40

Turbo SSB 75

Turbo SSB 125

2 - 5 bar

2 - 10 bar

2 - 6 bar

Turbodisc & Chemidisc 2 - 4 bar

Torus & Chemitorus 1 - 4 bar

Sanidisc 2 - 4 bar

Troll Ball 3 - 12 bar

2.3.3 Flow volume

For the safe operation of the orbital cleaner, flow monitoring is required, see

chapter "Safety instructions” and chapter "Flow monitoring” Section 5.10,

Page 19.

The specified flow volumes must not deviate more than 10% from the specified

values and must be monitored. For safer operation, the safety instructions and

operating parameters of TRGS-727: 2016 (see chapter 4.2) must be observed.

Operating flow rate and pressure requirements for cleaner, Cyclone – 3 mm nozzles

Required

flow

Throughput

[m3/h] 2.5 2.8 3.1 3.3 3.5 3.7 4.0

[l/min] 42 47 51 55 59 62 66

[USgpm] 11.1 12.4 13.5 14.5 15.6 16.4 17.4

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Safety

Operating Conditions

430BAL011767EN_3

28.05.2018 11

Operating flow rate and pressure requirements for cleaner, Cyclone – 4 mm nozzles

Required

flow

Throughput

[m3/h] 4.0 4.5 4.9 5.2 5.6 5.9 6.2

[l/min] 67 75 82 87 93 98 103

[USgpm] 17.7 19.8 21.7 23.0 24.6 25.9 27.2

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Twister

Operating flow rate and pressure requirements for cleaner, Twister – 3 mm nozzles

Required

flow

Throughput

[m3/h] 2.7 2.9 3.2 3.4 3.6 3.8 4.1

[l/min] 45 49 54 57 60 64 68

[USgpm] 11.9 12.9 14.3 15.1 15.9 16.9 18.0

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Operating flow rate and pressure requirements for cleaner, Twister – 4 mm nozzles

Required

flow

Throughput

[m3/h] 3.9 4.3 4.7 5.0 5.3 5.6 5.8

[l/min] 65 72 78 84 88 93 97

[USgpm] 17.2 19.0 20.6 22.2 23.2 24.6 25.6

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Typhoon

Operating flow rate and pressure requirements for cleaner, Typhoon – 3 mm nozzles

Required

flow

Throughput

[m3/h] 2.9 3.4 4.0 4.4

[l/min] 48.0 57.0 66.0 73.0

[USgpm] 12.7 15.1 17.4 19.3

Required

Pressure

[bar] 4.0 6.0 8.0 10.0

[psi] 58.0 87.0 116.0 145.0

Operating flow rate and pressure requirements for cleaner, Typhoon – 4.5 mm nozzles

Required

flow

Throughput

[m3/h] 5.6 6.2 6.7 6.9 7.1 7.3 7.6

[l/min] 93.3 103.3 111.7 115.0 118.3 121.7 126.7

[USgpm] 24.7 27.3 29.5 30.4 31.3 32.1 33.5

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Operating flow rate and pressure requirements for cleaner, Typhoon – 6.0 mm nozzles

Required

flow

Throughput

[m3/h] 7.4 8.2 8.9 9.6 10.0 10.3 10.5

[l/min] 123.3 136.7 148.3 160.0 166.7 170.8 175.0

Safety

Operating Conditions

430BAL011767EN_3

12 28.05.2018

Operating flow rate and pressure requirements for cleaner, Typhoon – 6.0 mm nozzles

[USgpm] 32.6 36.1 39.2 42.3 44.0 45.1 46.2

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Tempest

Operating flow rate and pressure requirements for cleaner, Tempest– 7 mm nozzles

Required

flow

Throughput

[m3/h] 12.0 13.7 15.3 16.7 18.0 18.6 19.2

[l/min] 200 227.5 255.0 277.5 300.0 310.0 320.0

[USgpm] 52.8 60.1 67.4 73.3 79.3 81.9 84.5

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Operating flow rate and pressure requirements for cleaner, Tempest– 8 mm nozzles

Required

flow

Throughput

[m3/h] 13.5 15.8 18.0 19.5 21.0 22.2 23.4

[l/min] 225.0 262.5 300.0 325.0 350.0 370.0 390.0

[USgpm] 59.4 69.3 79.3 85.9 92.5 97.7 103.0

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Tornado

Operating flow rate and pressure requirements for cleaner, Tornado – 11 mm nozzles

Required

flow

Throughput

[m3/h] 14.6 15.4 16.1 18.3 20.4 21.6 22.7

[l/min] 243.3 255.8 268.3 304.2 340.0 359.2 378.3

[USgpm] 64.3 67.6 70.9 80.4 89.8 94.9 99.9

Required

Pressure

[bar] 4.0 5.0 6.0 7.0 8.0 9.0 10.0

[psi] 58.0 72.5 87.0 101.5 116.0 130.5 145.0

Tornado 4

Operating flow rate and pressure requirements for cleaner, Tornado 4 – 8 mm nozzles

Required

flow

Throughput

[m3/h] 14.2 16.9 19.2 21.3

[l/min] 236.0 282.0 320.0 355.0

[USgpm] 62.3 74.5 84.5 93.8

Required

Pressure

[bar] 4.0 6.0 8.0 10.0

[psi] 58.0 87.0 116.0 145.0

Safety

430BAL011767EN_3

28.05.2018 13

20180607_Konformitätserklärung_Orbital_Breconcherry_1_EN.docx

1/1

EU-Conformity Declaration according to ATEX 2014/34/EU

Manufacturer:

Breconcherry Ltd.

Westfalia House, Old Wolverton Road

Milton Keynes, MK12 5PY, United Kingdom

Hereby we declare that the following named devices

Model: Orbital cleaners

Type:

Planetary Gear Stainless Steel Planetary Gear PEEK

Cyclone: Cy TSG x CPTFE y Cy TSG x CPTFE/PEEK y

Twister: Tw TSG x CPTFE y Tw TSG x CPTFE/PEEK y

Typhoon: Ty TSG x CPTFE y Ty TSG x CPTFE/PEEK y

Tempest: Te TSG x CPTFE y Te TSG x CPTFE/PEEK y

Tornado: To TSG x CPTFE y To TSG x CPTFE/PEEK y

Tornado 4: To4 TSG x CPTFE y To4 TSG x CPTFE/PEEK y

x: Nozzle diameter / y: Connection

because of their design and construction, as well as in the form we have placed on the market, comply with the essential

health and safety requirements of the following directive:

Relevant EC directives:

Designation:

EU 2014/34

A

TEX Directive

Planetary Gear Stainless Steel Planetary Gear PEEK

Typhoon, Tempest, Tornado Tornado 4: Typhoon, Tempest, Tornado Tornado 4:

II 1G Ex h IIC T3…T6 Ga

II 1D Ex h IIIC T140°C Da

0°C ≤Ta≤140°C

II 1G Ex h IIB T3…T6 Ga

II 1D Ex h IIIC T140°C Da

0°C ≤Ta≤140°C

Cyclone Twister: Cyclone, Twister:

II 1G Ex h IIC T3…T6 Ga

II 1D Ex h IIIC T140°C Da

0°C ≤Ta≤140°C

II 1G Ex h IIC T3…T6 Ga

II 1D Ex h IIIC T140°C Da

0°C ≤Ta≤140°C

The notified body TÜV Süd Product Service GmbH (0123) has carried out an EC type sample examination and issued the

following certificate: TPS 18 ATEX 22040 001 X

A

pplied harmonized standards, in particular:

Other applied standards and

Technical Specifications:

EN 1127-1:2011

EN ISO 80079-36:2016

EN ISO 80079-37:2016

TRGS 727:2016

Comment:

The ATEX operating instructions, including their intended use and safety instructions, must

be observed.

Electrical / electronic and other equipment and components in connection with the

aforementioned devices must undergo their own conformity assessment according to ATEX.

A

uthorized person for the compilation and delivery of

technical documentation:

Breconcherry Ltd.

CE Documentation Officer

Westfalia House, Old Wolverton Road

Milton Keynes, MK12 5PY, United Kingdom

Milton Keynes, 20 June 2018

________________________________

Ilija Aprcovic

Managing Director

4 Cleaning

4.1 The cleaning of the tanks in explosive atmospheres

4.1.1 Basics

When cleaning containers, especially when blasting and spraying liquids, high

and dangerous electrostatic charges may occur, resulting in spark discharge

processes.

Impacting cleaning jets form droplets or mists during dicing that may be charged

and then generate electrical charges in the container. Existing turbulences

distribute the charged mist throughout the container and thus can create high

space charge density with high field strengths.

At the same time, the cleaning liquid itself or the medium in the tank can be

combustible and thus form an explosive atmosphere.

Thus, the three basic conditions for explosions with dangerous effects are

created:

•Flammable gas / flammable dust

•Effective ignition sources

•Acid.

4.1.2 Guidelines

If there is a risk of explosion with dangerous effects, the following guidelines must

be applied in all EU countries, among others: see table "Guidelines to be

applied".

Applicable guidelines

Manufacturer responsibility Operator responsibility

Directive 2014/34/EU. Directive 1999/92/EG.

Explanation of ATEX conformity for a

product or declaration that the product

has no potential sources of ignition

Preparation of the explosion protection

document for an installation:

ATEX conformity includes:

Determination of the category and

additional limits of use

This includes:

Definition of the explosion zones and

the additional plant conditions

Category 1 *) ==>

Category 2 *) ==>

Category 3 *) ==>

For Zone 0 *)

For Zone 1 *)

For Zone 2 *)

*) Particular limitations must always be considered, e.g. Temperature classes.

In addition, the regulations of the local supervisory authority apply.

Outside the EU, separate and divergent regulations apply to protect against

explosions and their damaging effects, e.g. in the US, the NEC National Electric

Code set of rules along with the UL standards. These regulations must be applied

in these countries. Some of them require their own approval procedures.

Cleaning

The cleaning of the tanks in explosive atmospheres

430BAL011767EN_3

28.05.2018 15

4.2 Selection of the cleaning parameters according to TRGS 727:2016

For the information, Breconcherry assumes no responsibility. If there is a risk of

explosion due to the use of cleaners, all current ATEX relevant standards and

regulations must always be applied.

4.2.1 Cleaning with water jets with pressures of up to 12 bar

When cleaning with water jets up to 12 bar and with up to 20 nozzles, no

dangerous charges are to be expected as long as the liquid flow rate does not

exceed 7 l/s and the tank volume does not exceed 10 m3 .

4.2.2 Clean with solvents of low and medium conductivity from pressures up to 12 bar

(1) When cleaning liquids of low and medium conductivity, e.g. organic solvents,

are used, the proportion of a second phase, e.g. water or solid, may not exceed

1%.

(2) Cleaning agents may only be run in a closed circuit if the impurities are kept

below 1%.

Hint!

The accumulation of liquid in the container during cleaning should be

avoided.

Hint!

Low-conductivity liquids, such as hydrocarbons, are less charged

during spraying than water because they contain only a small

concentration of dissociated ions.

Cleaning

Selection of the cleaning parameters according to TRGS 727:2016

430BAL011767EN_3

16 28.05.2018

5 Maintenance

5.1 Putting cleaner in the tank - mechanically generated sparks

If the cleaner is not permanently installed in the tank, but is retracted or retracted

automatically or manually, there is a risk of mechanically generated sparks during

collisions.

To avoid sparks,

•the lowering and lifting speed must not exceed 1 m/s

•the impact energy does not exceed 500 J

•It must be avoided that the cleaner comes into contact with aluminium and

other light metals.

If this can not be avoided, further requirements from the standards must be met,

see EN ISO 80079-36:2016. The risk of sparks generated by single strikes must

always be considered in the ignition hazard analysis of the cleaning system.

For cleaning, the cleaner must be firmly connected to the tank via a mounting

flange or via a manhole cover plate.

Additional safety measures must be taken so that the cleaner starts only in the

container.

Proper condition and safe handling of the device must be ensured by the

operator.

5.2 Manhole cover

If a cleaner in a potentially explosive area is placed in a tank with a manhole

cover plate, it must rest flat. Open ventilation holes must not be installed.

It must be taken into account that the cleaner has no flame arrester and the

connection of the cleaner housing ==> Cleaner lance and container interior is not

flame-proof.

5.3 Electric functions

If the cleaner is equipped with electrical components, e.g. sensors and motors,

they must have their own ATEX approval. The operator must ensure the correct

connection and secure cable routing.

In particular, cable entry points must comply with the valid technical regulations

and must not show any kinks or sharp edges.

5.4 Grounding - electrical load

Tanks must be grounded. Tankers must be grounded via copper cable and

connectors.

The cleaner (orbital cleaner, rotating and static cleaners) must be introduced into

the system via the grounded piping.

The operator is obliged to ensure equipotential bonding with the tank for the

cleaner. All conductive parts of the system must be grounded.

Maintenance

Putting cleaner in the tank - mechanically generated sparks

430BAL011767EN_3

28.05.2018 17

5.5 Filling the tanks

The container outlet must be open during the cleaning process. Thus, it is not a

filling process.

5.6 Inerting

In the case of an explosive atmosphere in the tank and tank dimensions that

exceed the container diameter of 3 m, an inert gas, for example, may only be

introduced so that a formation of mist or sublimate is avoided. Wet steam and

CO2 are not suitable. Nitrogen and noble gases, for example, are suitable. The

inert gas must be introduced solids-free and slowly through the largest possible

openings.

5.7 Foreign material in the fluids.

There is a risk that a foreign body shoots out of the nozzle when the mesh size of

the sieve has fallen or the sieve is defective (torn). The foreign bodies are

embedded in the liquid, since the operation of the device is only allowed when

liquid is present.

The following applies: The operator must ensure that only permissible media are

used that contain no solids.

Before putting the system into operation, all foreign objects such as screws, nuts

and welding beads must be removed.

The cleaning medium must be removed after spraying and must not be pumped

through the cleaner again. Corresponding preparation is acceptable, the quality

of the medium must be guaranteed and is the duty of care of the operator.

5.8 Petroleum vehicles

The hazardous area for petroleum vehicles is defined in the Ordinance on

Flammable Liquids (TRbF).

5.9 Maintenance / servicing

5.9.1 Authorized personnel / OEM replacement parts

The cleaners may only be serviced and repaired by authorized personnel. Only

OEM spare parts intended for use in potentially explosive atmospheres must be

used, which must be requested from Breconcherry.

Changes to the cleaners are not permitted without the consent of the ATEX

officer of Breconcherry.

If changes are made or if OEM spare parts are not used for applications in

potentially explosive atmospheres, the enclosed ATEX declarations lose their

validity and their use in potentially explosive atmospheres is no longer permitted.

5.9.2 Maintenance

The cleaner must be regularly checked for damage and function, taking into

account the operating conditions. Breconcherry recommends a visual inspection

at every cleaning process.

Maintenance

Filling the tanks

430BAL011767EN_3

18 28.05.2018

Maintenance of the ATEX cleaner is mandatory after a maximum of 150

operating hours. Depending on the operating conditions, the operator must

specify shorter maintenance intervals.

The performed maintenance must be logged.

Only original Breconcherry maintenance and wear kits intended for ATEX may

be used.

If the maintenance instructions are not followed, the cleaner loses its ATEX

conformity and must not be used in explosive areas.

5.10 Flow and operational parameter monitoring for orbital cleaners

In order to ensure that the orbital cleaner is operated with fluid, the operator must

use a suitable monitoring system.

ATEX approved flow monitoring systems recommended by Breconcherry:

•Flow switch type SF311A; Manufacturer ifm electronic GmbH

•Evaluation unit type SR2301; Manufacturer ifm electronic GmbH

•Evaluation unit type SN2301; Manufacturer ifm electronic GmbH

The instructions and manufacturer's instructions for maintenance and calibration

of the flow monitoring system must be taken into account. The ignition protection

system should have ignition protection level b1, (see EN ISO 80079-37:2016).

The monitoring of the temperature, the pressure and the flow volume must be

guaranteed, (see chapter “Operating Conditions” Section 2.3, Page 9).

Maintenance

Flow and operational parameter monitoring for orbital cleaners

430BAL011767EN_3

28.05.2018 19

6 Additional information on cleaner selection

6.1 Possibilities of ATEX classification

6.1.1 Cleaner with its own potential ignition source

Ignition protection measures are required so that the cleaner is grouped into a

category depending on the likelihood of a potential ignition hazard and other

limiting factors.

This restricts the application to certain zones (Directive 1999/92/EC) and places

additional restrictions on operation.

Hint!

The declaration of conformity according to 2014/34/EU must be

available in any case and belongs in the explosion protection

document.

The Orbital Cleaner of the company Breconcherry are EC type approved

and can be safely used under the following classification.

Planetary gear stainless steel Planetary gear PEEK

Typhoon, Tempest, Tornado, Tornado 4 Typhoon, Tempest, Tornado, Tornado 4

Fig.13 Fig.14

II 1G Ex h IIC T3..T6 Ga

Fig.15 Fig.16

II 1G Ex h IIB T3..T6 Ga

0°C ≤Ta≤140°C 0°C ≤Ta≤140°C

Fig.17 Fig.18

II 1D Ex h IIIC T140 °C Da

Fig.19 Fig.20

II 1D Ex h IIIC T140 °C Da

0°C ≤Ta≤140°C 0°C ≤Ta≤140°C

Cyclone, Twister Cyclone, Twister

Fig.21 Fig.22

II 1G Ex h IIC T3..T6 Ga

Fig.23 Fig.24

II 1G Ex h IIC T3..T6 Ga

0°C ≤Ta≤140°C 0°C ≤Ta≤140°C

Fig.25 Fig.26

II 1D Ex h IIIC T140 °C Da

Fig.27 Fig.28

II 1D Ex h IIIC T140 °C Da

0°C ≤Ta≤140°C 0°C ≤Ta≤140°C

Hint!

The maximum surface temperature depends mainly on the operating

conditions. The allowable temperatures can be found in the chapter

Operating Conditions.

Additional information on cleaner selection

Possibilities of ATEX classification

430BAL011767EN_3

20 28.05.2018

This manual suits for next models

1

Table of contents

Other Breconcherry Ultrasonic Jewelry Cleaner manuals

Popular Ultrasonic Jewelry Cleaner manuals by other brands

CIXI V-MART

CIXI V-MART VSC28A instruction manual

inventum

inventum RR410 instruction manual

Graymills

Graymills HANDI-KLEEN PL364 Operation and maintenance instructions

Wilson Electronics

Wilson Electronics 9506-2200 Operating instructions & service manual

Melissa

Melissa 631-102 user guide

Belanger

Belanger DuraBlaster owner's manual

Kärcher

Kärcher 1.084 Series manual

Nilfisk-Euroclean

Nilfisk-Euroclean Compact Patio operating instructions

Miele

Miele SEB 213 operating instructions

formlabs

formlabs Form Wash Installation and usage instructions

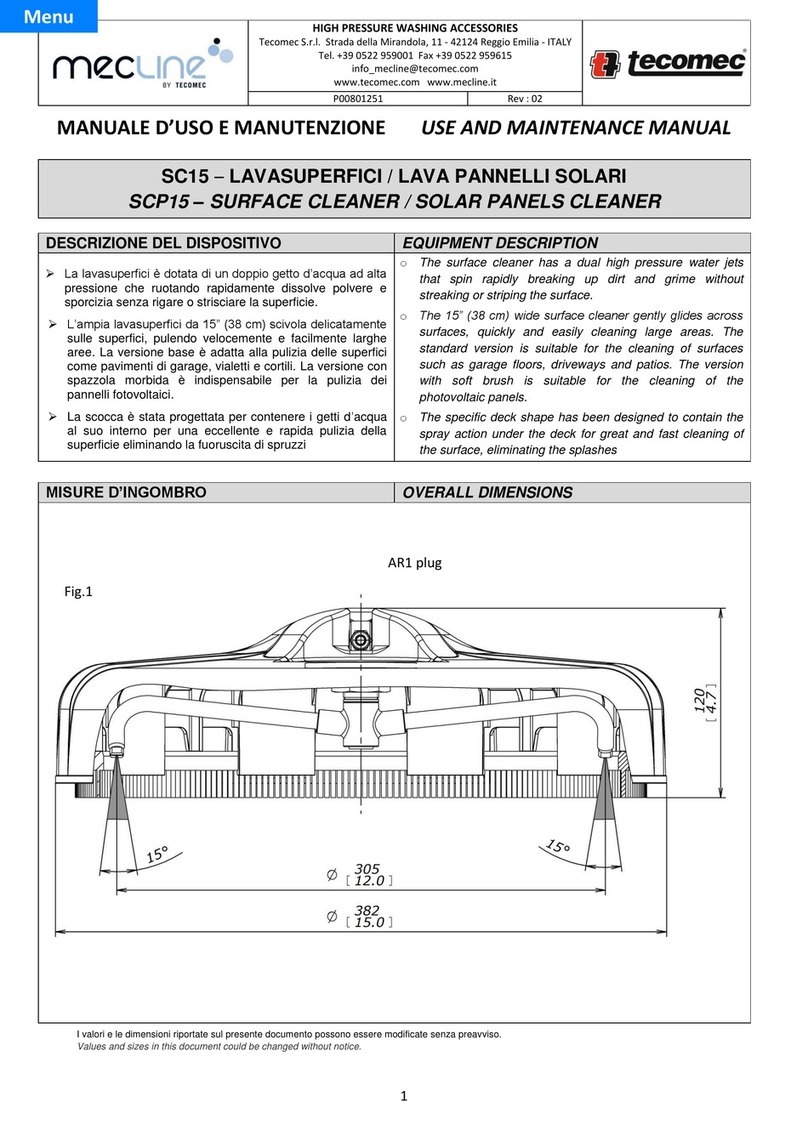

Tecomec

Tecomec Mecline SC15 Use and maintenance manual

Kränzle

Kränzle Round Cleaner UFO light operating manual