brent Corner Auger User manual

OPERATOR'S MANUAL

PARTS CATALOG

Unverferth

Manufacturing Co., Inc.

27612 Temple Ave.

Shell Rock, IA 50670

PH: 319-885-6571

Fax: 319-885-6576

Part #250475

Manufactured At:

MODELS

674 & 672

Corner AugerTM GRAIN CART

Model 674 Beginning With Serial Number B1651100

Model 672 Beginning With Serial Number B1649100

®

250915H

1-2

SECTION II - PARTS PAGE

PTO ASSEMBLY ...................................... 2-2

PTO CLUTCH........................................... 2-3

UNDERCARRIAGE ................................... 2-4

AUGER..................................................... 2-6

BOX & ELECTRICAL................................ 2-8

DECALS ................................................. 2-10

SIDE BOARDS ....................................... 2-11

LOWER AUGER & DRIVELINE .............. 2-12

DRIVE LINE U-JOINT ASSEMBLY ......... 2-13

HUB ........................................................ 2-14

120 - 154" ADJUSTABLE AXLE ............. 2-16

45OGEAR BOX...................................... 2-18

14" AUGER CYLINDER.......................... 2-19

36" FLOW CONTROL DOOR CYLINDER.. 2-19

HYDRAULIC PTO DRIVE (OPTIONAL) .. 2-20

SCALE (OPTIONAL) ............................... 2-22

ELECTRICAL ............................................2-23

HYDRAULIC DRIVE KIT (OPTIONAL) .......2-24

SECTION III - SCALE

SCALE KIT LAYOUT & INSTALLATION ......3-2

SCALE MODEL 2000

OPERATION.......................................... 3-4

OPTIONAL FEATURES ......................... 3-5

INSTALLATION REQUIREMENTS......... 3-6

SHORT-FORM SET-UP/CALIBRATION ..... 3-7

SECTION IV - TARP

TARP PARTS ........................................... 4-2

TARP INSTALLATION .............................. 4-4

SECTION I - OPERATION PAGE

INTRODUCTION....................................... 1-3

SAFETY .................................................... 1-4

SET UP FOR FIELD OPERATION ........... 1-6

PLASTIC HOSE PIPE INSTALLATION..... 1-7

ELECTRICAL HOOK-UP .......................... 1-8

DUAL WHEELS ........................................ 1-9

TRACTOR HOOK-UP ..............................1-10

HYDRAULIC HOOK-UP ...........................1-10

OPERATION IN FIELD ............................1-10

AUGER FOLD ADJUSTMENT.................1-11

HYDRAULIC AUGER OPERATION .........1-12

ADJUSTABLE UNLOADING CHUTE .......1-13

SCALE WEIGHING PROCEDURE ..........1-13

LUBRICATION, MAINTENANCE .................1-14

SEASONAL STORAGE ...........................1-14

SERVICE TIPS ........................................1-15

AUGER....................................................1-15

120 - 154" ADJUSTABLE AXLE .............1-16

PTO .........................................................1-17

OPERATION.........................................1-17

SHIELDS ..............................................1-17

JOINTS .................................................1-17

SIZE......................................................1-18

LUBRICATION ......................................1-18

COUPLING PTO DRIVE SHAFT ..........1-18

CHAINS ................................................1-19

CLUTCHES...........................................1-19

GUARD.................................................1-20

CONE ...................................................1-20

QUICK DISCONNECT ..........................1-21

CLUTCH ...............................................1-22

DRIVELINE SAFETY PRECAUTIONS .....1-23

TABLE OF CONTENTS

•

• 09-22-03/122904-2

1-3

Your new Brent Corner AugerTM Grain Cart is designed to meet today’s

exacting operating requirements. You have chosen a product with numerous

operating features that will increase your harvesting efficiency for years to come.

A single auger, along with a rugged design throughout, will help keep

maintenance to a minimum. You have also purchased a unit that has other options

as your operation may change; such as a bolt-on axle that allows you to match new

tillage practices and row crop widths. There is an optional electronic scale package

that will provide yield per acre or accumulate bushels per field.

Your new Brent Grain Cart will add the efficiency, flexibility, and dependability

to profit in today’s agriculture.

The following pages will provide you information regarding operating and

maintenance instructions. Use this book to familiarize yourself with this new machine

and provide operating instructions to others.

INTRODUCTION

Wheel bolts tightened (re-check after initial use)

Tire pressures checked

Hardware tightened

Machine lubricated

Guards and shields in place

Safety and operating procedures reviewed

Field adjustment information reviewed

Lubrication procedures reviewed

Warranty information reviewed

Hydraulic hoses properly routed/fittings tight

PRE-OPERATIONCHECKLIST

THANK YOU FOR YOUR PURCHASE!

Please supply this information when you have questions or when ordering repair or re-

placement parts. Your dealer needs this information to give you prompt, efficient service.

Please fill out and retain this portion for your records. For warranty consideration, please

contact dealer where purchased.

The serial number plate is located on the front side of your Corner AugerTM Grain Cart.

Date of Purchase Model Serial #

Owner name Farm/Co. name

Address City

State Zip Code Phone # ( )

Dealer City State

1-4

.

ACCIDENTS

CAN BE PREVENTED

WITH YOUR HELP!

No accident-prevention program can be successful without the whole-hearted

cooperation of the person who is directly responsible for the operation of the equipment.

A large number of accidents can be prevented only by the operator anticipating

the result before the accident is caused and doing something about it. No power-driven

equipment, whether it be transportation or processing, whether it be on the highway, in

the harvest field, or in the industrial plant, can be safer than the person who is at the

controls. If accidents are to be prevented--and they can be prevented--it will be done

by the operators who accept the full measure of their responsibility.

It is true that the designer, the manufacturer, and the safety engineer can help;

and they will help, but their combined efforts can be wiped out by a single careless act

of the operator.

It is said that, "the best kind of a safety device is a careful operator." We, at

Unverferth Mfg. Co., Inc. ask that you be that kind of operator.

SAFETY PRECAUTIONS

Read this manual carefully before operating.

Never enter the grain cart while the auger is running.

Make sure PTO guard is kept in place.

Never allow anyone on the unit while moving through the field.

Be careful when moving unit near electrical lines with discharge auger up.

Never tow a loaded unit more than 8 m.p.h. or on a road.

Never exceed the maximum recommended hitch pin size which allows for

uneven terrain.

Make use of night-time lighting provided on your new cart.

Use caution when unloading on the go, while moving through gullies, wash-

outs, and uneven terrain.

Always check behind you before backing up.

Counter-weight your tractor front end.

Be careful on steep slopes. A loaded grain cart is hard to stop.

Do not fold or unfold auger while moving.

When auger is not in use, be sure to fold to the rest position.

Never unhook a grain cart while it is being loaded.

Turn the tractor power off and remove the key from the ignition before servicing

the attached implement.

Tow only an empty cart on-road and have a rated safety chain attached.

•

•12-19-01

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1-5

•04-01-02

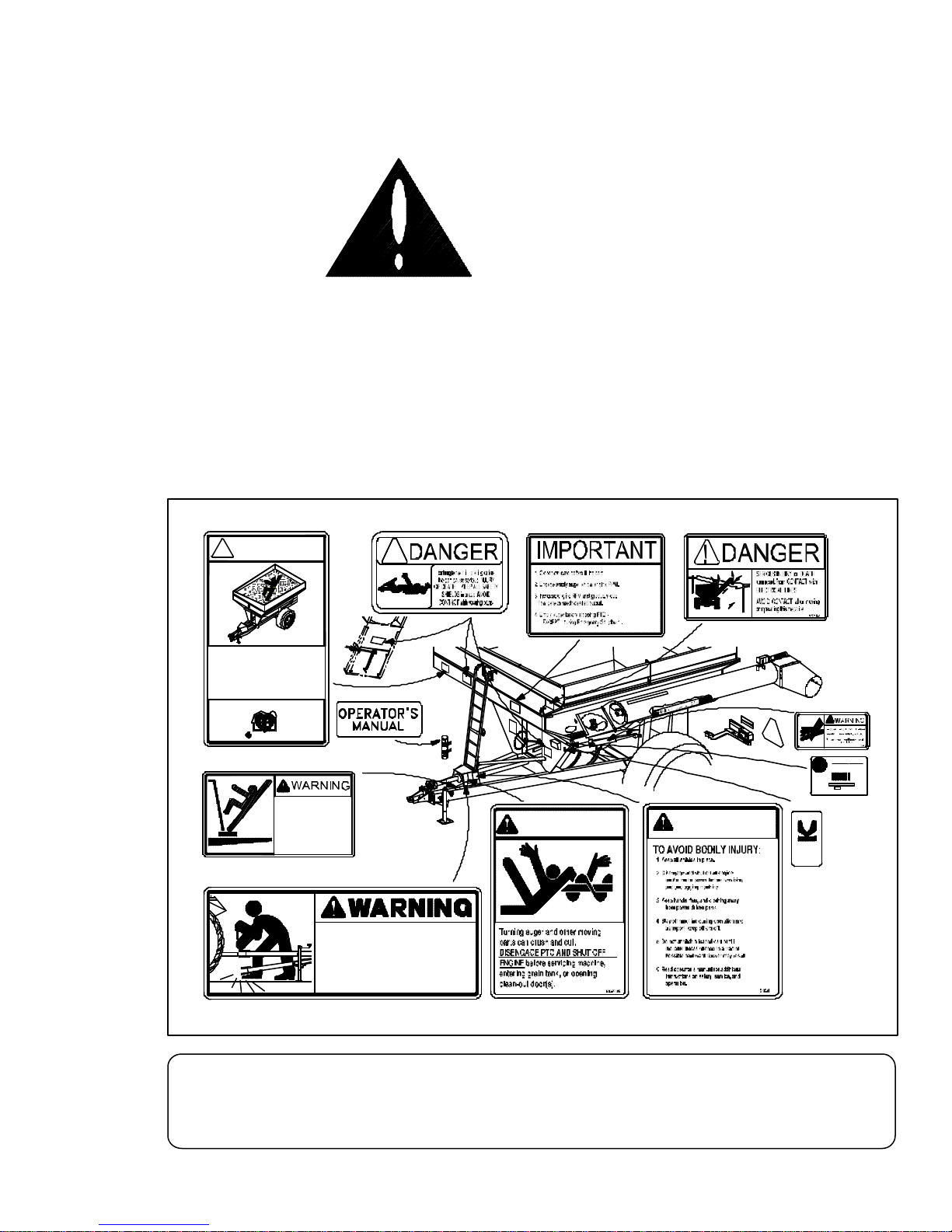

NOTE! This SAFETY ALERT SYMBOL is found throughout this manual. It is used

to call attention to instructions involving your personal safety and the safety of others.

Failure to follow these instructions can result in INJURY OR DEATH.

SIGNAL WORDS:

DANGER: Indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation that, if

not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation that, if

not avoided, may result in minor or moderate

injury.

This symbol means

ATTENTION!

BECOMEALERT!

YOURSAFETYISINVOLVED!

IMPORTANT

Replacelost,damaged,painted,orunreadabledecalsimmediately. Ifpartsthathavedecalsare

replaced,also make sureto install newdecals. These decals inform andremind theoperator

with operational information and safety messages.

251924

TAKEWEIGHTOFFOFTHETONGUE.

AND RAISE OR LOWER HITCH TO

LOWER JACK STAND INTO POSITION

BEFORE REMOVING HITCH PIN,

96764

TONGUE CAN DROP RAPIDLY

CAUTION

NO RIDERS

FALLING OFF can

cause SERIOUS

INJURY or DEATH

9003476

9003477

WARNING

Just Kids 9003478

NEVER PLAY

FLOWING GRAIN TRAPS

VICTIM in SECONDS !

Farm Safety

and SUFFOCATES

IN or ON the GRAIN

! DANGER !

95046A

9003478

9003476

9003475

95046 9003474

9003477

95445

TM

419-532-3121

MFG. CO., INC. - U.S.A.

Unverferth

SERIAL NO.

PRODUCT:

FEMA

ASSOCIATION

MANUFACTURERS

FARMEQUIPMENT

MEMBER

91605

9000917

9000917

91302

96764

Table of contents

Other brent Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions