1

1. PREFACE

WARNING

During this period, the manufacturer will repair or

replace the parts returned or the machine itself,

sustaining the costs but not accepting responsibility for

normal wear and tear, incorrect use or transportation,

or failure to carry out maintenance. The manufacturer

will not inform the customer about any improvements to

the products or the upgrading of the production line.

INTRODUCTION

The purpose of this manual is to provide the owner and

operator of this machine with a set of safe and practical

instructions for the use and maintenance of the wheel

balancer. If such instructions are carefully followed, the

machine will offer you the levels of efficiency and

duration.

The following paragraphs define the levels of danger

regarding the machine.

DANGER: Refers to immediate danger with the risk of

serious injury or death.

WARNING: Dangers or unsafe procedures that can

cause serious injury or death.

ATTENTION: Dangers or unsafe procedures that can

cause minor injuries or damage to property.

Read these instructions carefully before using the

machine. Keep this manual and the illustrated materials

supplied with the equipment in a folder near the place

of operation so as to allow the machine operators to

consult the documentation at any time.

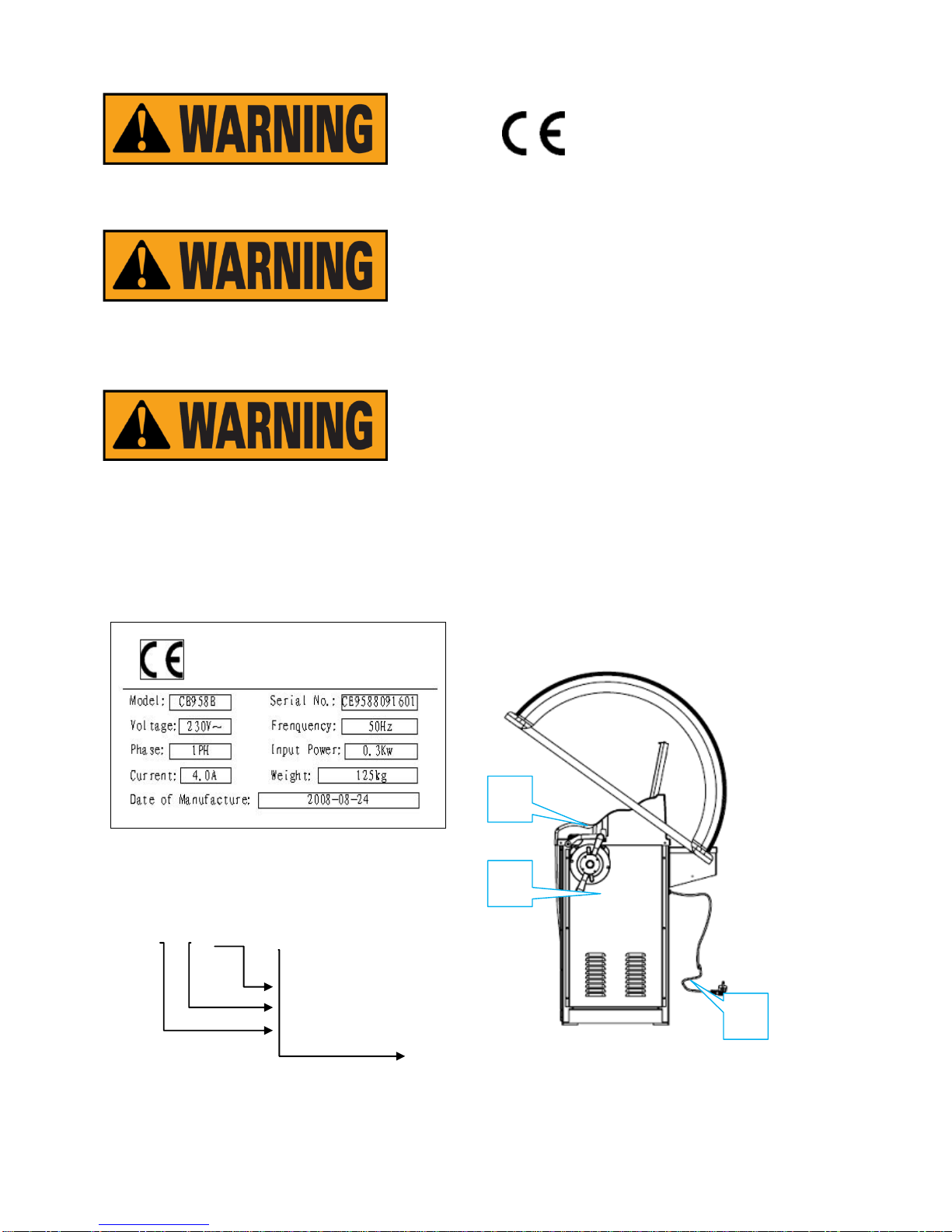

The manual is only to be considered valid for the

machine serial number and model stated on the

attached nameplate.

The instructions and information described in this

manual must always be complied with: the operator will

be held responsible for any operation not specially

described and authorized in this manual.

Some of the illustrations contained in this booklet have

been taken from pictures of prototypes: standard

production machines may differ slightly in certain

respects. These instructions are for the attention of

personnel with basic mechanical skills. We have

therefore condensed the descriptions of each operation

by omitting detailed instructions regarding, for example,

how to loosen or tighten the fixing devices. Do not

attempt to perform operations unless properly quailed

or with suitable experience. If necessary, please

contact an authorized Service Centre for assistance.

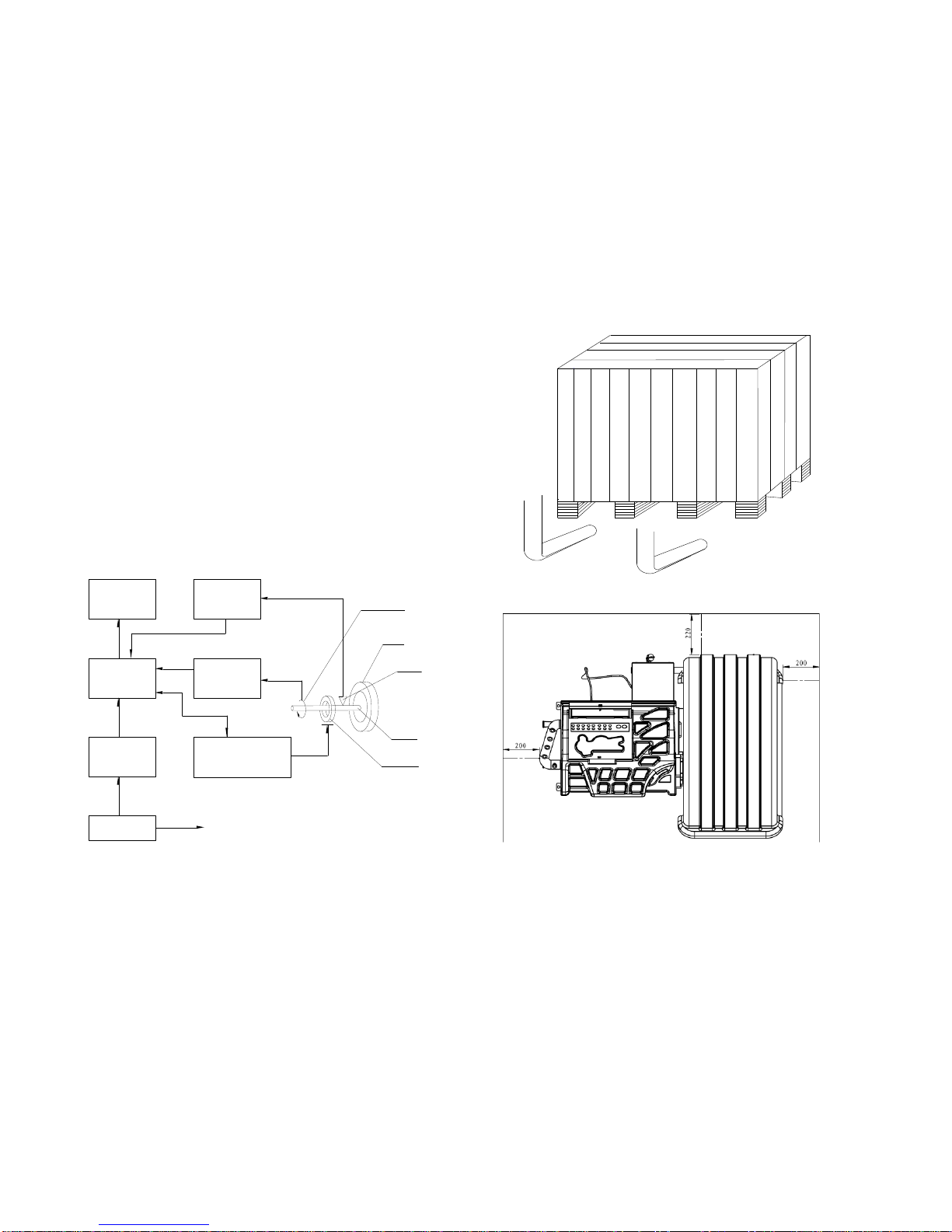

INSTALLATION

Take the utmost care when unpacking, assembling,

lifting and setting up the machine as indicated below.

Failure to observe these instructions can damage the

machine and compromise the operator's safety.

Remove the original packing materials after positioning

them as indicated on the packaging.

All regulations in force concerning safety at work must

be complied with when choosing the installation