Brinly P20-500BH User manual

Call Customer Service, Toll-Free: 877-728-8224

Important: This manual contains information for the safety

of persons and property. Read it carefully before

assembly and operation of the equipment!

Visit us on the web!

www.brinly.com

PUSH SPREADER

MODEL:

P20-500BH

P20-500BHDF-A

OWNER'S MANUAL

• Assembly

• Installation

• Operation

• Repair Parts

1008066-E© 2022 Brinly-Hardy Company

English, Spanish &

French Manual

English Manual 1008066-E

2

==================================================================================================

INTRODUCTION AND SAFETY

CONGRATULATIONS on your new Brinly-Hardy Spreader! This accessory has been designed, engineered and

manufactured to give you the best possible dependability and performance.

Should you experience any problem you cannot easily remedy, please do not hesitate to contact our knowledgeable

customer service department toll-free at 1-877-728-8224. We have competent, well trained technicians to help you with

the assembly and use of your spreader.

CUSTOMER RESPONSIBILITIES

- Please read & retain this manual. The instructions will enable to assemble and maintain your product properly.

- Please carefully read and observe the SAFETY SECTION of this manual.

- Follow a regular schedule in maintaining and caring for your Brinly-Hardy product.

TABLE OF CONTENTS

Safety ........................2-3

Parts Breakdown ...............4-5

Assembly .....................6-9

Operation and Maintenance ..... 10-11

Application Rate Chart ......... 12-15

Warranty ......................16

Manual en Español

Manual en Français

SAFETY

This symbol will help to point out important

safety precautions throughout this manual.

It means: ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED.

The machine safety labels shown in this section are placed in

important areas on your machine to draw attention to potential

safety hazards.

On your machine safety labels, the words DANGER, WARNING,

and CAUTION are used with this safety-alert symbol. DANGER

identies the most serious hazards.

The operator’s manual also explains any potential safety

hazards whenever necessary in special safety messages that

are identied with the word, CAUTION, and the safety-alert

symbol.

RECORD PURCHASE INFORMATION

Record your purchase information in

the spaces provided below:

Date of Purchase _________________________________

Company Name _________________________________

Company Phone _________________________________

Serial Number _________________________________

REQUIRED TOOLS

FOR ASSEMBLY

• 10 mm Wrench (x2)

English Manual 1008066-E

3

==================================================================================================

SAFETY

STOP

Installation Questions?

Missing Parts? Replacement Parts?

DON’T GO BACK TO

THE STORE!

Please call our Customer Service

Department, Toll Free: 877-728-8224

or customerservice@brinly.com

- Keep bystanders away when you operate this machine.

- Use this machine for intended purpose only.

- This machine is intended for use in lawn care and home

applications.

- Do not let children or an untrained person operate

machine.

- Keep all parts in good condition and properly installed. Fix

damaged parts immediately. Replace worn or broken parts.

- Do not modify the machine or safety devices. Unauthorized

modifications to the machine may impair its function and

safety, and void the warranty.

- Do not let anyone sit or ride on equipment during

operation. Keep riders off attachment.

- Wear substantial footwear and long trousers. Do not

operate the equipment when barefoot or wearing open

sandals.

- Do not wear loose fitting clothing that can get caught in

moving parts.

- Always wear eye protection when operating the equipment.

- Stay alert for holes in the terrain and other hidden hazards.

- Watch out for traffic when crossing or near roadways.

- Before you operate any feature of this machine, observe

your surroundings and look for bystanders.

- Always wash hands after contact with fertilizers and

pesticides.

- Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

OPERATE SAFELY NOTES

English Manual 1008066-E

4

==================================================================================================

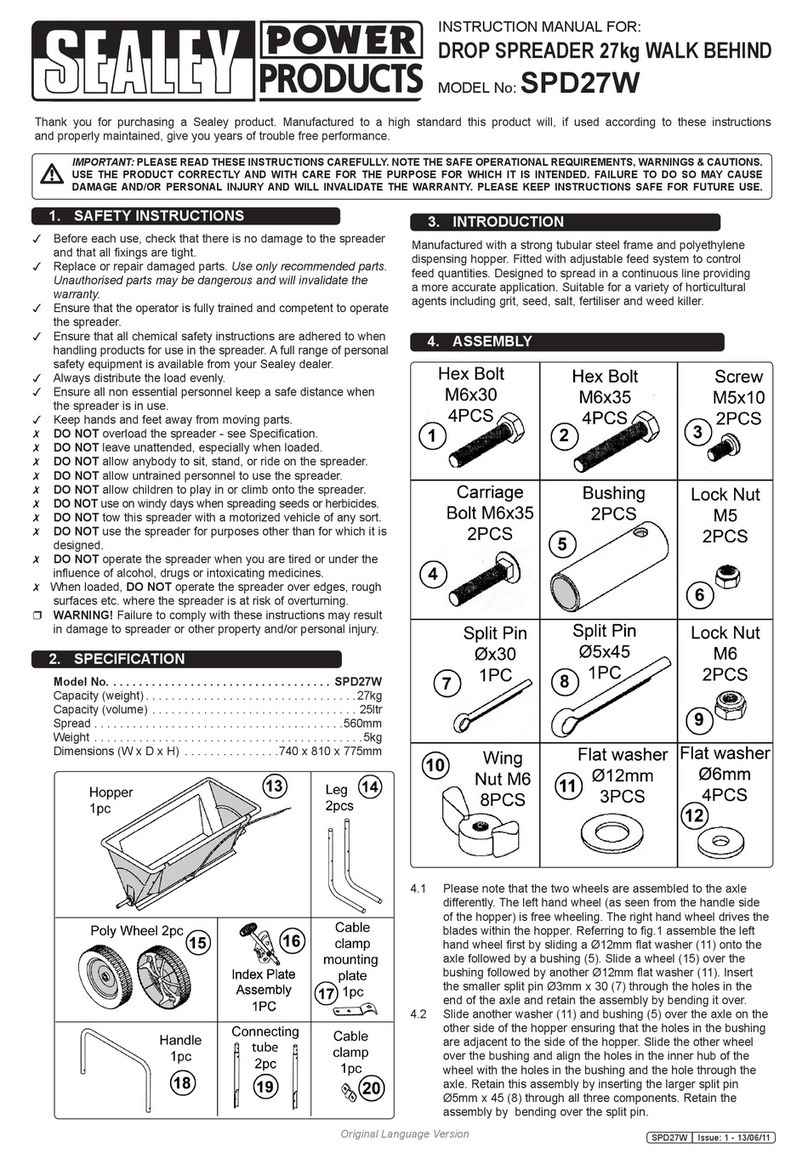

PARTS BREAKDOWN

Ref # Part # Description Qty

33 1007113 Bolt, M6 x 35 2

34 1007114 Flat washer, M16 1

35 1007115 End cap 2

36 1007116

1008781

Pneumatic Wheel (Yellow Hub)

Pneumatic Wheel (Gray Hub)

2

2

37 1007117 Axle bushing 2

38 1007118 Axle bearing 2

39 1007119 Gearbox& axle assembly 1

40 1008031 Cotter Pin, 2.9 x 28mm, SS 1

41 1007121 Screw, M4 x 20 1

42 1007122 Impeller 1

43 1007123 Screw, M6 x 40 4

44 1007124 Hex Locknut, M5 1

45 1007125 Cross brace 1

46 1007126 Adjust connect rod, B 1

47 1007127 Hex bolt, M5 x 60 1

48 1007128 Washer, Flat M6 3

49 1008098 Cotter Pin, Small 2

50 1007531 Washer, Nylon, Black 4

51 B-5924 Decal, Logo, 3.5 x 12.1 1

Included with P20-500BHDF-A:

52 1007520 Deector Kit 1

53 1007521 Plate, mount 1

54 1007522 Deector Shield, Side 1

59 1007573 Cover, 50# Spreader 1

55 1007552 Fastener Bag 1

56 1007553 - 6 mm x 45 mm Screw SS 2

57 1007524 - Bolt, Carriage M6 x 140, SS 1

58 1007575 - Knob, Deector 1

Ref # Part # Description Qty

1 1007081 Handle spacer 1

2 1007082 Carriage bolt, M6 x 25 1

3 1007083 Washer; 6M 1

4 1007084 Gauge and lever assembly 1

5 1007085 Adjust handle assembly 1

6 1007086 Adjustable handle knob side 1 1

7 1007087 Adjustable handle knob side 2 1

8 1007088 Screw; M4 x 18 1

9 1007089 Handle spacer 1

10 1007090 Wing nut, M6 1

11 1007091 Bolt; M6 x 45 7

12 1007092 Washer; Nylon 1

13 1007093 Flat washer, M 6,big SS 1

14 1007094 Screen 1

15 1007095 Handle cover 2

16 1008017 Hopper Assembly, Black * 1

17 1007097 R pin, M2 diameter 1

18 1007098 Hopper bushing 1

19 1007099 Pivot and bracket asm. 1

20 1007100 Wheel frame tube 2

21 1007101 Nut, M6 2

22 1007102 End cover 2

23 1007103 Upper handle 2

24 1007104 Nut, Lock M6 SS 11

25 1007105 Control rod A 1

26 1007106 Handle shaft 1

27 1007107 Shut o plate 1

28 1007108 Flat washer, M4, big 3

29 1007109 Screw, M4 x 12 3

30 1007110 Frame 1

31 1007111 Frame brace 2

32 1007112 Bolt, M6 x 60 2

* Assembly includes Part Numbers: 16, 18, 27, 28, 29

Please call our

Customer Service Department:

Toll Free: 877-728-8224

or customerservice@brinly.com

Installation Questions?

Missing Parts? Replacement Parts?

DON’T GO BACK TO THE STORE!

STOP

English Manual 1008066-E

5

==================================================================================================

22 15

23

24

26

4

48

1

23 8

7

24

13

5

12

25

21

46

48

24

11

31

30

45

31

32

33

24

24

32

14

17

18

30

39

41 40

36

43

47 35

44

36

37

38

38

37

50

50

34

35

20

28

51

27

29

42

20

16

33

11

20

20

11

15

6

10

9

3

2

22

Hopper/Frame/Axle Exploded

Handle/Frame Exploded

50

50

49

11

19

PARTS BREAKDOWN

English Manual 1008066-E

6

==================================================================================================

TOOLS REQUIRED: 2- 10mm Wrenches

1. Using a wrench and socket,

remove two M6 locknuts

and M6 x 45mm long bolts

to remove pivot and bracket

assembly from wheel

frame tubes.

NOTE:

Set bolts and nuts to the

side. You will re-install

them on Step 3.

ASSEMBLY

2. Tilt arm assembly, and insert rod

into flow control handle.

Step 2

Step 1

English Manual 1008066-E

7

==================================================================================================

3. Insert the arm assembly

between frame tubes.

ASSEMBLY

4. Tighten nuts and bolts on

both sides of spreader at

locations shown.

Step 4

Step 3

Re-install pivot

and bracket assembly

through wheel frame

tubes and arm assembly

with two M6 x 45mm bolts

and M6 locknuts removed

in Step 1.

English Manual 1008066-E

8

==================================================================================================

10

15

20

25

30

10

15

20

25

30

5. Push the flow control

handle downward to the

fully closed position, and

close the shut off plate

under the hopper.

ASSEMBLY

6. NOTE: The edge of the wingnut is the marker, and not the

center of wingnut. When the flow control handle is opened

fully, the edge of the wingnut should be on the 30 mark.

Set edge of wingnut on 30 mark and tighten.

Move flow control handle upward and back downward, and

verify the shut off plate under hopper opens and closes

properly. If necessary, adjust linkage rod nuts and

tighten hand tight.

Step 6

Step 5

Hand tighten bottom

nut on linkage rod

until snug.

Then, hand tighten

the top nut on linkage

rod until snug.

English Manual 1008066-E

9

==================================================================================================

IMPORTANT:AVOID DAMAGE!

Only use a wrench on the LOWER nut.

DO NOT use a wrench

on the upper nut.

7. Once adjustment is

complete, tighten lower nut

on linkage rod with wrench.

Step 7

8. Handle can be

lowered by removing

bolts and nuts and

moving handle

assembly downward,

using upper holes for

bolts and nuts.

Step 8

ASSEMBLY

English Manual 1008066-E

10

==================================================================================================

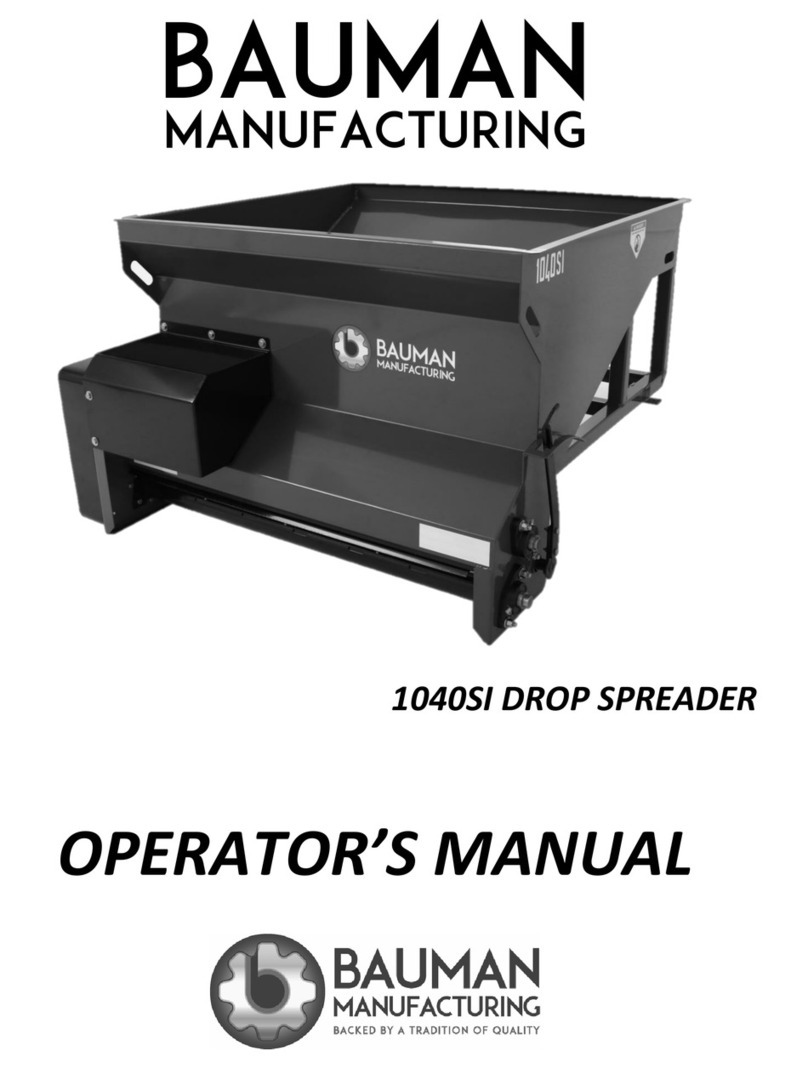

Gently tip and rotate the

spreader, resting it on the

right side.

Remove two M6x40 screws (A)

from the left side of the hopper

frame (30).

Align and attach the

deflector mounting plate (53)

as illustrated, using the two

provided 6mm x 45mm

screws (56).

Align the deflector (54)

against the deflector bracket

as illustrated. Attach with the

provided carriage bolt (57)

and knob (58).

The deflector (54) will keep material

from moving towards left side of hopper.

TO ENGAGE AND

DISENGAGE DEFLECTOR:

Loosen the knob (58) and rotate the

deflector up or down. Re-tighten knob

to stay in position, up or down.

ASSEMBLY

Continue for assembly instruction to attach the deflector.

This deflector comes with the P20-500BHDF-A or is an optional accessory

available for purchase in our part store (see additional info on page 17).

Step 9 NOTE: Deflector Must Be Installed On The Left Side Of The Hopper.

53

54

57

58

30

56

A

58

54

English Manual 1008066-E

11

==================================================================================================

USE AND CARE

MODELS:

P20-500BH

P20-500BHDF-A

USE AND CARE SECTION

SPECIFICATIONS

Practice walking with the spreader, opening and closing

the rate gate at the appropriate times.

Travel at a constant speed and operate the spreader lever position.

Remember: Open the rate gate after the spreader is in motion at

operating speed (about 3 mph, or at a brisk walking pace).

Close the rate gate while spreader is still at operational speed.

OPERATING SPEED

Hopper Capacity .........50 lbs

Spread Width ...........8'-12'

Wheel Type ......... Pneumatic

Wheel Size ........... 12" x 3"

Inflation Pressure ....... 30 psi

Tire pressure may be reduced to increase

wheel traction or to reduce shock, although

it should not be reduced to below 70%

of the maximum rated pressure.

Dimensions

- Product Length ........ 36 in

- Product Width ......... 23 in

- Product Height ........ 38 in

The flow control lever operates the control plate. The control lever plate

is marked 0-30. The position selected determines the amount of material

to be broadcast. The higher the number, the heavier the application of the

material. This allows for accurate control of the spreading rate.

The fan speed and the spread width are controlled by the speed at which

you operate the spreader. The spread width also depends on the volume/

density, and the particle size of the material.

The spread thins or feathers at the outer edges, eliminating sharp, "Edge

Of Spread" lines which cause stripes and streaks. Extra coverage can be

given under trees and other heavy feeding areas without showing "Edge

Of Spread" lines.

Gaps and double overlaps are less likely. Small errors in travel are

forgiven and do not show.

FLOW CONTROL SETTING INFORMATION

English Manual 1008066-E

12

==================================================================================================

ROTARY AGITATOR

USE AND CARE

READ BEFORE USING:

Become familiar with the operation of the spreader

BEFORE you put material in the hopper.

• Read chemical container label for handling instructions.

A Material Safety Data Sheet (MSDS) should be

supplied by the chemical dealer and provides proper

safety information.

• Wear proper clothing and safety equipment

while handling or applying chemicals.

• Prohibit all smoking, drinking, and eating around chemicals.

• When spreading products containing herbicides, exercise

extreme caution with respect to careless spreading and

to wind-drift. CONTACT OF SOME PRODUCTS ON

SOME PLANTS CAN BE FATAL.

WARNING: AVOID INJURY!

Chemicals can be dangerous.

Avoid injury to operator or bystanders:

FILLING THE SPREADER

• Push ow control lever down towards

the hopper to close the rate gate.

• Fill the spreader on a at, level surface only. Fill on

sidewalk, driveway, cardboard, etc. to avoid material loss.

• DO NOT overload with more than the maximum

capacity of 50 lbs.

• DO NOT use on windy days.

• When lling hopper with material, always use

screen to help break up clumps.

• Keep spinner blade clean. Excess material build-up

can cause an uneven spread pattern.

• Keep the impeller level when spreading.

OPERATING TIPS

Use the rotary agitator only if needed.

Free-owing, lump-free materials will not require the agitator.

The rotary agitator is easily installed or removed.

Never leave fertilizer or other material in the hopper. It

can draw moisture, form clumps, and cause unnecessary

rusting or jamming of controls and other parts. Ice melt

residue is especially corrosive. Clean and oil spreader

immediately after each use.

SPREADING MATERIAL

Determine setting required for the product you are spread-

ing

(See Application Rate Chart). If a setting is not found,

use a similar

size/weight material. Determine a ow control

setting on the low

side. If the setting proves to be too low,

cover the area more than

one time. A higher setting can be

used when a proven setting is

established. Generic Grass

Seed and Fertilizer Settings are shown at the end of the list.

REMEMBER: Published ow control settings are approximate

only. The operation of the spreader, the condition of the material

(damp or dry or over-pulverized) and weather conditions, are all

contributing factors. For these reasons, it is often a good idea to

spread the area 2 times - or one-half rate - in cross directions.

One-half rate settings are highly recommended under damp

and humid conditions.

10

15

20

25

30

10

15

20

25

30

NOTE:

When determining

required setting, the

edge of the wingnut

is the marker, and not

the center of wingnut.

When the ow control

handle is opened

fully, the edge of the

wingnut should be on

the 30 mark.

IMPORTANT: REMEMBER TO START AND STOP

THE SPREAD WHILE MOVING. Do not open the ow

control lever while stopped or material will simply run onto

the ground without being spread.

English Manual 1008066-E

13

==================================================================================================

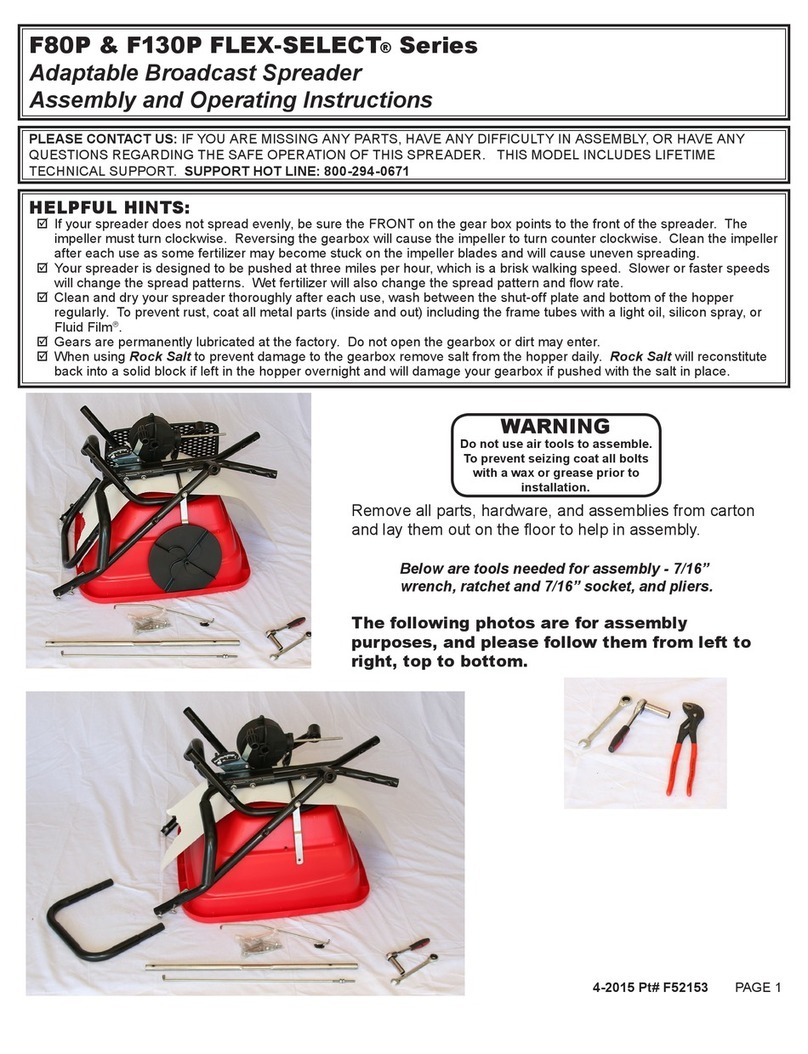

Header

6’ 6’3’

Header

USE AND CARE

HEADER STRIPS

Spread header strips at each end of area. This allows

a turn-around area to align spreader for next pass. Then

start on the edge of the area to be spread. Spread until

you hit the header area. Turn the ow control handle to

o while still moving. Make your turn and start down the

next row. Turn the ow control handle back on as you hit

the edge of your header area. Turn the ow control

handle on while moving.

TROUBLESHOOTING

Flow control handle is hard to actuate or will not move:

Check for buildup of material between bottom of hopper and

shut o plate. Clean as needed.

SPREADING ICE MELT

• Remove screen from hopper to prevent damage.

• Start with ow control setting at 20 and make a trial pass.

Adjust as needed to increase or decrease coverage.

• When complete be sure to thoroughly clean spreader as

ice melt can be highly corrosive.

• Re-install screen when complete.

CALIBRATING SHUT OFF PLATE

See Steps 6 and 7 on pages 8 - 9.

MAINTENANCE

• To ensure years of trouble-free

service, clean the spreader thoroughly

after each use. Move ow control handle

as you rinse to avoid build up of material.

• For rust on frame parts, sand lightly and paint with enamel.

• Periodically lubricate all bearing surfaces.

• Never allow material to remain in

hopper for extended periods of time.

• Periodically check all fasteners for tightness.

English Manual 1008066-E

14

==================================================================================================

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

Lesco, continued

30-3-7 3.3 16.0

28-5-12 3.6 16.0

24-5-11 4.2 16.0

19-19-19 5.3 16.0

18-24-12 4.2 15.0

24-2-11 4.2 15.0

26-2-11 3.8 15.5

24-0-11 4.2 16.0

18-0-18 Fall/Winter 4.2 16.0

17-17-17 All Purpose 5.9 16.0

16-4-8 6.3 16.0

15-5-10 6.7 16.0

15-0-15 6.7 16.0

Atrazine +17-2-11 6.0 16.0

Dimension .015% +19-3-6 3.5 16.0

Mach 2™ 1.33% +24-5-11 3.4 16.0

Merit® 0.2% +24-5-11 3.5 15.5

Momentum® + Fertilizer 3.6 15.0

PCNB 12.5% 10-0-20M 75%PPSCU 4.0 15.5

PRE-M® 1.5% + Fertilizer 2.3 15.0

PRE-M® 0.86% + Fertilizer 4.0 16.0

Talstar® 0.069% + Fertilizer 3.3 16.0

Weed & Feed +18-0-9 4.0 15.5

Weed & Feed +18-2-9 4.0 15.5

Dylox® 6.2* 3.0 16.0

Master Turf

Ultimate Tall Fescue Blend 8 17.0

4 15.0

Milogranite 6-2-0 8 17.0

16 20.0

Miracle-Gro

Lawn Fertilizer

plus Weed Control 28-3-3 3.2 13.5

Starter Lawn Fertilizer 20-27-5 3.6 13.5

Starter Lawn Fertilizer 29-3-4 3.1 12.0

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

All American

All Purpose Fertilizer 10-10-10. 10 16.0

Bayer

Season Long Grub Control 3.8 15.0

2.9 13.5

Complete Insect Killer 3 13.5

2 12.0

Power Force Multi-Insect Killer 3 12.0

2 11.0

Grub Control 3 12.0

2 12.0

Lawn Fertilizer Plus Weed Control II

30-3-4 3.2 13.5

Season Long Grub Control 3.8 13.5

Season Long Grub Control 2.9 12.0

Lawn Starter Fertilizer 20-27-5 3.6 13.5

Lawn Fertilizer Plus Crabgrass

Preventer 30-3-4 3.2 13.5

Eliminator

Ant, Flea, and Tick Killer Granules

3 13.5

2.5 12.0

2 12.0

5% Diazinon Insect Killer Granules 2 13.5

Howard Johnsons

All-purpose Fertilizer 8-8-8 7 15.0

All-purpose Fertilizer 10-10-10 7 15.0

All-purpose Fertilizer 12-12-12 7 15.0

Ironite 1-0-0 5 13.5

Klay

Soft Pelletized Gypsum Soil

Conditioner

4 13.5

3 12.0

2 12.0

Lesco

46-0-0 2.2 15.5

39-0-0 2.6 15.5

34-3-11 2.9 16.0

32-3-8 3.1 16.0

APPLICATION RATE CHART

English Manual 1008066-E

15

==================================================================================================

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

Ortho

Lawn Insect Killer Granules

9.6 16.0

4.8 13.5

2.4 11.5

1.2 11.5

Max Insect Killer for Lawns

4 13.5

2 12.0

1 11.5

Parkers

Super Soilife Lawn & Garden Fertilizer

10-10-10 10 16.0

Super Soilife Lawn & Garden Fertilizer

16-4-8 6.5 13.5

Pennington

Lawn Starter Fertilizer 18-24-6 3.6 15.0

Master Turf High Trac

Lawn Seed Mixture

10 18.0

5 16.0

Master Turf Shady Lawn

Seed Mixture

8 18.0

4 16.0

Master Turf Sun & Shade

Lawn Seed Mixture

10 18.0

5 16.0

Lawn Food 27-4-6 3.6 16.5

Centipede Food 18-0-18 4.0 17.0

St. Augustine, Bahia & Bermuda Food

26-6-9 4.0 18.0

Fall Lawn Food 10-5-15 4.0 15.5

Crabgrass Preventer plus Fertilizer

5-10-25 4.0 16.5

Lawn Starter 18-24-6 3.6 16.5

Weed & Feed w/Atrazine 25-4-6 4.0 17.0

Fescue Food 28-5-10 4.0 16.5

Weed & Feed w/Triamine 25-4-6 3.6 16.5

Real-Kill

Multi-Purpose Lawn

and Garden Insect Killer

2 12.0

2.5 12.0

Rebel's

Supreme Blend Grass Seed

for Sun & Shade

10 18.0

5 16.0

APPLICATION RATE CHART

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

Ringer

Lawn Restore 10-2-6 10 18.0

Sam's Choice

Crabgrass Preventer 30-3-4

12.3 19.0

8.1 16.0

6 16.0

5.4 15.0

Insect Control Plus Fertilizer 28-4-6 3 12.0

Lawn Food 29-3-4 3.2 13.5

Starter Fertilizer 20-27-5 6 16.0

3.6 13.5

Scotts

Classic Grass Seed Fall

Grass Seed Mix

4 16.0

2 13.5

Grubex 2.3 12.0

Grubex Season

Long Grub Control

3.1 13.5

2.3 13.5

Lawn Fungus Control 1.4 12.0

2.7 13.5

Pure Premium Kentucky

Bluegrass Mix

2.2 13.5

1.1 12.0

Pure Premium Sun & Shade

Grass Seed Mixture

2.5 13.5

1.25 12.0

Starter Fertilizer 20-27-5 3.6 13.5

5.9 13.5

Turf Builder 28-3-8 2.7 13.5

Turf Builder Lawn Fertilizer 29-3-4 3.1 12.0

Turf Builder with Summer Guard 2.7 13.5

Turf Builder Plus Weed Control 2.9 13.5

Winterizer 22-4-1 3.3 11.5

Turf Builder + Halt 25-3-3 3.6 15.0

Turf Builder Plus 2 Weed Control &

Lawn Fertilizer 26-3-3

3.5 14.5

Turf Builder Lawn Fertilizer New

Concentrated Nuggets 34-4-4

2.7 13.5

Starter Fertilizer 17-23-6 4.0 15.0

Lawn Disease Preventer 2.7 15.5

Lawn Weed Control 25-4-6 1.0 11.5

Turf Builder 28-3-3 3.2 17.0

5.0 20.0

Weed & Feed 33-3-3 2.5 13.5

English Manual 1008066-E

16

==================================================================================================

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

Scotts Four Season Program

Step 1 - Crabgrass Preventer plus

Fertilizer

3 15

Step 2 - Weed Control plus Fertilizer 2.5 15

Step 3 - Insect Control plus Fertilizer 3.1 16.5

Step 4 - Lawn Fertilizer 2.8 15.5

Sevin

Lawn Insect Granules

4.6 13.5

2.33 13.5

2.25 13.5

Spectracide

Grub Stop 3 13.5

Triazicide Insect Killer Granules 3 11.5

Sta-Green

Lawn Fertilizer 29-2-5 3.6 13.5

Lawn Weed Control 2 12.0

200 Plus Weed & Feed 28-3-3 3.2 13.5

Starter Fertilizer 18-24-10 3.6 13.5

Weed & Feed 28-2-4 3.2 13.5

Sun & Shade Grass Seed Mixture 10 18.0

5 16.0

Vigoro

Insect Control Plus Fertilizer 3 11.5

Starter Fertilizer 3.6 13.5

Turf Fertilizer 29-3-4 3.2 13.5

Ultra Turf Winterizer 22-3-14 3 12.0

Weed and Feed 3.2 13.5

Wal-Mart

Gardens Kentucky Bluegrass

Grass Seed

4 16.0

2 13.5

Gardens Kentucky 31

Tall Fescue

8 18.0

4 16.0

Weed & Feed 28-3-3 3.2 13.5

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

Scotts Pro Turf

Fungicide VII 8-2-1

25.0 25.0

12.7 27.0

13.4 13.0

Turf Builder Lawn Fertilizer 29-3-4 8.2 15.5

Turf Starter w/ Poly S 16-26-12 4.1 18.0

Fertilizer + Fungicide VIII 23-3-3 1.6 13.5

HD Fertilizer + Iron 29-3-3 3.2 14.5

HD Fairway Fertilizer 32-3-10 3.1 16.5

Fertilizer with Minors 26-4-13 3.9 14.5

Hi K Greens Fertilizer 15-0-30 3.4 13.5

HD Starter (Small Granule) 19-26-5 3.5 14.5

Hi K Fertilizer 15-0-30 3.4 15.5

Moss Control 16-0-0 3.9 13.0

Iron-S 16-0-0 1.7 13.5

Super Greens Fertilizer 19-0-17 4.6 14.5

Turf Fertilizer + 2% Fe w/ Poly S

25-3-10

3.3 16.5

ProTurf Fertilizer w/ Poly S 34-3-6 2.8 16.5

NPK Turf Fert. w/ Poly S 21-3-20 4.6 16.5

Fungicide X 4.9 15.5

FF-II 14-3-3 4.7 13.5

Systemic Fungicide 2.6 15.0

Fertilizer

Plus Preemergent

Weed Control 22-4-4

3.3 18.0

3.8 18.5

4.5 19.5

4.9 20.0

Turf Fertilizer

Plus Preemergent

Weed Control 22-0-6

3.8 18.5

4.2 19.5

4.9 20.0

5.8 21.0

6.1 22.0

8.7 27.0

9.6 30.0

APPLICATION RATE CHART

English Manual 1008066-E

17

==================================================================================================

APPLICATION RATE CHART

Media

lbs /

1000

square

feet

Flow

Control

Setting

at 3MPH

Generic Fertilizers

(if you don't have any

other method)

1 12

2 13

3 14

4 15

5 17

6 18

7 19

8 20

9 22

10 24

Generic Grass Seed

(if you don't have any

other method)

2 18

3 20

4 22

5 24

QUALITY CONTINUES

WITH QUALITY SERVICE

If you have installation questions, are

missing parts or need replacement parts, don’t go back to

the store! Please find your product serial number and model

number, then contact our Customer Service department:

SERVICE

In North America and Canada call

Toll-Free: 877-728-8224

Chat online: www.brinly.com

Email: customerservice@brinly.com

ONLINE: BRINLY.COM

Additional info and videos are

available on our website. Please visit

the URL above OR scan one of these

QR codes:

P20-500BH

NOTE: Additional accesories are also

available in our Parts Store online: shop.brinly.com

OPTIONAL ACCESSORY

DEFLECTOR KIT

1007520

Make sure that product is spread accurately

and eciently, reducing wasted distribution and

protecting sections of your lawn from salt spread

in the winter.

The deector kit easily

ips up and out of the

way when not in use.

English Manual 1008066-E

18

Brinly-Hardy Company warrants the products listed below against

defects in material and workmanship, and will at its option, repair or

replace, free of charge, any part found to be defective in materials

or workmanship. This limited warranty shall only apply if this prod-

uct has been assembled, operated, and maintained in accordance

with the Operator’s manual furnished with the product, and has not

been subject to misuse, abuse, commercial use, neglect, accident,

improper maintenance, alteration, vandalism, theft, re, water, or

damage because of other peril or natural disaster.

Parts found to be defective within the warranty period will be re-

placed at our expense. Our obligation under this warranty is ex-

pressly limited to the replacement or repair, at our option, of parts

found to be defective in material and workmanship.

HOW TO OBTAIN SERVICE:

Warranty parts replacements are

available, only with proof of purchase, through our Customer Ser-

vice Department. Call 877-728-8224.

No implied warranty, including any implied warranty of mer-

chantability of tness for a particular purpose, applies after

the applicable period of express written warranty above as to

the part as identied below. No other express warranty whether

written or oral, except as mentioned above, given by any per-

son or entity, including a dealer or retailer, with respect to any

product, shall bind Brinly-Hardy Co. During the period of the

warranty, the exclusive remedy is repair or replacement of the

product as set forth above.

The provisions as set forth in this warranty provide the sole

and exclusive remedy arising from the sale. Brinly-Hardy Co.

shall not be liable for incidental or consequential loss or dam-

age including, without limitation, expenses incurred for substi-

tute or replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, or limitations on how long an implied warran-

ty lasts, so the above exclusions or limitations may not apply to you.

During the warranty period, the exclusive remedy is replacement of

the part. In no event shall recovery of any kind be greater that the

amount of the purchase price of the product sold. Alteration of safety

features of the product shall void this warranty. You assume the risk

and liability for loss, damage, or injury to you and your property and/

or to others and their property arising out of the misuse or inability

to use this product. NOTE: This limited warranty shall not extend to

anyone other than the original purchaser or to the person for whom

it was purchased as a gift.

This limited warranty lasts as long you own your product purchased

from an authorized seller. Coverage terminates once you sell or

otherwise transfer the product.

This limited warranty does not cover any purchaser other than the

original purchaser of the product, nor does it cover any product pur-

chased from an unauthorized third-party. If you are not the original

purchaser of this product, your product is not covered by our limited

warranty and you take the product “AS IS” and “with all faults.”

We may require proof of purchase from you demonstrating that you

are the original purchaser of the product, purchased the product from

an authorized dealer, and are eligible to make a valid claim under this

limited warranty.

How state law relates to this warranty: This limited warranty gives

you specic legal rights, and you may also have other rights which

vary from state to state.

IMPORTANT:

The Warranty period stated below begins with the proof of purchase.

Without the proof of purchase, the Warranty period begins from the

date of manufacture determined by the serial number manufacturing

date. All parts replaced under warranty will be considered as part

of the original product, and any warranty on the replaced parts will

expire coincident with the original product warranty.

The limited warranty set forth below is given by Brinly-Hardy Company with respect to new

merchandise purchased and used in the United States (its possessions and territories) and Canada.

This limited warranty does not provide coverage

in the following cases:

a. Routine maintenance items such as lubricants & lters.

b. Normal deterioration of exterior nish due to use or exposure.

c. Transportation and/or labor charges.

d. The warranty does not include commercial and/or rental use.

MANUFACTURER’S LIMITED WARRANTY

SPREADERS

If this equipment is being used in a commercial application and / or for

multiple properties, the warranty is 90 days after purchase for all parts.

WARRANTY PERIOD:

See applicable parts listed below.

Standard / Residential Use:

Steel Frame & Steel Parts ............. 2 years

Hopper ........................... 2 years

Tires / Wheels ..................... 90 days

Drive: Gears ...................... 90 days

All other normal wear parts or component failures

will be covered on this product for a period of 90 days.

Brinly-Hardy Company • 3230 Industrial Parkway • Jeersonville, IN 47130 • (877) 728-8224 • brinly.com

Other manuals for P20-500BH

2

This manual suits for next models

1

Table of contents

Other Brinly Spreader manuals

Brinly

Brinly BS-26BH-A User manual

Brinly

Brinly PS10-70BH User manual

Brinly

Brinly BS-36 User manual

Brinly

Brinly BS-26BH User manual

Brinly

Brinly BSW-20 BH User manual

Brinly

Brinly P20-500BH User manual

Brinly

Brinly P20-500BH User manual

Brinly

Brinly AS2-40BH-G User manual

Brinly

Brinly AS-40BH User manual

Brinly

Brinly BTS-150 BH User manual