5.2.3 Emergency brake.................................................................................................................. 50

5.3 Parking brake ........................................................................................................................ 52

5.4 Overrun brake with automatic reversing ............................................................................... 53

5.5 Wheel chocks........................................................................................................................ 53

5.6 Safety chain for implements without brake system............................................................... 54

5.7 Immobiliser for towing device................................................................................................ 54

5.8 Drawbars............................................................................................................................... 55

5.9 Hydraulic connections........................................................................................................... 56

5.9.1 Coupling the hydraulic hose lines ......................................................................................... 57

5.9.2 Decoupling the hydraulic hose lines...................................................................................... 58

5.10 Hyclick electro-hydraulic preselection................................................................................... 58

5.11 PTO shaft.............................................................................................................................. 59

5.11.1 Coupling the PTO shaft......................................................................................................... 61

5.11.2 Uncoupling the PTO shaft..................................................................................................... 62

5.12 Main shutter slide .................................................................................................................. 63

5.13 Double shutter....................................................................................................................... 64

5.14 Fertiliser chain rake (option).................................................................................................. 65

5.14.1 Chain rake, removable.......................................................................................................... 65

5.14.2 Chain rake on the double shutter.......................................................................................... 65

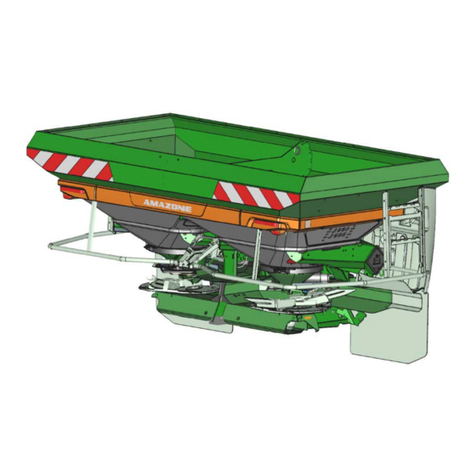

5.15 Spreading granular fertiliser with spreading discs OM.......................................................... 67

5.16 Spreading lime with lime spreading discs............................................................................. 69

5.17 Spreading granulated fertiliser with lime spreading discs..................................................... 70

5.18 Spreading of bone meal with bone meal spreading discs..................................................... 71

5.19 Spreading disc holder............................................................................................................ 71

5.20 Boundary and side spreading with the boundary spreading Limiter..................................... 72

5.21 Conveyor belt........................................................................................................................ 72

5.21.1 Belt conveyor driven hydraulically......................................................................................... 73

5.21.2 Ground wheel drives of conveyor belt................................................................................... 74

5.22 Foldable ladder...................................................................................................................... 75

5.23 Stand..................................................................................................................................... 76

5.24 Charging sieves..................................................................................................................... 77

5.25 Swivelable hopper cover (optional)....................................................................................... 77

5.26 Camera system..................................................................................................................... 77

5.27 Setting chart .......................................................................................................................... 78

5.28 ZG-B Drive ............................................................................................................................ 80

5.28.1 AMATRON 3 in-cab terminal................................................................................................. 80

5.28.2 Control block and machine computer.................................................................................... 81

5.28.3 TrailTron tracking control ...................................................................................................... 81

5.29 Weighing technology with weighing terminal ........................................................................ 84

5.29.1 Tare the weighing equipment................................................................................................ 84

5.29.2 Menu layout........................................................................................................................... 85

5.30 AMALOG+as hectare counter for ZG-B Super..................................................................... 87

5.30.1 Product description................................................................................................................ 87

5.30.2 Work display Starting work................................................................................................. 88

5.30.3 Installing the terminal ............................................................................................................ 89

5.30.4 Settings ................................................................................................................................. 90

5.30.5 Calibration value.................................................................................................................... 91

5.30.6 EasyCheck ............................................................................................................................ 93

5.30.7 Mobile test rig........................................................................................................................ 93

6Commissioning ......................................................................................... 94

6.1 Checking the suitability of the tractor .................................................................................... 95

6.1.1 Calculating the actual values for the total tractor weight, tractor axle loads and load

capacities, as well as the minimum ballast ........................................................................... 95

6.1.2 Requirements for tractor operation with attached machines................................................. 99

6.1.3 Machines without their own brake system .......................................................................... 102

6 ZG-BBAG0003.18 01.19