Model 435 Page 3

TABLE OF CONTENTS

INTRODUCTION ..........................................................................................................................................................2

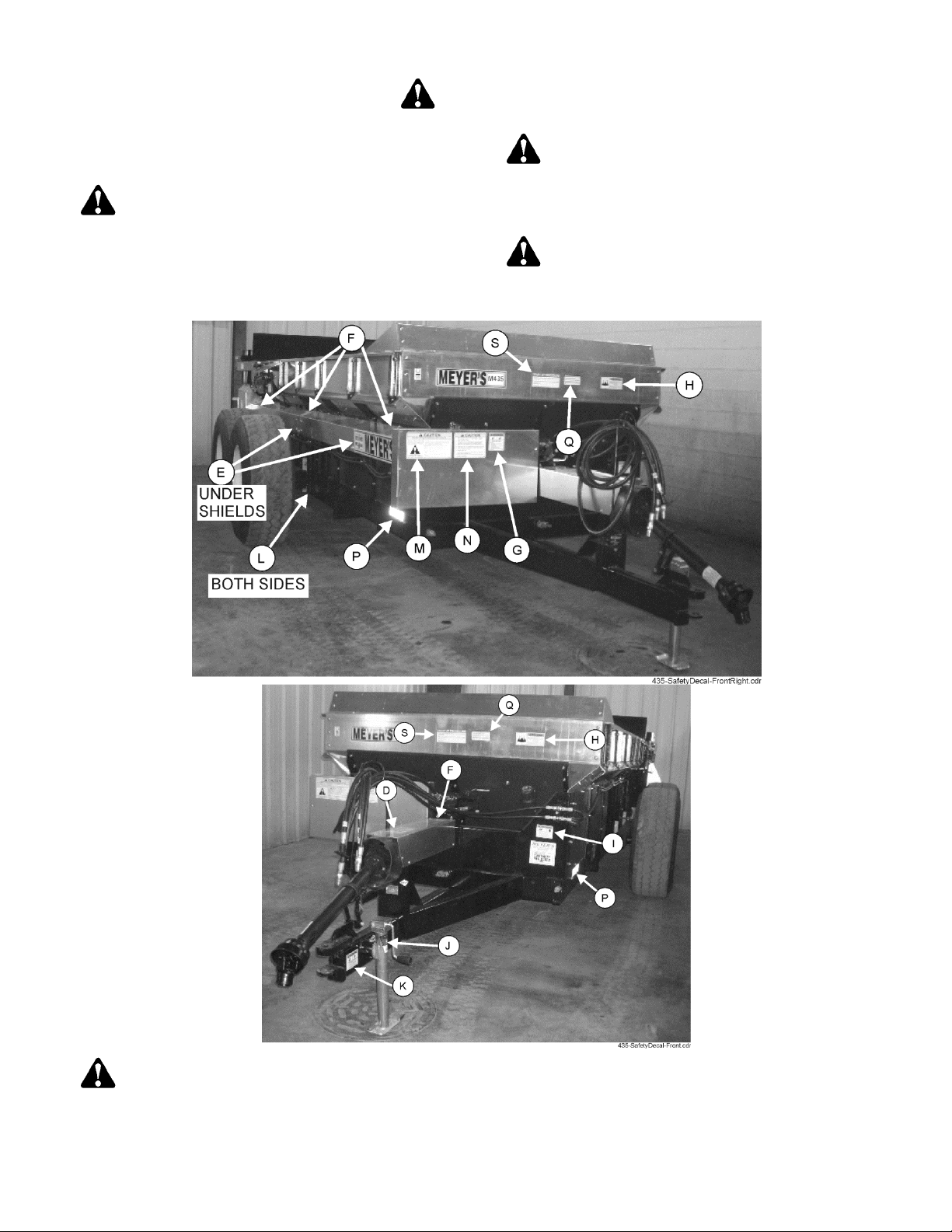

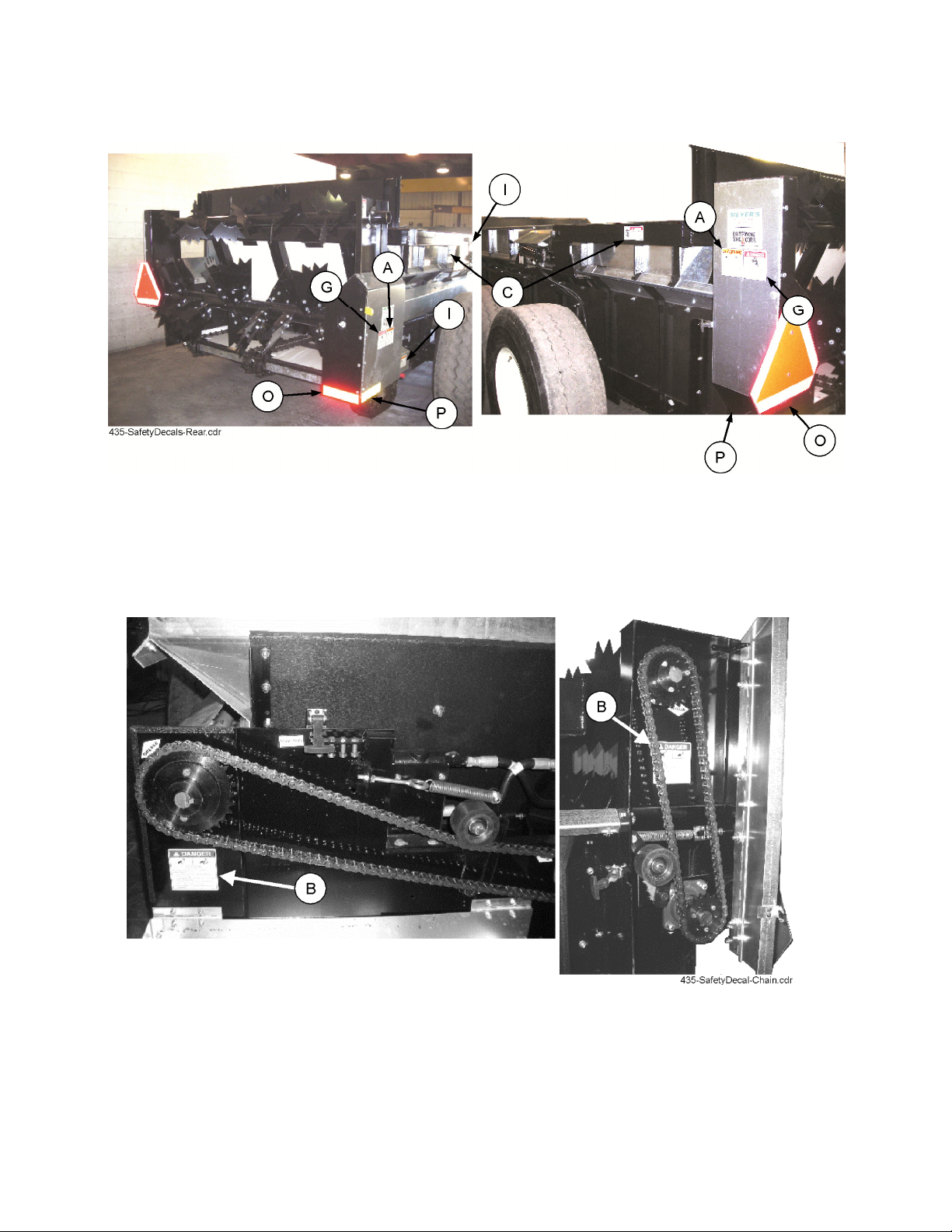

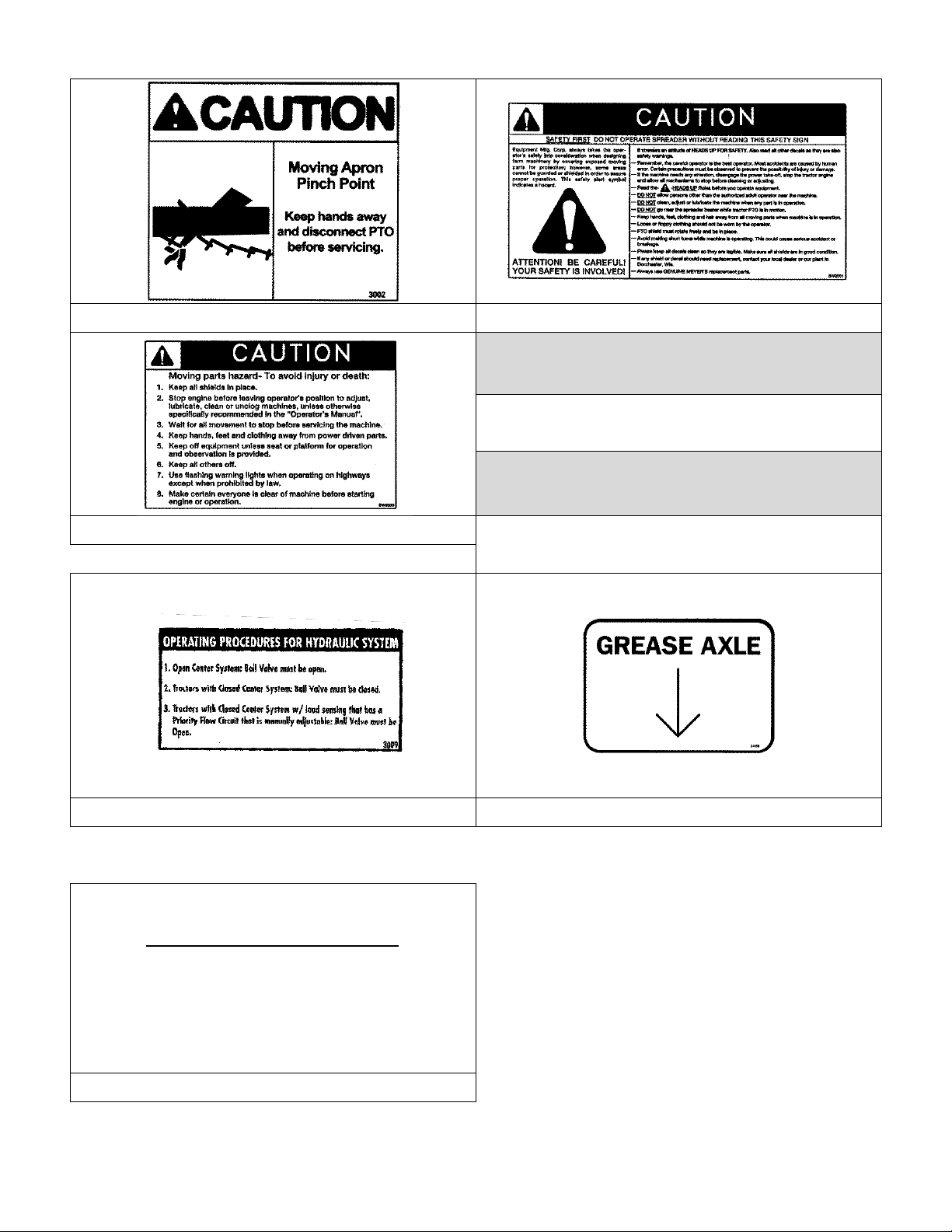

SAFETY ........................................................................................................................................................................4

MANURE SPREADER SAFETY...................................................................................................................................8

MANDATORY SAFETY SHUTDOWN PROCEDURE .................................................................................................9

PRE-OPERATION ......................................................................................................................................................10

General....................................................................................................................................................................10

Tractor Hookup........................................................................................................................................................10

Tractor Requirements..........................................................................................................................................10

Tractor Size .........................................................................................................................................................10

Tractor Towing Size Requirements .....................................................................................................................10

Material Estimated Weight Per Cubic Foot .........................................................................................................10

Tractor Hookup....................................................................................................................................................11

Hydraulic Apron Drive .............................................................................................................................................11

Hydraulic System ....................................................................................................................................................11

Transporting ............................................................................................................................................................12

Use Safety Chain.................................................................................................................................................12

OPERATION...............................................................................................................................................................13

DANGER.....................................................................................................................................................................13

Loading....................................................................................................................................................................13

Unloading ................................................................................................................................................................13

Hydraulic Apron Drive Operation ............................................................................................................................13

Hydraulic End Gate Operation ................................................................................................................................14

Unhook Spreader From Tractor ..............................................................................................................................14

MANDATORY SAFETY SHUTDOWN PROCEDURE ...............................................................................................14

MAINTENANCE, LUBRICATION & ADJUSTMENTS ................................................................................................15

Cleaning And Storage .............................................................................................................................................15

Lubrication ...............................................................................................................................................................15

Shear Pin Hub Maintenance ...................................................................................................................................16

Adjustments.............................................................................................................................................................17

Apron Chain.........................................................................................................................................................17

Roller Chain Adjustment......................................................................................................................................17

REPAIR PARTS..........................................................................................................................................................20

Main Frame and Box Parts......................................................................................................................................20

Axles, Wheels, Spindles and Related Parts............................................................................................................22

Jack .........................................................................................................................................................................24

Hydraulic End Gate .................................................................................................................................................26

End Gate Hydraulics ...............................................................................................................................................28

Front and Side Drive Shaft and Related Parts........................................................................................................30

Apron Parts .............................................................................................................................................................32

Apron and Lower Beater Drive................................................................................................................................34

Apron Drive Gear box..............................................................................................................................................36

5490-0672 Gear Box Complete 540 RPM Beater Drive Gearbox ..........................................................................38

5490-0685 Gear Box Complete 1000 RPM Beater Drive Gearbox ........................................................................40

E01300W Gear box Complete 540 RPM Beater Drive Gearbox ............................................................................42

4190-0532 Gear Box Complete 1,000 RPM Beater Drive Gearbox .......................................................................44

Beaters and Related Parts ......................................................................................................................................46

Apron Drive Hydraulics............................................................................................................................................48

PTO Shaft Assembly ...............................................................................................................................................50

LIMITED WARRANTY STATEMENT .........................................................................................................................52