Contents

B109 06/16 Rev.2 ZIRKON D060 V – D140 V 2

1Contents

1Contents ........................................................................................................ 2

2Introduction ................................................................................................... 3

2.1Information relating to the operating instructions ................................ 3

2.2Limited liability .................................................................................. 3

2.3Copywrite.......................................................................................... 3

2.4Spare Parts ....................................................................................... 4

2.5Servicing ........................................................................................... 4

2.6EC-Declaration of Conformity.............................................................. 5

3Safety ............................................................................................................ 6

3.1General ............................................................................................. 6

3.2Description of safety instructions ........................................................ 6

3.3General safety instructions ................................................................. 6

3.4Personnel Requirements..................................................................... 7

3.5Definitions......................................................................................... 8

3.6Prescribed Operation.......................................................................... 8

3.7Non-prescribed operations ................................................................. 9

3.8Safety measures by the operator/user ................................................ 9

4Technical data ...............................................................................................10

4.1Model (type) plate ............................................................................10

4.2Technical Information .......................................................................10

5Operating procedures ...................................................................................11

5.1Start-up conditions ...........................................................................11

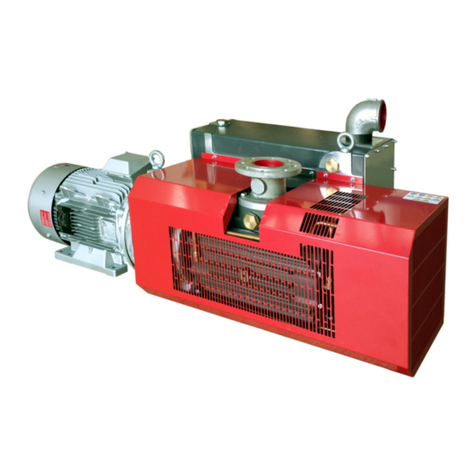

5.2Construction.....................................................................................12

5.3Function...........................................................................................12

6Transport storage ..........................................................................................13

6.1Safety instructions during transport ...................................................13

6.2Lifting and transporting the machinery...............................................13

6.3Storage ............................................................................................13

7Start-up ........................................................................................................14

7.1Assembly .........................................................................................14

7.2Installation .......................................................................................14

7.3Start-up ...........................................................................................16

8Operation......................................................................................................17

9Maintenance..................................................................................................18

9.1Air Filter ...........................................................................................18

9.2Discs................................................................................................20

10Fault diagnosis ..............................................................................................22