Serious injury or death may result from the use of this

product. Exercise extreme caution when using these Jacks.

•User must ensure product is installed according to these

instructions. Purchaser, owner or user must not alter or

modify the product.

Serious injury or death may result to operator or bystanders.

•If this product has a pivot tube mount, make certain the

pivot tube pin is fully inserted through both sides of the

pivot tube and the pivot tube mounts.

•If this product is a swivel jack, Ensure the plunger pin is

locked into a hole on the mounting bracket before

operating the jack.

•If this product has a snap ring, ensure the snap ring

groove is cleared of any and all debris before and after

attachment of the snap ring. Ensure snap ring is fully

seated into the snap ring groove.

•Do not weld “Bolt-On” brackets or straps to the tongue.

•If this product has a drop foot or drop leg, Never attempt

to adjust a drop foot or drop leg when it is under load.

Always remove drop foot or drop leg from product before

towing trailer to maximize ground clearance.

•If this product is a rack jack, never raise the ger housing

above the inner tube.

•Always replace any and all bent broken or worn parts on

this product before using this product.

•These jacks are not designed to be used on a round tube

tongue.

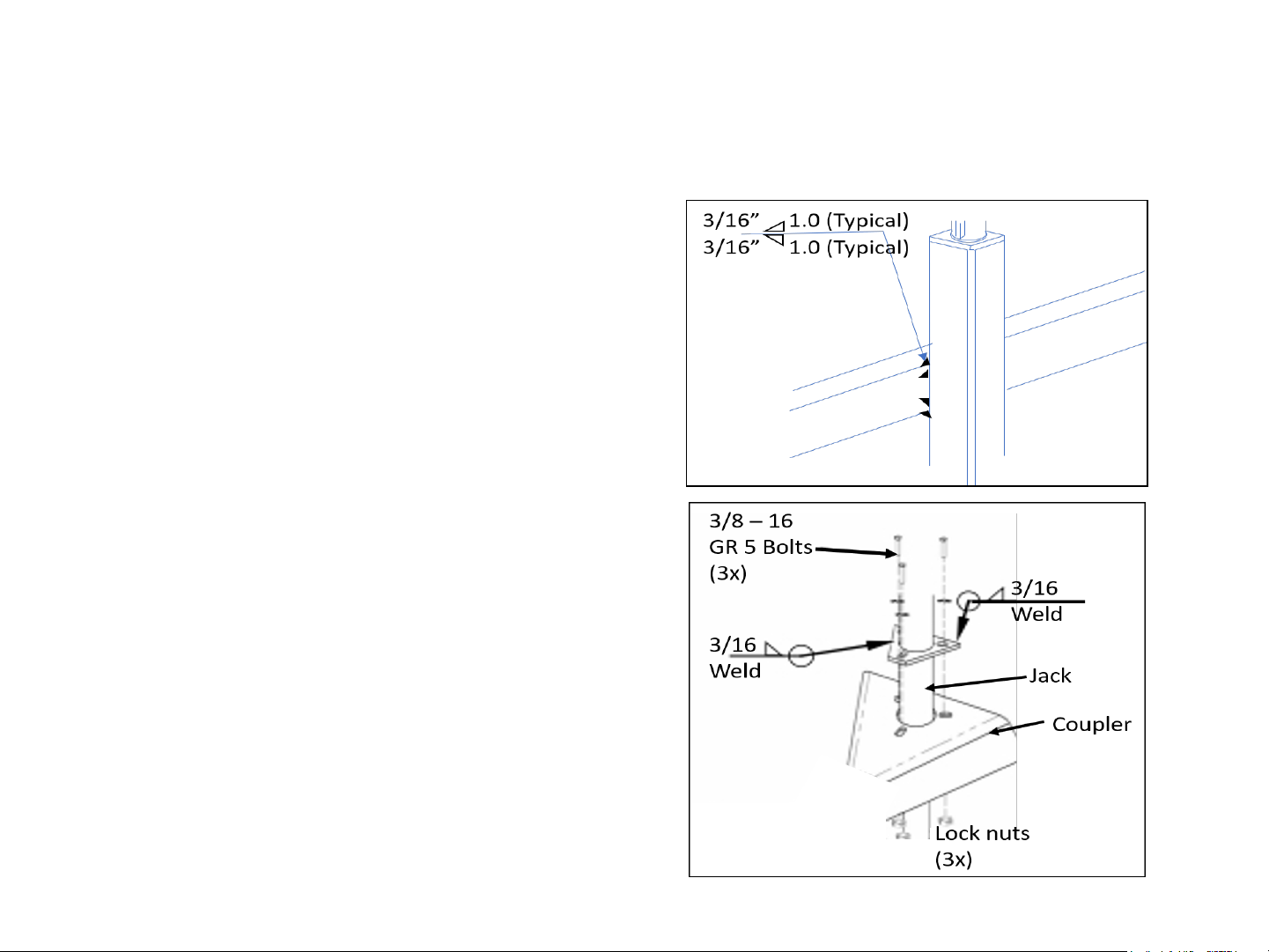

•All welding must be performed by a certified AWS welder

Serious Injury or death may result to operators and bystanders.

•Never position any part of the body under any portion of this

product or the load being applied to at any time.

•Always fully rotate and secure the jack in a fully retracted

manner to ensure complete clearance form the road or road

obstacles before traveling.

•When using this product to bear the weight of the load

always ensure wheels are fully chocked and trailer and load

are prevented from moving or rolling.

•This is not a transport device. Minimize any movement of the

trailer or load while this product is engaged with the ground.

•Do not allow children to play on the jack or the load that it is

applied to.

•Do not exceed jack capacity. Jack capacity is limited to the

lesser of the foot plate, caster or jack capacity.

•Never exceed the maximum rated capacity of the jack. Jack

capacity is located on the jack’s decals or stampings.

•Do not allow excessive side loading of the jack. The jack is

designed for vertical loading only.

•Lower jack to lowest position before manually moving trailer.

•Always replace bent broken or worn parts before using this

this product.

The attachment or use of this product is critical and beyond

the control of bROK Products LLC. bROK Products is not

responsible for the use or attachment or installation. bROK

Products neither guarantees nor will it be liable for any

damage resulting from the attachment, use or misuse of the

this product or assembled product. The liability of this product

is limited to its purchased price if it is proved to be the result

of poor workmanship or defective material.

Trailer Jacks:

32908, 32909, 32923, 32924,

32925, 32932 , 15936 Rev A

1