4 Copyright 2013, Brooks Automation Inc Part Number 8040705, Revision A, 01/11/2013 ECO Number 63723 Brooks Automation Inc www.brooks.com Printed in U.S.A 1

800-367-4887 USA

978-262-2400 International

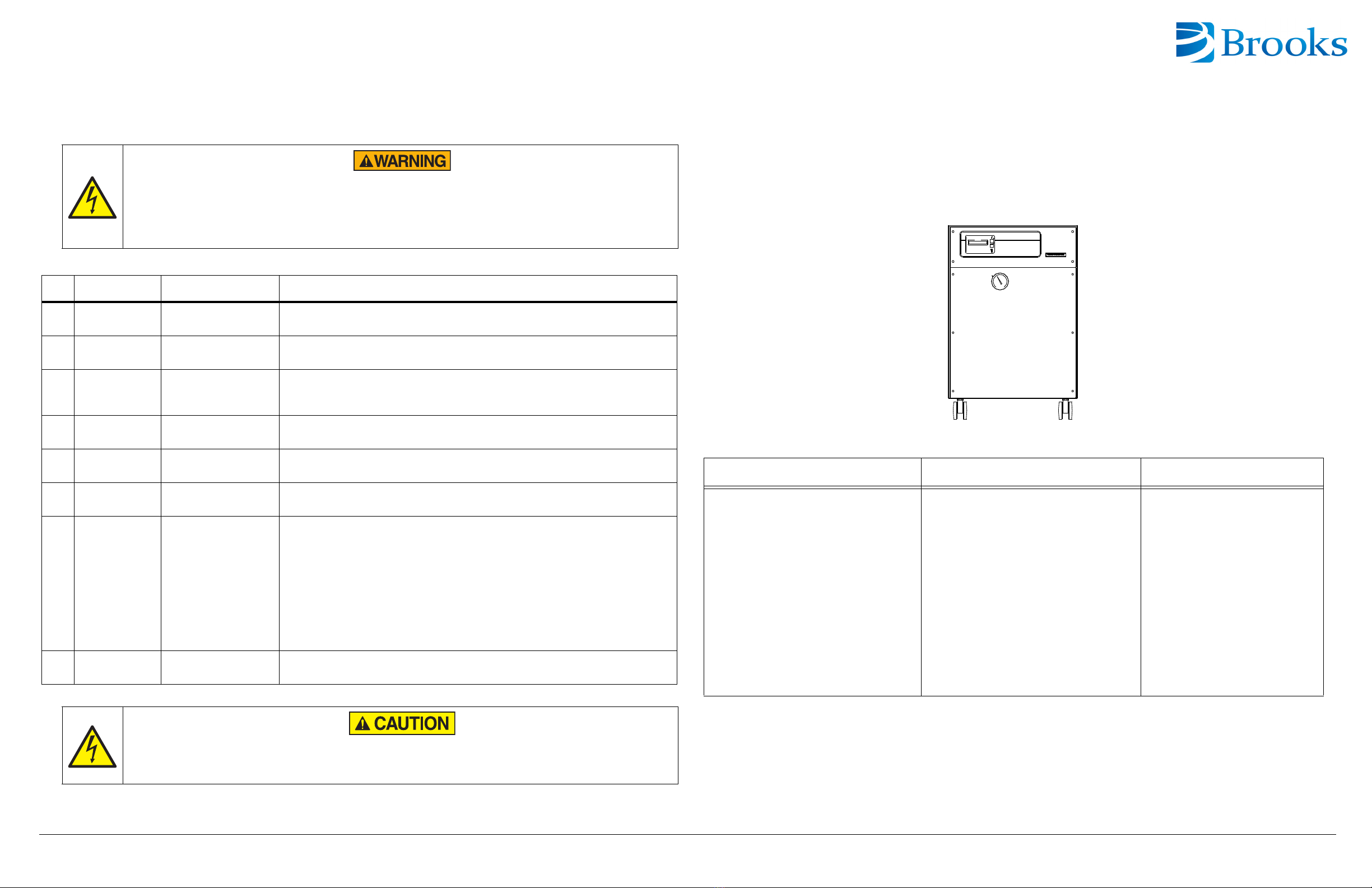

Troubleshooting

Look in Table 1 to find the error message that is displayed on the 8600 Compressor elapsed time meter/error message

display. Press the RESET switch to cancel the failure signal, and the status display will show the elapsed time. If the

failure message is not cancelled when the RESET switch is pressed, wait fifteen minutes and press the RESET switch

again. If the thermal switch operates, it takes about 15 minutes to reset. For more detailed information, see the Cryo-

Torr ®8600 Compressor Installation, Operation and Maintenance Manual (8040707). 8600 Compressor

Quick Installation Guide

Part Number 8040705, Revision A, 01/11/2013

ECO Number 63723

High Voltage

Disconnect the 8600 Compressor from its power source before performing any troubleshooting procedures.

The 8600 Compressor pump is hot after operating. Wait for the pump to cool down before working on the inside

of the compressor. Do not change or modify any 8600 Compressor internal wiring circuits, this may cause

failure of the compressor and cold head due to improper phasing.

Table 1: 8600 Compressor Troubleshooting Procedures

No. Message Possible Cause Corrective Action

1. Cooling Water Thermal switch (TS3)

operates. Check the cooling water requirements.

2. Low Pressure Low pressure switch

(LPS) operates. Add helium gas.

3. Overload Overcurrent relay (TS)

operates.

1. Check the power source requirements.

2. Check the cooling water and ambient temperature.

3. Check the static helium pressure.

4. Others Thermal switch (TS1 or

TS2) operates. Contact Customer Support.

5. Reverse Phase Reverse 3 phase at

input power. Change phase at input power connector.

6. Cir Protector-2 Circuit Protector (CP2)

operates. Turn on the Cir P2. Contact the customer support center.

7. Power Failure Power failure of more

than 2 seconds.

1.) When the NORMAL/C20 switch is in the NORMAL position, the 8600 Compressor

runs automatically when power fails within seconds.

2.) When the NORMAL/C20 switch is in the C20 position, the following occurs:

The POWER FAILURE message is not displayed if the operation signal is OFF within

50 msec after the power is cut. Pushing the RESET button is unnecessary.

When the operation signal is OFF after 50 msec, the 8600 Compressor runs automati-

cally when power fails within seconds.

3.) Regeneration: If the temperature of the 20HP Cryopump second stage is 20K or

more (or at a pressure of 1X10-2Pa or more) due to the power failure, regenerate the

cryopump.

8. Ref. Fuse

(C30V Only) The fuse blows. Replace the fuse and contact Customer Support.

High Voltage

When an irregular stop occurs due to a failure not listed in Table 1 , shut off the power supply and then turn on

the power supply.

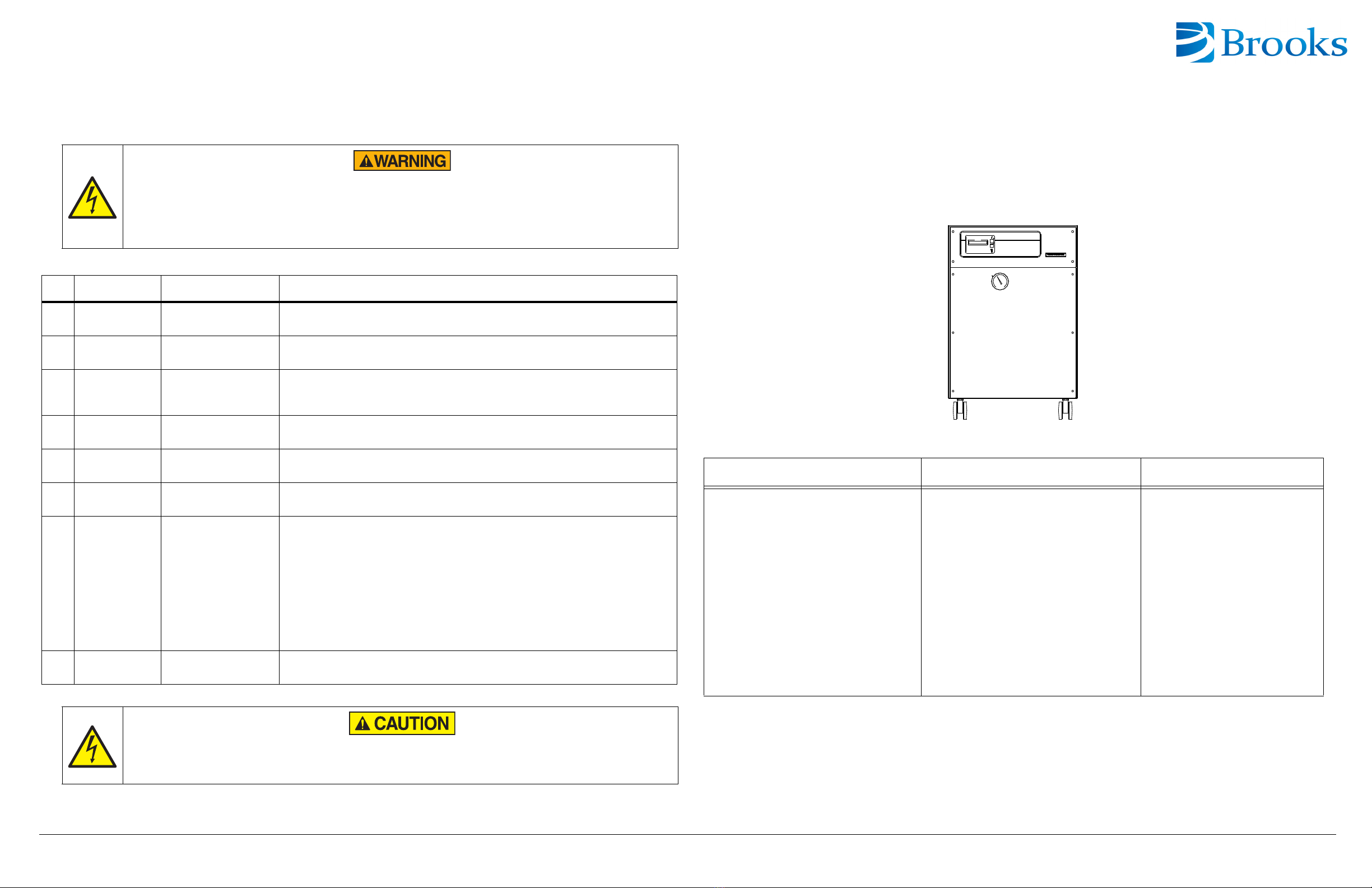

8600 Compressor Specifications

Cooling Water General Electrical

Maximum Inlet Temperature: < 101 psig

(0.7MPA (gage)

Minimum Inlet Temperature: 40º F (5º C)

Flow Rate: 1.0~3.3 gpm (5~15L/min)

Pressure Drop (Inlet-to-outlet): 2.9 - 24.6 psi

(0.02~0.17MPa). Refer to Water Flow Rate

chart in product manual, 8040707.

Maximum Inlet Pressure: < 101 psig (< 0.7

MPa (gage))

Part Number: 8175001g001

Input Power Cable: Supplied

Static Helium Pressure: 200 psig ± 6 psi (1.4

± 0.04MPa)

Interface: Cryopump power receptacle mates

with Brooks’ cryopump power cable for single

pump use.

Gas Supply And Return Connectors: 1/2-

inch Aeroquip® Self-sealing Couplings

Remote Control Receptacle: Supplied

Adsorber Service Schedule: 24,000 Hours

Inclination Angle: < 5º

Ambient Operating Temperature: 50 - 100º F

(10 ~ 38º C)

Must be installed in a dust-free and moisture-

free area.

Power Source: 190 - 220 VAC 50Hz

and 200 - 230 VAC 60Hz

Phase: 3

Power (Normal Operation): 5.2kW @

50 Hz and 6.8kW@60 Hz

Minimum Electrical Service: 30

AMPS