DH4-B981

H. Setting the sewing speed ................................ 36

I . Setting the mode ............................................ 37

J . Setting panel protection ................................. 37

K.

Setting the cloth setting position (-52 specifications)

... 37

L .

Setting the number of eyelet buttonholes (-52 specifications)

... 38

6-5.

Setting the number of home position start cycles

... 38

6-6. Using the select switch (option) ........................ 39

6-7.

Moving the cloth feed bar (-52 specifications) ....40

6-8. Using the memory switch....................................

40

6-9. List of error codes ............................................. 41

7. SEWING................................................................ 43

7-1. Using the EMERGENCY STOP switch............. 43

7-2. Sewing .............................................................. 44

7-3. Adjusting the thread tension ............................. 45

7-4. Needle and knife position ................................. 46

7-5. Setting the feed bracket to the front position .... 47

7-6.

Switching between single-pedal and dual-pedal operation

.... 47

7-7. Using feed mode............................................... 48

7-8. Using manual mode .......................................... 49

8. CLEANING AND MAINTENANCE................... 50

8-1. Cleaning............................................................ 50

8-2. Draining the oil.................................................. 51

8-3. Checking the air filter ........................................ 51

9. STANDARD ADJUSTMENTS........................... 52

9-1.

Adjusting the height of the spreader and looper

...

52

9-2. Adjusting the needle and looper timing............. 53

9-3. Adjusting the loop stroke .................................. 54

9-4. Adjusting the height of the needle bar .............. 55

9-5.

Adjusting the clearance between the looper and needle

... 55

9-6. Adjusting the needle guard ............................... 56

9-7. Adjusting the spreader mounting positions....... 56

9-8. Adjusting the spreader timing ........................... 57

9-9.

Adjusting the needle racking width (stitch width) ...

57

9-10.

Changing the knife cutting length (Replacing the hammer).....

58

9-11.

Adjusting the contact between the knife and the hammer .......

59

9-12. Replacing the knife ......................................... 60

9-13. Adjusting the cutting pressure ........................ 60

9-14. Adjusting the cloth opening amount................ 61

9-15. Adjusting the trimming of the upper thread..... 62

9-16.

Adjusting the trimming of the lower thread and gimp

........... 62

9-17.

Adjusting the gimp length after trimming (-02, -52)

.. 63

9-18. Lower thread presser ...................................... 63

9-19. Auxiliary clamp arm ........................................ 64

9-20.

Adjusting the cloth feeding speed (-52 specifications)

... 64

9-21.

Adjusting the cloth feed bar home position (-52 specifications)

... 65

9-22.

Adjusting the indexer hole spacing (-52 specifications)

... 66

9-23.

Adjusting the position of limit switch L (-52 specifications)

... 67

9-24.

Adjusting the position of limit switch R (-52 specifications)

.. 67

10. SUMMARY OF DIP SWITCHES..................... 68

10-1. Front panel DIP switches................................ 68

10-2. Circuit board DIP switches.............................. 70

11. TROUBLESHOOTING ..................................... 72

1. NAMES OF EACH PART................................... 1

2. SPECIFICATIONS............................................... 2

2-1. Specifications.................................................... 2

2-2. Optional parts.................................................... 3

2-3.

BAS-PC/300, Programming Software for Electronic Pattern sewer (peripheral device)

... 3

2-4.

Replacement parts list for specification changes

... 4

3. INSTALLATION................................................... 5

3-1. Table processing diagram................................. 5

3-2. Installing the motor............................................ 6

3-3. Installing the motor pulley ................................. 7

3-4. Installing the control box ................................... 7

3-5. Installing the machine head .............................. 8

3-6. Installing the oil container ................................. 9

3-7. Tightening the V-belt......................................... 9

3-8. Installing the spool stand .................................. 10

3-9. Installing the hand switch..................................10

3-10. Installing the air unit and the valve unit........... 10

3-11. Connecting the wiring ..................................... 11

3-12. Connections inside the control box .................12

3-13. Connecting the motor cables .......................... 13

3-14. Connecting the air tubes .................................13

3-15. Securing the cables ........................................ 14

3-16. Installing the air tubes .....................................15

3-17. Connecting the power cord ............................. 16

3-18. Installing the select switch (option) ................. 17

3-19. Installing the foot switch (option).....................17

3-20. Installing the indexer (option).......................... 18

4. LUBRICATION ....................................................23

4-1. Adding oil .......................................................... 23

4-2. Lubrication ........................................................ 23

5. CORRECT USE ................................................... 25

5-1. Initializing settings............................................. 25

5-2.

Changing the lower thread and gimp thread trimming

... 25

5-3. Installing the needle ..........................................26

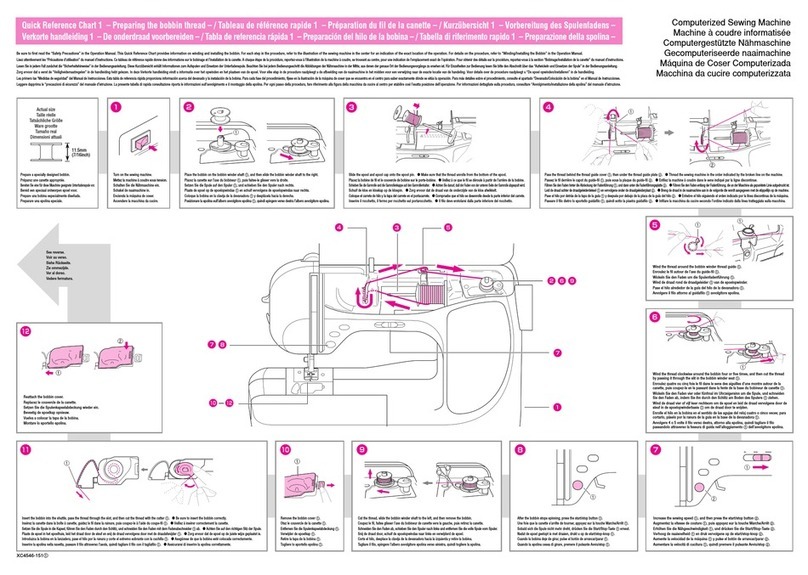

5-4. Threading the upper thread .............................. 26

5-5. Threading the lower thread ...............................27

5-6. Threading the gimp ...........................................28

5-7. Setting the material ...........................................28

5-8.

Setting the installation position for cloth feed plate (L) (-52 specifications)

... 30

5-9. Replacing the PROMs ...................................... 31

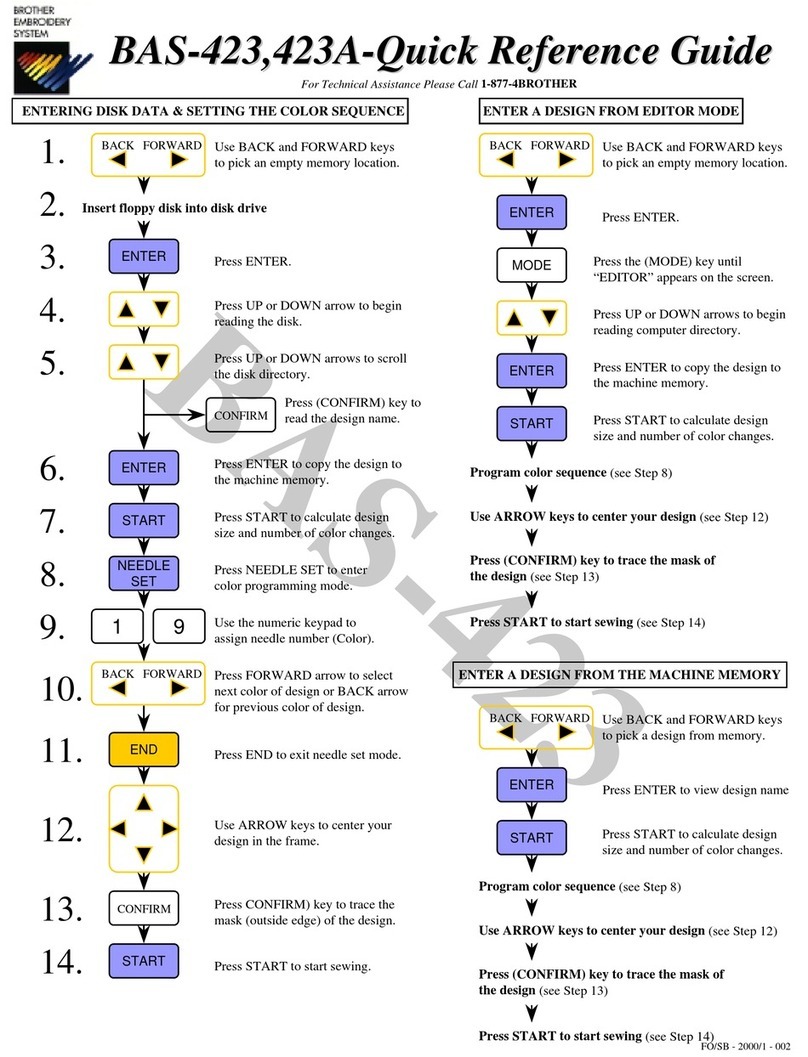

6. USING THE OPERATION PANEL ................... 32

6-1. Panel switch and indicator names .................... 32

6-2. Setting the buttonhole length ............................ 33

6-3. Turning cutting on and off ................................. 33

6-4. Setting by changing the panel DIP switches.....34

A. Setting the stitch pitch .................................... 34

B. Setting the number of eyelet stitches ............. 34

C. Setting the taper bar tacking length................35

D. Setting the knife operation method ................35

E. Setting the eyelet shape................................. 35

F.

Setting the offset (setting the taper bar tacking overlap)

... 36

G. Setting the cutting space ................................36

CONTENTS