Foreword

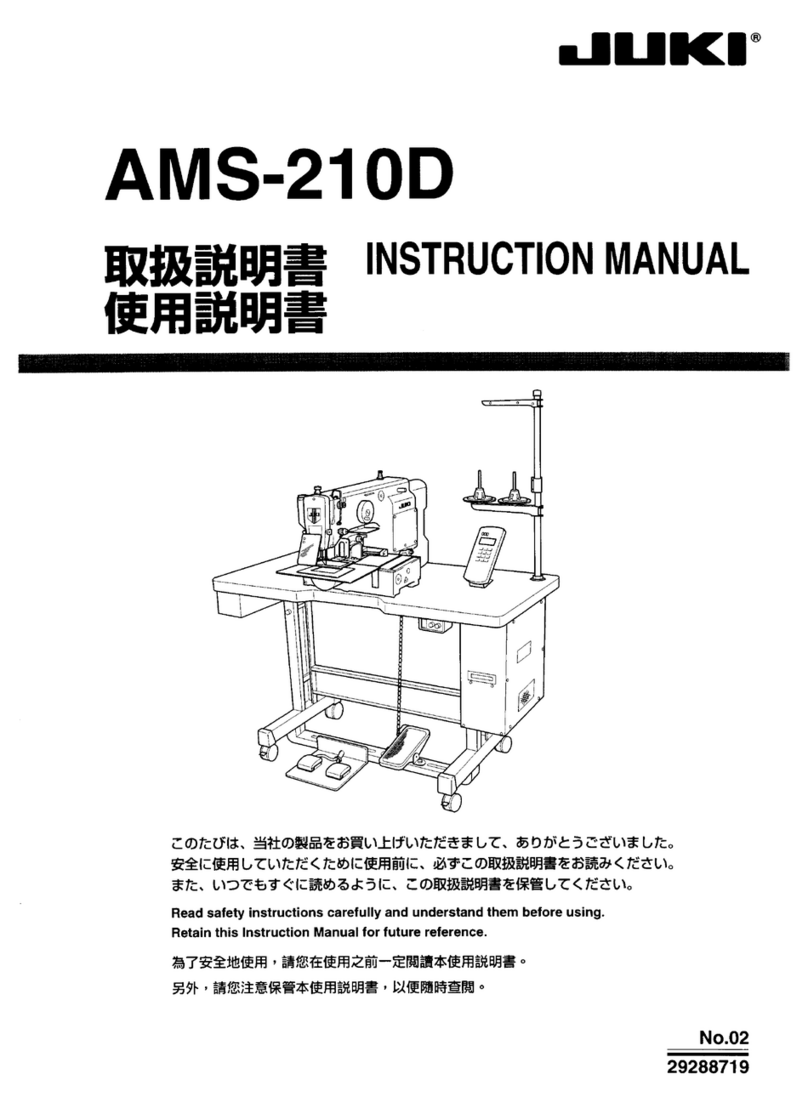

Welcome to use the products of our company and it’s the right investment choices of clothing

industry! This is the product reference manual of the company's newly developed "suction line cut".

Please carefully read this manual to better use the company's products!

⚫Before reading this manual, please note the following requirements:

1. Before practicing,the user must be grounded to ensure personal safety!(Ground resistance : <

4Ω)

2. Non-professionals do not disassemble the control box;

3. Please use at room temperature above 5 ℃,below 45 ℃;

4. Please work in 30% to 90% of the relatively humid environment;

5. Rated voltage 220V±10%,frequency 50/60HZ;

6. Use soft cotton cloth to clean the upper and lower infrared light before daily use.

⚫Safety Precautions:

1. Do not put your feet on the pedal when the power is connected;

2. This product requires professional installation and commissioning;

3. Do not open the control box when power is on;

4. Turn off the power when changing the needle, threading or replacing the

bottom thread;

5. Turn off the power when installing, removing and repairing;

6. Turn off the power when turning or lifting the sewing machine;

7. Away from high-frequency electromagnetic waves and radio waves, etc, in order to avoid the

servo drive being interference by the electromagnetic waves and leading to the wrong action.

⚫Warranty strategy:

1. Any quality problems other than man-made damage during the warranty period may be free

of charge;

2. Without the consent of the company to disassemble, modification damage will not give the

warranty;

3. If you can’t solve a problem, you can contact the company;

4. The company has the final interpretation of this manual