Retractable Ski Pylon (Sea-Doo) (Kit P/N 295 100 457)

The following symbols may be used in this document:

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION Indicates a hazard situation which, if not avoided, could result in minor or moderate injury.

NOTICE Indicates an instruction which, if not followed, could severely damage vehicle components or other property.

WARNING

– For safety reasons, this kit must be installed by an authorized BRP dealer.

– This kit is designed for specific applicable models only (authorized BRP dealers will confirm model(s)). It is not rec-

ommended for units other than the one (those) for which it was sold.

– This instruction sheet MUST be given to the purchaser.

– Should removal of a locking device (e.g. lock tabs, self-locking fasteners, etc.) be required when undergoing dis-

assembly/assembly, always replace with a new one.

– Torque wrench tightening specifications must strictly be adhered to.

– Always wear EYE PROTECTION AND APPROPRIATE GLOVES when using power tools.

– Unless otherwise specified, engine must be OFF when performing any operation on the vehicle.

– Always be aware of parts that can move, such as wheels, transmission components, etc.

– Some components may be HOT. Always wait for engine to cool down before performing work.

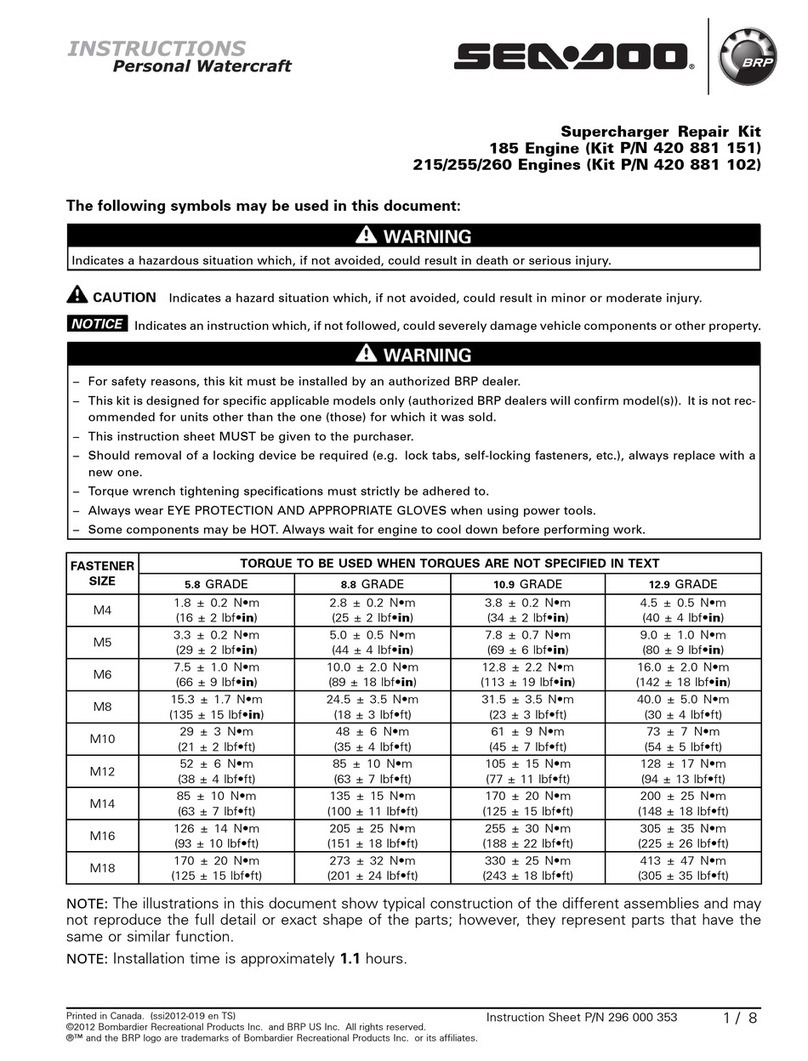

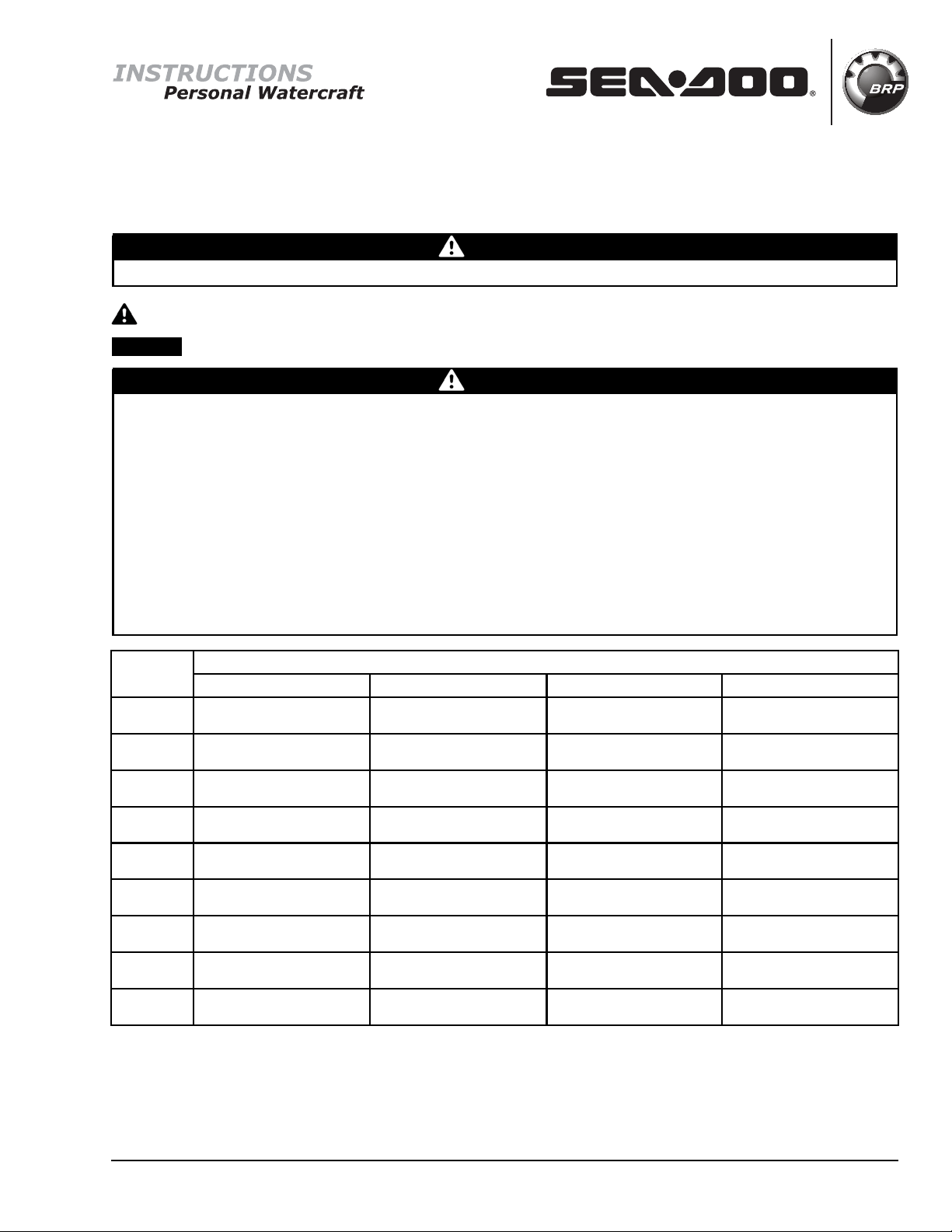

TORQUE TO BE USED WHEN TORQUES ARE NOT SPECIFIED IN TEXT

FASTENER

SIZE 5.8 GRADE 8.8 GRADE 10.9 GRADE 12.9 GRADE

M4 1.8±0.2N•m

(16±2lbf•in)

2.8±0.2N•m

(25±2lbf•in)

3.8 ± 0.2 N•m

(34±2lbf•in)

4.5±0.5N•m

(40±4lbf•in)

M5 3.3±0.2N•m

(29±2lbf•in)

5.0±0.5N•m

(44±4lbf•in)

7.8 ± 0.7 N•m

(69±6lbf•in)

9.0±1.0N•m

(80±9lbf•in)

M6 7.5±1.0N•m

(66±9lbf•in)

10.0 ± 2.0 N•m

(89 ± 18 lbf•in)

12.8 ± 2.2 N•m

(113 ± 19 lbf•in)

16.0 ± 2.0 N•m

(142 ± 18 lbf•in)

M8 15.3 ± 1.7 N•m

(135 ± 15 lbf•in)

24.5 ± 3.5 N•m

(18±3lbf•ft)

31.5 ± 3.5 N•m

(23±3lbf•ft)

40.0 ± 5.0 N•m

(30±4lbf•ft)

M10 29 ± 3 N•m

(21±2lbf•ft)

48 ± 6 N•m

(35±4lbf•ft)

61 ± 9 N•m

(45±7lbf•ft)

73 ± 7 N•m

(54±5lbf•ft)

M12 52 ± 6 N•m

(38±4lbf•ft)

85 ± 10 N•m

(63±7lbf•ft)

105 ± 15 N•m

(77 ± 11 lbf•ft)

128 ± 17 N•m

(94 ± 13 lbf•ft)

M14 85 ± 10 N•m

(63±7lbf•ft)

135 ± 15 N•m

(100 ± 11 lbf•ft)

170 ± 20 N•m

(125 ± 15 lbf•ft)

200 ± 25 N•m

(148 ± 18 lbf•ft)

M16 126 ± 14 N•m

(93 ± 10 lbf•ft)

205 ± 25 N•m

(151 ± 18 lbf•ft)

255 ± 30 N•m

(188 ± 22 lbf•ft)

305 ± 35 N•m

(225 ± 26 lbf•ft)

M18 170 ± 20 N•m

(125 ± 15 lbf•ft)

273 ± 32 N•m

(201 ± 24 lbf•ft)

330 ± 25 N•m

(243 ± 18 lbf•ft)

413 ± 47 N•m

(305 ± 35 lbf•ft)

NOTE: The illustrations in this document show typical construction of the different assemblies and may

not reproduce the full detail or exact shape of the parts; however, they represent parts that have the

same or similar function.

NOTE: Installation time is approximately 1.0 hour.

Printed in Canada. (ssi2011-030 en JT)

©2010 Bombardier Recreational Products Inc. and BRP US Inc. All rights reserved. Instruction Sheet P/N 487 800 755 1/11

®™ and the BRP logo are trademarks of Bombardier Recreational Products Inc. or its affiliates.