To

measure

the

strain

on

the

test

object

a resistance strain gage should be

used and a Strain Gage

Apparatus

1516

will be

found

ideal as

the

measuring

bridge. The

output

voltage from

the

Strain Gage Apparatus can be fed

directly

to

a Level Recorder with linear

potentiometer

for

automatic

record-

ing.

An example

of

such a recording,

taken

on

a

thin

metaI bar, showing

the

mechanical strain and indicating its resonant frequency,

is

shown

in

Fig

.

5.21.

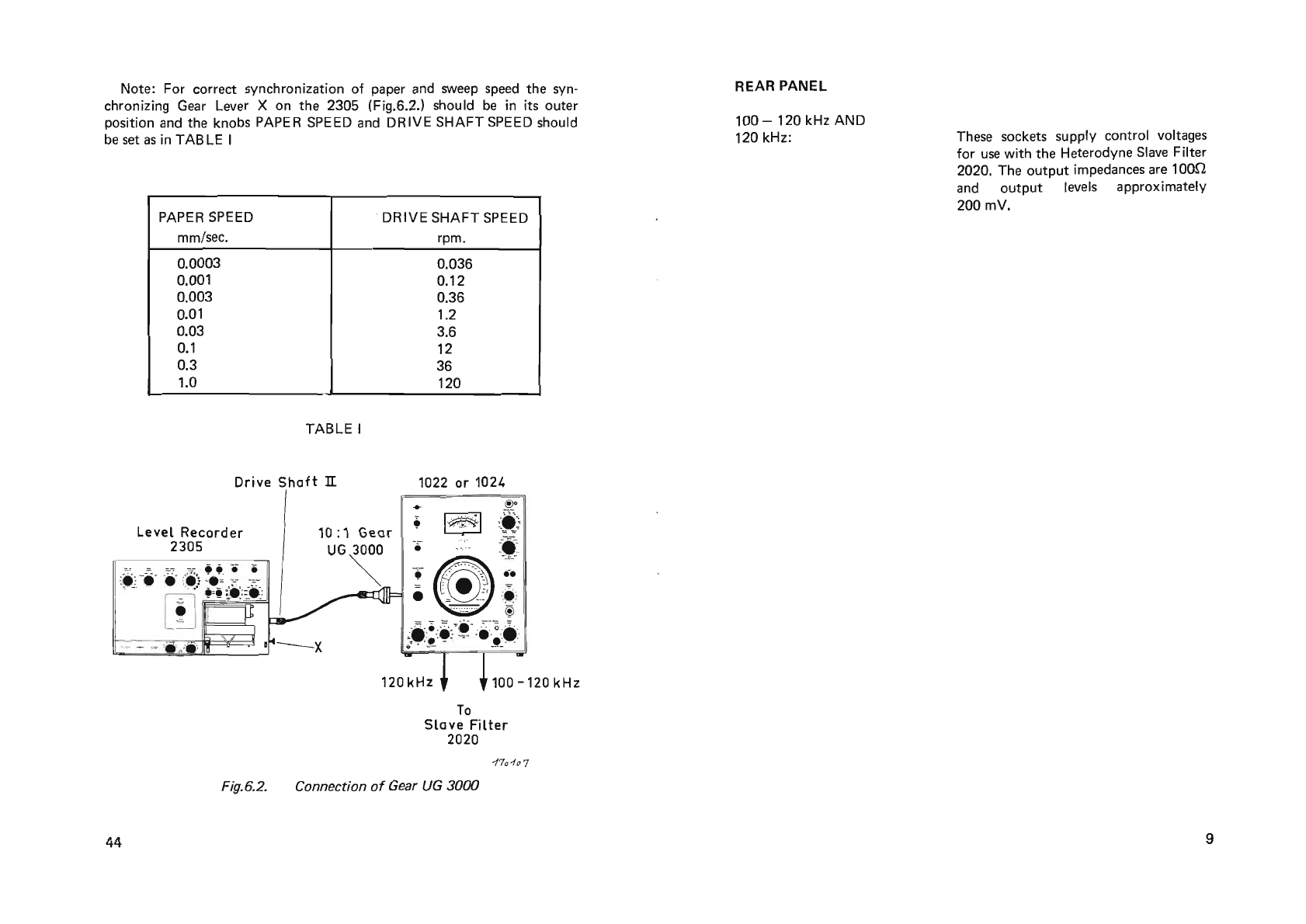

DDDDDDOOOODDODODDDDDDDODDDJ

50

db

20

10

o

50

100

200

Hz

300

~o

1?DD

I{q

Fig.5.21. Recording

of

mechanical strain in a

bar.

Instrumentation set-up

as

in Fig.5.20.

The

reactance circuit

is

needed

to

controi

the

actual frequency deviation

(modulation swing)

of

the

fixed oscillator by producing an inductive react-

ance across

the

oscillator's

tuned

collector. The deviation can be varied

linearly from O

to

±

250

Hz

where

the

sensitivity

is

approximately

5 mV/Hz.

A

saw·tooth

generator determines

the

frequency

of

modulation i.e.

the

rate

of

change

of

the

frequency swing

of

the

oscillator. Frequencies

of

1-1.6-2.5-4-6.3-10-16-25

Hz

are available. Provision

is

also made

for

modulation by an external generator. Alternative modulation frequencies

or

wave shapes can

the

n be chosen and frequency swings

of

up

to

±

300

Hz

obtained

(but

the

modulation sensitivity varies).

The

signal

from

the

fixed oscillator

is

passed

to

aregulating

amplifier

which controls

the

output

level.

The

regulating amplifier

is

used

to

perform

the

oscillator

stop

and dead zone blocking. A compressor amplifier can

be

switched

in

to

controi

the

regulating amplifier so

that

constant

output

level

is

obtained.

When

the

instrument

is

being used for instance

to

power a

loudspeaker,

the

compressor circuit can be used with a

microphone

to

main-

tain a

constant

sound pressure level.

The

compressor circuit consists

of

an amplifying stage and a full-wave

averaging rectifier stage.

The

signal from

the

rectifying stage

is

then

used

to

varv

the

gain

of

the

regulating amplifier. A variable

potentiometer

(Com-

pressor Voltage)

in

the

input

circuit

of

the

regulating amplifier

can

be used

to

controi

the

output

power from

the

instrument

when

automatic

regula-

tion

is

used.

The

speed with which

the

variation

in

output

level

is

regulated

back

to

normal

depends

on

the

setting

of

the

Compressor Speed knob,

but

also

depends

to

a certain

extent

on

the

amount

of

the

deviation from

the

normal

level. Compressor speeds

of

30

-

100

-

300

-

1000

dB/sec. are available

and are

determined

by

the

integration time

constant

of

the

rectifying cir-

cuit.

The

input

impedance

of

the

Compressor Input

is

approximately

25

kQ

and

the

maximum

range

of

regulation

is

50

dB. Regulation characteristics

for

different

positions

of

the

Output

Level

potentiometer

are shown

in

Fig.3.2.

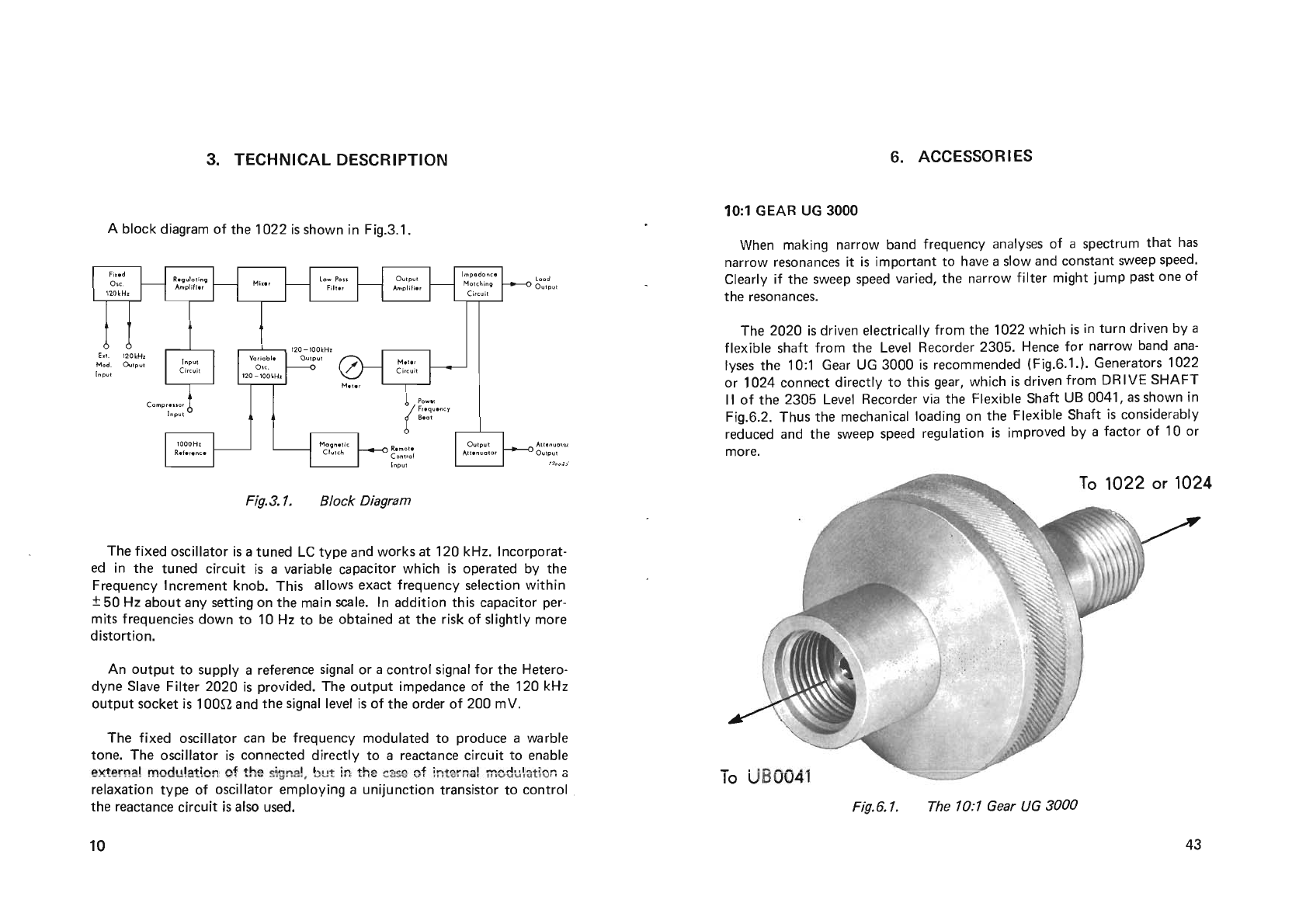

The

variable oscillator

is

of

similar design

to

the

fixed

one

except

that

it

has a variable capacitor

in

its

tuned

circuit

to

varv

the

oscillation

frequency

between

100

and

120

kHz. A worm gear,

connected

to

the

capacitor

42

11