4

Congratulations

CongratulationstothebuyingoftheBrunner-anlikervegetablecutter.Thisrobust

and high-performance machine will achieve you good service in various

applications. The design in total aluminium or high-grade steel respectively

makes it especially durable. After use it can be cleaned without difficulty. We

are sure that the vegetable cutter will render you good services for many years

and will confirm the rightness of your investment.

Safety references

Yet with construction of the vegetable cutter a lot of safety has been integrated

it is necessary that attention should be paid to certain safety instructions. Read

this precautions attentively.

• While setting up and attaching:

The machine should be placed on even and stable work surface or terrain

respectively.TheMulticut240 must belockedon two rearwheelsand examined

for safely blocking. It should be installed preferably near to a power socket. To

avoid a trip over do not lay the cable over a passageway.

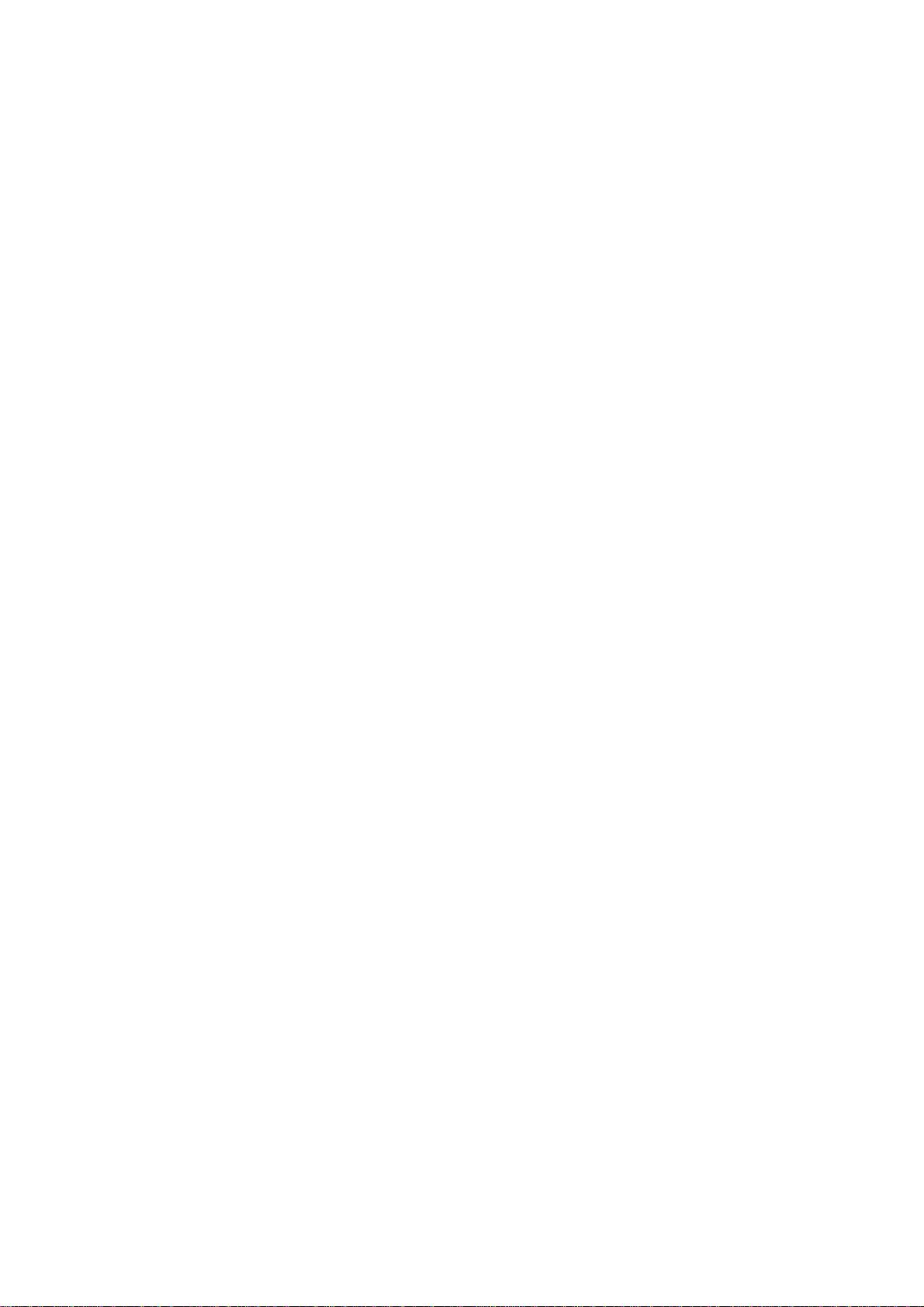

• While changing the cutting disc:

The machine turns off automatically as soon as the fastening lever is released.

The cutting discs should be gripped with both hands at the shell surfaces only.

Caution ! The blades are extremely sharply polished !

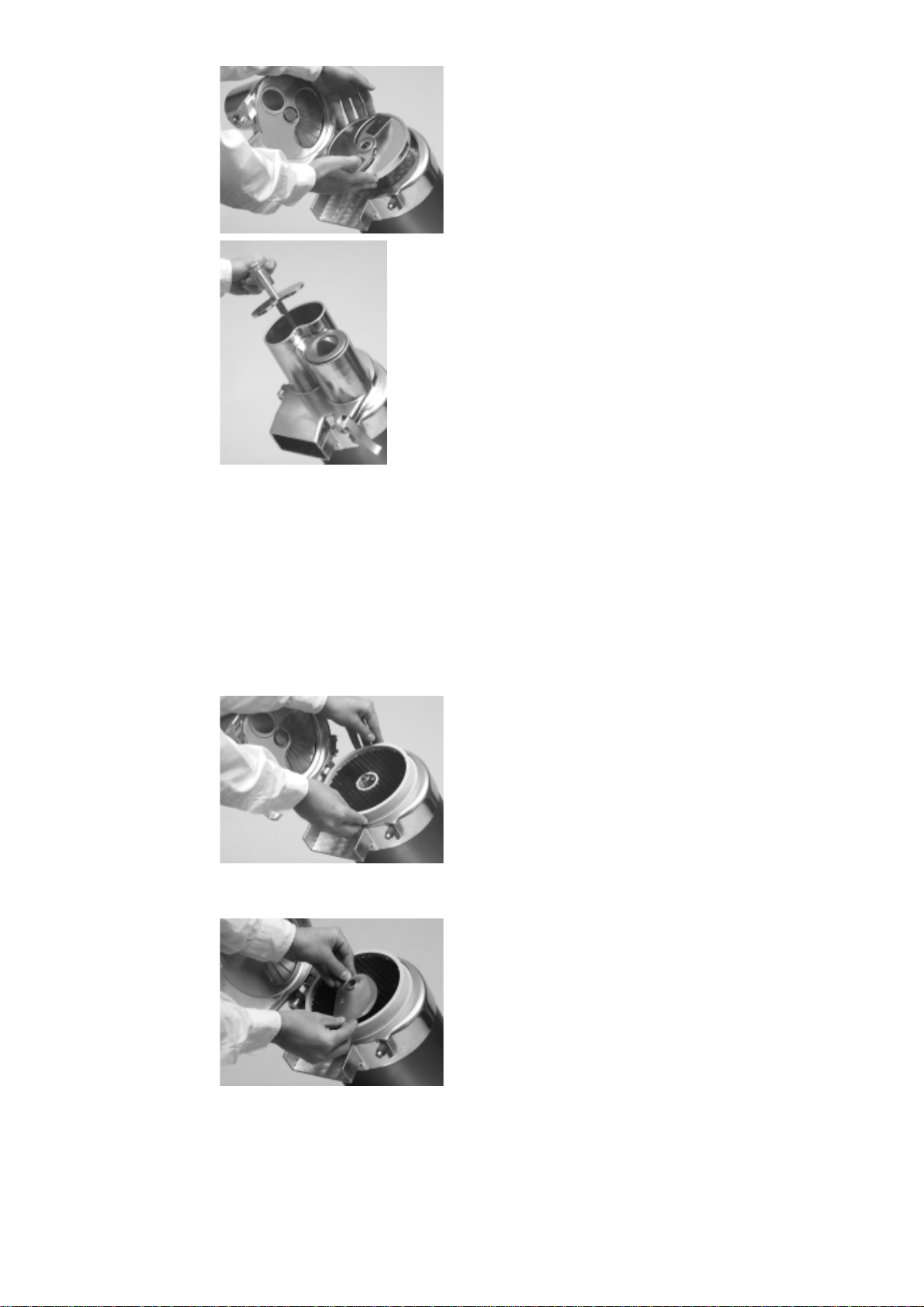

• While loading of vegetables:

No contaminant should get into the loading way. Do under no circumstances

gripp into the loading way ! Neither to distribute the vegetable nor to take out

contaminant. In this case the fastener lever should be released to stop the

machine. The cap is to be swivled to empty the cutting area entirely.

• While cleaning:

Take apart only as far as arranged for user. The vegetable cutter may not be

hoseddown withahighpressurecleaner,nordippedintorinsingwater.Therefore

it should be wiped off with a damp cloth and dish washing detergent.

• In case of disturbances: Emergency - stop

First procedure upon possible disturbances: Release the fastening lever – or, if

the occasion should arise pull out the gamma profile! Therewith the machine is

stopped.Pleasenote that thereisno special emergencystopbutton.Thepower

plug must be pulled out in case of unpleasant exhalation.