2

218-692-1050 | brushwolf.com

SITE INSPECTION

Before operating your brush cutter, carefully

inspect the area to be cleared. Remove any

items that may be picked up and thrown

by the cutting blades, such as wire, pipes,

rocks, etc. Mark objects that are too large

to move. This is an important step to avoid

personal injury, damage to property, the

brush cutter, or your compact utility loader/

skid steer. If an object is struck while

operating the brush cutter, immediately shut

down power to both the brush cutter and

the compact utility loader/skid steer. Any

damage should be corrected and tested

before the continuation of cutting.

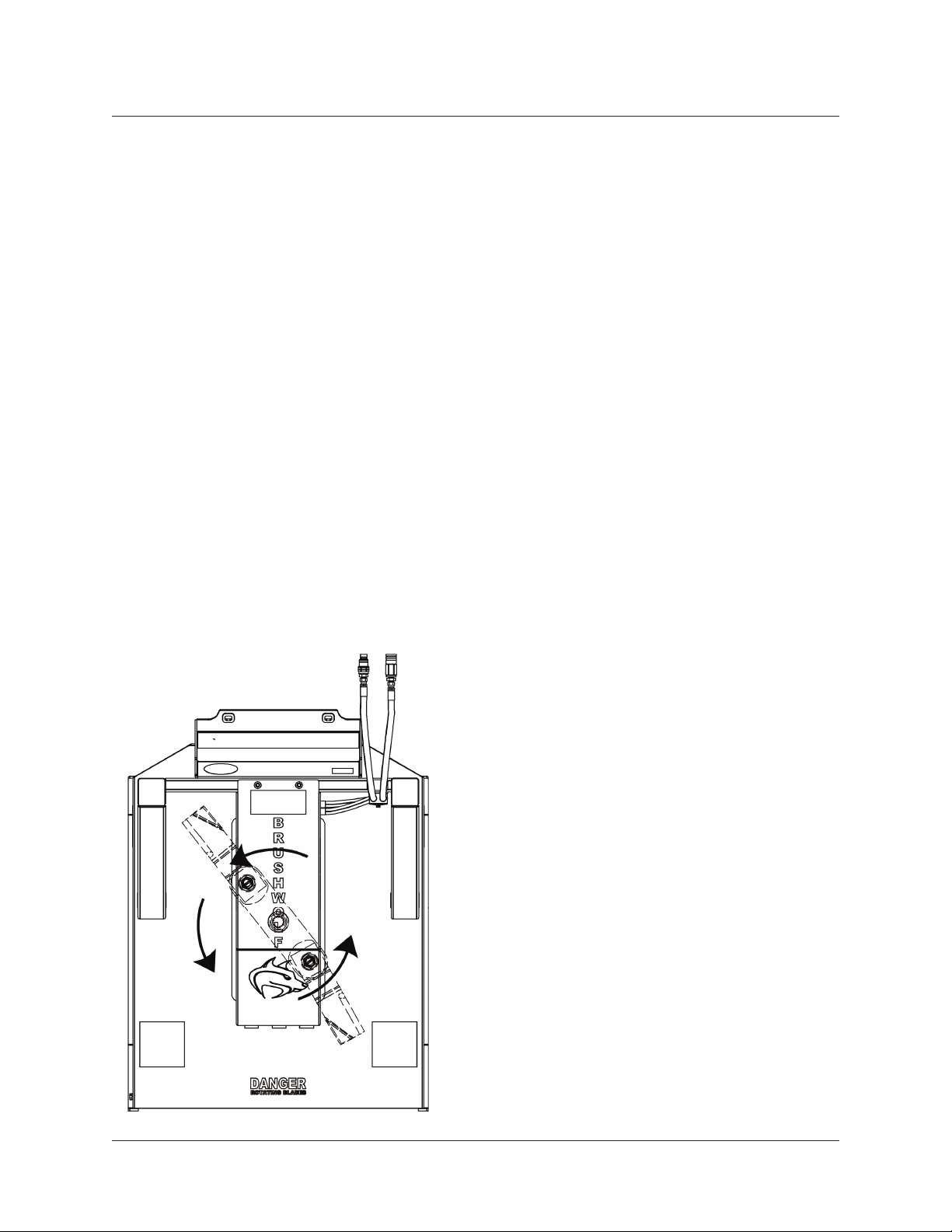

COMPACT UTILITY LOADER/SKID

STEER AUXILIARY HYDRAULIC FLOW

Check the specifications of your brush

cutter’s rated gallons per minute (GPM) to

correctly match the hydraulic flow of your

compact utility loader/skid steer to ensure

proper operation.

FOR YOUR SAFETY, READ THESE INSTRUCTIONS.

The following safety instructions are provided to alert you to precautions that, if

not followed, may cause serious injury to yourself or to others. Please read these

instructions completely. Brush Wolf/Cross-Tech Manufacturing cannot cover every

incident that might be a hazard. Extreme caution should be used at all times. Only

use your Brush Wolf brush cutter for the purpose for which it has been designed.

EQUIPMENT INSPECTION

Disconnect the unit from the compact utility

loader/skid steer. To inspect or to make

repairs under the cutter deck, always block

the unit securely to prevent accidental

release of the lift mechanism.

Inspect all hydraulic connections to ensure

they are tight, and hoses and shields are in

good condition before applying pressure.

Hydraulic fluid can escape under pressure

and may cause serious injury or death. If

this type of injury occurs, seek medical

attention immediately.

SAFETY GEAR

Wear safety goggles, hearing protection, and

a hard hat. If using a skid steer, only operate

the skid steer behind a shatterproof forestry-

rated door and cab.

SAFETY FIRST!