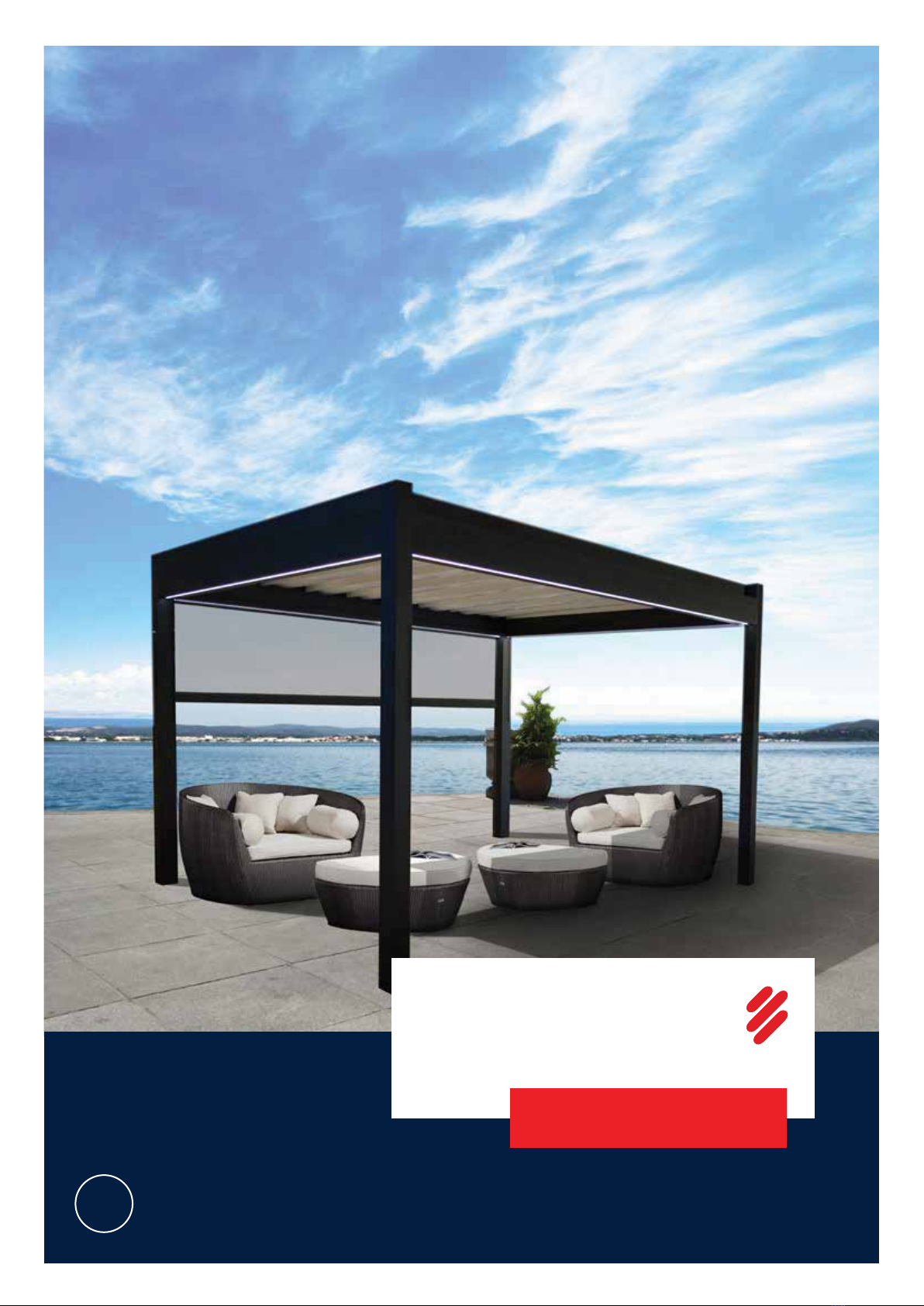

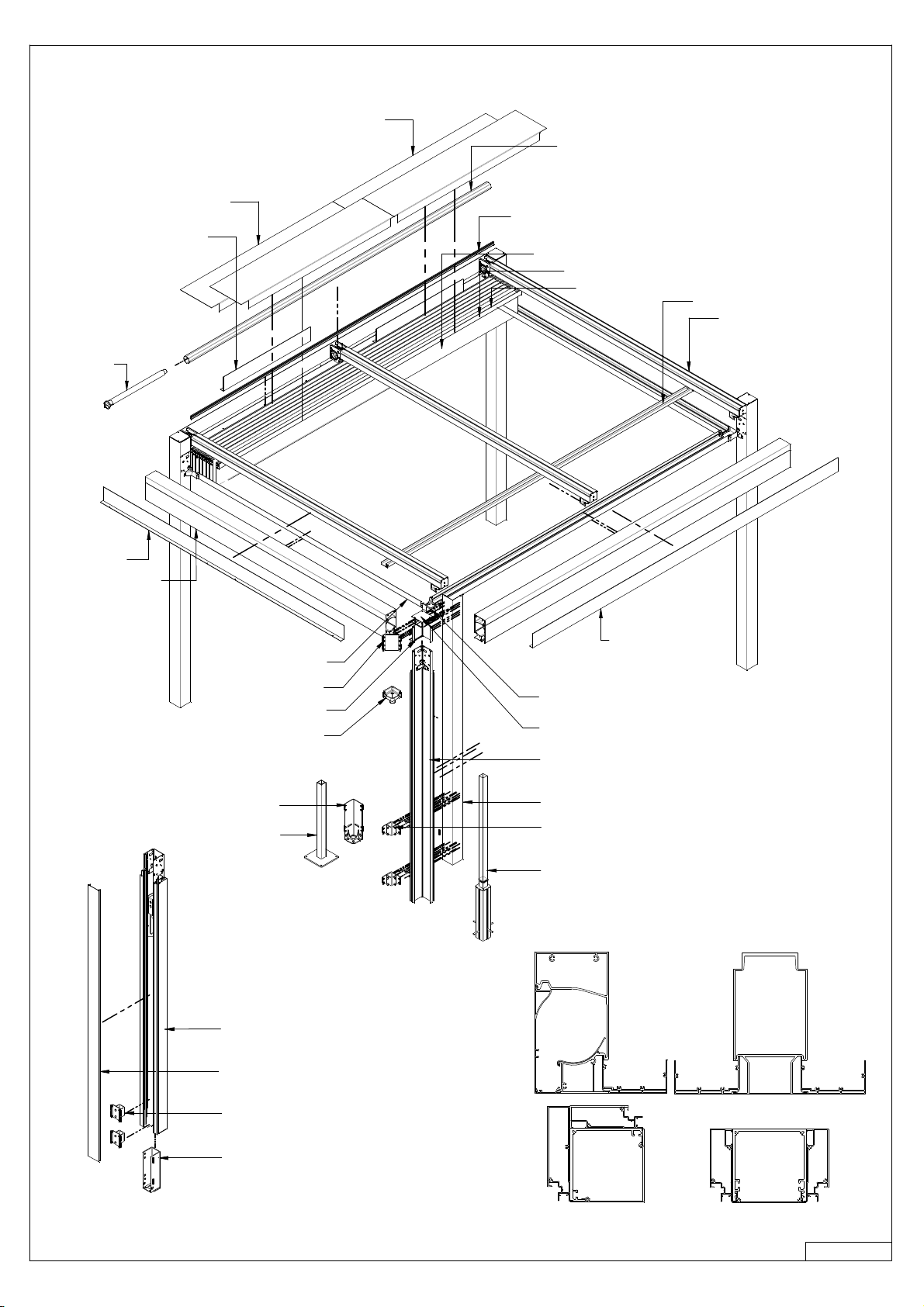

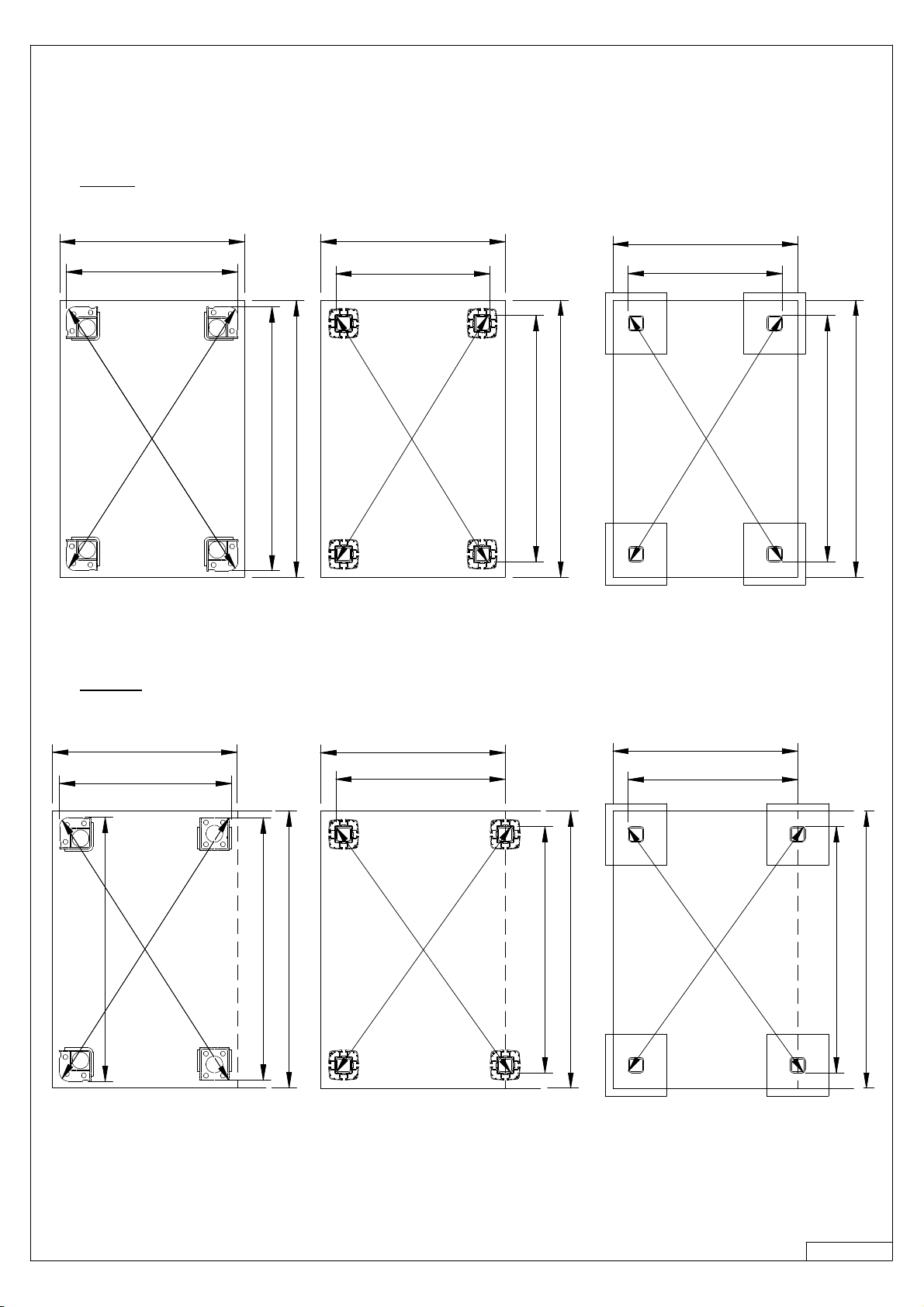

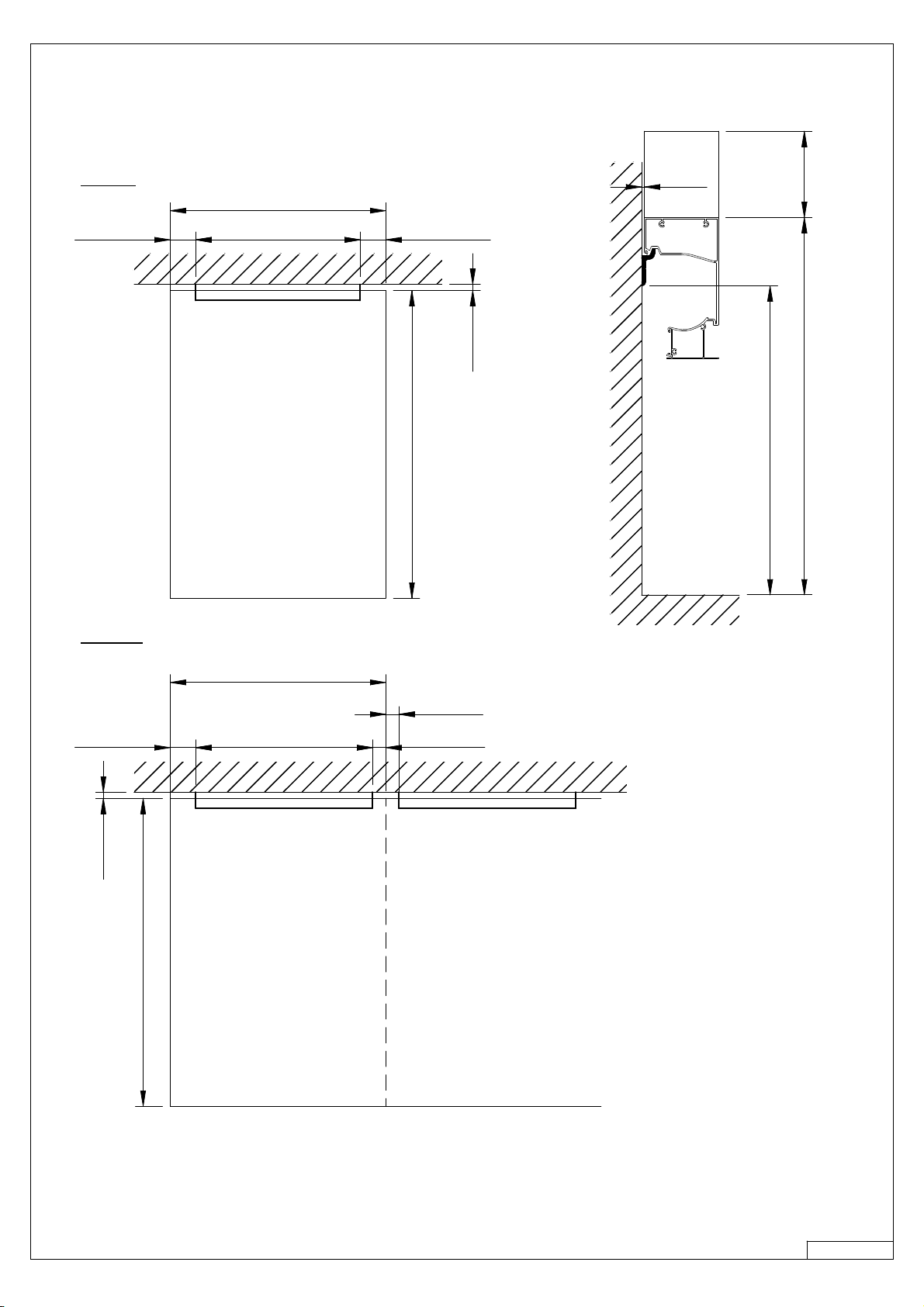

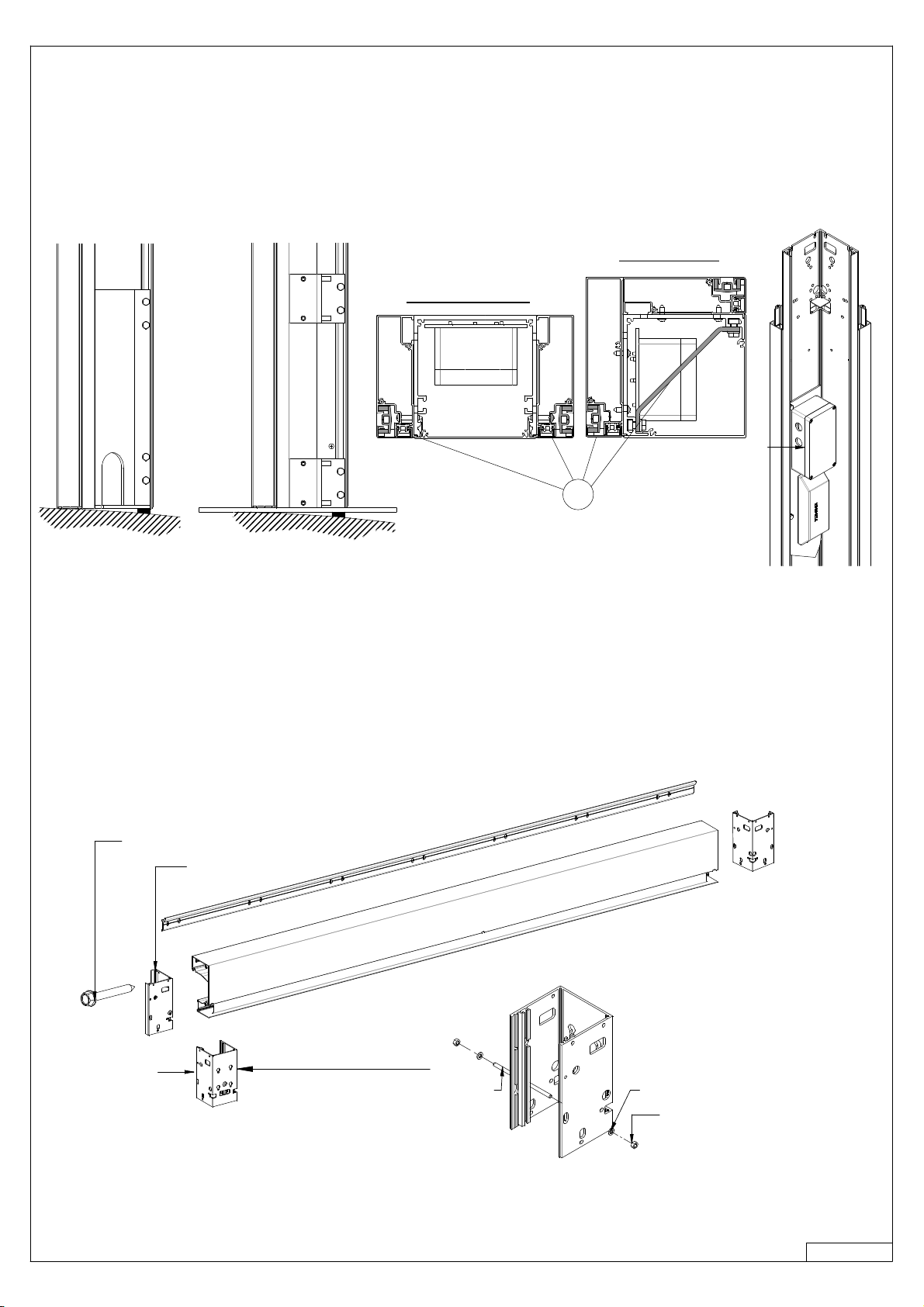

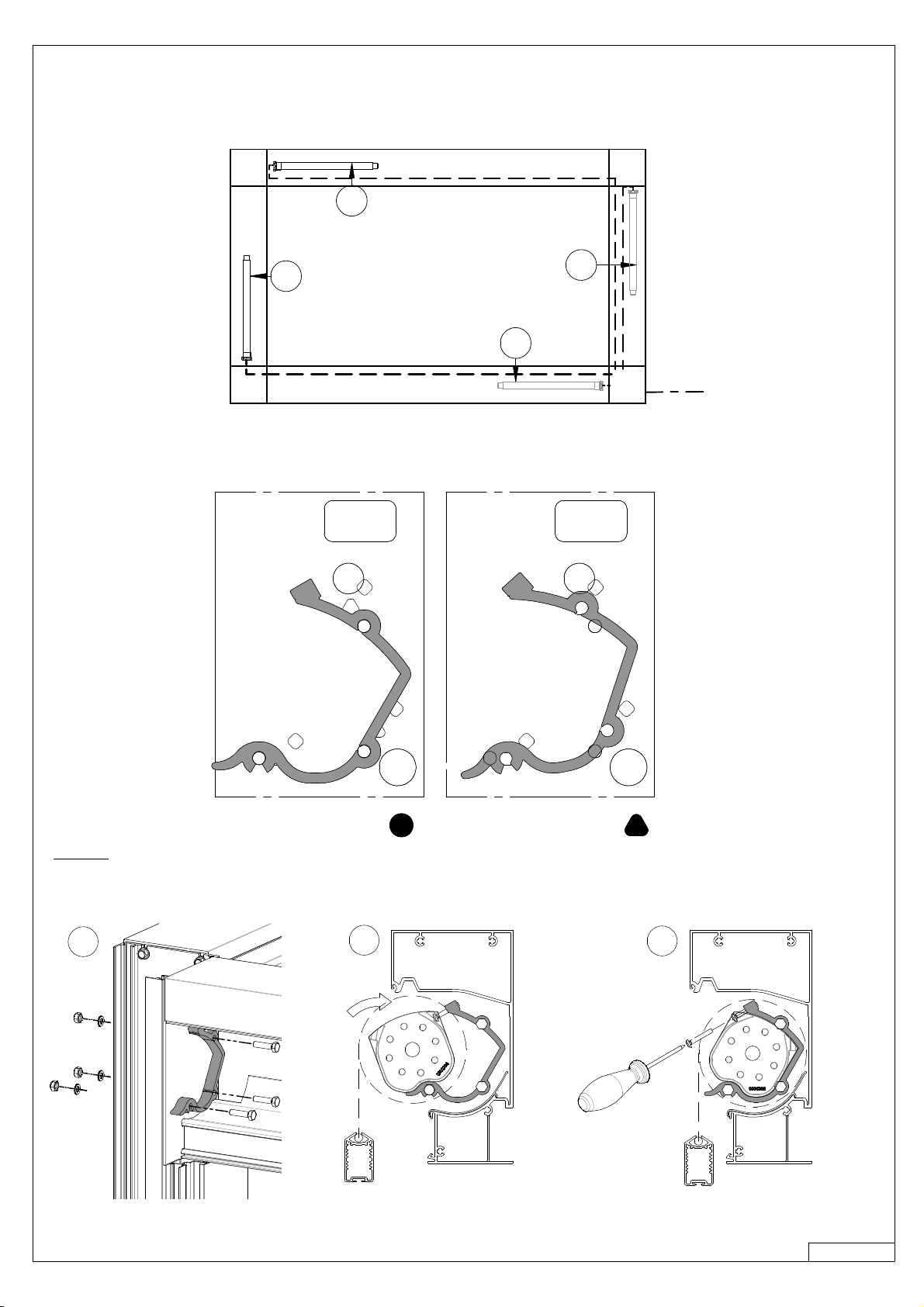

BRUSTOR B300XL User manual

Other BRUSTOR Outdoor Furnishing manuals

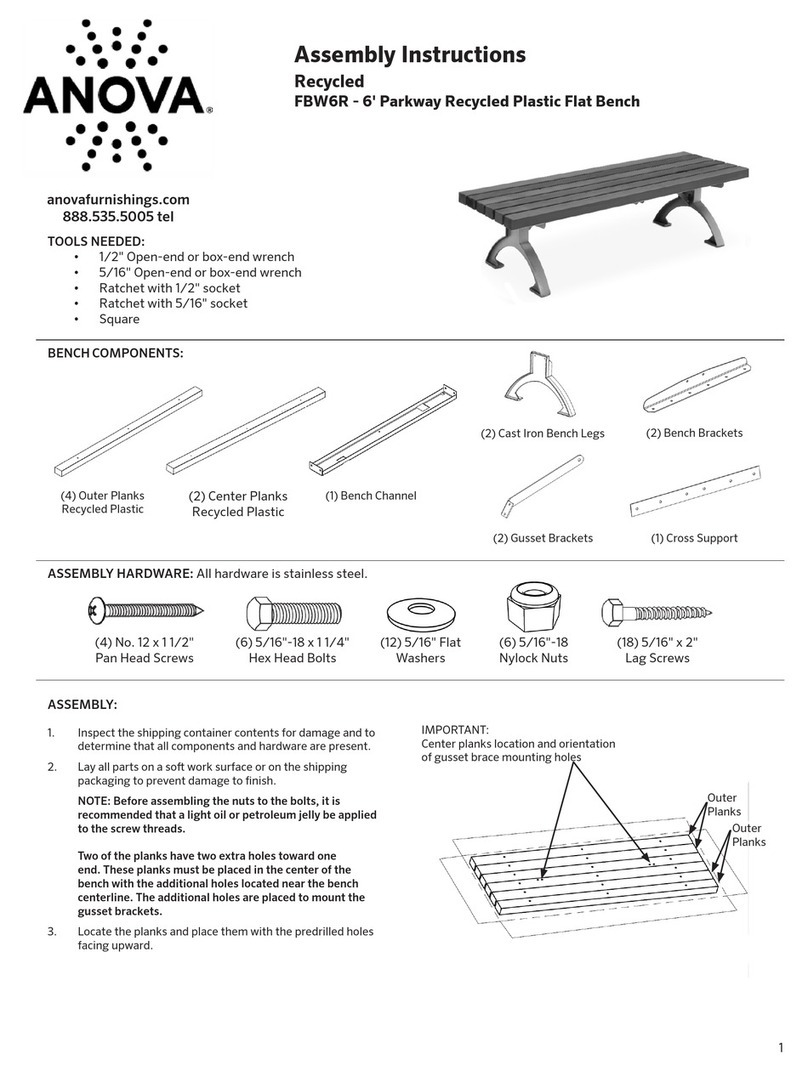

Popular Outdoor Furnishing manuals by other brands

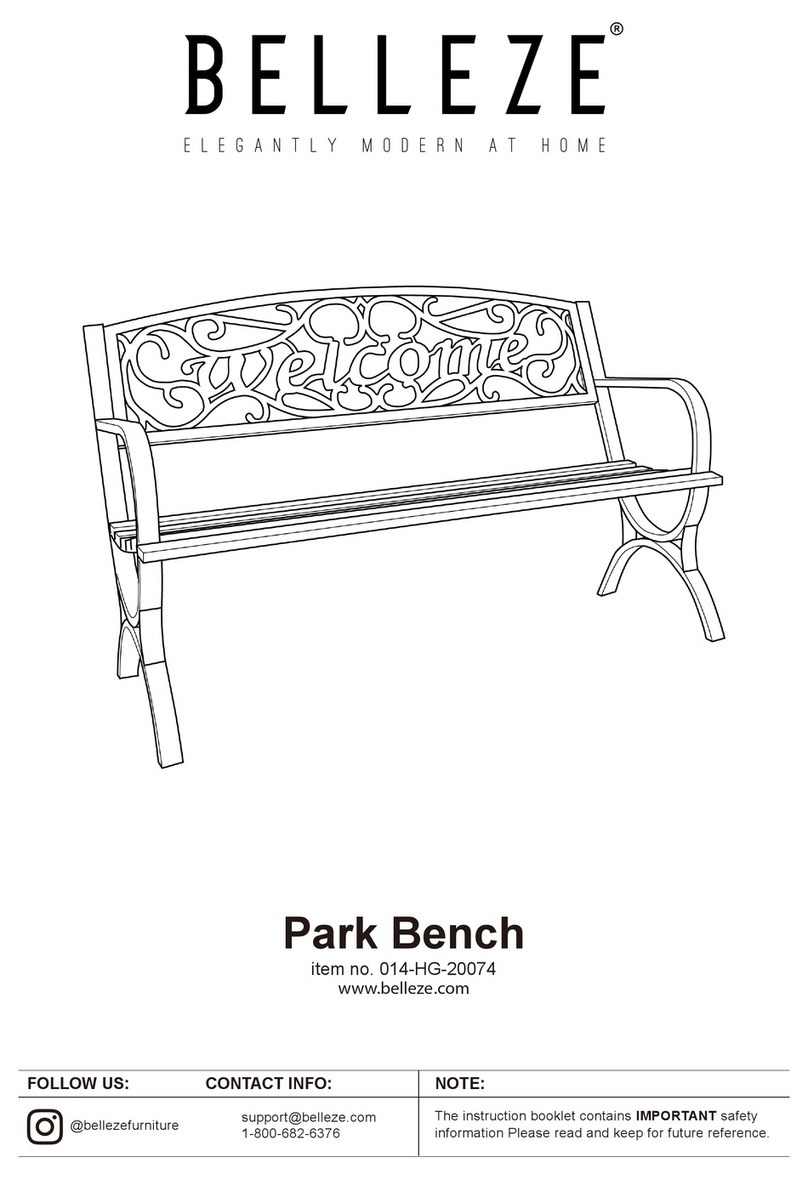

Belleze

Belleze 014-HG-20074 manual

Hatteras Hammocks

Hatteras Hammocks DCA1-K-HH instructions

Kozyard

Kozyard Morgan Aluminum Pergola Assembly manual

Lemeks

Lemeks Palmako PA120-5959 Assembly, installation and maintenance manual

OLT

OLT 24 Assembly manual

forest-style

forest-style HACIENDA 2354 Building instructions

Courtyard Creations

Courtyard Creations RUS0188-WM Assembly instructions

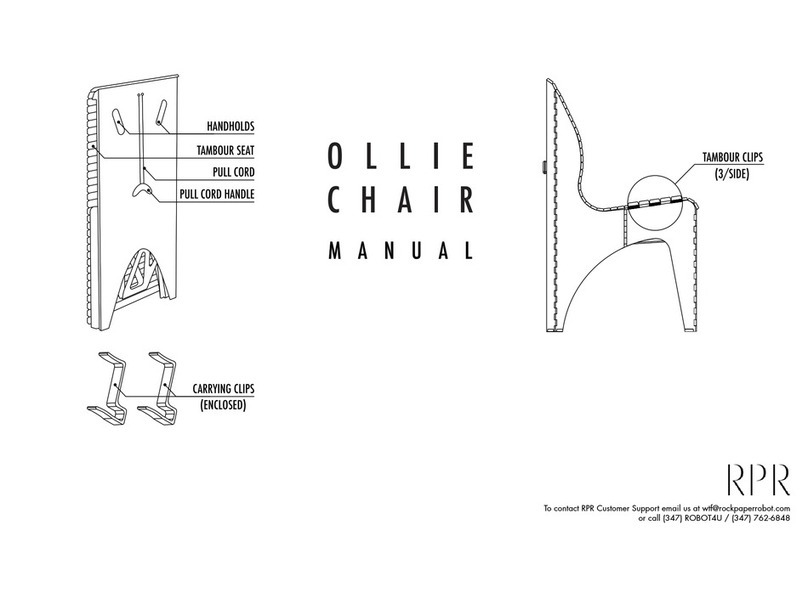

RPR

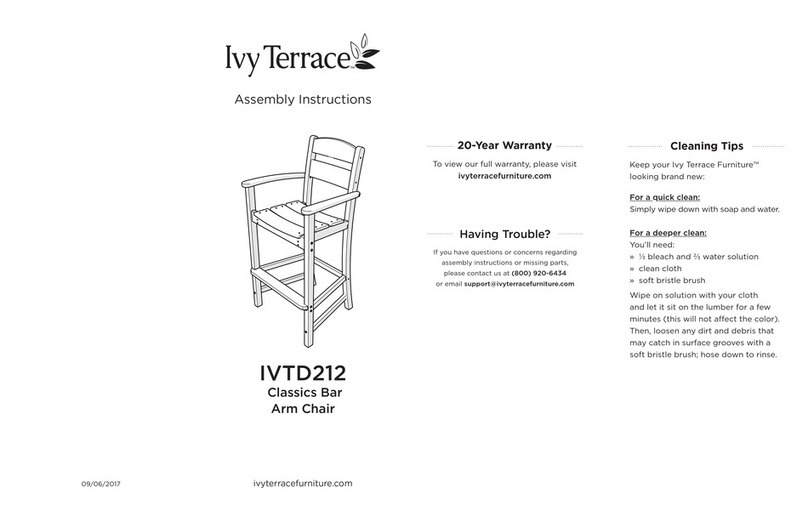

RPR OLLIE CHAIR manual

kingsley-bate

kingsley-bate MC-55 Assembly instructions

Weltevree

Weltevree Carrier product manual

Grange Fencing

Grange Fencing Elite Arch Assembly instructions

Grosfillex

Grosfillex AUVENT YR14 Assembly instructions