9

Be sure to inspect the unit before proceeding with these steps. Start with problem 1, then problem 2 and so on.

Table 1 – Troubleshooting

Problem: SPossible causes: SYou should try this:

1 Infinity Air Purifier power indicator light

located on the door is off.

SPower switch is not in the on (closed) position. SMake sure the switch is on and using a

multimeter check to see that 115 Volt power is

available.

SDoor is not closed. A magnet in the door is used

to activate safety reed switches in the power

supply when the door is installed.

SThe door magnet is missing or has fallen out. SRe-cement loose door magnet with a suitable

adhesive.

SThe door safety reed switches may be defective.

SIf the unit switch is on and 115 Volt power is

available through the service cord, a door

magnet moved in close proximity of the power

supply will cause the reed switches to audibly

click and the power supply will turn on.

SFurnace blower is not operating. Power will not

be supplied from the furnace control’s EAC

terminals unless the blower is running.

SMake sure the furnace blower is operating.

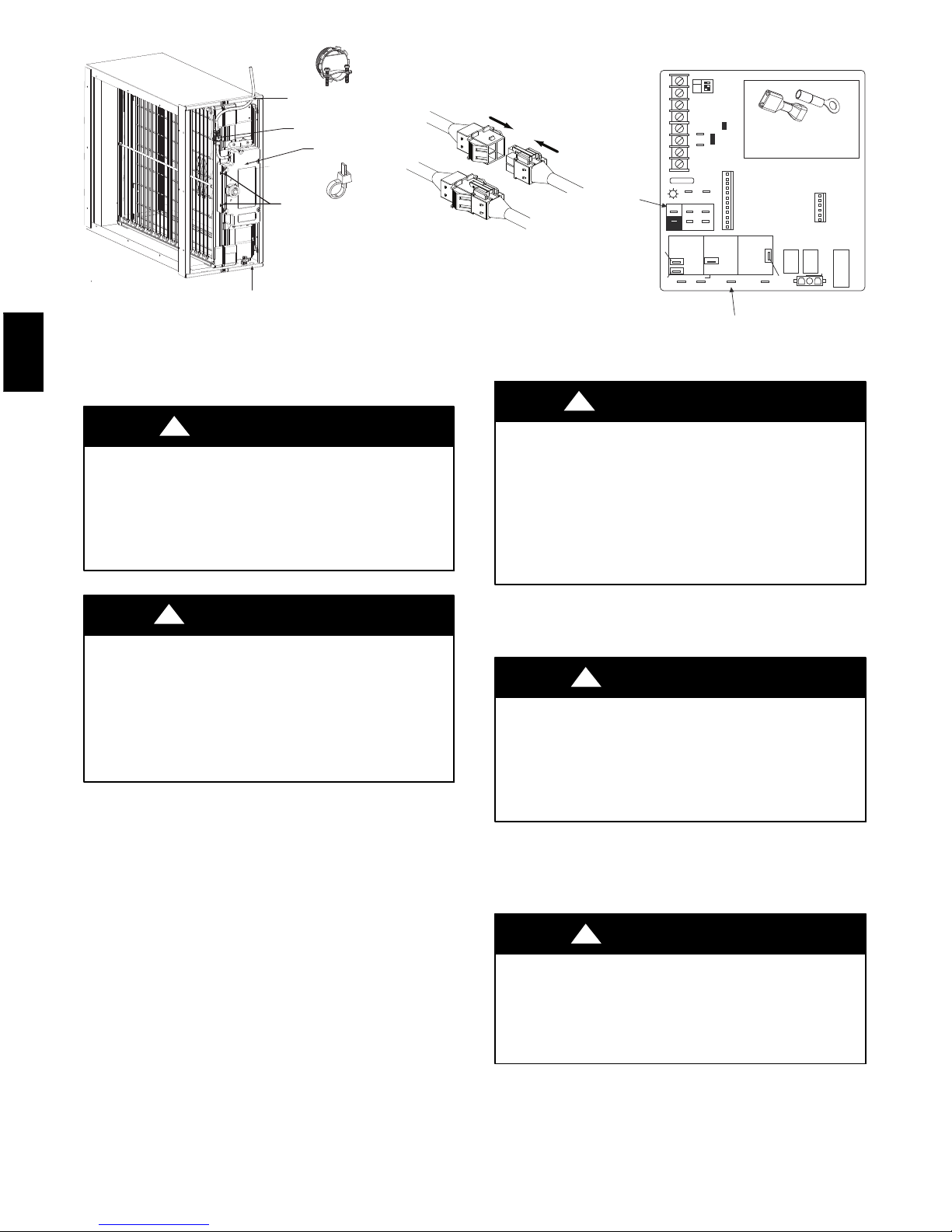

SBent pins or loose connection in the molex plug

of the service cord.

SReplace Service cord or replace entire power

supply / field enhancement module assembly if

required.

SThe power supply may be defective. SReplace entire power supply / field enhancement

module assembly.

SThe light pipe transferring the light from the

LED’s on the power supply to the door may be

broken.

SReplace access door.

2 Power Indicator light cycles on and off

intermittently.

SOverload condition activating the safety

circuitry S

SUnit is wet. (Water may be entering the unit from

a source such as condensate or dripping from a

frozen evaporator coil.)

SRemove the access door and the air purifier

cartridge. Power the unit then use a spare door

magnet or “service” magnet to activate the air

purifier power supply. Turn out the lights and

observe for arcing.

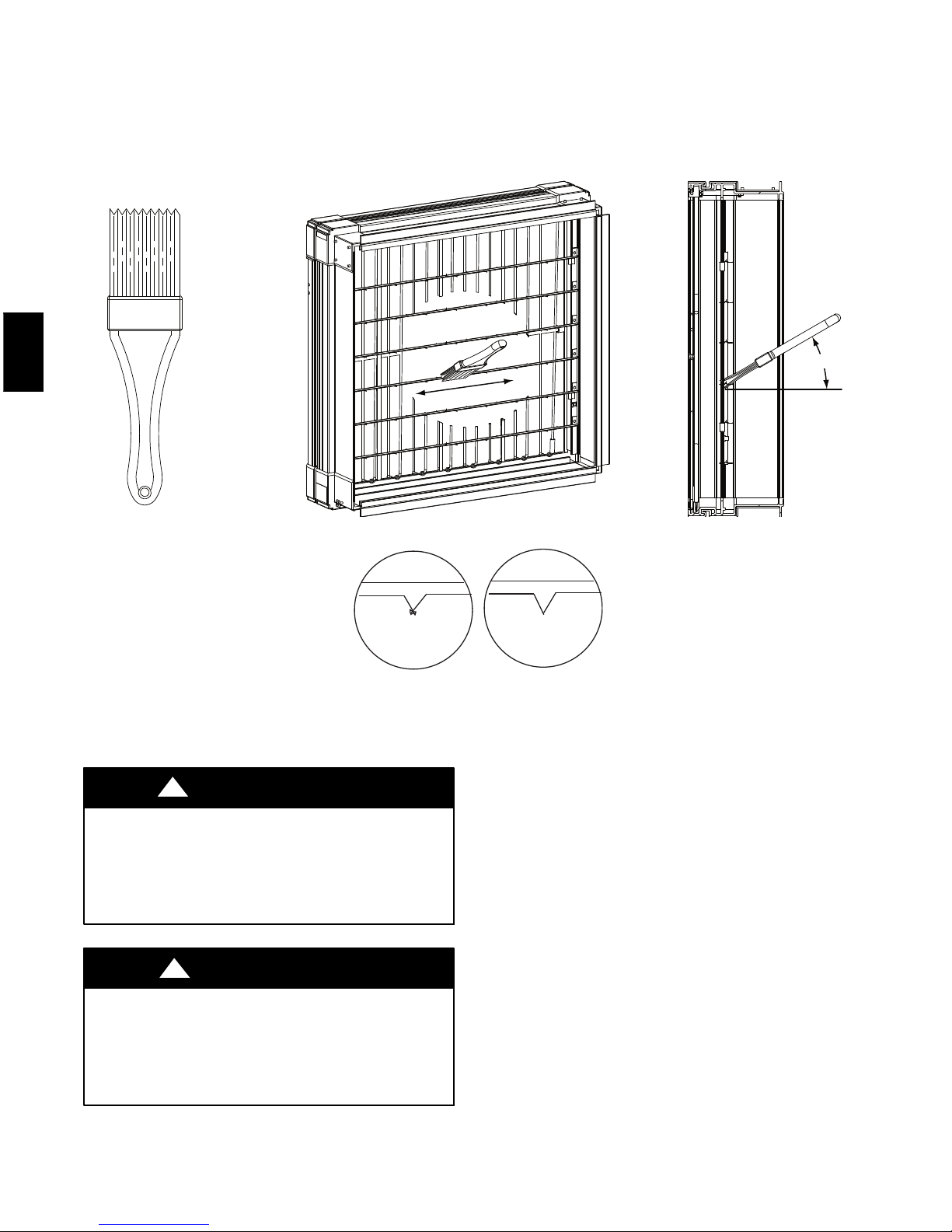

SGrounding paths in the unit are interrupted due

to breakage , corrosion or loose contact.

SMake sure all three grounding clips (FEM to

cabinet, safety screen to cabinet, cartridge to

cabinet on the leaving air side) are securely in

place and making clean contact.

SArcing to ground (such as unit cabinet ) is

occurring.

SMake sure the safety screen is clear and remove

debris.

SArcing to ground is occurring due to debris

lodged in the safety screen or across ionization

grid.

SMake sure the ionization grid is secured in place

with all four clips and centered in the FEM

housing.

SIonization grid is not centered or isloose and not

clipped in place, possibly touching the air

purifier cartridge or safety screen.

SVerify that the ionization grid is clean and intact.

SElectrode wire is loose and making contact with

the enhancement module wall.

SMake sure the field electrode wire is wound

through the spools on the enhancement module

with sufficient tension and tied to itself at the end

termination. If it is loose rewind and retie it.

SField electrode wire is damaged or nicked.

SIf the field electrode wire is damaged or nicked,

replace entire power supply / field enhancement

module assembly.

3 AirPurifier Cartridgehas smallsinge orchar

marks on the frame. SThe cartridge is installed backwards

STurn off the unit and remove the access panel.

SReplace the air purifier cartridge with Factory

Authorized Replacement Cartridge and ensure

airflow direction arrows are correct.

4 The wall control will not work.

SThe wire in the wall OR the wall control may be

defective.

SRemove the wall control and test it right beside

the unit using another shorter wire. If the wall

control works there, change the wire. If it does

not, change the wall control.

SThe wires may be in reverse position. SEnsure that the color coded wires have been

connected to their appropriate places.

SThewiresmaybebroken. SInspect every wire and replace any that are

damaged.

SThere may be a short-circuit. SWith the help of a multimeter, check for

continuity.

5 The 20-minute lighted push- button switch

doesn’t work OR its indicator light doesn’t

stay on.

SThe switch may be defective.

SJump the OL and OC terminals. If the unit

switches to high speed, then the wires are not the

problem. Replace the push-button.

SThe wires may be defective OR may not be

connected properly.

SEnsure that the color-coded wires have been

connected to their appropriate places.

GAPAA