NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory authorized kits or accessories when

modifying this product. Refer to the individual instructions pack-

aged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves.

Read these instructions thoroughly and follow all warning or

cautions attached to the unit. Consult local building codes and

National Electric Code (NEC) for special requirements.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on unit or in instructions and manuals,

be alert to potential for personal injury.

Understand the signal word DANGER, WARNING, or CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions that will result in enhanced installation, reliability, or

operation.

INTRODUCTION

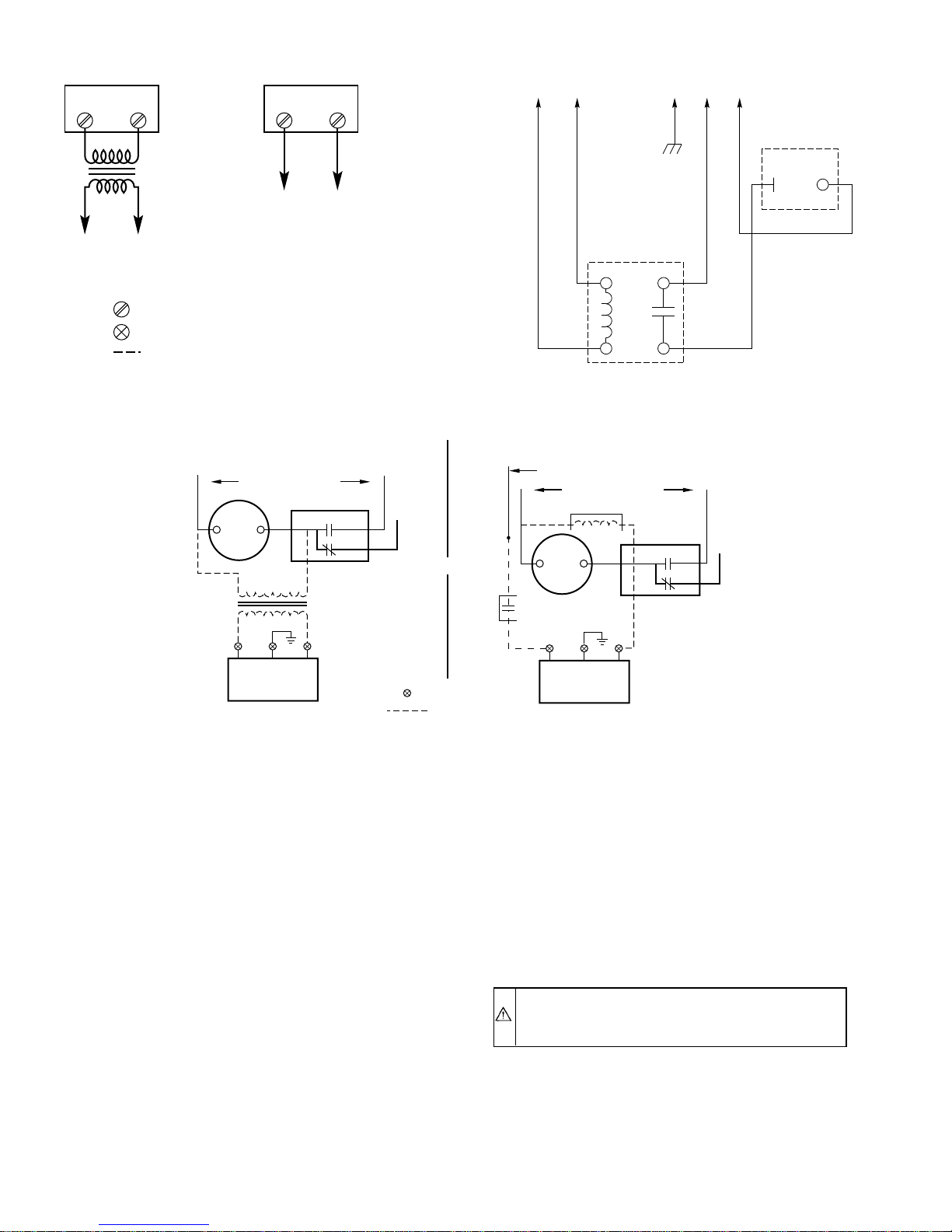

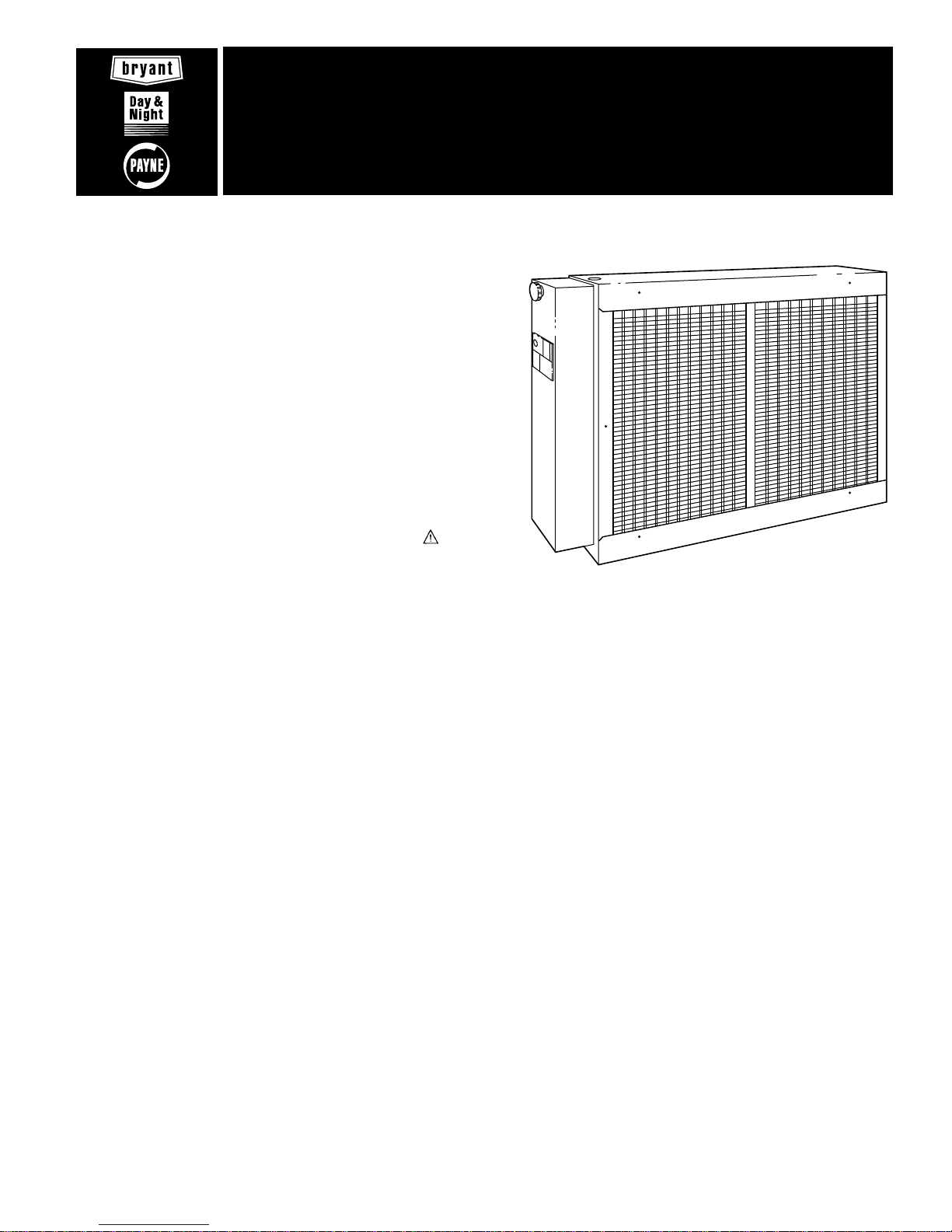

Model 9011KAX Electronic Air Cleaner (EAC) is available in 3

sizes: 012 (300 to 1400 CFM), 016 (500 to 1800 CFM), and 020

(700 to 2000 CFM). (See Fig. 1.)

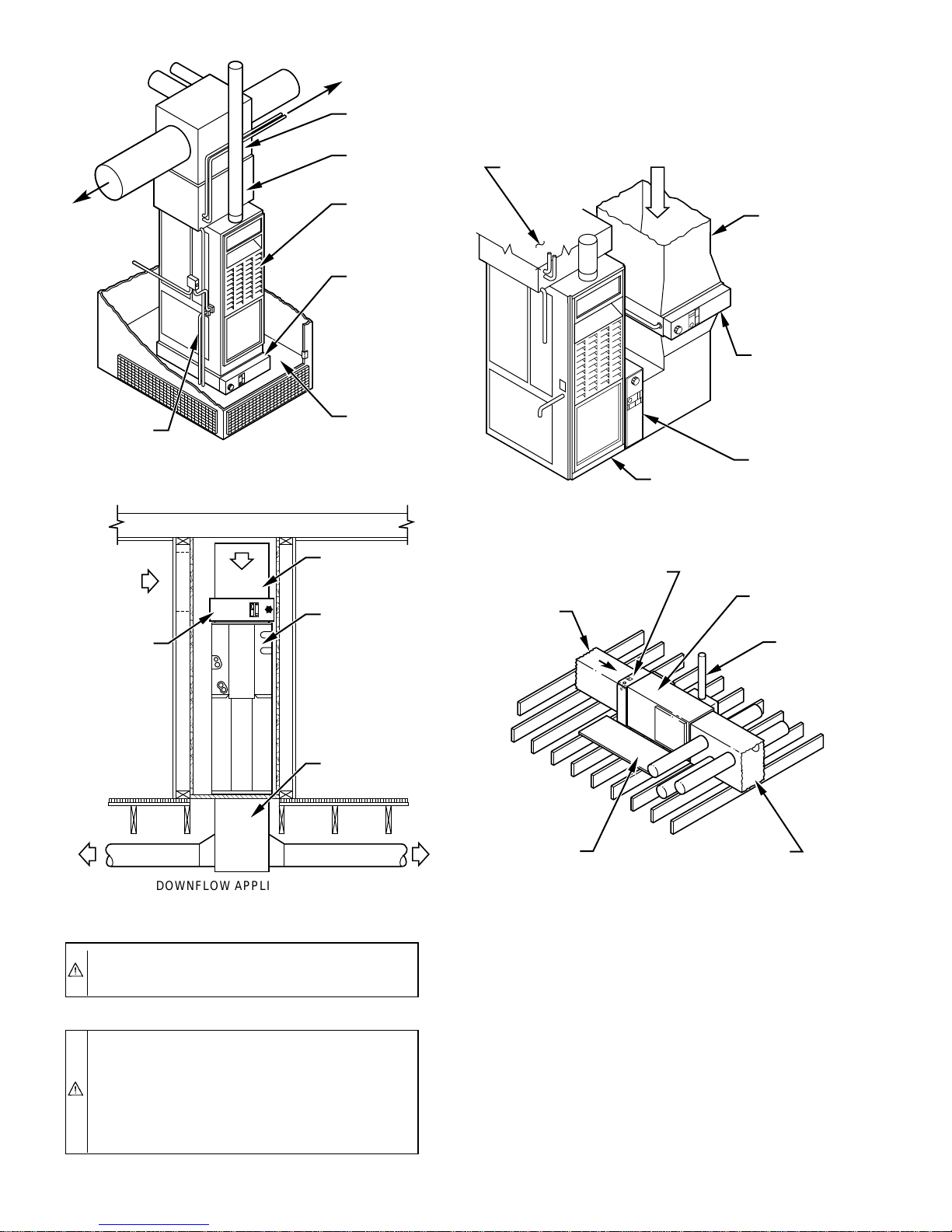

These plate-type air cleaners are designed for use with residential

and light commercial forced-air heating and/or cooling systems.

They may be installed in the vertical or horizontal section of a

typical return-air duct system. (See Fig. 2.)

These air cleaners are easily field-converted from right- to left-

hand units. Cabinets are designed to support up to 400 pounds

when used in under-the-furnace applications.

A. Cabinet

The cabinet includes an electrical junction box and power safety

interlock, and houses the air cleaner components. These compo-

nents are:

1. Mechanical pre-filters—Expanded aluminum mesh first-

stage filter that removes lint and large dust particles.

2. Cell assemblies—Cells consisting of combined ionizer

wires and collector plates.

Ionizer part of cell has tungsten wires that receive positive

charge and are mounted between grounded aluminum

channels supported by glazed ceramic insulators.

Collector part of cell consists of alternately charged collec-

tor plates.

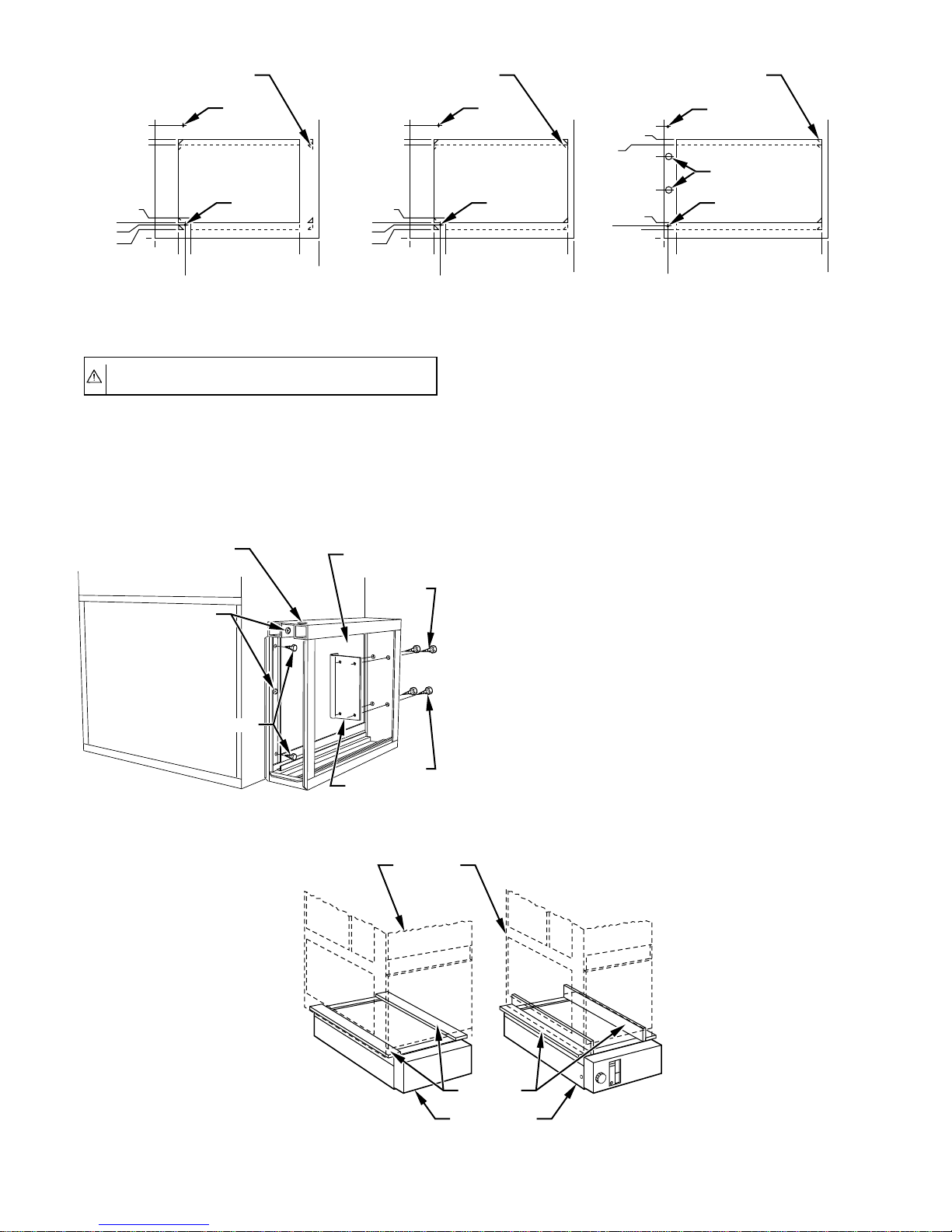

The EAC components are listed below and shown in Fig. 3.

1. Power door assembly.

2. Two pre-filters.

3. Cabinet containing 2 air-cleaning cell assemblies.

4. A parts bag including electrical bushing, plug buttons, wire

chase, and airflow label.

B. Power Door Assembly

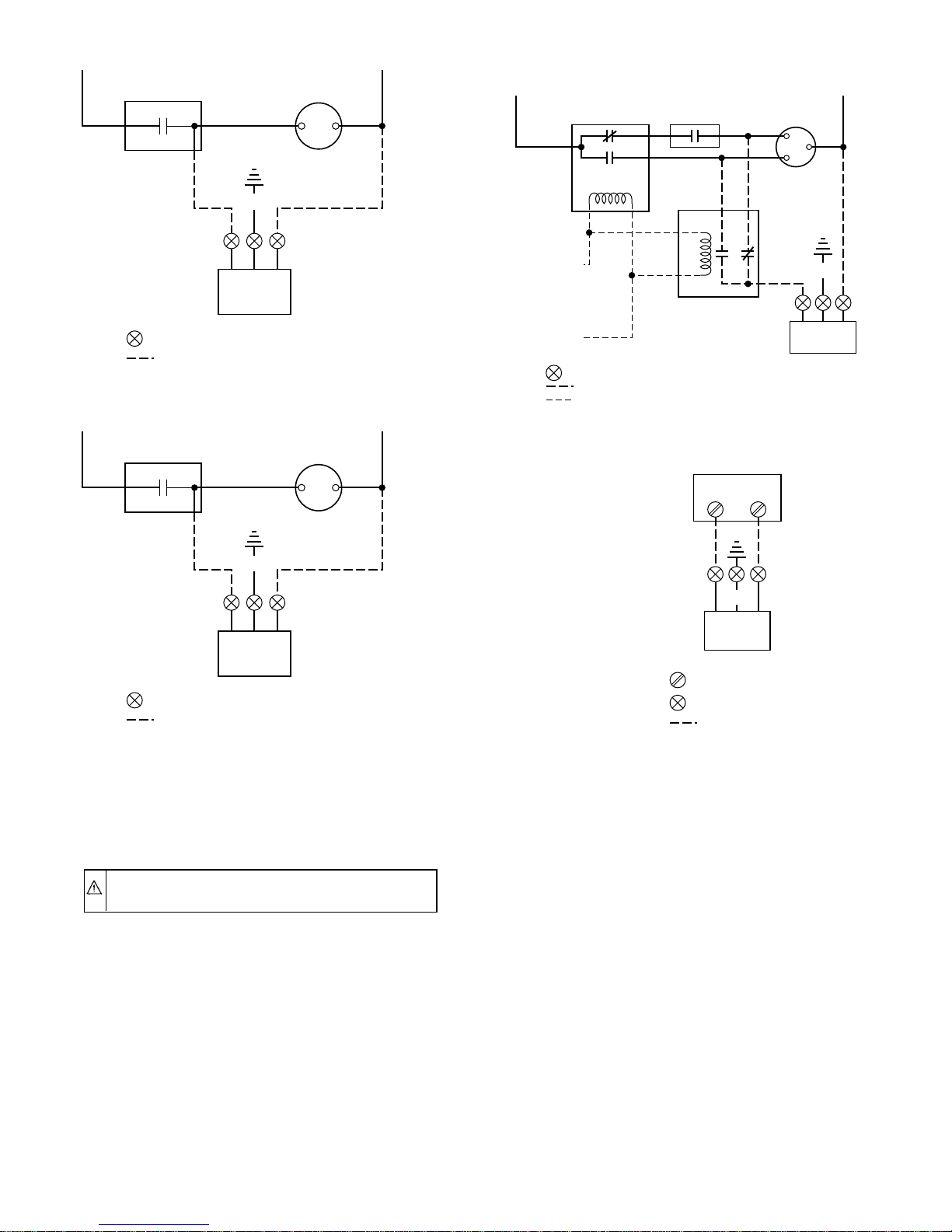

The power door assembly consists of:

1. Unit operation light, ON-OFF switch, and door attachment

knob—all installed on door cover.

2. Door base plate contains a solid-state power pack that

converts 120vac to high voltage DC (a 240v Conversion

Kit, KEAVC0101240 is available). All wiring is mounted

internally. A line-voltage disconnect (male plug) and high-

voltage buss bar are mounted on the base plate externally.

Four screws must be removed to expose the power pack and

wiring.

The supply circuit to the power pack, which is wired across the

furnace blower motor, is controlled by an ON-OFF power switch.

With the power switch ON (assuming power door is in place and

blower motor is operating), 120vac ±10 percent single-phase, 60

Hz power is applied to the power pack (240v conversion kit

transformer converts 240v to 120vac). Output of the power pack

assembly is approximately 7300vdc.

These Installation Instructions consist of the following:

Section I—Locating Unit

Section II—Installation

Section III-Electrical Connections

Section IV-Startup and Adjustments

Section V—Routine Maintenance and Service

Fig. 1—Model 31KAX A91465

Installation, Start-up

and Service Instruction

ELECTRONIC AIR CLEANER

Cancels: II 901K-12-3 II 901K-12-4

10-01-94

901KAX

—1—