BST KLC 20 User manual

Operating Manual

Flame Detector KLC 20 / KLC 21

Content

1 General aspects 4

1.1 Introduction 4

1.2 Warning notes 4

1.3 Copyright protection 5

1.4 Disposal information 5

1.5 Warranty 5

1.6 Obligation of the operating company 6

1.7 Liability disclaimer 6

1.8 Declaration of conformity 7

1.9 Address of the manufacturer 7

2 Safety 8

2.1 Intended use 8

2.2 Requirements on persons 8

2.3 Safety instructions 9

2.4 Safety devices 9

2.4.1 Fundamental aspects 9

2.4.2 Safety devices on the flame detektor 10

2.5 Safety instructions in case of maintenance

and troubleshooting 10

2.5.1 Fundamental aspects 10

2.5.2 Electrical / electronic devices 11

2.5.3 Inspection in accordance with the Ordinance

on Industrial Safety and Health 11

2.5.4 Safety test 11

3 Technical data 12

3.1 General characteristic features 12

3.2 Electrical system, optical system, mechanical system 12

3.3 Weight 13

3.4 Dimensions 13

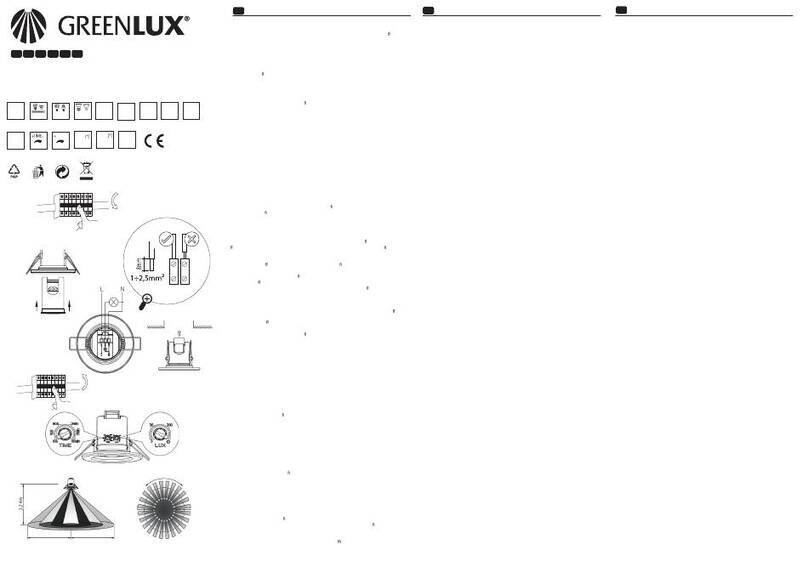

3.5 Block diagram KLC 20 / KLC 21 13

4 Transport, installation and connection 14

4.1 Scope of delivery 14

4.2 Packaging 15

4.3 Shipping instructions 15

4.4 Dimensions 15

4.5 Installation 16

4.5.1 Mounting flange KLC 16

4.5.2 Viewing angle adapter KLC for radial adjustment 17

4.5.3 Adapter ADP 17

4.6 Connection 18

4.6.1 Electrical connection 18

4.6.2 Connector diagram 18

4.7 Storage 18

5 Description 19

5.1 Functional description 19

5.2 Disturbing frequency cut off (optional) 19

5.3 Optionally function blocks for KLC 19

5.3.1 Relay module for flame detectors RMF 1 19

6 Operation of the flame detektor 20

6.1 Test of the flame detektor 20

6.2 Operating indicator LED 20

6.3 Diagnostic with KLC-Com 20

7 Maintenance and servicing 21

7.1 Cleaning 21

7.2 Maintenance interval 21

7.3 Safety-related check 21

8 Troubleshooting 22

9 Order data 23

10 Accessories 24

CONTENT

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 4

1 | General aspects

1.1 Introduction

This operating manual is an essential guide for the successful and safe operation of the flame

detector. It contains important information on how to operate the system safely, properly

and economically. Observance of these instructions helps to avoid dangers, to reduce repair

costs and downtimes and to increase the reliability and service life of the unit. All illustrati-

ons and drawings in this operating manual are for general illustration purposes and are not

authoritative for the design in detail.

The operating manual must be available on the unit at all times. It must be read and used by

every person who is assigned to work with/on the unit,

for example:

• Operation,

• troubleshooting during operation,

• maintenance,

• maintenance (servicing, inspection, repair) and/or

• transport

The operator should have this confirmed in writing.

1.2 Warning notes

The following warning notes are used in these operating instructions:

DANGER

!

This warning level indicates an imminent hazardous situation. If the hazardous situation is

not prevented, this will result in death or severe injury. Follow the instructions that accom-

pany this warning to prevent the risk of death and severe personal injury.

WARNING

!

This warning level indicates a potentially hazardous situation. If the hazardous situation is

not prevented, this may result in death or severe injury. Follow the instructions that accom-

pany this warning to prevent the potential risk of death and severe personal injury.

CAUTION

!

This warning level indicates a potentially hazardous situation. If the hazardous situation is

not prevented, this may result in slight or moderate injuries. Follow the instructions that ac-

company this warning to prevent the injury of persons.

This warning level indicates potential damage to property. If this situation is not prevented,

it may result in damage to property. Follow the instructions that accompany this warning to

pre-vent damage to property.

NOTICE

A notice indicates additional information that will make the handling of the device easier.

GENERAL ASPECTS

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 5

1.3 Copyright protection

This operating manual has to be treated as confidential. They may only be used by authorised

staff. Access by third parties may only be granted upon written agreement of BST Solutions.

All documents are protected in keeping with the German copyright law.

The disclosure and reproduction of documentation, in whole or in part, as well as the ex-

ploitation and communication of its content shall not be permitted unless expressly stated

otherwise. Offenders are liable for prosecution and the payment of damages.

We reserve all rights to exercise industrial property rights.

1.4 Disposal information

The flame detector is equipped with electrical and electronic components and

must be disposed separate from household waste. Follow the local and actual

regulations for waste disposal.

1.5 Warranty

Read these operating manualcarefully and in full before operating the flame detektor KLC20

/ KLC21!

The manufacturer is not liable for damage or operating malfunctions that result from the

operating manual not being observed. The operating manual must be supplemented by the

operator with operating instructions based on existing national regulations for accident pre-

vention and environmental protection, including information on supervisory and reporting obli-

gations to take account of special operational features, e.g. with regard to work organisation,

work processes and personnel deployed. The recognised technical rules for safe and profes-

sional working also have to be observed in addition to the operating manual and the regula-

tions on accident prevention applicable to the country and place of use.

The warranty shall become void, for example, in the event of:

• inappropriate use

• use of impermissible equipment

• incorrect connection

• prior works that are not part of the supplied product or service

• non-use of original spares and accessories

• conversion, if this has not been approved by BST Solutions

• non-performance of specified maintenance work

It is recommended that the operator of the device concludes a service contract with BST

Solutions. This guarantees that the device is regularly checked by our service staff and en-

sures that any required wearing and spare parts are available without long delivery periods.

This warranty does not cover damage in transit, lens glass breakage (photo element) or other

damage caused by unqualified handling, incorrect adjustment or inadequate maintenance.

NOTICE

NOTICE

GENERAL ASPECTS

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 6

1.6 Obligation of the operating company

The flame detektor KLC20 / KLC21 may cause hazards if it is operated inappropriately or in

an improper condition.

The operating company is under the obligation to operate the machine in proper state only.

The operating company has to secure hazardous areas that exist between BFI devices and

the customer‘s own equipment.

The operating company has to appoint and instruct responsible staff:

• Only deploy trained or instructed staff.

• Clearly set out the responsibilities of the staff with regard to operation, set-up, maintenan-

ce and repair.

• Regularly check that staff are safety conscious and aware of hazards and are observing the

operating instructions.

• Before starting work, staff who are assigned to work with/on the device have to have read

and understood the operating instructions, in particular the chapter on „Safety“, as well as

the relevant regulations.

• The operating manual and relevant regulations have to be stored in such a way that they are

accessible to operating and maintenance staff.

• Set out who will have responsibility for device operation and ensure that this person has

the authority to overrule any unsafe instructions of third parties.

1.7 Liability disclaimer

All technical information, data and guidance on device operation that are contained within

this operating manual are, to the best of our knowledge, correct at the time of printing, taking

into account our present understanding and experience.

We reserve the right to make technical changes with respect to the further development of

the flame detector outlined in this operating manual. No claims can be made based on the

specifications, illustrations and descriptions of this operating manual.

We shall not be liable for damage or operating malfunctions that result from operating errors,

inappropriate repairs or the non-observance of the operating manual. We expressly state that

only original spare parts and accessories approved by us may be used. This also applies to

the components of other manufacturers that have been used.

The installation or use of non-approved spare and accessory parts and any unauthorized

retrofits and modifications are not permitted for safety reasons and exclude any liability by

BST Solutions for consequential damages.

Generally valid legal and other binding regulations on accident prevention and envi-

ronmental protection have to be observed and instructed, in addition to the operating

instructions.

NOTICE

GENERAL ASPECTS

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 7

BST Solutions is liable for possible errors or omissions with the exclusion of additional claims

entered into in the framework of the warranty obligations conceded to in the contract. Claims

for damages, on whatever legal basis they may be, shall be excluded.

Translations into foreign languages are carried out in good faith. We cannot accept any lia-

bility for translation errors; this also applies where the translation has been carried out or

has been commissioned by us. The original text alone shall be binding. Descriptions and il-

lustrations do not necessarily depict the delivered product or a possible spare parts order.

Drawings and graphics are not to scale.

1.8 Declaration of conformity

1.9 Address of the manufacturer

BST Solutions GmbH

Ruegenstr. 7 . 42579 Heiligenhaus . Germany

T +49 2056 989 47-0 . E-Mail: info@flamonitec-bst.com

www.flamonitec-bst.com

GENERAL ASPECTS

BST Solutions GmbH

Rügenstr. 7

42579 Heiligenhaus

Germany

Tel.: +49 2056 98947-0

Web: www.bst-solutions.de

EU Konformitätserklärung

EC Declaration of Conformity

Produkt Flammenwächter KLC2x mit oder ohne RMF1

Product Flame detector KLC2x with or without RMF1

Typ KLC20, KLC21, KLC22, KLC2002 mit oder ohne RMF1

Type KLC20, KLC21, KLC22, KLC2002 with or without RMF1

Hiermit erklären wir, dass der nachstehend bezeichnete Flammenwächter in seiner Konzipierung und

Bauart sowie in der von uns in Verkehr gebrachten Ausführung den grundlegenden Sicherheitsanfor-

derungen folgender EU-Richtlinien entspricht

This is to confirm that the below described system in its design and type of construction complies with the

provisions of the Directive of the Council of the European Communities on the approximation of the laws of the

member states relating to

Verordnungen

EU/2016/426

Gasgeräteverordnung

Regulations

Gas appliances regulation

2014/35/EU

Niederspannungsrichtlinie

Low voltage directive

2014/30/EU

EMV Richtlinie

EMC directive

Benannte

Stelle

Notified body

DVGW Cert GmbH

0085

CE-Zertifikat vom

CE certificate from

Gültig bis

Valid until

19.02.2018

19.02.2028

CE-0085BP0001

Baumusterprüfbescheinigung

Type examination certificate

Prüfgrundlagen

EU/2016/426 A III B (09.03.2016)

Test basis

EN 298:2012

Ausgestellt durch BST Solutions GmbH

Issued by

Rechtsverbindliche

Unterschrift

Legally binding signature

Name Funktion Ort, Datum

Function Place, Date

Eberhard Röllecke Geschäftsführer Heiligenhaus, den 29.03.2021

General Manager

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 8

2 | Safety

2.1 Intended use

The flame detector provides the burner control with the safety-related, switched ionization

current simulation.

The KLC 20 / KLC 21 is approved for intermittent operation. When a voltage is applied, it per-

forms a self-test. The flame detector must restart at least once every 24 hours.

The manufacturer/supplier shall not be liable for damage resulting from use for non-inten-

ded purposes. The user/operating company alone shall bear the risk.

Do not allow any persons who are being apprenticed, educated, instructed or on a general

training programme to work on the device without the constant supervision of an experien-

ced person.

Persons who are under the influence of drugs, alcohol or medication that affects reactivity

shall not be permitted to carry out work on the device.

Connection, set-up, maintenance and repair work may only be carried out by qualified spe-

cialist staff.

This device may cause hazards if it is operated inappropriately by untrained staff or if it is not

used for its intended purpose.

Generally valid legal and other binding regulations on accident prevention and environmental

protection in addition to basic health and safety requirements have to be observed. The op-

erating company has to instruct its staff accordingly.

2.2 Requirements on persons

SAFETY

Danger when improperly used! The device may cause hazards if it is not used as in-

tended and/or for any other purposes. The device has to be used only for the purpo-

ses for which it is intended. The procedures described in the operating manual have

to be observed.

DANGER

!

Work on/with the device may only be performed by persons authorized to do so based

on their training and qualification. Furthermore, such persons have to have been com-

missioned by the operating company.

NOTICE

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 9

2.3 Safety instructions

Before working at the flame detector switch off the power supply. Before first commissioning

or replacement of the device check external wiring!

The following instructions on accident prevention have to be observed when operating the

flame detector:

2.4 Safety devices

2.4.1 Fundamental aspects

Check the safety equipment and locking devices on the device for safe operational condition.

Only operate the device if all safety devices are present and enabled. The operating company

or operator of the flame detektor is responsible for the proper operation of the device.

SAFETY

Only operate the device if it is in a proper state.

• Do not remove or disable safety devices.

• Check for externally noticeable damage and defects prior to using the device. Imme-

diately notify the appropriate authority/person of any changes that occur (including

changes in operating performance). If necessary, stop and secure the device imme-

diately.

• Allow only authorised specialist staff to carry out set-up and/or maintenance work.

• Replace worn or defective parts.

• Use suitable maintenance tools only.

• After repair work, refit all safety devices and carry out electrical and mechanical

checks.

• Check the operating manual for details of displays as well as switch-on and switch-

off procedures.

• Prior to switching on the device, make sure that no-one can be endangered by the

device.

• The operating manual always have to be kept close to the device and be readily at

hand.

• Any non-compliance with the safety instructions outlined in this operating manual

may lead to damage to property, personal injury or even death.

The device has been fitted with warning and danger signs for the protection of ope-

rating staff. These signs have to be observed. Damaged or illegible signs have to be

replaced immediately.

NOTICE

NOTICE

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 10

2.4.2 Safety devices on the flame detektor

The flame detektor has been fitted with the following safety devices:

• Housing (protection against accidental contact)

• Selftest function at power up

2.5 Safety instructions in case of maintenance and troubleshooting

2.5.1 Fundamental aspects

• Deadlines set or indicated in the operating manual for repetitive checks / inspections shall

have to be observed!

• Appropriate workshop equipment is essential for performing maintenance work.

• In conformance with the electrical regulations, work on the electrical equipment of the

system may only be carried out by an electrical specialist or by trained staff under the di-

rection and supervision of an electrical specialist.

• The adjustment, maintenance and inspection activities and deadlines stipulated by BST

Solutions, including information on the replacement of parts / assemblies, have to be ob-

served! These tasks may only be carried out by authorised specialist staff.

• Operating staff have to be informed before maintenance or other special work is carried

out. A supervisor has to be appointed.

• Screw connections which have been loosened during maintenance and servicing work, have

to be tightened.

• If maintenance and repairs require safety devices to be dismantled, these devices have to

be remounted and checked as soon as the maintenance and repair work has been com-

pleted.

• Ensure safe and environmentally friendly disposal of replacement parts!

• Spare parts supplied by BST Solutions or approved of by BST Solutions only may be used.

SAFETY

Due to the safety function of the disturbance frequency fading out (optional), a simula-

tion of the flame by means of a simple artificial light source is not possible. If a flame

simulation is required, e.g. for final testing of the burner without a real flame, a light

source with a constantly changing frequency between 60 and 150 Hz or the flame si-

mulation unit TG10 must be used.

NOTICE

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 11

2.5.2 Electrical / electronic devices

2.5.3 Inspection in accordance with the Ordinance on Industrial Safety and Health

In the event of the combination or installation of units from different manufacturers or sup-

pliers, a precise test must be carried out by the operator before commissioning in accordan-

ce with the applicable industrial safety regulations and the applicable electrical engineering

rules.

In case of queries, please get in touch with BST Solutions.

2.5.4 Safety test

SAFETY

Danger to life caused by electrical current!

Contact with live wires or components presents a danger to life!

Prior to any work on the electrical equipment, disconnect the flame detector from the

power supply network!

DANGER

!

In keeping with the electrical regulations, work on electrical / electronic parts / com-

ponents may only be carried out by electrical specialists.

NOTICE

To ensure proper operation, the flame detector must be tested several times in all

applications by starting and stopping the burner several times. The flame relay must

switch off reliably in all cases when there is no flame. This test should be carried out

in different operating situations (see technical data sheet). This is an indispensable

prerequisite for safe and proper operation of the unit!

WARNING

!

Important rules of conduct

• Check the device in regular intervals. Any defects or faults ascertained have to be corrected

immediately. Switch off the device until the defects have been corrected.

• Equipment parts undergoing inspection, maintenance or repair work have to be made de-

energised, if required. First check that the disconnected parts are no longer live, then short

to earth (ground). Also isolate neighbouring live parts!

• If work is required on live parts, a second person has to be assigned who can disconnect

the power supply in case of an emergency. Only use insulated tools!

• Fuses must not be repaired or bridged. Only use original fuses with the specified current!

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 12

TECHNICAL DATA

Optical features

VIS/IR

350 to 1100 nm , max. sensitivity at 920 nm

Selftest function Fully electronical at power up

Selftest time < 2 s

Switch-on time Typically 0.5 s

Switch-off time < 0,6 s

Flicker range 15 – 400 Hz

Switch-on frequency 25 Hz, other frequencies on request

Switch-off frequency 15 Hz, other frequencies on request

Accepted flame signal loss duration ca. 280 ms

Output

max. switching current

max. switching power

max. switching voltage

15 mA

0.3 W

280 V AC/400 V DC

Input 230/240 V AC 50/60 Hz

120 V AC (optional)

24 V AC/DC (optional)

Consumption max. 6 mA

Operating temperature

KLC 20

KLC 21

-20 to +60°C

-20 to +75°C

Humidity max. 95% r.H., non-condensing

Connection Plug connector

Kind of protection IP 41

Operating position any position

Protection class II

Cable length 1 m (other length on request)

3 | Technical data

3.1 General characteristic features

• Selftest function after power up

• Intermittent operation

• UV/VIS/IR-Sensor

• Fully electronic construction

• Spectral analyzing process

• CE approved CE0085PB0001

3.2 Electrical system, optical system, mechanical system

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 13

TECHNICAL DATA

3.3 Weight

Weight approx. 0.029 kg

3.4 Dimensions

Length ( with plug ) 115 mm

Width 30 mm

Height 22 mm

Dimensional drawing see under point 4.4

3.5 Block diagram KLC 20/KLC 21

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 14

TRANSPORT, INSTALLATION AND CONNECTION

4 | Transport, installation

and connection

4.1 Scope of delivery

• Flame detector KLC 20 / KLC 21

• Operating manual (optional, customer-dependent)

• Connection cable (optional)

• Mounting flange (optional)

• Angle adapter KLC(optional)

• Adapter ADP (optional)

• Diagnostic tool KLCcom (optional)

• Flame simulation device TG10 (optional)

Refer to the order papers for the exact scope of delivery and compare with the delivery note.

Checking for completeness

Check the entire delivery for completeness against the accompanying delivery note. Please

refer to our terms of sale and delivery otherwise.

Report any damage

After arrival of the device and accessories, notify the shipping agent, the insurance company

and BST Solutions immediately in case of any damage caused by transport or inadequate

packaging.

Take steps to minimise and prevent further damage.

Report the insurance case to the insurance company without delay and transmit the full

claim documents at once in order to expedite the claims settlement (at the latest in suf-

ficient time before the expiry of any periods of preclusion and/or limitation relating to the

compensation claims against third parties).

All installation and connection work may be carried out by qualified and approved spe-

cialist staff only!

Observe the legal stipulations and adjustment instructions of the plant operator!

NOTICE

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 15

TRANSPORT, INSTALLATION AND CONNECTION

4.2 Packaging

The flame detektor is shipped in different packaging materials.

The most frequently used packaging materials are cardboard and plastics (foils, foamed material).

4.3 Shipping instructions

4.4 Dimensions

see the following illustration:

Packaging has to be disposed of in an environmentally friendly way and in accordance

with the relevant provisions on disposal.

Do not subject the appliance to heavy impacts during transport. Do not subject the

appliance to any humidity!

NOTICE

NOTICE

115

30

22

13.5

55

50

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 16

TRANSPORT, INSTALLATION AND CONNECTION

4.5 Installation

All installation and connection work may be carried out by qualified and approved

specialist staff only! The legal regulations as well as adjustment instructions of the

plant operator have to be observed!

NOTICE

The KLC 20 / KLC 21 should be mounted close to the flame with straight alignment. The compact

flame detector should be mounted with the mounting flange KLC or another suitable holder with

Ø14 mm opening. The radial adjustment to the flame is realised with the viewing angle adapter KLC

and replaces the mounting flange KLC. Fix the detector with the holder. The best flame signal will

be achieved from strong flickering parts of the flame radiation. The angle of view, especially with

sight tubes, must be of appropriate dimensions to avoid any reduction of flame radiation. Protect

the sensor against other light sources.

To prevent faults, the direct view of an ignition spark must be avoided. Faults in the prepurge phase

can be caused by this. The maximum cable length of the connection cable must be observed. The

connection cable must be kept separate from high-energy ignition and mains cables and must not

be laid parallel to them over long distances.

Attention: For safety reasons and technical regulations a controlled burner shut down of at least

once per 24 hours must be guaranteed.

For the mounting BST Solutions offers different accessories:

4.5.1 Mounting flange KLC

The mounting flange KLC serves for to the admission, attachment and adjustment of the flame

detector. Two overall heights with 7 and 13 mm are available. By means of an O-ring the mounting

flange KLC can be simply sealed to the burner housing.

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 17

TRANSPORT, INSTALLATION AND CONNECTION

4.5.2 Viewing angle adapter KLC for radial adjustment

With the optionally available angle adapter, the radial alignment of the KLC 20 / KLC 21 to the fla-

me axis is carried out by means of an optimally shaped mirror surface. The angle adapter simul-

taneously replaces the KLC holder. A separate flame detector type is therefore not required. With

maintenance work the reflector surface should be protected from possible contamination and if

necessary it is to clean with a clean, soft and lint free cloth.

4.5.3 Adapter ADP

The ADP adapter makes it possible to mount the flame detectors KLC 20 / KLC 21 with additional

axial alignment directly on a combustion chamber opening. A quartz glass serves as a pressure

barrier and prevents the escape of heating gases from the combustion chamber. For the applica-

tion of the flame detector KLC at high surface temperatures, the version made of heat-insulating

material should be used.

26

19

48

35

7.5

4.5

69 7

all dimensions in mm

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 18

TRANSPORT, INSTALLATION AND CONNECTION

4.6 Connection

4.6.1 Electrical connection

4.6.2 Connector diagram

Control boxes from Dungs / Satronic

Ask for connector details of other burner control boxes.

4.7 Storage

Do not unpack packed flame detector and accessories.

The following regulations apply to storage:

• Store in a dry place. Maximum relative humidity: 95 % r. h., non-condensing.

• Ensure that the packages are not stored outdoors.

• In addition, ensure that the floor of the storage room is dry during storage.

• Protect from direct sunlight. Storage temperature -20 to +60 °C

• Store dust-free

• Avoid mechanical shocks and damage.

Danger to life caused by electrical current!

When connecting, observe the safety instructions and the locally applicable safety

regulations!

DANGER

!

Type of control box

Wire colour

MPA22 TF 8 DKO 9..

DKW 9..

DMO 9..

TMO

720-4

Blue terminal no.: 12 – 5 N 2 2 2

Black terminal no.: 12 – 3 Ion 1 1 1

Brown terminal no.: 6 – 17 L1 9 9 9

LED

Refer to the Technical Data chapter and the following wiring diagram for connection data.

Check that the mains voltage corresponds to the voltage indicated on the type plate.

Before connecting, check the device and the connecting cables for visible damage.

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 19

DESCRIPTION

5 | Description

5.1 Functional description

The flame detector KLC 20 / KLC 21 is a compact flame detector specially developed for blue-

burning combustion systems in forced draft burner applications in the household sector. The

patented evaluation of the signal is carried out via the flicker frequency of the radiation of the

upcoming flame. A processor enables the evaluation and conversion of the flame signal to a

digital signal in the value required for the flame signal amplifier of the corresponding firing

system. No adjustments are necessary during commissioning or maintenance.

The KLC 20 / KLC 21 only evaluates the flickering of the flame to be monitored. A device ver-

sion with interference frequency suppression is available as an option.

In this case, uniform light radiation and any constant frequencies do not lead to permanent

flame detection. Interfering sources of extraneous light, e.g. from fluorescent tubes or low-

frequency background radiation from glowing brickwork, are blanked out. Unintentional in-

fluences on the flame detection can thus be avoided.

Via the LED display as an optical interface, it is possible to read out various relevant ope-

rating parameters (e.g. monitoring of the flame signal, serial number). The flame detector

provides the burner control unit with the safety-related binary signals for „flame ON/OFF“.

The KLC 20 / KLC 21 activates its self-test function during power up. Therefor the flame de-

tector is approved for intermittend operation. For safety reasons and technical regulations a

controlled burner shut down at least once per 24 h must be guaranteed.

5.2 Disturbing frequency cut off (optional)

The KLC is optionally aviable with the “disturbing frequency cut off – function”. Here the

KLC20 / KLC21 detects only real flames, which are characterized by unsteady changing fre-

quencies. DC lights and any kind of constant frequencies, e.g. form fluorescent tubes or

other electrical lamps, will be blanked out and will not lead to a constant flame de-tection.

After the sensor is admitted with constant frequencies of a light source, this function will

enable at first the switching output, but after approximatly 5 up to 9 seconds the output

will be disconnected again. Therefore it is to paid attention during a inspection of the flame

detector KLC20 / KLC21, that this performance is intended and describes not a malfunction.

5.3 Optionally function blocks for KLC

5.3.1 Relay module for flame detectors RMF 1

The flame detector KLC20/KLC21 is a low power signal output equipped to simulate ionizati-

ontion or LDR signal. If a relay switch contact is required, the use of RMF 1 is recommended.

The RMF 1 has an electrically isolated changeover contact with a maximum switching voltage

of 250 V AC, a maximum switching current of 1 A and a maximum rating of 250 VA. More in-

formation can be found in the operating manual of the RMF1 in its current version.

This option is mandatory for use in gas applications!

NOTICE

BST Solutions GmbH | FLAME DETECTOR KLC 20 / KLC 21 Page 20

OPERATION OF THE FLAME DETEKTOR

6 | Operation of the flame detektor

6.1 Test of the flame detektor

To ensure the proper operation, the flame detector has to be testet several times by starting

and stopping the burner. As long as there is no flame in all cases the flame relays has to be

switched off solid.The test should be repeat for differnt operation situations (see also data

sheet). This is a essential condition for a safe and proper operation.

6.2 Operating indicator LED

Via the built-in LED the flame detector KLC 20 / KLC 21 is indicating the following operating

conditions:

6.3 Diagnostic with KLC-Com

With the data interface KLC-Com, consisting of optical adapter with cable, USB-Interface and

software BST-Com, the following information can be read from the KLC20 / KLC21:

• Impulses

• Serial Number

• Version / Edition

• present flicker frequency

For this purpose, the USB-optoadapter KLC-Com must be inserted into the recess of the

LED. Via the connection cable and the interface, the data can be read into a laptop or PC

using the corresponding BST-Com software. Further information can be found in the BST-

Com operating instructions.

LED Meaning

off KLC is not active or without potential

blinking Selftest finished, KLC is active, no flame detected.

on Selftest finished, KLC is active, flame detected.

Other manuals for KLC 20

1

This manual suits for next models

2

Table of contents

Other BST Security Sensor manuals