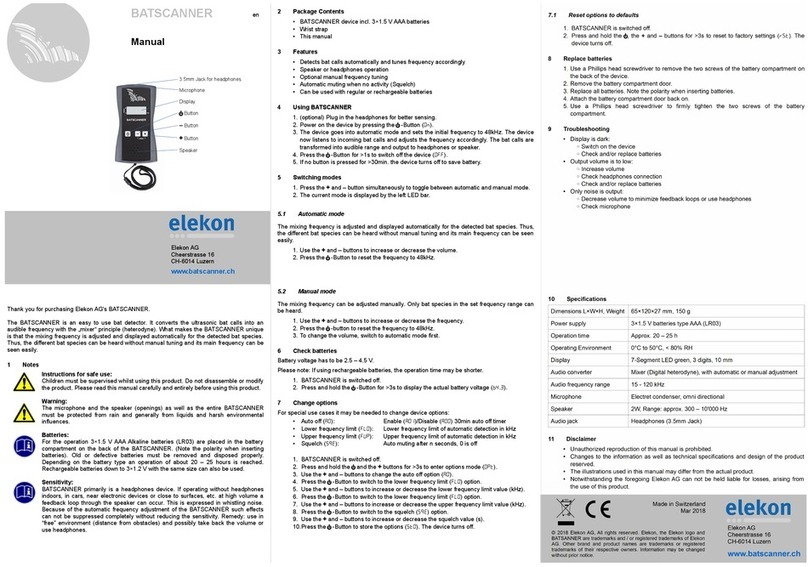

BST KLC 10 Manual

KLC 10

Technical information

UV -

flame detector KLC 10

dual fuel burners

for

Description

The KLC 10 is a co

mpact UV flame detector, which h

combustion which produces

little

modulation/flicker frequency.

The

no

t react to background radiation from hot refractory or

The flame detector is equipped with an optical interface

intensity. The KLC 10 can

be

It is compatible in its

physical dimensions and

detectors. All KLC

accessories are identical

components used

in production and

The flame detector KLC 10

Standards EN298:2012-11

for

after

normal burner shut down when the

KLC 10

(formerly known as KLC 1000)

Technical information

flame detector KLC 10

for oil -, gas- and

for

intermittent

burner operations

mpact UV flame detector, which h

as been

developed f

little

light or radiation in the visible spectrum

and has

The

design of the UV sensor

ensures that the

t react to background radiation from hot refractory or

from any other infra

The flame detector is equipped with an optical interface

which visibly

indicate

be

connected

directly to the ionisation or LDR input of the control box.

physical dimensions and

connection capability

to other series KLC flame

accessories are identical

and therefore this

reduce

in production and

makes it simpler for field application and

The flame detector KLC 10

has been developed to meet the requirements of European

for

burner management control units which

make a ‘no

normal burner shut down when the

flame amplifier is permanently

energised.

TB_KLC10_EN_REV0.DOCX

(formerly known as KLC 1000)

burner operations

developed f

or single flame

and has

very low flame

ensures that the

flame detector does

from any other infra

-red light source.

indicate

s the flame signal

directly to the ionisation or LDR input of the control box.

to other series KLC flame

reduce

s the variety of

makes it simpler for field application and

service.

has been developed to meet the requirements of European

make a ‘no

-flame’ check

energised.

0085

- 2 -

TB_KLC10_EN_REV0.DOCX

Safety Instruction

The KLC 10 is a safety component, and repair or adjustment must never be attempted. Replacement of

the flame detector is recommended in all cases of damage, due to impact shock, excessive moisture, or

other problems rendering it inoperable. Repair work must never be attempted and is strictly forbidden by

the relevant European Standards.

Prior to commissioning the unit; please carefully check that the wiring connections have been

made correctly. Also, before removing or checking the flame detector please ensure the power

supply is switched-off.

Technical Data

Input: AC 230 V ~ (-15/+10 %)

Frequency 50 – 60 Hz

Consumption 5, 5 mA

FET-Output: Switch-On delay after Flame-On typically 0, 5 sec.

Switch-Off time after Flame-Off < 0, 5 sec.

max. switched current 15 mA

max. switched power 0,3 W

max. switched voltage 280V AC / 400 V DC

Optical Features: Spectral range 185 – 260 nm

Acceptable loss of flame signal ca. 200 ms

Adjustment: radial, left

optional axial (reduced sensitivity at approx. 40%)

Lifetime of the UV-tube: > 10.000 h

Operating Temperature: -20ºC to +60°C (temperatures >50°C reduces the lifetime of the UV-tube)

Humidity max. 95%, no condensation permitted

Operating position: Any position

Kind of protection: IP 41

Protection Class: II

Protection against

Electric shock: DIN/EN 60730-2-5

Weight: 0,028 kg

Max’m length of

connection cable: 1 m (options available for longer cables)

Certification: CE-0085BS0448

Block diagram

- 3 -

TB_KLC10_EN_REV0.DOCX

Mounting instructions

The KLC 10 should be mounted as close as practical to the flame and on the same axis. The flame

detector is compact and should be mounted with the KLC mounting flange or other suitable holder having

a 14mm Ø opening. Fix the detector in the holder taking care to protect the sensor from other light

sources.

To avoid any problems at start-up; please avoid alignment of the KLC detector with the ignition spark

electrode as the flame detector may react with the ignition spark and cause burner shut-down during the

air pre-purge/ignition start-up sequence. The maximum length of the connection cable must be in

accordance with the technical data. Please ensure that the flame detector connection cable is kept well

apart and is completely separated from high-energy igniters- and power cables to avoid electrical

interference problems.

Attention: For safety reasons and within the technical regulations, a controlled burner shut-down of

the burner must occur and be guaranteed to happen at least once in every 24 hours of

operation. With the Model KLC 10 it is mandatory that the Control Box Unit or Burner

Management System is of the type which performs a flame check for ‘no flame presence’

on burner shut down. Such that both the burner is checked for possible ‘after burn’ and

that the UV tube itself is checked for soundness in accordance with the European

Standard EN298:2012-11. The Model KLC 10 can only be used with intermittent Control

Units which perform this flame check on shut-down. Otherwise use the model KLC 11.

If you are unsure about any application using this flame detector, please email, or fax the manufacturers

or the authorised distributor.

Mounting flange KLC

The mounting flange allows the detector to be

held and adjusted in a suitable position to view

the flame. Two overall widths of 7mm and 13mm

are available. An O-ring seal is available which

will give the mounting flange an air tight seal to

the burner housing if required.

Adapter ADP

The adapter ADP enables to install

the flame detector series KLC10 with

optional axial direction directly at a

combustion chamber. A quartz glass

serves as a barrier and prevents the

flow of heating gas from the

combustion chamber. For the use of

flame detector KLC at high ambient temperatures, a variant model of heat-insulating materials

reduces the transition temperature.

ADP 1 0 - UV

glass type

UV = quartz glass

thread

0 = NPSM ½“-14

1 = R ½“

material

1 = aluminum

2 = heat-insulating material

series

ADP = Adapter KLC

- 4 -

TB_KLC10_EN_REV0.DOCX

13,5

Dimensions

115

50 55

all dimensions in mm

Connector Diagram KLC 10

Dungs Control Box

Type of control box

MPA 22

Blue terminal no.:

12 – 5 N

Black terminal no.:

12 – 3 Ion

Brown terminal no.:

6 – 17 L1

Please ask for connection details for all other types/manufacturers burner control boxes.

Operating Indicator LED

The flame detector KLC 10 indicates the following operating conditions and flame signal strengths via the

built-in LED.

LED is OFF: KLC is not switched on – no power supply or ‘no flame’ is detected

LED is FLASHING: KLC has detected a flame; the quality of the flame signal is indicated by the

intensity of the flashing of the LED – fast flashing indicates a healthy flame signal

and vice versa - slow flashing indicates a weak flame signal.

LED is ON: KLC has detected the strongest level of flame signal.

LED

30

22

31

Radial

view opening

- 5 -

TB_KLC10_EN_REV0.DOCX

Commissioning and Maintenance

The installation and commissioning must be done by qualified personnel only. Before energising the KLC

flame detector please check the cable and wiring connections are in accordance to the diagram and

instructions given above. For good maintenance which will ensure trouble free operation of the KLC flame

detector; please keep the sight glass clean by wiping with a soft dry clean cloth. Warning: Do not use any

kind of cleaning sprays or fluids.

During commissioning and after any cleaning maintenance, the flame detector should be checked, as the

UV tube is subject to a natural ageing process and towards the end of its life span it is prone to

malfunction. To check that the flame detector is sound we recommend the following procedures be

followed:-

•Start the burner with the fuel supply closed-off or remove the flame detector from its mounting

flange and cover the UV tube using a soft cloth to avoid touching the glass lens. The control box

will lock-out at the end of the safety time due to absence of a flame signal.

•Remove the flame detector from its mounting flange. Start the burner while exposing the flame

detector to an external UV radiation source such as a cigarette lighter flame, or a small gas flame

(n.b. electric room lighting or a torch is inadequate). The burner Control Box must go to lock-out

due to detecting an extraneous light source either immediately or at the end of the air pre-purge

cycle, depending on the type/model of the Control Box.

•Close off the fuel supply or remove flame detector from its mounting flange and cover the UV tube

using a soft cloth when the burner is in the "run" position. The control box must go immediately to

lock-out resulting in the burner shutting down.

If any of these safety checks do not function as described i.e. they should always result in burner

shutdown and control box lock-out; then it is essential to replace the flame detector with a new KLC flame

detector. For safety and trouble free burner operation, we recommend that the flame detector should be

replaced after every 10,000 hours of burner operation or approximately every 30months for a burner

operating on an average of 10 hours per day.

Overview of

UV flame detectors and ancillary

Article

Flame detector KLC 10/230

Flame detector KLC 10/230,

with high sensitivity

Flame detector KLC 10/230

Flame detector KLC 10/230,

with high sensitivity

Mounting flange KLC

Mounting flange KLC

ADP 11 – UV*

ADP 21 – UV*

Connecting cable KLC

Connecting cable KLC

Connecting cable KLC

Connecting cable KLC

Connecting cable KLC

Connecting cable KLC

* only for flame detector with an axial orientation

**(reduced sensitivity at approx. 40%)

IMPORTANT:

For safety reasons and within the technical regulations, a controlled burner shut

the burner must occur and be guaranteed to happen at least once in every 24 hours of operation. With

the model KLC 10

it is mandatory that the Control Bo

type which performs a flame check for ‘no flame presence’ on burner shut down. Such that both the

burner is checked for possible ‘after burn’ and that the UV tube itself is checked for soundness in

accordance wi

th the European Standard EN298. The

Control Units which perform this flame check on shut

If you are unsure about any application using this flame detector, please

or the authorised distributor.

Disposal information

The flame detector is equipped with electrical and electronic components and

must be disposed separately

from household waste

authority regulations for

electrical component

BST Solutions GmbH

Eggerscheidter Straße 57

D - 40883 Ratingen

Telefon: +49 (02102) 1005959

Telefax: +49 (02102) 1005979

Email: info@bst-solutions.de

http://www.bst-solutions.de

©

BST Solutions 2015

DIN EN ISO 9001:2000

Zertifikat: 09 100 5438

- 6 -

UV flame detectors and ancillary

components available:

Version

optical direction radial

optical direction radial

optical direction radial and axial**

optical direction radial and axial**

overall height 7 mm

overall height 13 mm

Aluminum, R ½“, quartz glass

heat-insulated up to 180°C,

R ½“, quartz glass

length of 300mm

length of 350mm

length of 600mm

length of 1000mm

length of 2000mm

special lengths on request

* only for flame detector with an axial orientation

For safety reasons and within the technical regulations, a controlled burner shut

the burner must occur and be guaranteed to happen at least once in every 24 hours of operation. With

it is mandatory that the Control Bo

x Unit or Burner Management System is of the

type which performs a flame check for ‘no flame presence’ on burner shut down. Such that both the

burner is checked for possible ‘after burn’ and that the UV tube itself is checked for soundness in

th the European Standard EN298. The

model KLC 10

can only be used with intermittent

Control Units which perform this flame check on shut

-down. Otherwise use the

If you are unsure about any application using this flame detector, please

email, or fax the manufacturers

The flame detector is equipped with electrical and electronic components and

from household waste

. Please follow your local

electrical component

waste disposal.

BST Solutions 2015

technical modifications reserved

TB_KLC10_EN_REV0.DOCX

components available:

Part-No.

611145021000

611145021160

611145061000

611145061160

665001010000

665002010000

575010512210

575010512230

661030040100

661035040100

661060040100

661100040100

661200040100

For safety reasons and within the technical regulations, a controlled burner shut

-down of

the burner must occur and be guaranteed to happen at least once in every 24 hours of operation. With

x Unit or Burner Management System is of the

type which performs a flame check for ‘no flame presence’ on burner shut down. Such that both the

burner is checked for possible ‘after burn’ and that the UV tube itself is checked for soundness in

can only be used with intermittent

model KLC 11.

email, or fax the manufacturers

Revision 0

This manual suits for next models

1

Table of contents

Other BST Security Sensor manuals

Popular Security Sensor manuals by other brands

Optex

Optex Smart Line Series installation instructions

Energy Saving Sensors

Energy Saving Sensors HC-7B installation manual

AJAX

AJAX CombiProtect quick start guide

Satel

Satel micra MXD-300 manual

North American Rescue

North American Rescue Talon 60-0027 Instrcutions for use

Datasensor

Datasensor SE-SRT Series manual

netvox

netvox R313A user manual

Mini Gadgets

Mini Gadgets CD550Pro user manual

Busch-Jaeger

Busch-Jaeger Busch-Wachter 220 MasterLINE 6847 Series quick start guide

Johnson Controls

Johnson Controls DSDN quick start guide

Datalogic

Datalogic SR23 instruction manual

Micro Detectors

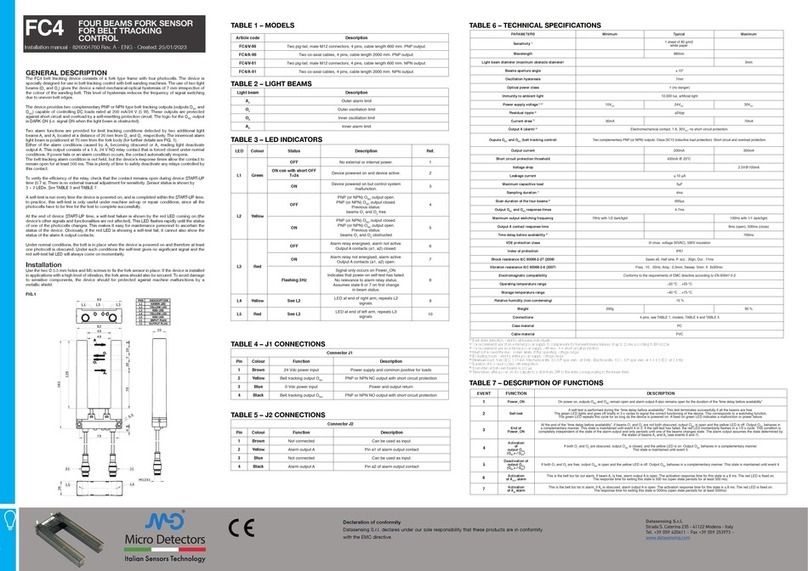

Micro Detectors FC4 installation manual