2

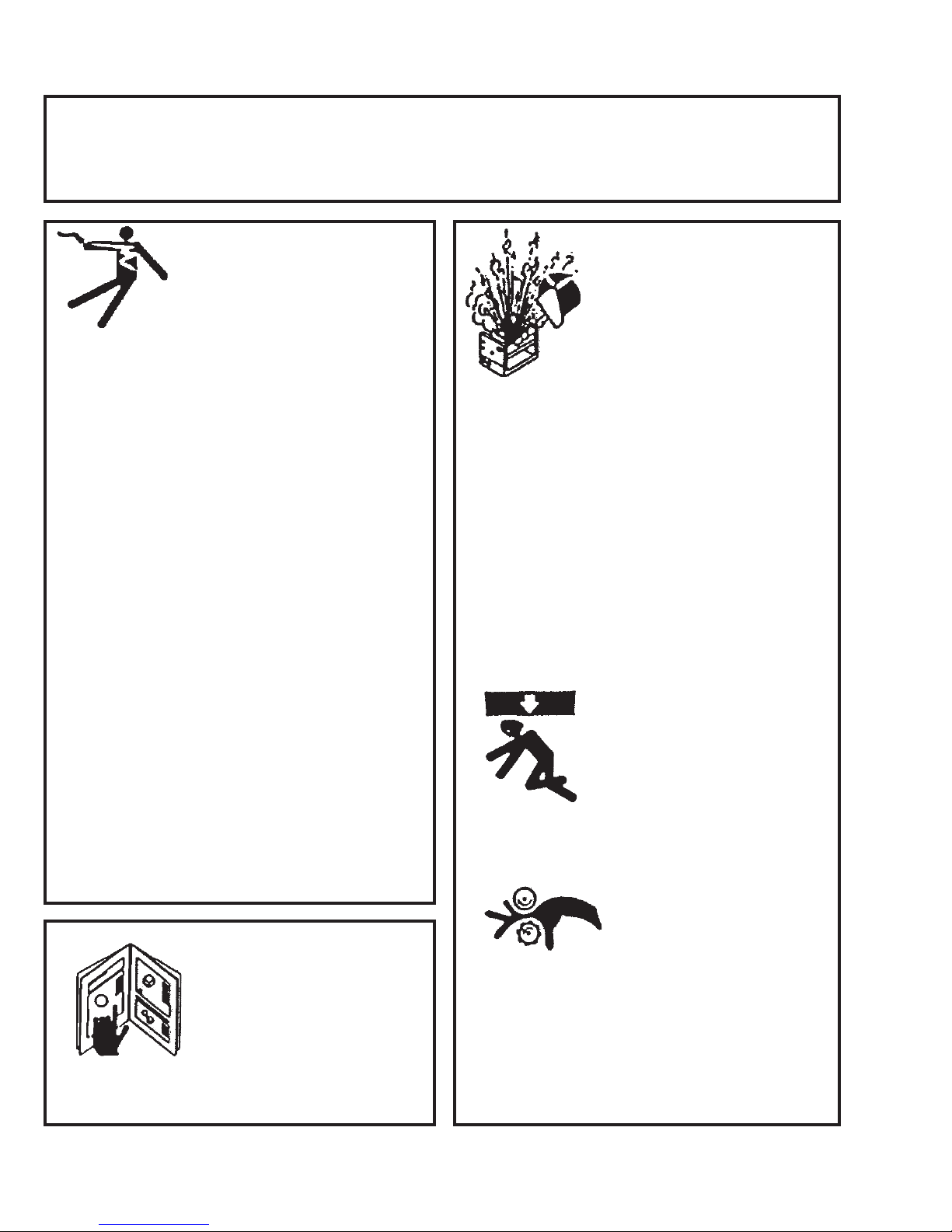

SAFETY

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY

QUALIFIED INDIVIDUALS.

EQUIPMENT DAMAGE

POSSIBLE.

ELECTRIC SHOCK can kill.

1) The equipment is not waterproof. Using

the unit in a wet environment may result

in serious injury. Do not touch equipment

when wet or standing in a wet location.

2) The unused connectors have power on

them. Always keep the unused connec-

tors covered with the supplied protective

panels. Operation of the machine without

the protective panels may result in injury.

3) Never open the equipment without rst

unplugging the power cord or serious

injury may result.

4) Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

5) Never remove or bypass the equipment

power cord ground. Verify the equipment

is grounded in accordance with all appli-

cable local and national electrical safety

codes. If none exist, use International

Electric Code (IEC) 950.

READ INSTRUCTIONS.

Read the instruction manual before

installing and using the equipment.

1) Do not plug in the power cord without rst

verifying the equipment is OFF and the

cord input voltage is the same as required

by the machine or serious damage may

result.

2) Always verity both the pinion and wheels

are fully engaged before applying power

or equipment damage may occur.

3) Do not leave the equipment unattended.

4) Remove from the work site and store in

a safe location when not in use.

1) Never try to stop the pinion from moving

except by removing power or by using the

STOP control.

2) Do not remove any protective panels,

covers or guards and operate equipment.

MOVING PARTS can

cause serious injury.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or walk

underneath equipment.