Optional Features

Dual Inline TDS Meter DM-1

Measures the total dissolved solids (TDS) in

your water supply. TDS meters are a common

tool used to estimate the purity or quality of

water.

A dual TDS meter is most commonly installed on the “in” and “out”

of the deionization resin stage. The “in” connection monitors the RO

system performance and the water feeding the DI resin.

The “out” connection monitors DI resin performance and the quality of

your product water for the aquarium. The “out” reading should always

read zero TDS.

Please note: The RO system needs to operate for 10 minutes before

an accurate reading can be achieved.

Oil-Filled Pressure Gauge

Displays the water pressure entering the RO

membrane. The gauge is installed in-line between the

last carbon block and the RO membrane.

Proper RO membrane performance is very dependent

on maintaining proper pressure feeding the membrane.

Greater than 50 psi is ideal, less than 35 and you will

likely need to install a booster pump.

A significant decrease in the operating pressure would indicate

that the pre-filters (and in particular the sediment filter) need to be

changed.

Membrane Flush Kit

The membrane flush kit is a ball valve

installed on the black waste water line

that bypasses the flow restrictor. Opening

this valve increases the flow through the

waste line and flushes deposits off of the

RO membrane. Flushing the membrane

increases membrane life and system performance.

On a RO system that is only used a few times a month flush the

membrane for 1-2 minutes before and after each use. If you use the

system frequently flush the system for 3-5 minutes a few times each

month.

Please note: In normal operation this valve should be closed. If you

are unsure if the valve is closed, check the flow rate out of the black

waste water line. When the valve is closed for normal operation, the

flow out of this line will be slower.

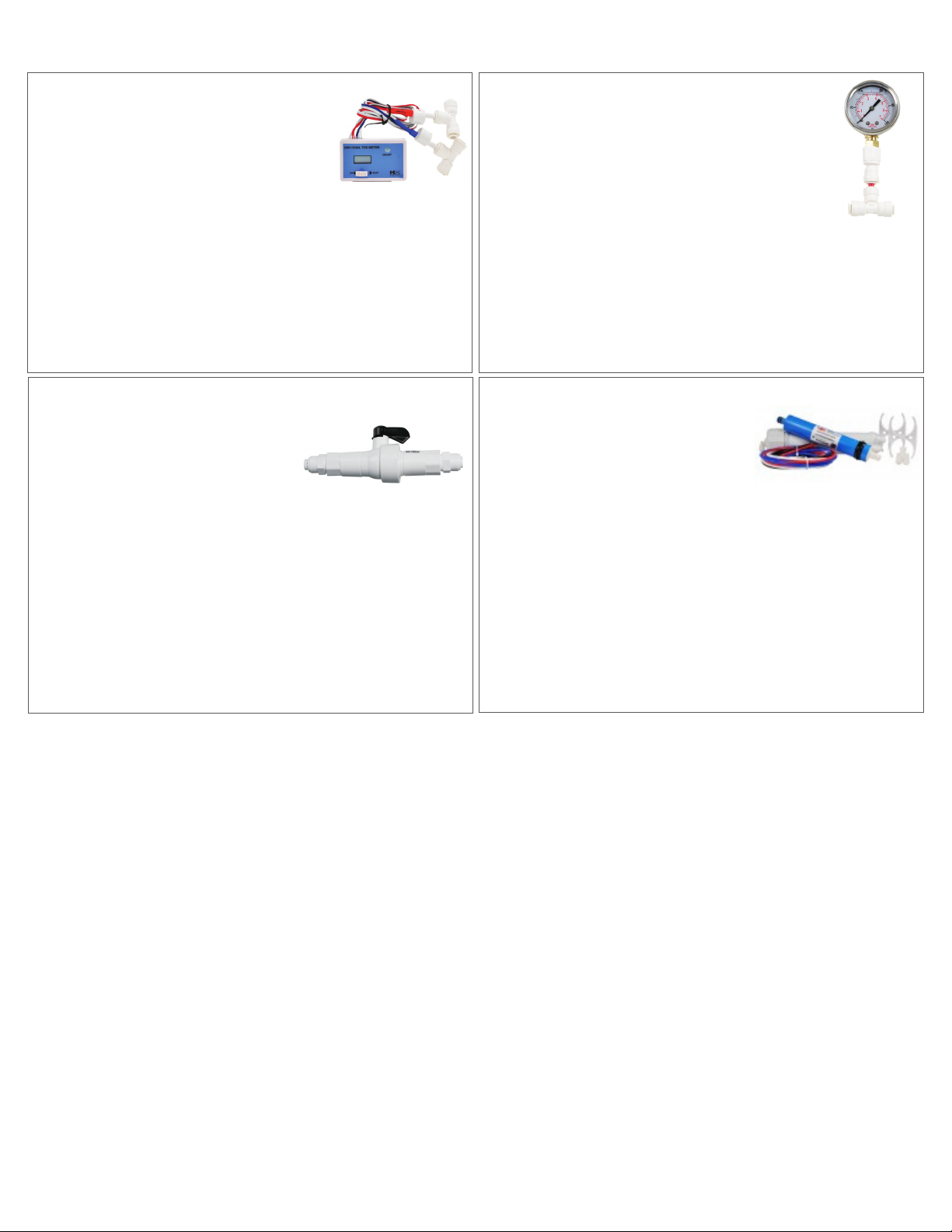

150 GPD Water Saver Upgrade Kit

This kit is designed to double product water

output while maintaining the same volume

of waste water which essentially cuts the

waste to product water ratio in half.

By running two 75 gallon per day membranes in series you are

doubling the volume of product water without significantly increasing

overall flow rates through the pre-filters. This will almost double the

amount of product water you can produce with a single set of pre-

filters.

This effect can be particularly noticeable if your water supply has

chloramines where filters are quickly consumed.