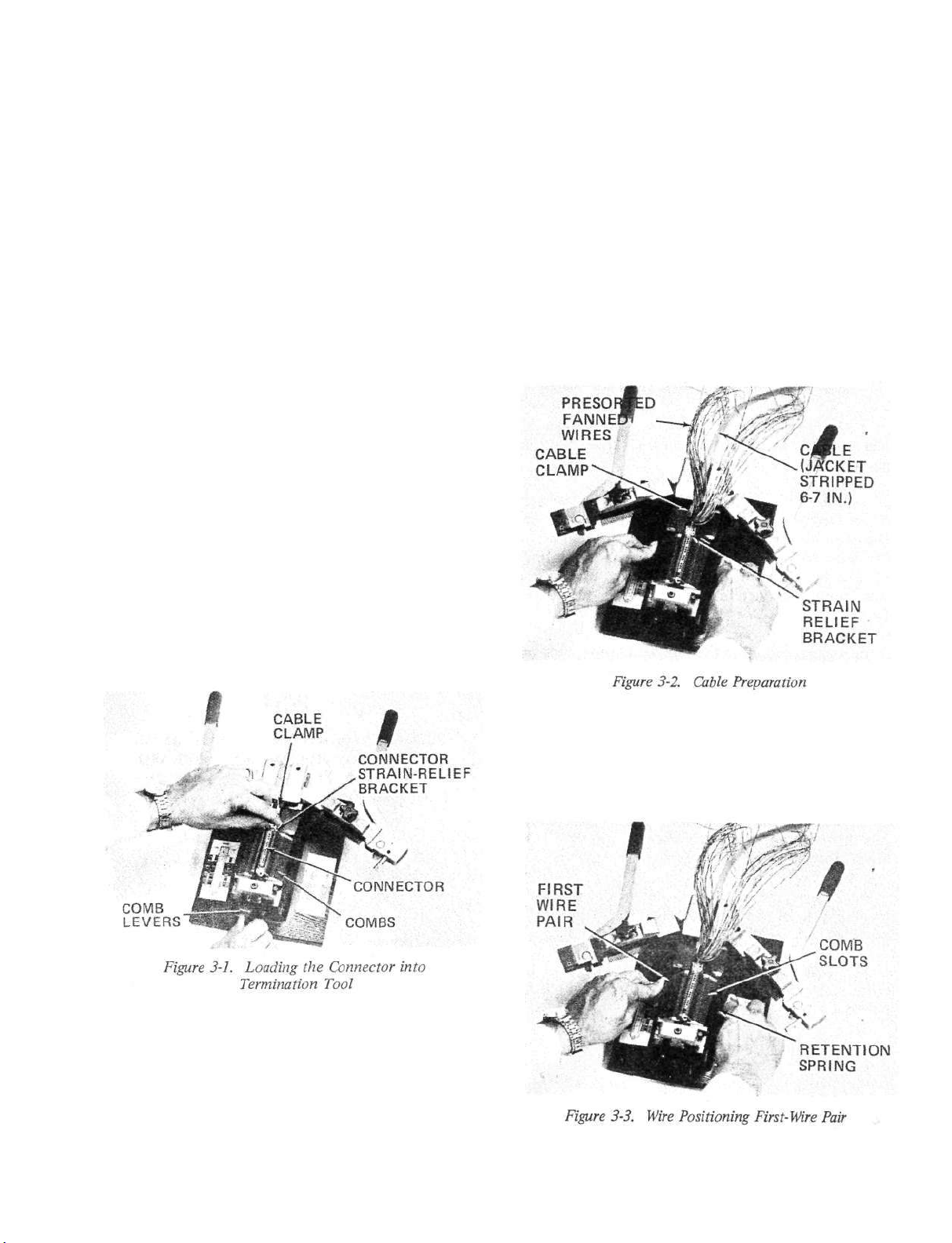

b.Positionthewiresothatitlaysoverthe

topoftheindexfingerandisheldtautand

guidedwiththethumb.

c.Keepthewiretautandslideyourindex

fingerdownthewiretoapproximatelytheslot

thewireistobeinserted.Relaxthetensionon

thewireandretractthetipofyourindexfinger

tothetipofyourthumb.Holdingthewireat

thispoint,a distinctbendshouldhavebeen

formed.

d.Usinga slightbackwardanddownmotion,

moveyourhandstowardthecombs,guidingboth

wiresintotheirappropriateslots.

e.Pullbothwirestautinanoutwardand

downmotion,beingcarefulnottoexertexcessive

tensiononthewiressothatthecombsopen.

f.Keepingthewirestautallowthemtoslip

thruyourfingerswhileyourhandsaremoving

straightoutanddownguidingthewiresthruthe

lowerslotsandintotheretentionsprings.

g.Repeattheaboveprocedureforeachsuc-

ceedingpairofwiresinthefirstcolorgroup;be

suretheyareinsertedintosucceedingslots.

h.Bendthenextcolorgroupup,perthe

colorcodechart,tofacilitatesortingasdonefor

thefirstgroup.

i.Proceedtofanthewiresintotheirproper

slots,andrepeatforeachcolorgroup.Asslots

fartherfromthecablearewired,allowthewires

toslipthruyourhandsandoveryourindex

8

fingerwhilekeepingthewiretaut,stoppingat

theappropriateslot.Thismethodwillstraighten

anybendsinthewire,allowforeasierslot

selection,andcreatethedesiredwirebendnear

theappropriateslot.

j.Whenallthewireshavebeenfannedinto

thecomb,inspectthemforpropercolorcode,

andbesureallthewiresrunthrutheirrespective

slotsandareintheretentionspringoneachside

ofthetool.

3-4.TERMINATINGTHECONNECTOR(Fig-

ures3-5and3-6)

a.Swingthetoothcarrierarmscontainingthe

toothplatespartiallyintothecombsuntilthey

touchthefirstwires.

b.Swingthecrimphandlesforwardmaking

suretheleversengagethepivotpins(9).

c.Continuetoswingthecrimphandlesto-

getheruntilthetoothcarrierarmsarecoveredby

theedgesofthearm retainer"T".Atthistime

botharmsshouldbeupagainstthepositivestop

andinparallelposition.Theratchetshouldnow

release.

d.Allwireshavenowbeencutandtermi-

nated.

NOTE

Ratchetinsuresthathandlesmustbefully

closedagainstarmretainerbeforeopen-

ing.Onlyinthiswaywilla complete,

reliableterminationbemade.