Step 4: Cleaning the condenser.

Usingasoftcleaningbrushattachment,gentlyvacuumthecondensercoilns.□

Usingaashlight,shinethelightthroughthecondensernstore-checkforcleanlinessordirtbetweenthens.□

Heavy build-up of grease in the condenser may require the use of a commercial condenser cleaner.□

Follow the manufacture warning and safety instructions along with how to instructions supplied with the cleaner.□

Step 5: Replacing the peristaltic pump tubing.

Open dispenser door.□

Removeallproductcontainersandplacetheminarefrigerated,(35-40ºF[1.6-4.4ºC]),environment.Disconnect□

all connections to ambient products from the bottle adapter.

Rinse all dispense stations using steps outlined in “DAILY RINSE PROCEDURE” in the operating manual.□

Disconnect dispenser from power source.□

Remove the dispense platform cover.□

Disconnect the dispense platform water line(s) from the supply line inside the refrigerated cabinet and disconnect□

the wiring connection(s) from the cabinet receptacle(s).

Remove the mounting screw(s) securing the dispense platform(s) to the cabinet.□

Pullthedispenseplatform(s)completelyoutofthecabinetandplaceitonaatworksurface.□

Close the dispenser door.□

Remove the 4 screws securing the pump head.□

Gently pull the pump head apart.□

Gently pull the pump tube from around the pump’s rotor.□

Release the clamps securing the old pump tubing to the plastic elbows.□

Pulltheplasticelbowsfromtheoldpumptubing,anddiscardtheoldpumptubing.□

Insert the plastic elbows into the new pump tubing and secure it with the clamps.□

Gently wrap the new pump tubing around the pump’s rotor.□

Reassemble the pump housing onto the platform assembly.□

Repeat this process for the remaining pumps.□

Replacethedispenseplatform(s)intotherefrigeratedcabinet,makingsuretoreconnectallelectricalandwater□

connections.

Replace the dispense platform cover.□

Turn power on to dispenser.□

Installcontainersofrinsewater,runeachstationandcheckforleaks.Repairleaksasnecessary.□

Replace product shelf and product containers. Reconnect any connections to ambient product containers.□

Prime the pumps.□

Step 6: Follow the daily parts washing procedure in the operating manual.

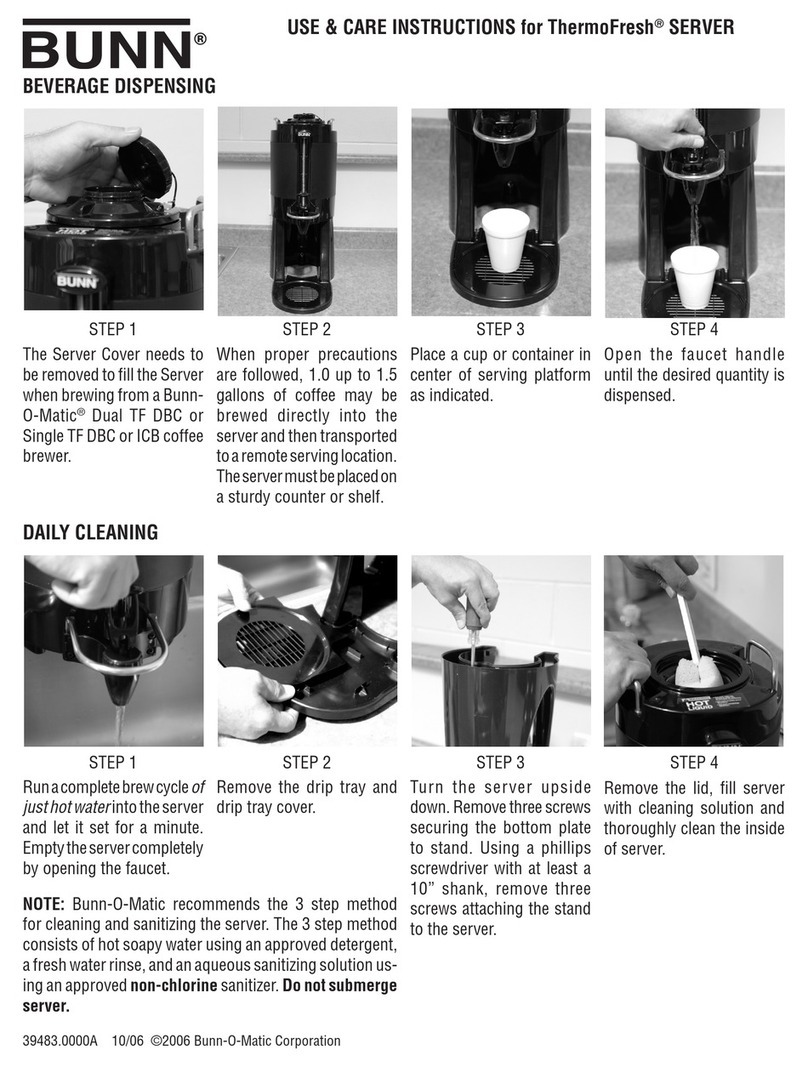

Removeandwashthedispensenozzle(s);mixingelement(s),driptrayanddriptraycoverinamilddetergent□

solution. Rinse thoroughly.

Wipesplashpanel,areasarounddispensenozzle(s),andrefrigeratedcompartmentwithaclean,dampcloth.□

Inspect door seal gasket for wear and cleanliness.□

Step 7: Examine all electrical connections and power cord for loose connection.

Step 8: Examine all water lines and supply for leakage.

Step 9: Check cabinet temperature with thermometer (Note: The dispenser must be on to perform this step).

Install thermometer in cabinet and monitor temperature to see if it comes down below 41 degrees Fahrenheit.□

Good idea always to leave thermometer in cabinet to monitor proper cooling process and temperature.

Checkforproperairowinsidecabinetaroundproduct.□

Step 10: Check product mix brix/ratio in their corresponding dispense station (Note: The dispenser must be on to

perform this step).

Water Flow Test and Adjustment□

Step 1: Place the pitcher beneath the dispense nozzle you are testing.

Step 2: Place the “Dispense Lockout” switch in the Off position.

Step 3:Pressandreleasetheappropriatedispensebutton,(“Stop/Plus”buttonifusingportioncontrol

option). The machine will dispense water from the dispense nozzle for 3 seconds.

Step 4: Measure the water dispensed.

Step 5:Adjustthewaterowifneeded,(seewaterowchartinthe“InstallationandOperatingGuide”).

Clockwisewillincreaseowrateandcounterclockwisewilldecreasetheowrate.

Rev. 05/19/09