2 08/54070/0 (Issue 5)

Table of Contents

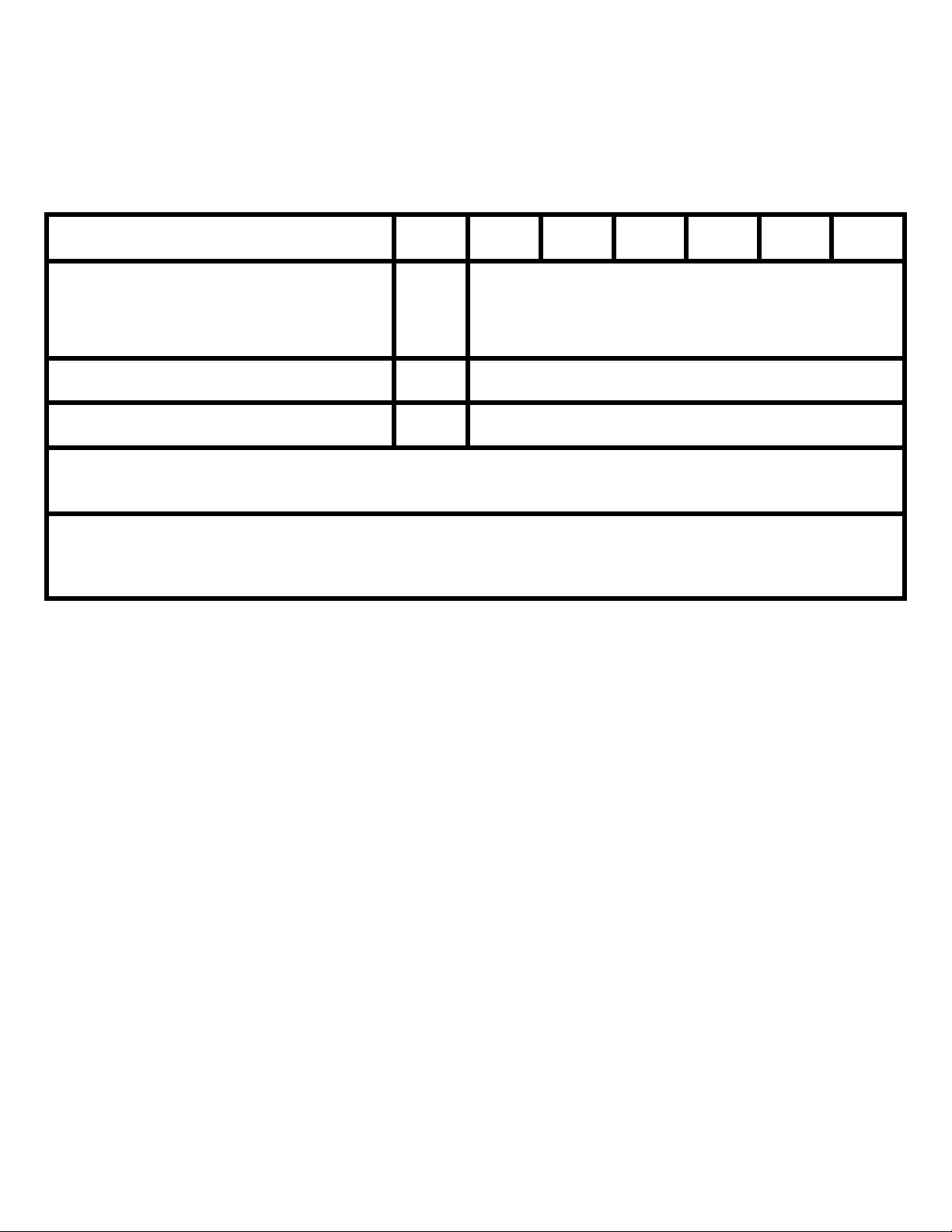

1.0 About my product .................................................................................................................................... 3

2.0 Scope of delivery...................................................................................................................................... 4

3.0 Warnings and Precautions ....................................................................................................................... 4

4.0 Introduction ............................................................................................................................................. 6

5.0 Warranty Information.............................................................................................................................. 6

6.0 Technical Data.......................................................................................................................................... 7

7.0 Burco boiler Installation........................................................................................................................... 8

7.1 Before connecting to the power supply............................................................................................ 8

7.2 Connecting to the water supply........................................................................................................ 8

7.3 Electrical Connection......................................................................................................................... 9

7.4 Fitting or replacing a plug (3kW models). ......................................................................................... 9

7.5 6kW Twin Tap Model ...................................................................................................................... 10

7.6 Overflow and Drainage ................................................................................................................... 10

8.0 Operating Instructions ........................................................................................................................... 11

8.1 Boiler Overview ............................................................................................................................... 11

8.2 Controller Overview ........................................................................................................................ 12

8.3 Controller Set Up............................................................................................................................. 13

9.0 Descaling & Cleaning advice and information ....................................................................................... 17

9.1 Descaling.......................................................................................................................................... 17

10.0 Changing Water Filter (Filtered models only)...................................................................................... 18

11.0 Cleaning Instructions............................................................................................................................ 19

12.0 Troubleshooting................................................................................................................................... 19

13.0 Disposal ................................................................................................................................................ 20

14.0 Spare / Replacement Parts List ............................................................................................................ 21

14.1 Countertop Version....................................................................................................................... 21

14.2 Slimline Countertop Version ......................................................................................................... 22

15.0 Frequently Asked Questions (FAQ’s). .................................................................................................. 23

16.0 Warranty Information.......................................................................................................................... 25

17.0 Terms and Conditions .......................................................................................................................... 27