Next, define the behavior for each of eight relay outputs.

Each relay may be set for momentary or latching output.

Check the Pair Relay Channels box in order for the relays

to act as mutually exclusive pairs. When this box is

checked, a command to one relay will cause the second

relay to de-energize.

Note: When the Pair Relay Channels box is checked, it is

recommended to configure the two paired relays with the same behavior (Latching / Latching or

Momentary / Momentary). If one relay is configured as Latching and the other as Momentary, a

command to the momentary relay will de-energize the latching relay. After the momentary

command is finished, both relays will remain de-energized until a new command is issued to

one of the relays.

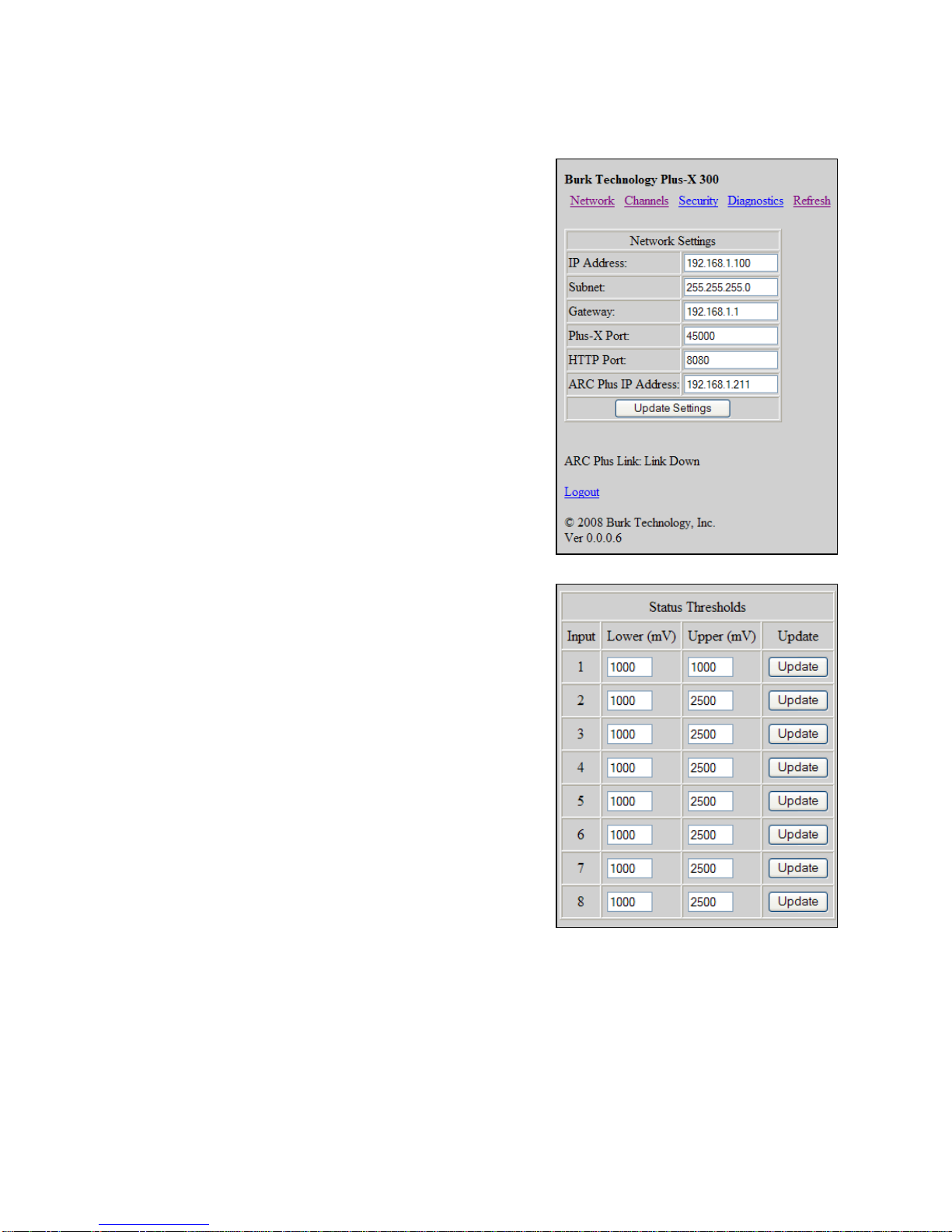

Security

Navigate to the Security page to set the

password for the Plus-X 300. This password is

used only to access the Plus-X configuration

screens. ARC Plus user names and passwords

are set up using AutoLoad Plus software.

The Plus-X 300 user name is always admin.

Adding Plus-X Channels to the ARC Plus

Now that you have configured the input and output channels on the Plus-X 300, these channels

may be added to the ARC Plus site using AutoLoad Plus. To add Plus-X 300 channels to the

ARC Plus:

1. Launch AutoLoad Plus and connect to the ARC Plus site to which the Plus-X 300 is

linked.

2. From the Edit menu, select Plus-X Devices…and click New.

3. When the Plus-X Settings window appears, select Plus-X 300 from the device type drop-

down. Enter a description of the Plus-X 300 for your own reference, followed by the IP

address and Plus-X port, both of which are already configured on the Plus-X 300.

4. Check the box marked Map Default Set of Channels to add all eight inputs and eight

relays to the ARC Plus. If you are not using all Plus-X 300 channels or if you do not wish

for them to appear in sequential order, you will need to manually map these channels

later. In this case, leave the Map Default Set of Channels box unchecked.

5. Press OK to close the Plus-X Settings window. Press OK to close the Plus-X Devices

window.

6. To manually map Plus-X 300 channels to the ARC Plus, click the Metering, Status or

Commands tabs, as appropriate. Locate an unused channel and click the […] button in

the Source column. This will bring up the Source dialog box. Click the Plus-X button and

choose the Plus-X 300 channel you wish to use. At least one meter channel and one