4

Type 8652

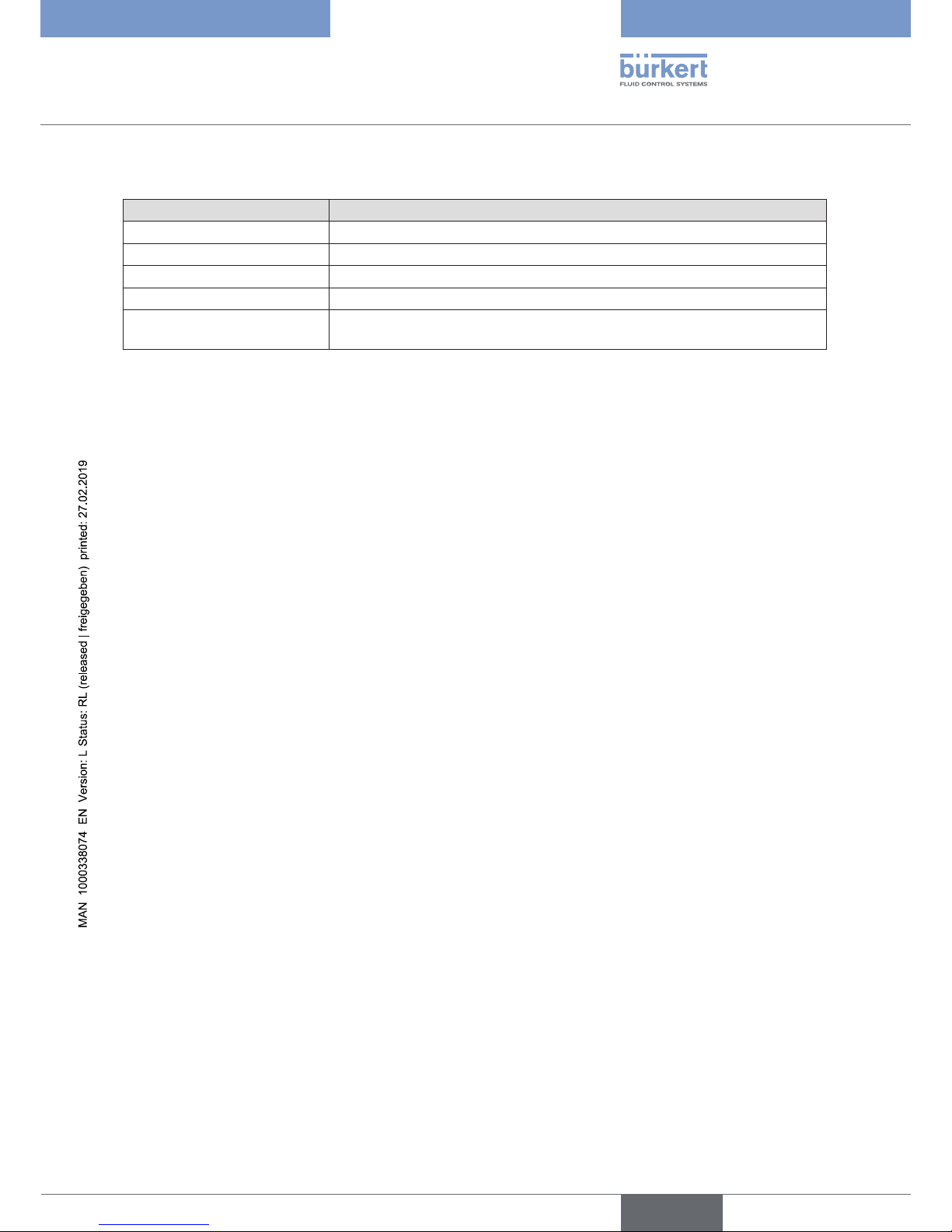

7ASSEMBLING THE VALVE TERMINAL IN THE CONTROL CABINET.................................................22

7.1 AssemblingontheoororwallofthecontrolcabinetwithAirLINEQuick ............................23

7.1.1 DimensionsofangettingAirLINEQuick................................................................. 24

7.1.2 Assembling the valve island in the control cabinet .................................................... 25

7.2 Assemblingonstandardrail......................................................................................................26

7.3 Connectingthefunctionalearth................................................................................................27

8ELECTRICAL CONNECTION................................................................................................................28

8.1 Electricalconnectioneldbusgateway ....................................................................................28

8.1.1 Gateway with CANopen interface / büS interface .......................................................28

8.1.2 Gateway with industrial Ethernet interface .................................................................29

8.1.3 Gateway with PROFIBUS DPV1 interface ..................................................................30

8.2 Electricalconnectionelectronicmodulewithdigitalinputs ....................................................31

8.3 ElectricalconnectionType6534valvesfor

safety-relatedshut-o(SIAvariant) ..........................................................................................32

9PNEUMATIC CONNECTION.................................................................................................................34

9.1 Assignmentofthepneumaticconnections ..............................................................................34

9.1.1 Allocation of valve outputs to the pneumatic connections of the valve terminal .......35

9.1.2 External and internal auxiliary pilot air........................................................................35

10 MICRO SD CARD .................................................................................................................................36

11 DESIGNING VIA THE BÜRKERT COMMUNICATOR...........................................................................37

11.1 UserinterfaceoftheBürkertCommunicator............................................................................37

11.2 EstablishingaconnectionbetweenthedeviceandtheBürkertCommunicator....................38

11.3 Basesettingsofthevalveterminal ...........................................................................................38

11.4 Basesettingsofindustrialcommunication ..............................................................................38

11.4.1 Selectingtheeldbusprotocol...................................................................................38

11.4.2 PROFIBUS DPV1 settings ..........................................................................................38

11.4.3 CCLink settings ..........................................................................................................39

11.4.4 Industrial Ethernet settings.........................................................................................39

11.5 Furtherpossiblesettings ...........................................................................................................40

11.5.1 Congurationarea“UnitX” ........................................................................................40

11.5.2 Congurationarea“Industrialcommunication”..........................................................41

11.5.3 Congurationarea“Generalsettings” ........................................................................42

11.6 Usingextensionmodules(EM)..................................................................................................45

11.6.1 Congurationoftheeldbus ......................................................................................45

11.6.2 Conguringthevalveislandwithextensionmodules.................................................46

11.6.3 ConguringthebüSnetwork......................................................................................46

12 SETTINGS OF THE FIELDBUS GATEWAY ..........................................................................................48

12.1 OperatingelementsofeldbusgatewayME43........................................................................48

12.2 Operationviathedisplayattheeldbusgateway ...................................................................48

12.2.1 Description of the keys...............................................................................................48

12.3 DisplayelementsofeldbusgatewayME43............................................................................49