Table of Contents

2 / 24 0870223347_LN3001-3002A_-0001_IM_en

Table of Contents

1 Safety........................................................................................................................... 3

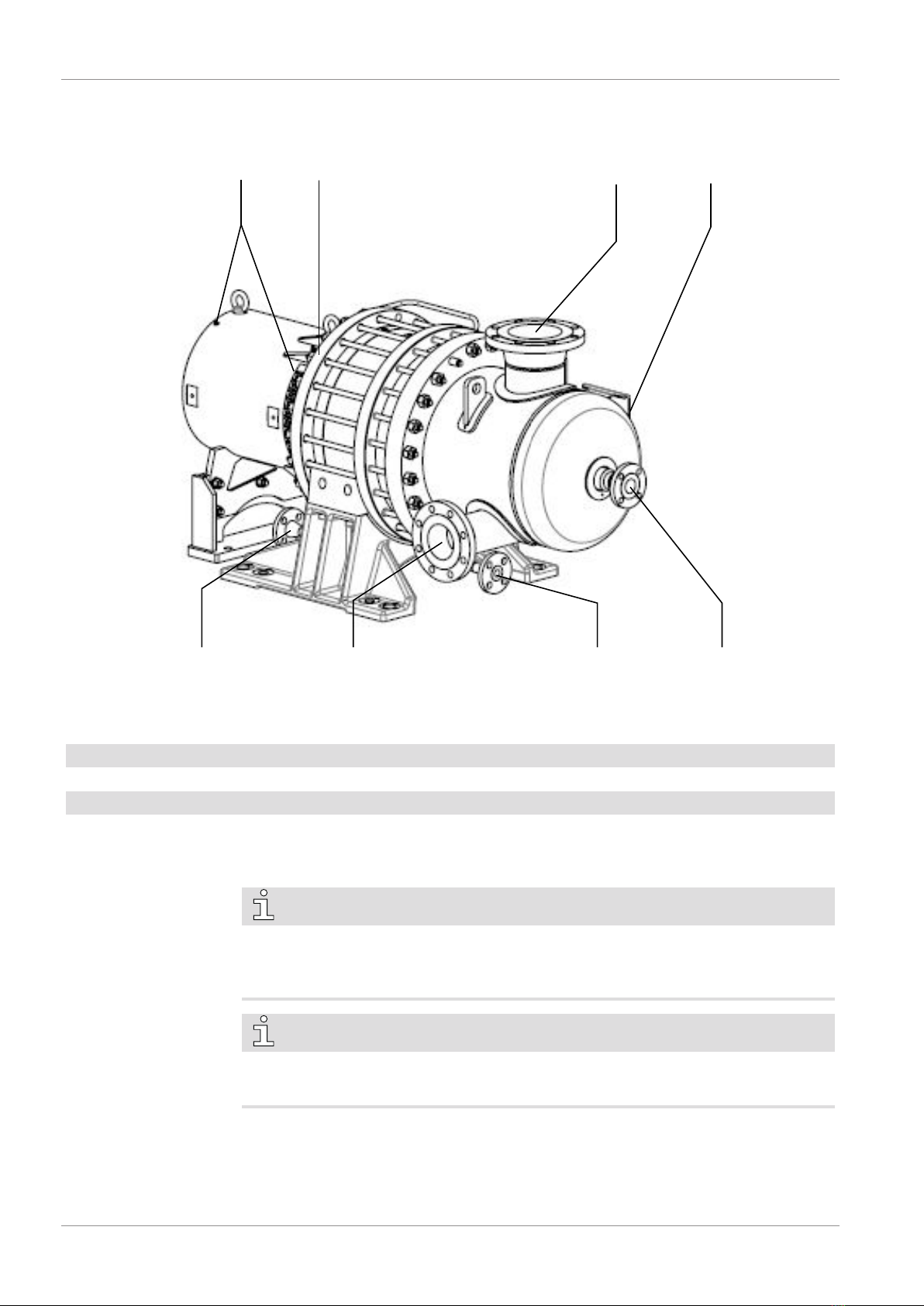

2 Product Description ..................................................................................................... 4

2.1 Operating Principle...............................................................................................5

2.2 Application ........................................................................................................... 5

2.3 Start Controls .......................................................................................................5

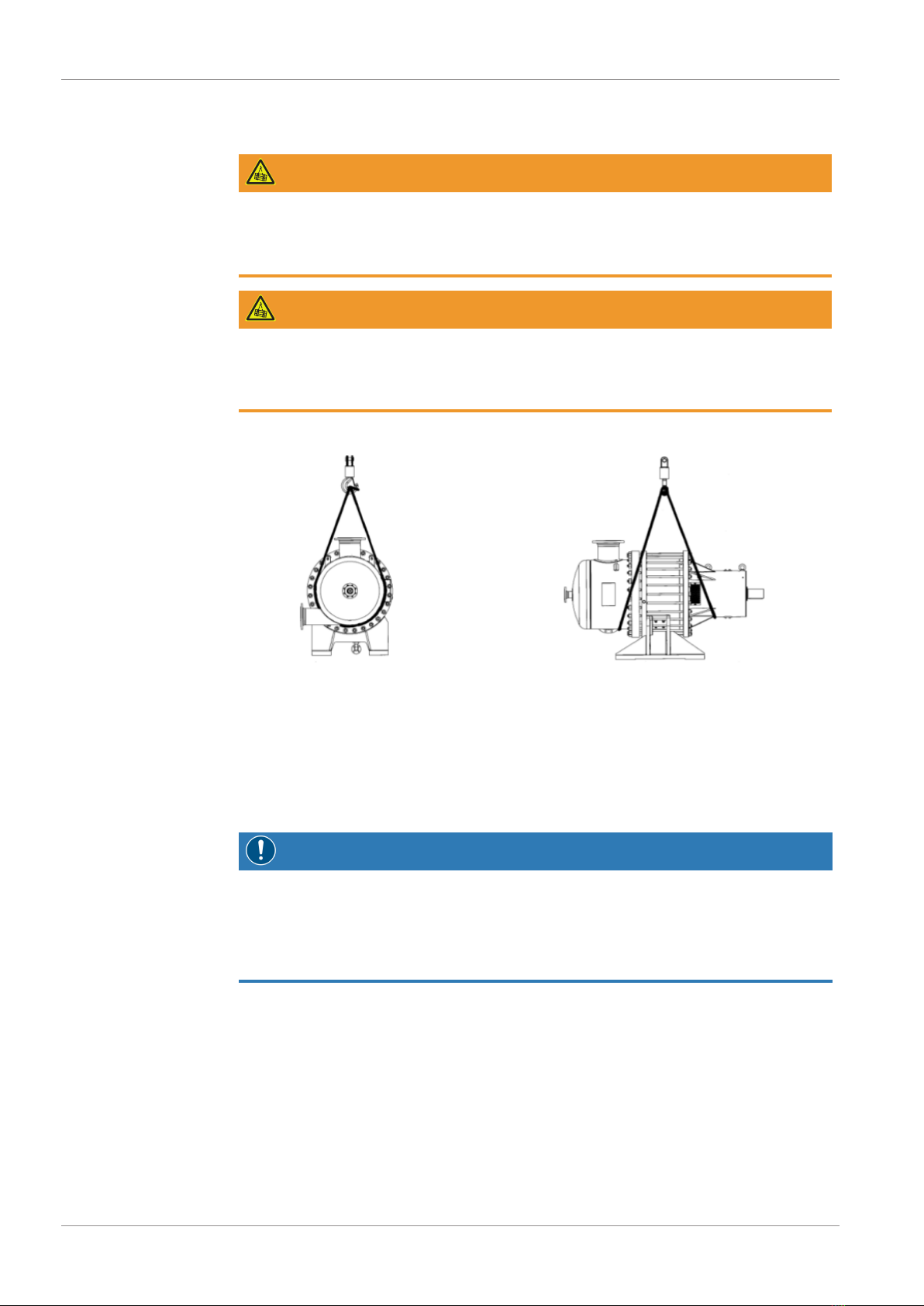

3 Transport ..................................................................................................................... 6

4 Storage......................................................................................................................... 6

4.1 Short Term (Up to 3 Months) ...............................................................................6

4.2 Medium Term (3 Months to 6 Months)................................................................7

4.3 Long Term (Over 6 Months).................................................................................7

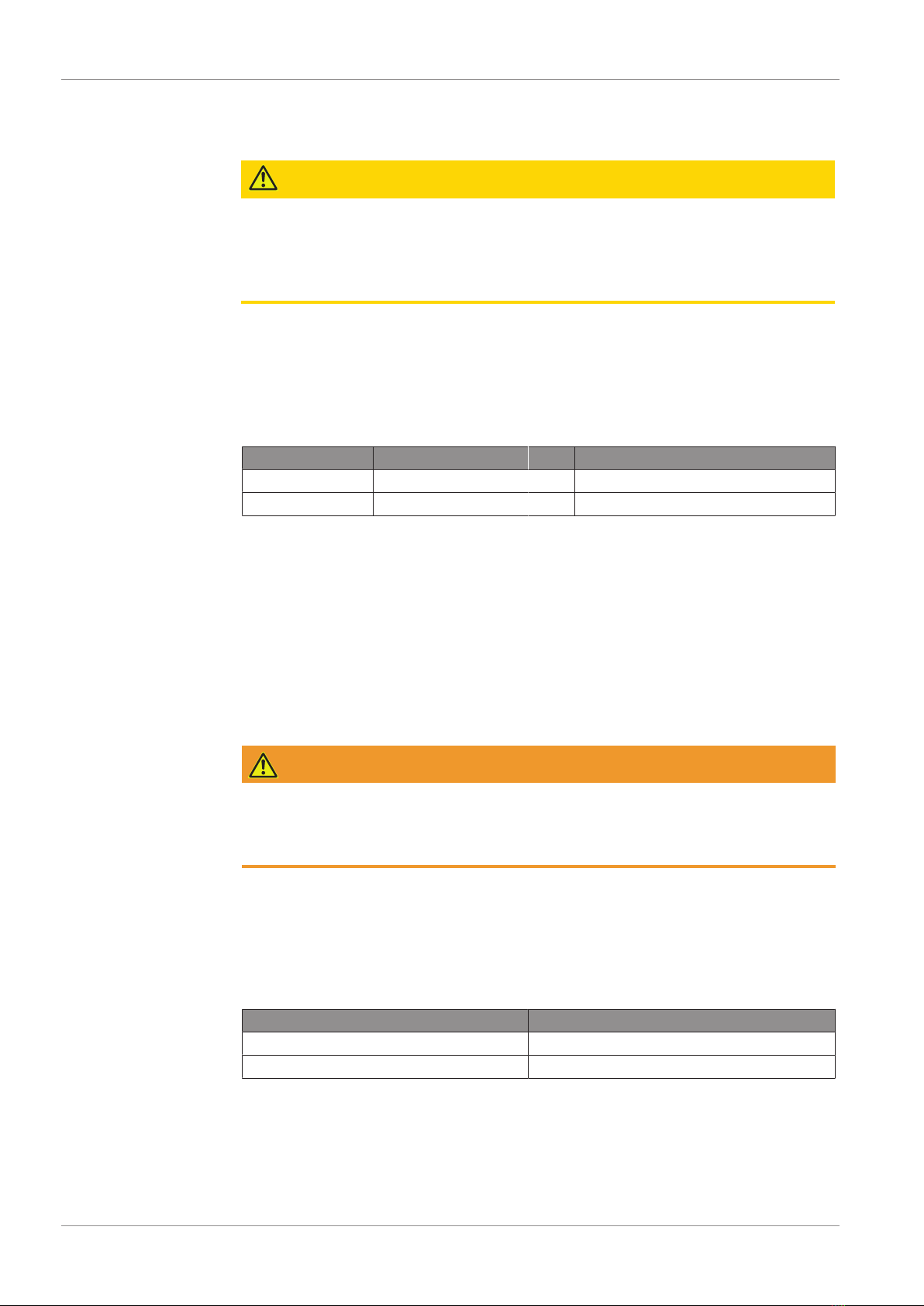

5 Installation................................................................................................................... 7

5.1 Installation Conditions ..........................................................................................7

5.2 Connecting Lines / Pipes ......................................................................................8

5.2.1 Suction Connection....................................................................................8

5.2.2 Discharge Connection................................................................................8

5.2.3 Operating Liquid Connection.....................................................................9

5.3 Operating Liquid Settings .....................................................................................10

5.4 Fitting the Coupling..............................................................................................10

6 Commissioning............................................................................................................ 11

6.1 Start-Up ...............................................................................................................12

7 Maintenance................................................................................................................ 15

7.1 Maintenance Schedule..........................................................................................15

8 Overhaul...................................................................................................................... 18

9 Decommissioning ........................................................................................................ 18

9.1 Dismantling and Disposal......................................................................................19

10 Spare Parts................................................................................................................... 19

11 Troubleshooting........................................................................................................... 20

12 Technical Data ............................................................................................................. 22

2.2.1 LN Series ...................................................................................................5

13 EU Declaration of Conformity ...................................................................................... 23

7.2 Lubrication ...........................................................................................................16

6.2 Shut-Down ..........................................................................................................14

6.2.1 Regular Shut-Down...................................................................................14

6.2.2 Emergency Shut-Down..............................................................................14

6.1.1 First-Time Start-Up....................................................................................12

6.1.2 Regular Start-Up........................................................................................13

7.2.1 Grease .......................................................................................................16

7.2.2 Oil .............................................................................................................17

5.2.4 Mechanical Seal Connection ......................................................................9