Table of Contents

2 / 36 0870153444_MA0018A_A0006_IM_en

Table of Contents

1 Safety .......................................................................................................................................3

2 Product Description ..................................................................................................................4

2.1 Operating Principle .......................................................................................................... 4

2.2 Application....................................................................................................................... 5

3 Transport ..................................................................................................................................5

4 Storage .....................................................................................................................................5

5 Installation................................................................................................................................6

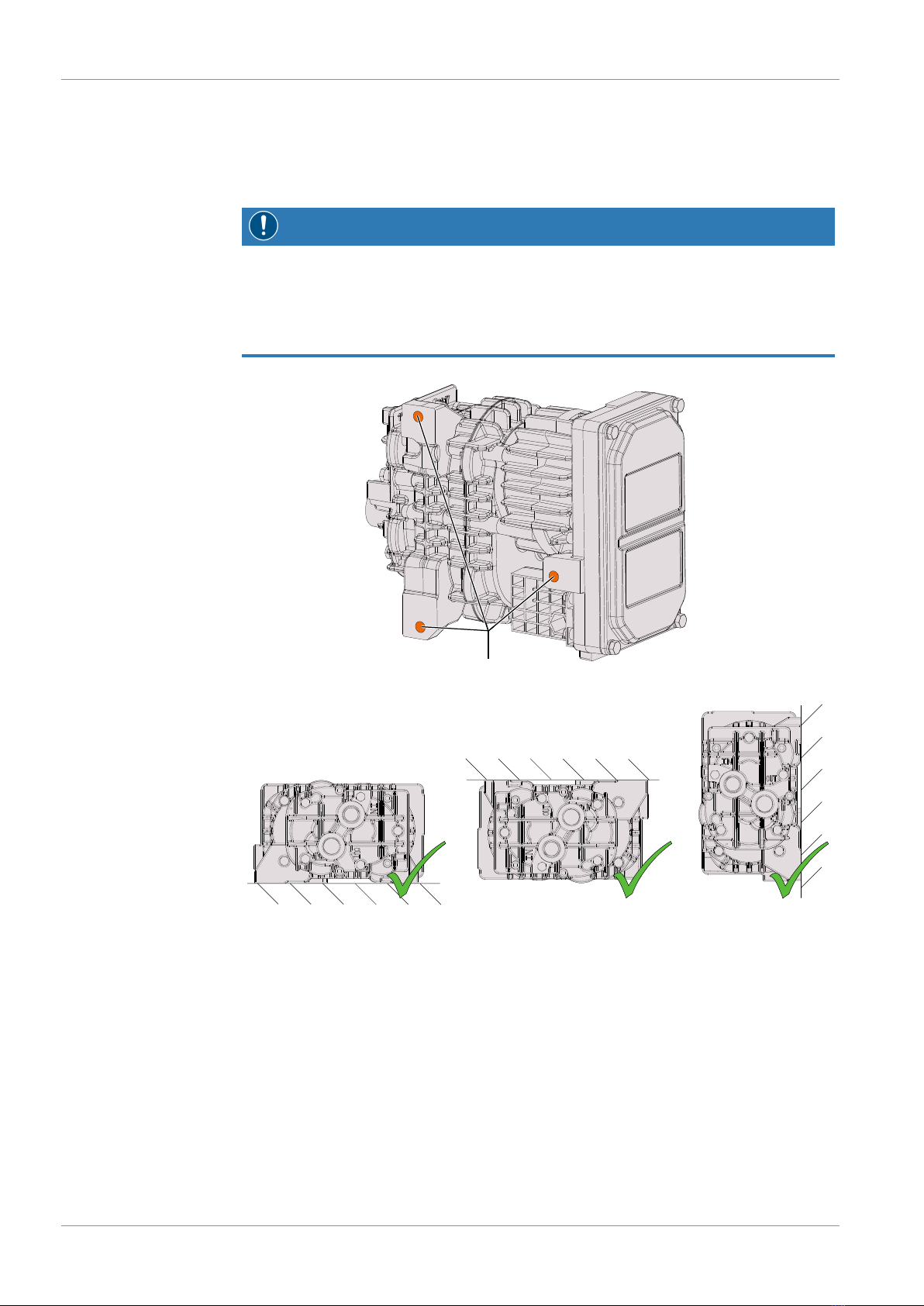

5.1 Installation Conditions...................................................................................................... 6

5.2 Connecting Lines / Pipes .................................................................................................. 7

5.2.1 Suction Connection ............................................................................................... 7

5.2.2 Discharge Connection ........................................................................................... 8

5.3 Electrical Connection ........................................................................................................ 8

5.3.1 Version with Analogue Speed Control ................................................................... 9

5.3.2 Version with CAN-Communication........................................................................ 9

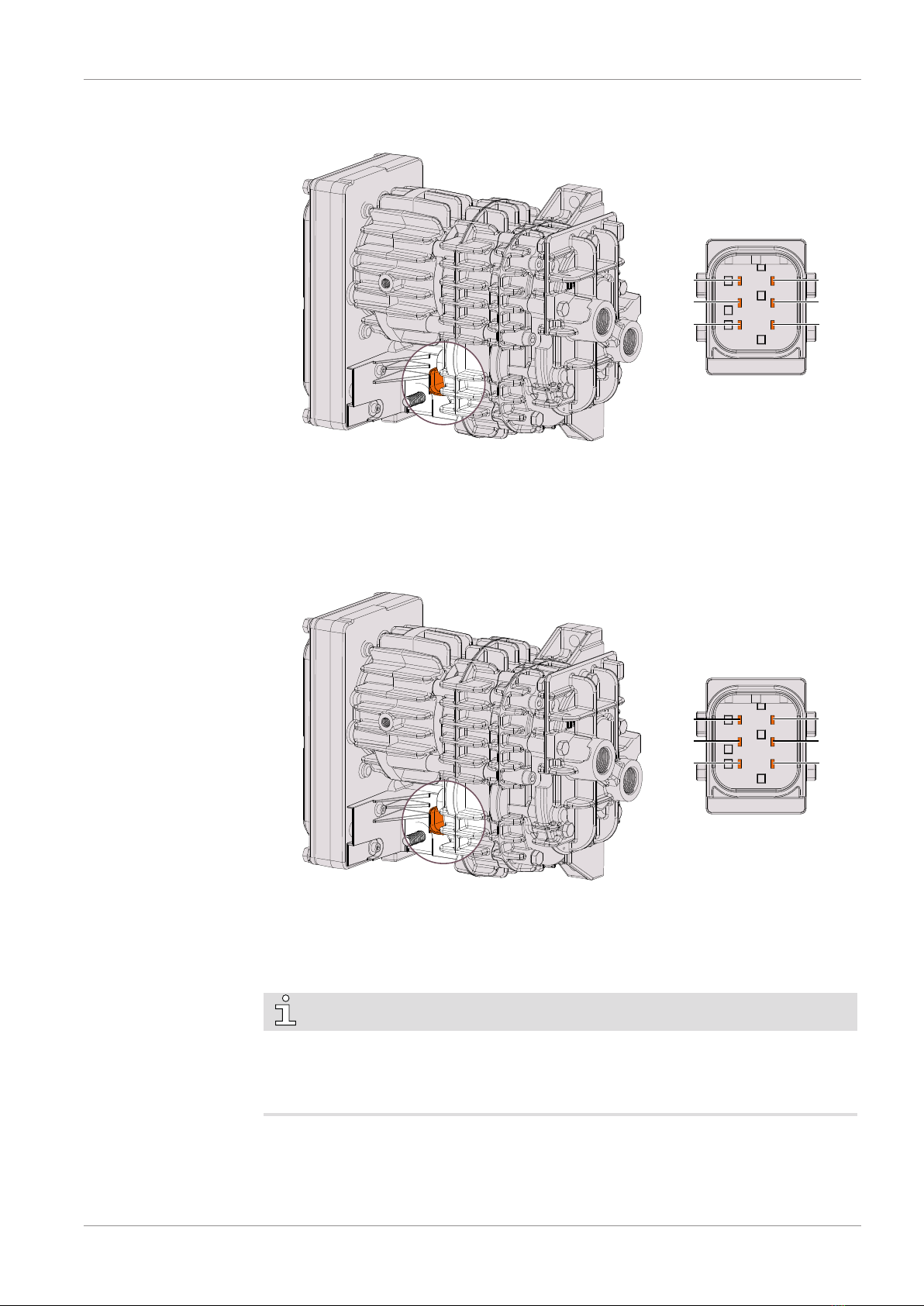

5.3.3 Motor Rotation Direction ...................................................................................... 10

6 Commissioning.........................................................................................................................10

6.1 Standard Version.............................................................................................................. 11

6.2 Version with Analogue Speed Control .............................................................................. 11

6.3 Version with CAN-Communication .................................................................................. 11

7 Maintenance.............................................................................................................................13

7.1 Maintenance Schedule ..................................................................................................... 13

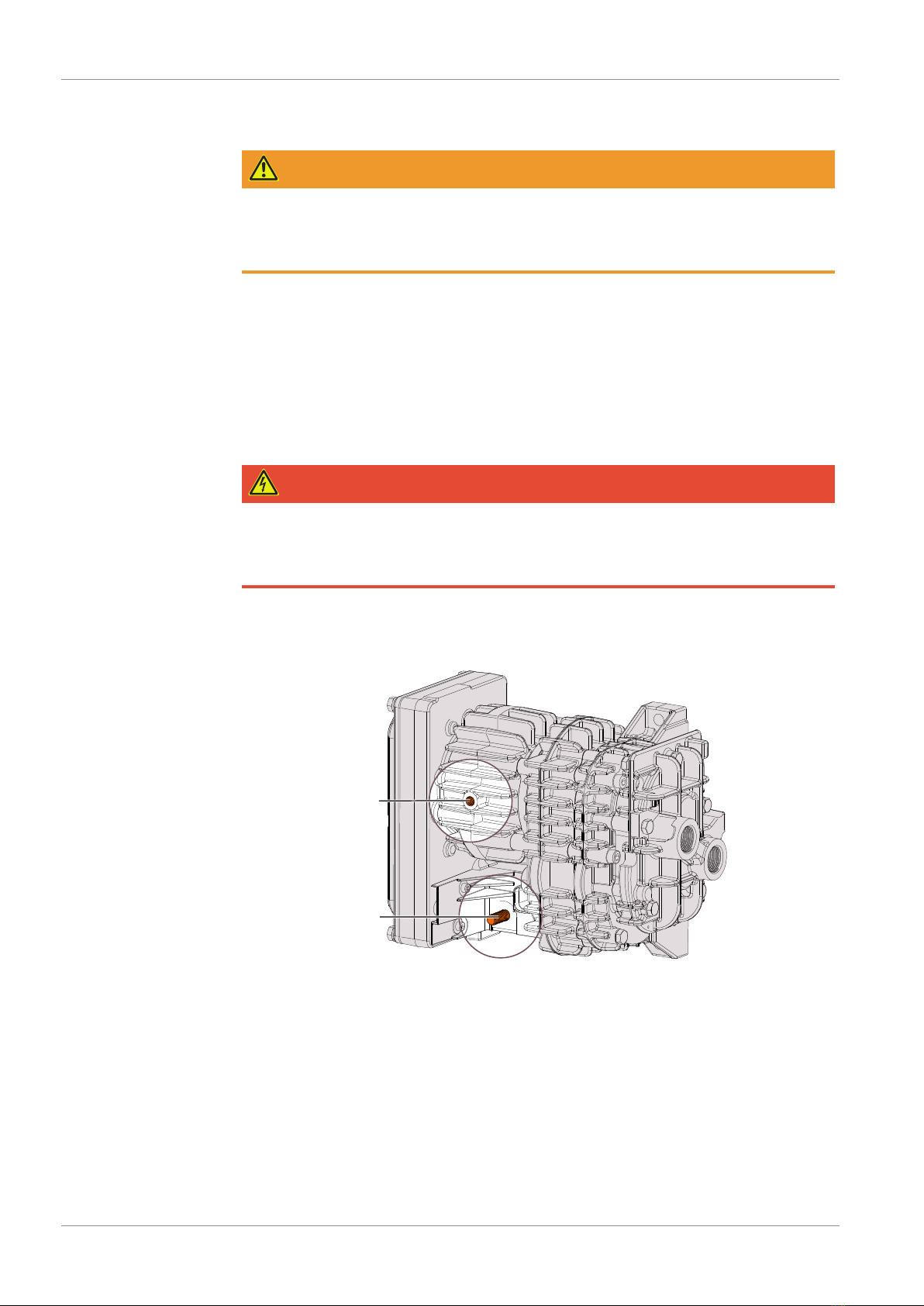

7.2 Oil Draining ..................................................................................................................... 14

7.2.1 Overall Information ...............................................................................................14

7.2.2 Draining Procedure................................................................................................ 15

7.2.3 Service Kit and Oil Type ........................................................................................ 20

7.3 Machine Stage Replacement ............................................................................................ 20

7.3.1 Stage Disassembly .................................................................................................21

7.3.2 Stage Replacement Package ..................................................................................24

7.3.3 Stage Reassembly..................................................................................................24

7.3.4 Stage Testing......................................................................................................... 26

7.3.5 Machine Identification...........................................................................................26

8 Overhaul...................................................................................................................................27

9 Decommissioning.....................................................................................................................27

9.1 Dismantling and Disposal ................................................................................................. 27

10 Spare Parts................................................................................................................................28

11 CAN Protocol............................................................................................................................29

11.1 Standard CAN Interface 250 kBit/s................................................................................... 29

11.2 CAN Interface 500 kBit/s ................................................................................................. 30

11.3 CAN Interface 250 kBit/s, DOT Yellow ............................................................................ 30

11.4 CAN Interface 250 kBit/s, DOT Red................................................................................. 30

11.5 CAN Interface 250 kBit/s, DOT Purple ............................................................................. 30

12 Technical Data..........................................................................................................................32

13 EU Declaration of Conformity...................................................................................................33

14 UK Declaration of Conformity ..................................................................................................34