Table of Contents

2 | 44 Instruction Manual MINK MM 1104-1142 BP ATEX_EN_en

Table of Contents

1 Safety..................................................................................................................................................................... 4

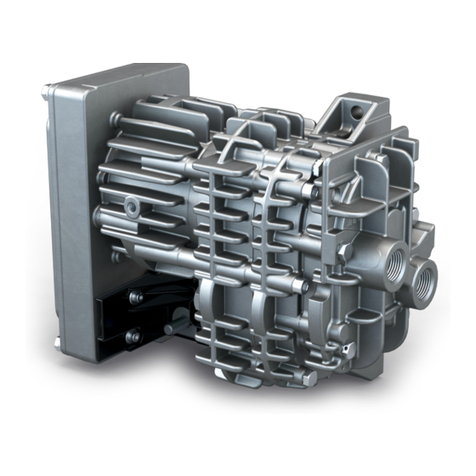

2 Product Description............................................................................................................................................. 5

2.1 Operating Principle ............................................................................................................................................. 6

2.2 Intended Use ....................................................................................................................................................... 6

2.3 Design Options .................................................................................................................................................... 7

2.3.1 Gas Tight Version .................................................................................................................................. 7

2.3.2 Aqua Version.......................................................................................................................................... 7

2.4 Accessories........................................................................................................................................................... 8

2.4.1 Temperature Monitoring ..................................................................................................................... 8

2.4.2 Pressure Monitoring............................................................................................................................. 8

2.5 Optional Accessories........................................................................................................................................... 8

2.5.1 Inlet Filter............................................................................................................................................... 8

2.6 Explanation of ATEX Classification .................................................................................................................... 9

2.7 Safety Concept..................................................................................................................................................... 10

2.7.1 ATEX Classifications and Associated Accessories.............................................................................. 10

3 Transport .............................................................................................................................................................. 11

4 Storage .................................................................................................................................................................. 12

5 Installation ........................................................................................................................................................... 13

5.1 Installation Conditions........................................................................................................................................ 13

5.2 Connecting Lines / Pipes .................................................................................................................................... 14

5.2.1 Suction Connection............................................................................................................................... 15

5.2.2 Discharge Connection .......................................................................................................................... 15

5.3 Earth Connection................................................................................................................................................. 15

5.4 Filling Oil............................................................................................................................................................... 16

5.5 Fitting the Coupling ............................................................................................................................................ 17

5.6 Electrical Connection .......................................................................................................................................... 18

5.6.1 Wiring Diagram Three-Phase Motor .................................................................................................. 19

5.7 Electrical Connection of the Monitoring Devices ............................................................................................ 20

5.7.1 Wiring Diagram Resistance Thermometer ........................................................................................ 20

5.7.2 Wiring Diagram Pressure Transmitter ............................................................................................... 21

6 Commissioning..................................................................................................................................................... 22

6.1 Conveying Condensable Vapors........................................................................................................................ 22

7 Maintenance......................................................................................................................................................... 23

7.1 Maintenance Schedule ....................................................................................................................................... 24

7.2 Oil Level Inspection............................................................................................................................................. 24

7.3 Cleaning from Dust and Dirt.............................................................................................................................. 25

7.4 Oil Change............................................................................................................................................................ 26

7.5 Pressure Relief Lines Maintenance (Gas Tight Version Only) ........................................................................ 28

7.6 Coupling Maintenance........................................................................................................................................ 29

7.7 Maintenance Monitoring Devices ..................................................................................................................... 31

7.7.1 Checking Function of the Measurement and Safety Instrumentation........................................... 31

8 Overhaul................................................................................................................................................................ 33

9 Decommissioning................................................................................................................................................. 34

9.1 Dismantling and Disposal .................................................................................................................................. 34

10 Spare Parts............................................................................................................................................................ 35

11 Troubleshooting................................................................................................................................................... 36