Table of Contents

2 / 24 Instruction Manual PUMA WP 0250-2000 D_EN_en

Table of Contents

1 Safety .......................................................................................................................................3

2 Product Description ..................................................................................................................4

2.1 Operating Principle .......................................................................................................... 5

2.2 Application....................................................................................................................... 5

2.3 Variants............................................................................................................................ 5

2.3.1 D2 Versions...........................................................................................................5

2.3.2 D4 Versions...........................................................................................................5

2.3.3 Water Cooling.......................................................................................................6

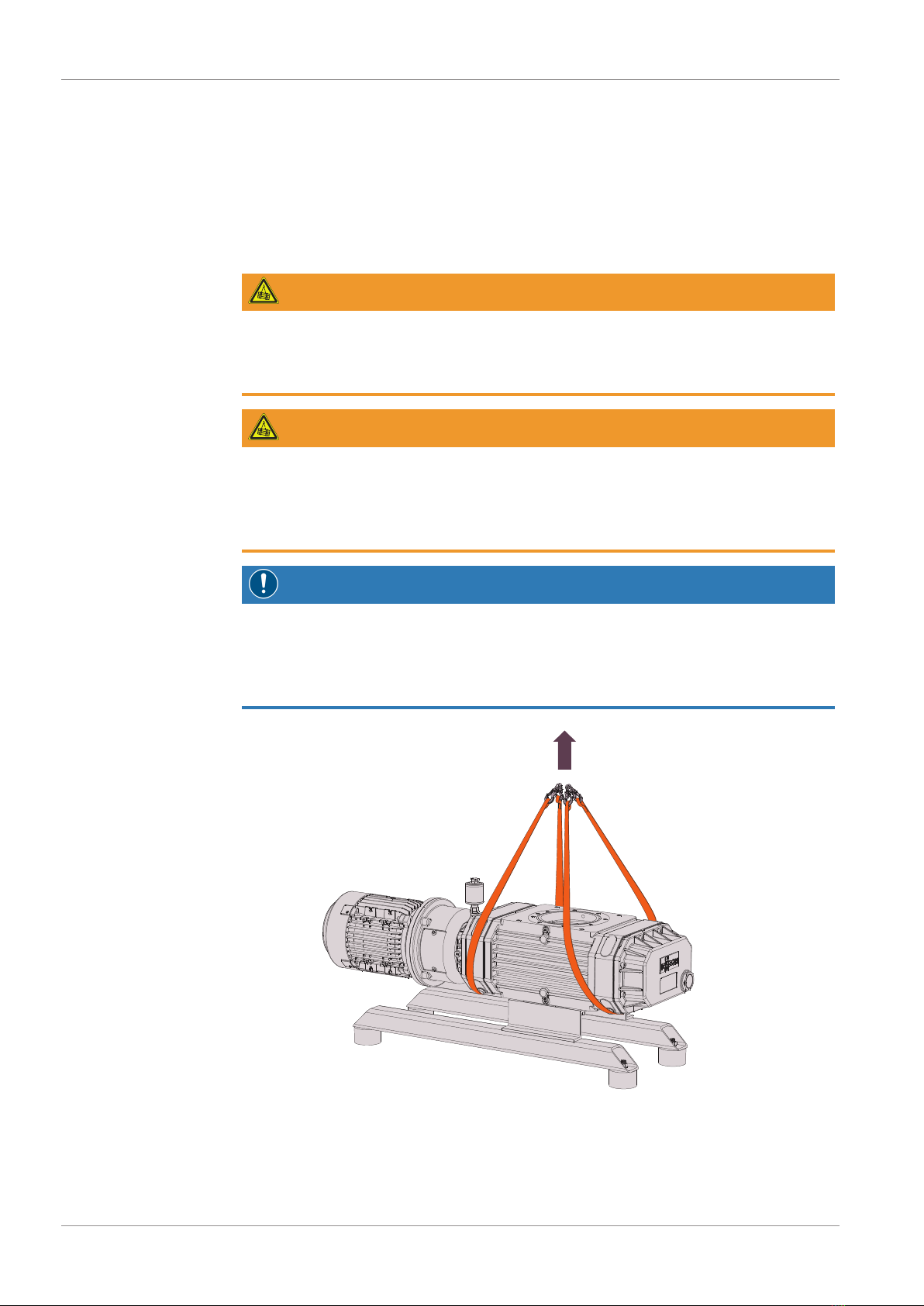

3 Transport ..................................................................................................................................6

4 Storage .....................................................................................................................................7

5 Installation................................................................................................................................7

5.1 Installation Conditions...................................................................................................... 7

5.2 Connecting Lines / Pipes .................................................................................................. 7

5.2.1 Gas Flow Variants.................................................................................................. 8

5.2.2 Suction Connection ............................................................................................... 8

5.2.3 Discharge Connection ........................................................................................... 8

5.2.4 Cooling Water Connection ....................................................................................9

5.3 Filling Oil.......................................................................................................................... 10

5.4 Electrical Connection ........................................................................................................ 11

5.4.1 Wiring Diagram Three-Phase Motor...................................................................... 12

6 Commissioning.........................................................................................................................13

7 Maintenance.............................................................................................................................14

7.1 Maintenance Schedule ..................................................................................................... 15

7.2 Oil Level Inspection.......................................................................................................... 15

7.3 Oil Colour Inspection ....................................................................................................... 16

7.4 Oil Change....................................................................................................................... 16

8 Overhaul...................................................................................................................................18

9 Decommissioning.....................................................................................................................19

9.1 Dismantling and Disposal ................................................................................................. 19

10 Spare Parts................................................................................................................................19

11 Troubleshooting .......................................................................................................................20

12 Technical Data..........................................................................................................................22

13 Oil ............................................................................................................................................22

14 EU Declaration of Conformity...................................................................................................23