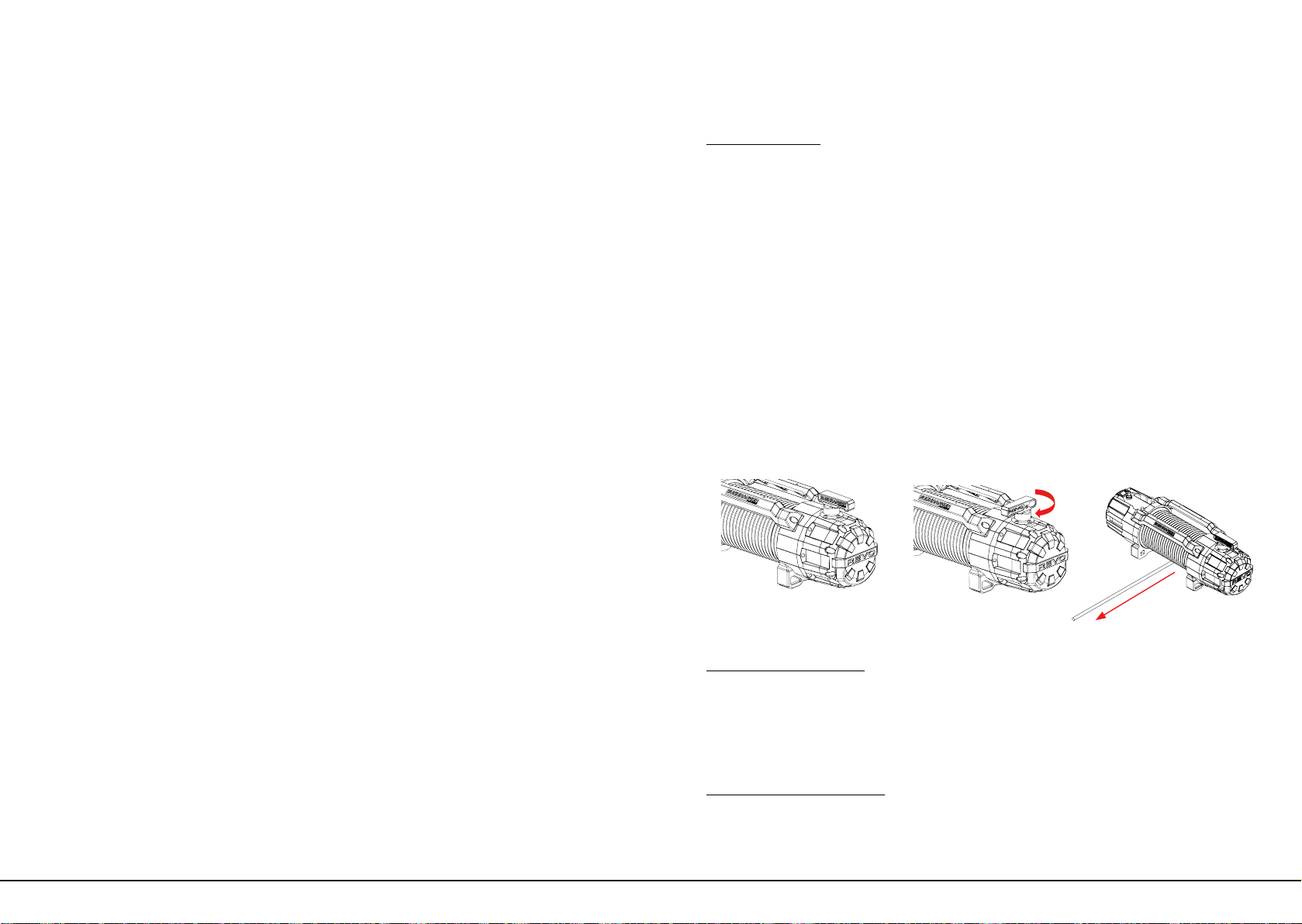

Cable-in/Cable-out Operation

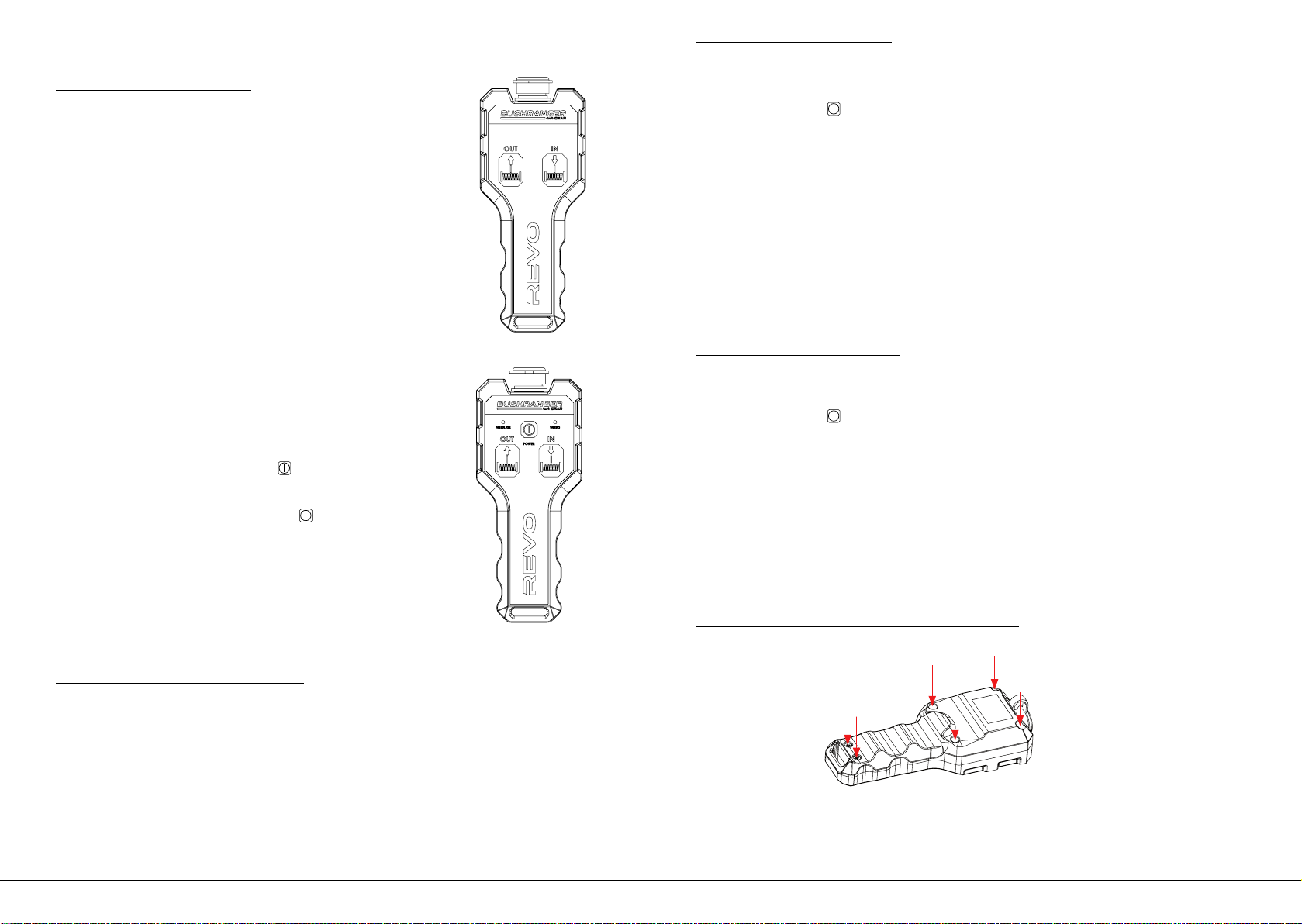

Wireless Hand Controller

Pairing of new Wireless Hand Controller

Wired Hand Controller

Connect Winch Hand Controller Cable

to Winch Control Box and to Hand Controller

Operating Procedure

To “Winch - Out”, Press and hold the “OUT” Button

To “Winch - In”, Press and hold the “IN” Button

To stop winching, releasing button.

The above operating procedure is the same for the Wireless

Hand Controller.

Activating Wireless Control

Press and hold the POWER Button ( ) for 3 seconds to

activate the Wireless Control. The WIRELESS light will

illuminate to indicate you are in WIRELESS mode. To turn

off,press and hold the POWER Button ( ) for 3 seconds

untilthe WIRELESS light turns off. The controller is also

equipped with an automatic power off function. If the

hand controller is not operated for 2 minutes it will turn off

automatically to conserve battery power.

The wireless hand controller can also be used in wired

Mode. When the cable is plugged in, the “Wired” light

will illuminate.

In the case of replacing a hand controller unit, or loss of pairing, a new controller

can be paired to the wireless receiver by following the steps below. If the wireless

receiver was previously paired to a hand controller, the previous pairing needs to

be cleared from the receiver memory rst.

Note: The wireless receiver is located in the control box and is usually wired into

the vehicles ignition system or on a separate switch (refer to the wiring diagram

on Page 10). Turn the key or ick the switch to turn the wireless receiver ON or OFF.

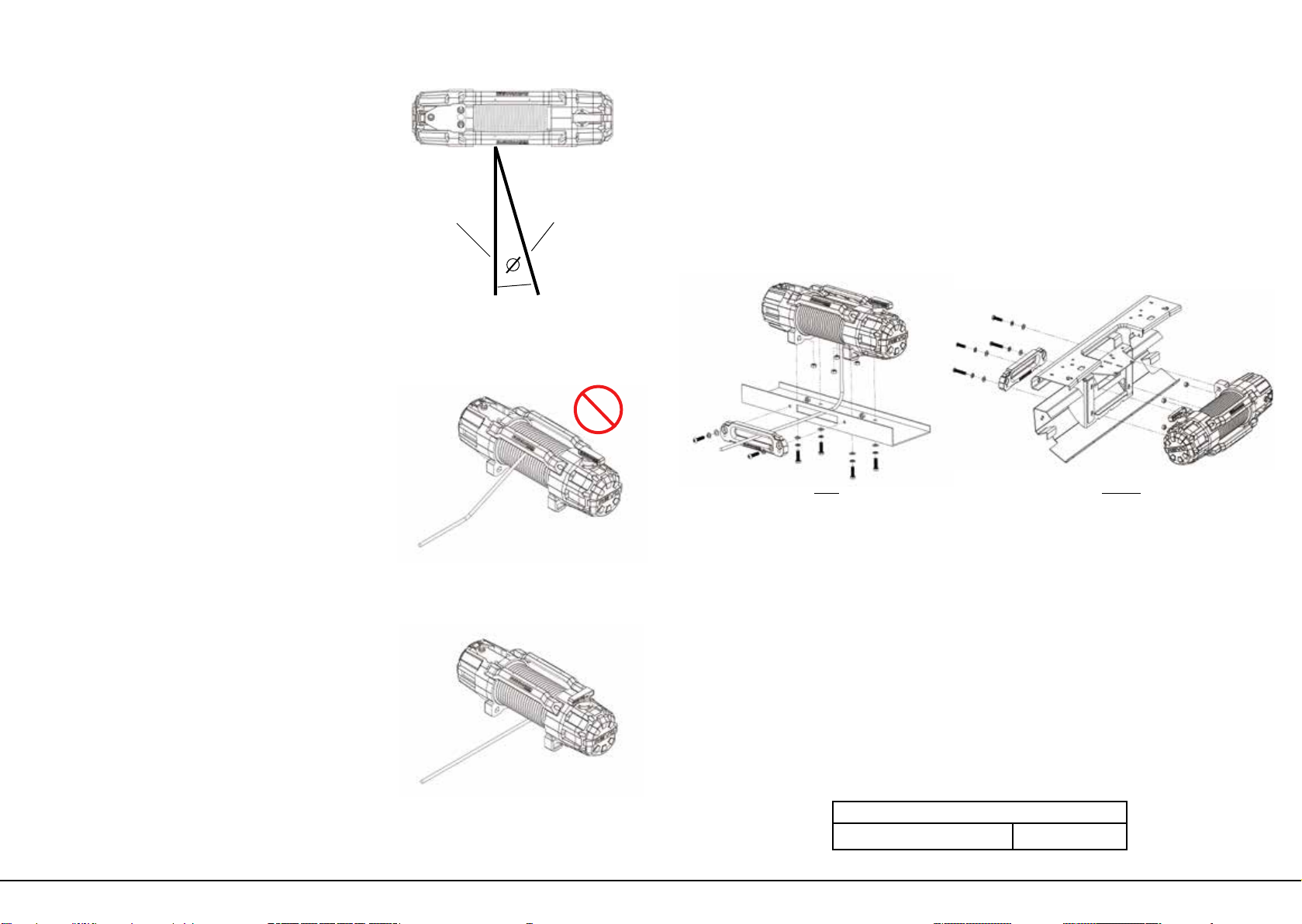

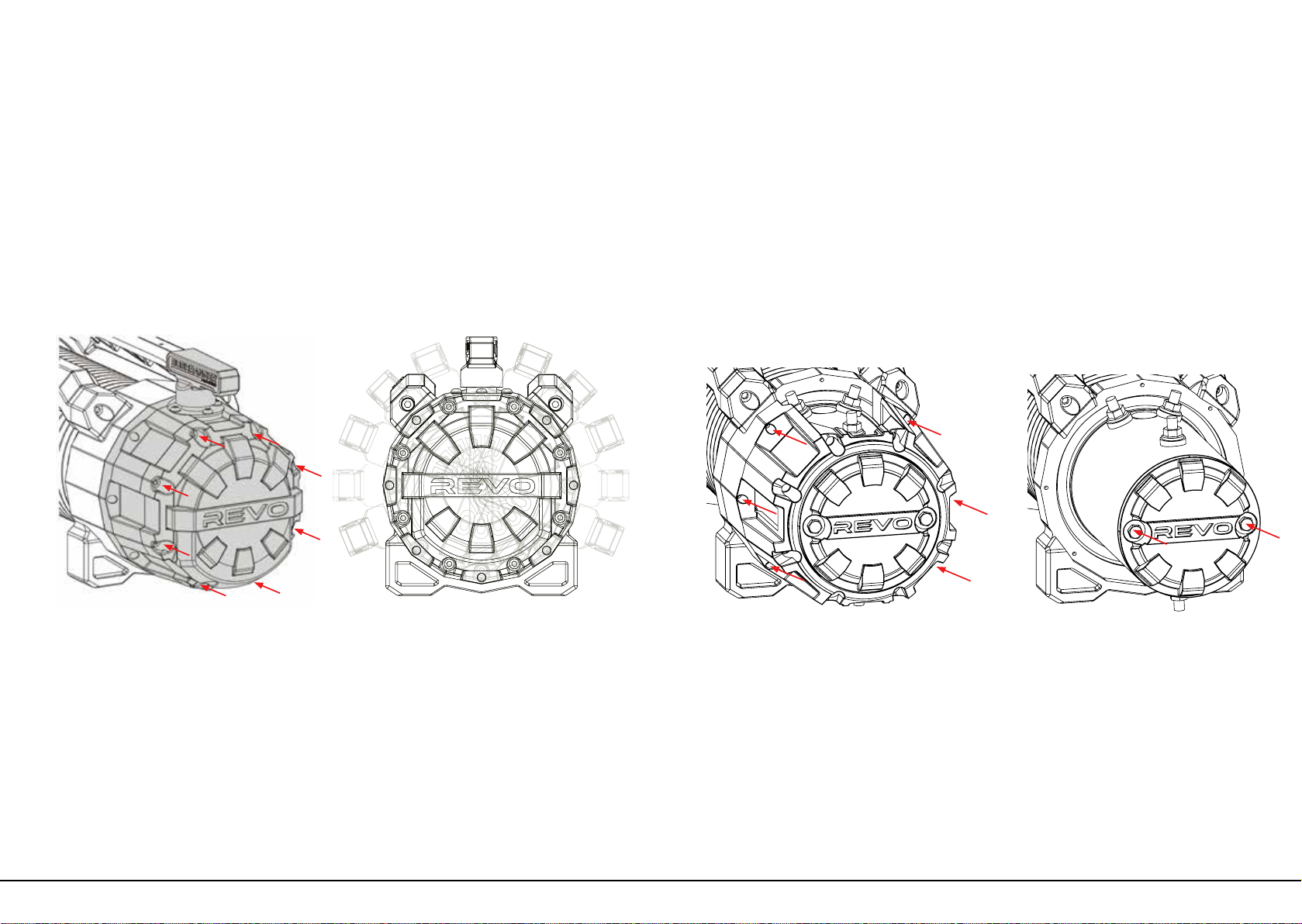

ISOMETRIC VIEW

N.T.S.

FLAT PATTERN

.

SCALE

ISOMETRIC VIEW

N.T.S.

FLAT PATTERN

.

SCALE

Pairing the new Hand Controller

Clearing the Receiver Memory

1. Ensure the new wireless hand controller is turned OFF

2. Turn on the new wireless hand controller in wireless mode by pressing and holding the

POWER button ( ) for 3 seconds.

3. Press and hold the “IN” and “OUT” buttons on the new hand controller at the same

time. While continuing to press both buttons, the following process will happen:

1. Ensure that the wireless receiver is turned OFF.

2. Turn on the new wireless hand controller in wireless mode by pressing and holding the

POWER button ( ) for 3 seconds.

3. Press and hold the “IN” and “OUT” buttons on the new hand controller at the same

time. While continuing to press both buttons, the following process will happen:

a. The “WIRELESS” green indicator light and “Wired” red indicator light

will illuminate solidly for 6 seconds.

b. The two indicator lights will then ash slowly.

a. The “WIRELESS” green indicator light and “Wired” red indicator light will

illuminate solidly for 6 seconds.

b. The two indicator lights will then ash slowly for another 6 seconds.

c. The two indicator lights will then disappear for another 6 seconds.

d. The two indicator lights will then start to ash quickly.

Changing battery in the WIRELESS Hand controller

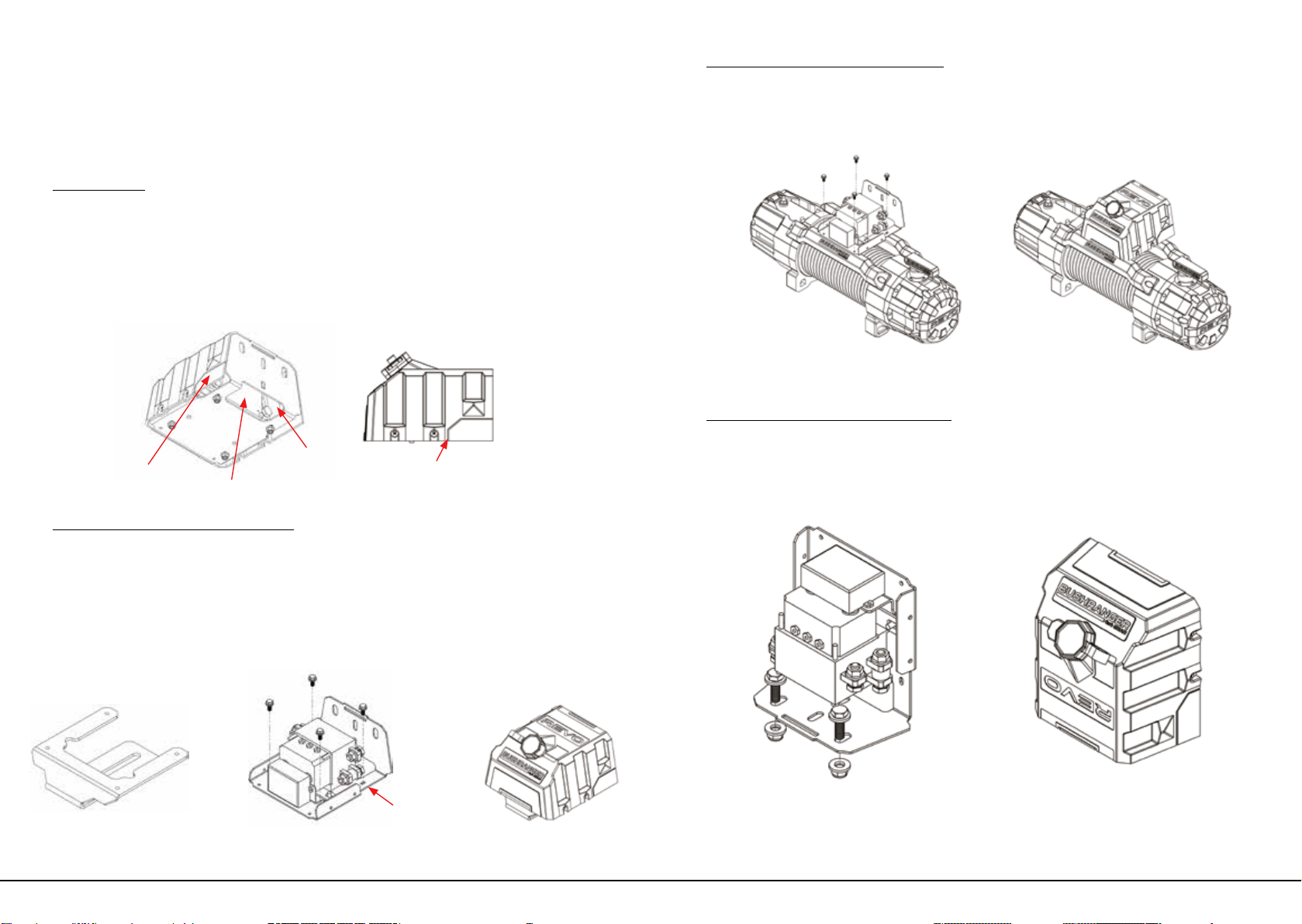

From the rear of the hand controller, remove the 6 screws as shown below.

Once the screws are removed, the rear half of the hand controller can be separated

allowing access to the battery. Replace the A23 battery and reassemble rear half of

hand controller. When reassembling the hand controller, ensure that the rubber seal is

aligned and not pinched. This will maintain the hand controller waterproof rating.

When the slow ashing begins, continue to hold the ”IN” and “OUT” buttons while

turning ON the wireless receiver. Keep pressing the “IN” and “OUT” buttons until the two

indicator lights disappear. Release the buttons and the hand controller is now paired.

When the quick ashing begins, continue to hold the ”IN” and “OUT” buttons while

turning ON the wireless receiver. Keep pressing the “IN” and “OUT” buttons until the two

indicator lights disappear. Release the buttons and the hand controller is now paired.

| REVO VEHICLE RECOVERY WINCH |REVO VEHICLE RECOVERY WINCH

Page 15 Page 16