WARNING

This press has been designed for general bending, toughening, axis and bearing extraction work etc.

Never use it for applications that should not be performed by a press. Always use the appropriate tool

for each specific task. Handle the press correctly and ensure that all parts and components are in good

condition and that no parts are missing prior to its use.

The press should only be used by authorized person should having read carefully and understood the

contents of this manual. particulary children, away from the working area.

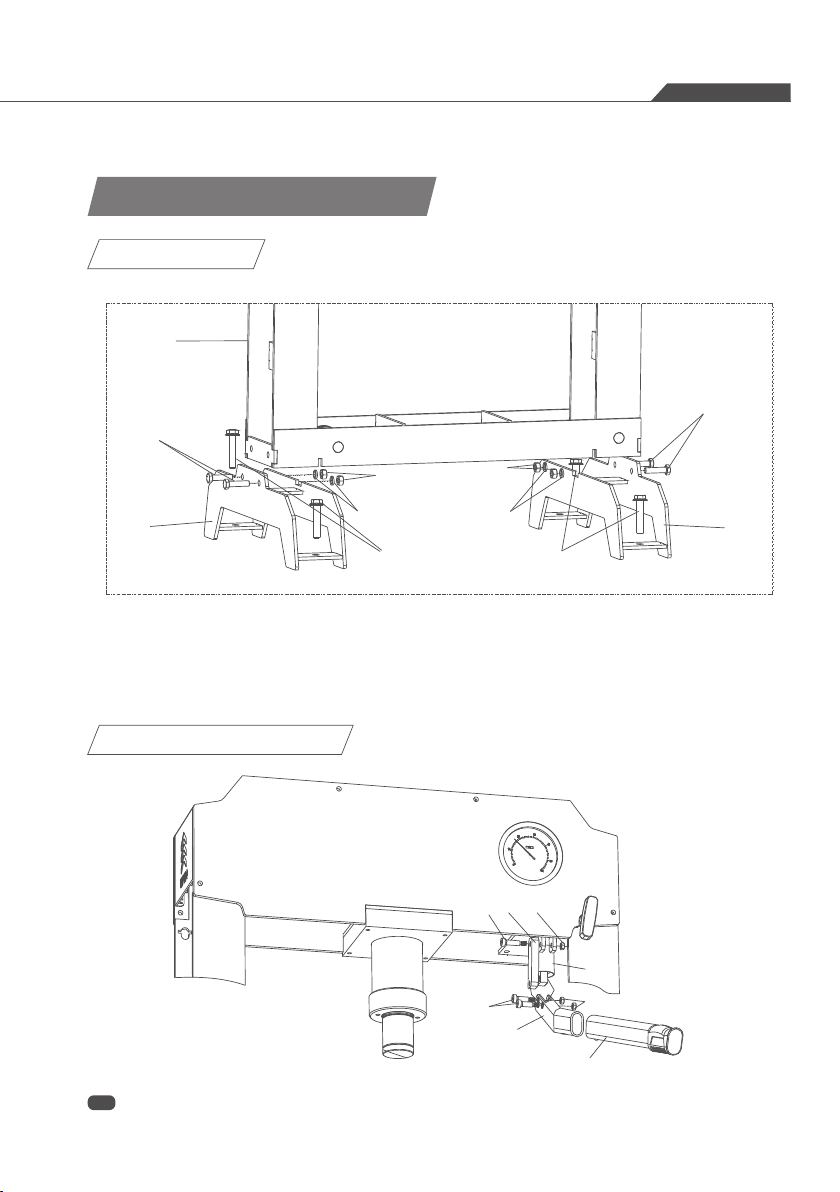

Always position the press against a wall. If the press is situated in the open workshop, it is essential

that a guard be placed at the rear of the unit. The press foot need to be amounted on the ground!

Make sure that the operator must wear protective cloth, gloves, safety helmet, shoes and ear protector

during operating. To avoid accidents, always be aware of any on-going work on the machine. Also,

always stay focused on the job to be done.

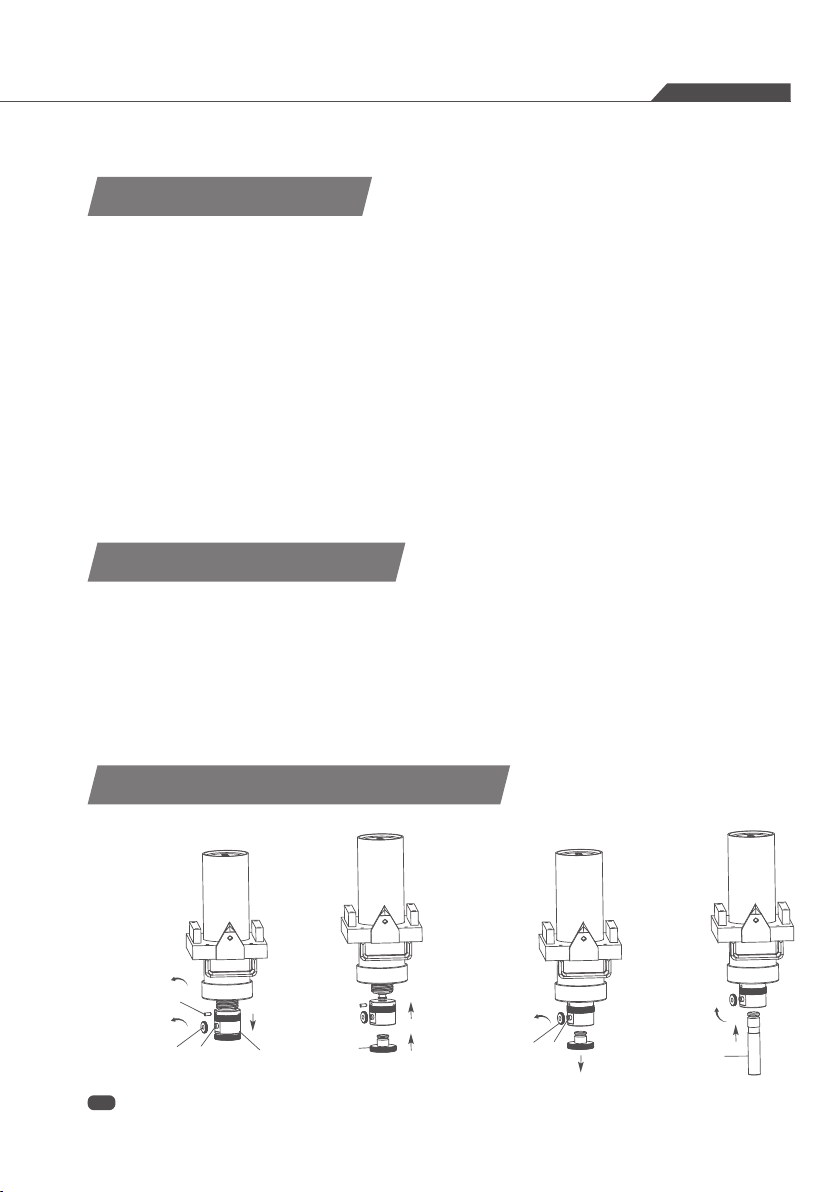

Do not modify the press in any way. Safety valve should not be tampered with under any circumstanc-

es.

Never exceed the rated capacity of the press and V-blocks.

Non-compliance with these instructions may result in injury or damage to the user, the press or the

piece being manipulated.

The manufacturer accepts no responsibility for the improper use of the press or the component

handled.

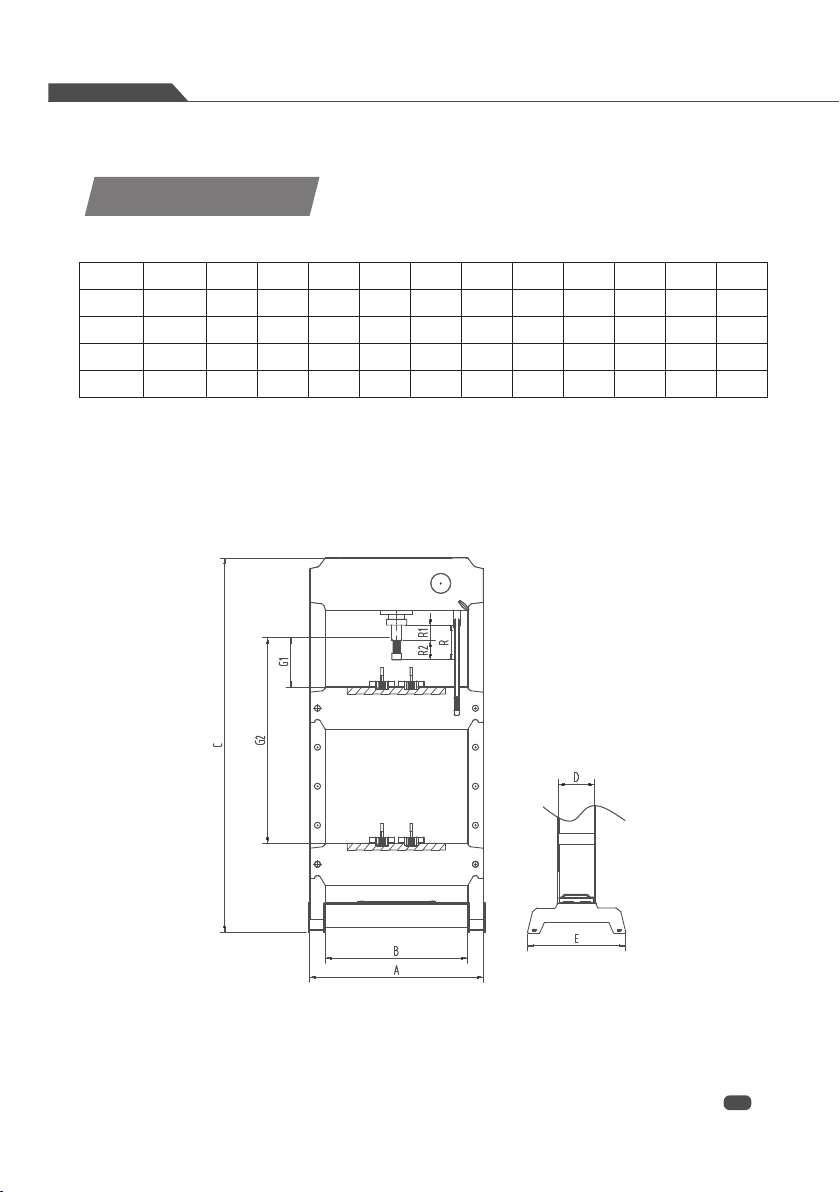

Item No.

SP-15HL

SP-20H

SP-20HAM

SP-30H

SP-30HM

SP-30HAM

SP-50HM

SP-50HAM

A

565

710

770

710

770

770

930

930

B

440

540

600

540

600

600

750

750

C

855

1800

1800

1800

1800

1800

1900

1900

D

134

134

152

134

148

148

200

200

E

355

505

505

505

505

505

535

535

G1

45

25

25

25

25

25

80

80

G2

340

850

850

850

850

850

780

780

R

170

220

220

220

220

220

220

220

R1

95

145

145

145

145

145

145

145

R2

75

75

75

75

75

75

75

75

M

200

/

200

200

280

280

/

Safety Instructions

WORKSHOP PRESSES

01

02

Technical Data

Capacity

15 Ton

20 Ton

20 Ton

30 Ton

30 Ton

30 Ton

50 Ton

50 Ton