RECOMMENDED HARDWARE

Hardware:

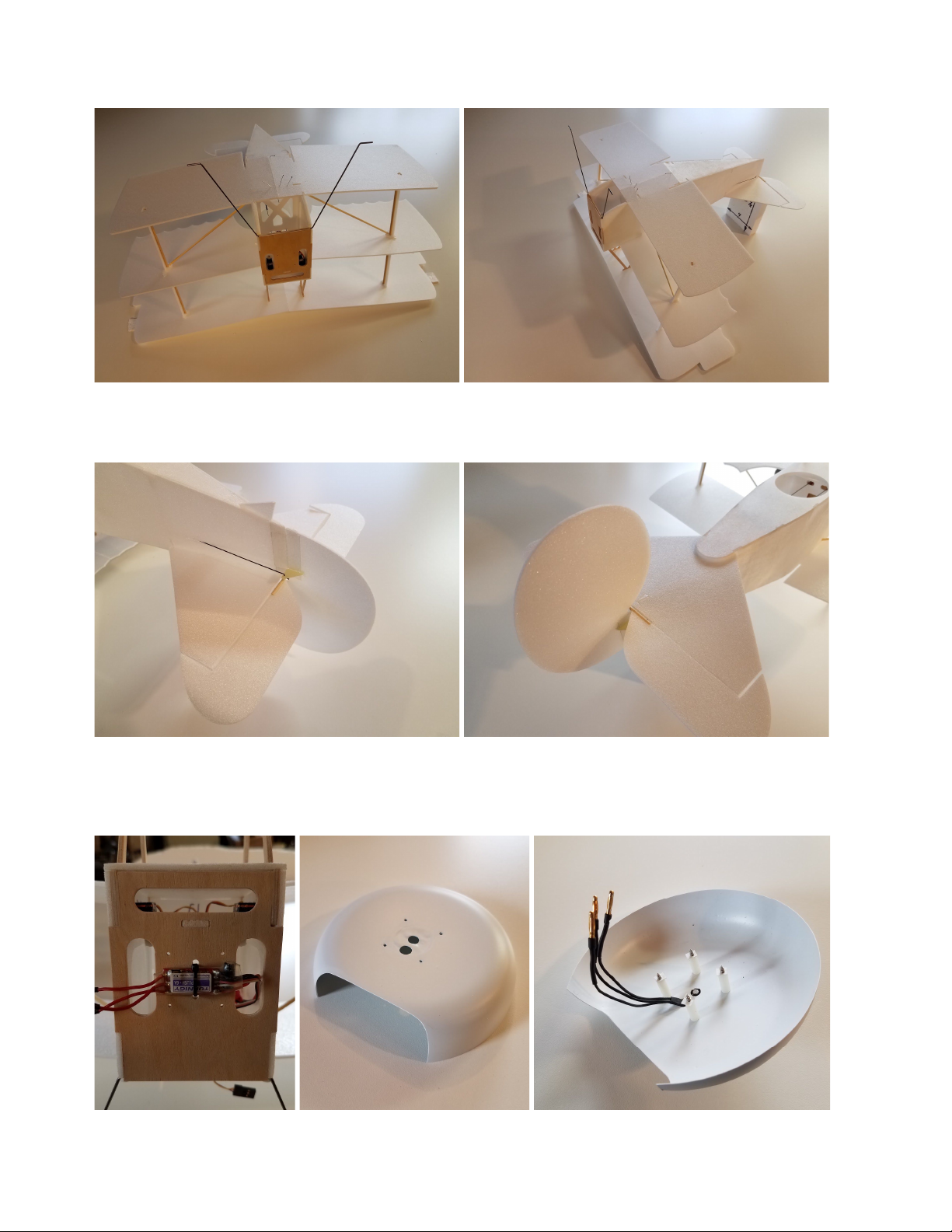

Motor: Any of the 250 series outrunner motors should work. Something in the 1000 to 2000kv range and around 15 to 20

grams in weight. You really want a low KV motor so you can swing a 9” or 10” prop.

Prop: A 9 or 10 inch prop with very low pitch, 3.7” or 3.8”

Speed control: Brushless 6-12 amp with BEC

Servos: Any micro servo around the 3.7 gram size.

Receiver: Needs to have at least three channels.

Battery: Any 2S lipo in the 400-600mah hour range.

Charger: Any charger that is capable of charging a small LiPo

battery

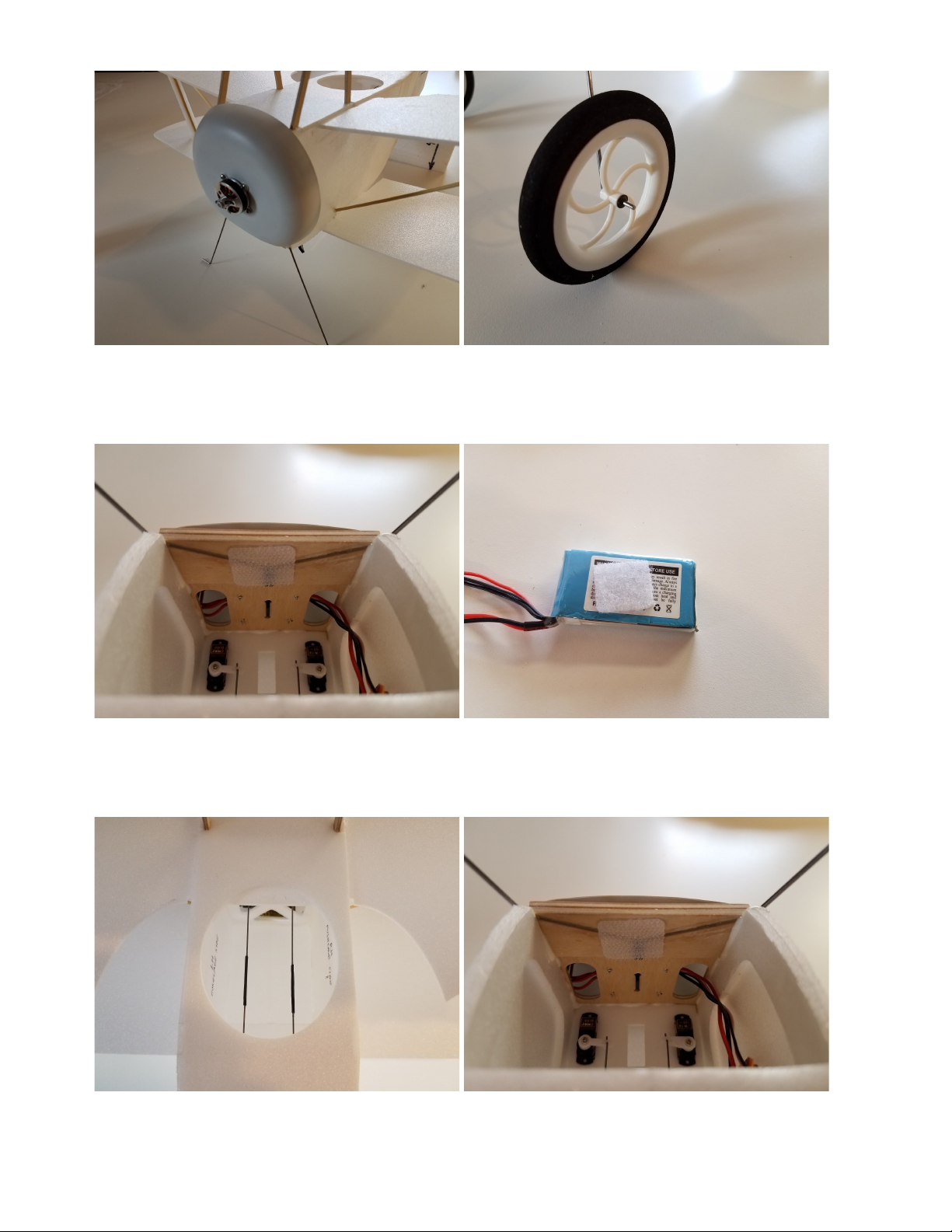

Transmitter: You will need at least three channels, throttle,

elevator, and rudder.

Transmitter setup: Refer to your transmitter’s instruction

manual for all settings.

1. Setup should result in 45 degrees of maximum

deflection for rudder and elevator.

2. Set exponential for rudder at 30%, and elevator at 50%.

Final Checklist:

1. Center of Gravity at between 25% and 33% behind leading edge of middle wing.

2. Check controls for proper direction and free movement.

3. Charge battery.

4. Range check transmitter, refer to transmitter instructions.

Flying Tips: The Fokkerish has a rather low wing loading and does not like much wind.

For your first flight, I would recommend flying either in a large indoor area such as a gymnasium, or wait for a dead

calm day outside. Once you get comfortable with the flying characteristics you will be able to fly in much smaller

areas, and outdoors in more wind.

8