BEFORE USE

1. Before using this product, read the instruction manual

completely and familiarize yourself thoroughly with the

product, its components and recognize the hazards

associated with its use.

2. Verify that the product and the application are compatible.

Inspect before each use. Do not use if bent, broken,

leaking or damaged components are noted.

3. Replace worn or damaged parts with BVA Hydraulics

authorized replacement parts only. Lubricate as

instructed in Maintenance Section.

4. Ensure method of confirming load is accurate and

working properly. Have gauge or load cell accuracy

verified by qualified personnel on a yearly basis.

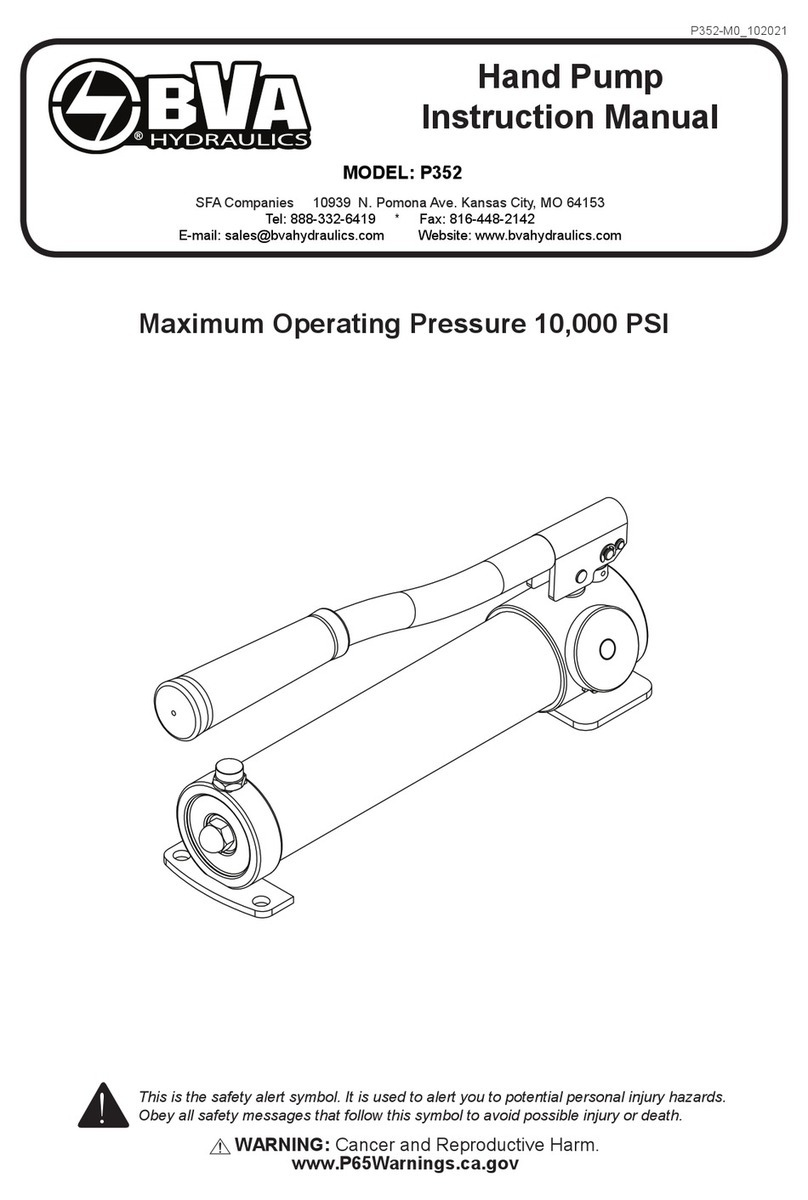

5. Turn the top cap of the vent screw counter-clockwise

to open the vent before use. Turn the cap clockwise to

close the vent screw when moving or storage.

4

Figure 3 - Turn the top cap counter-clockwise to

open the vent before use.

SETUP

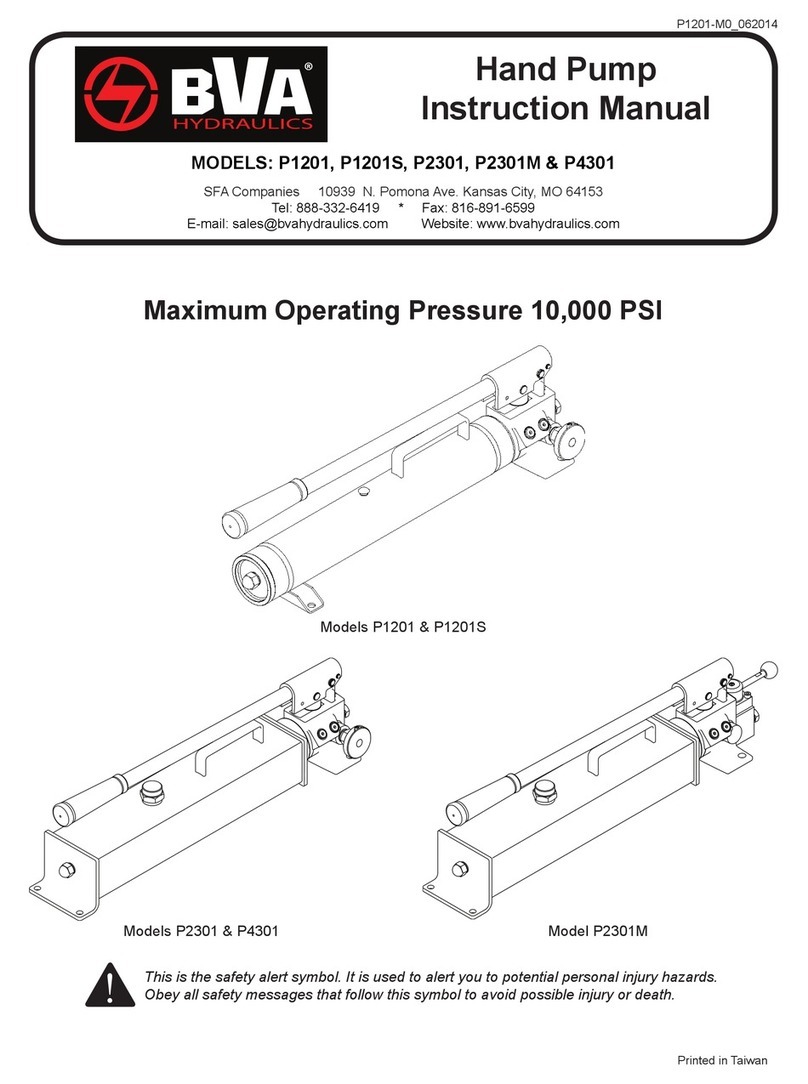

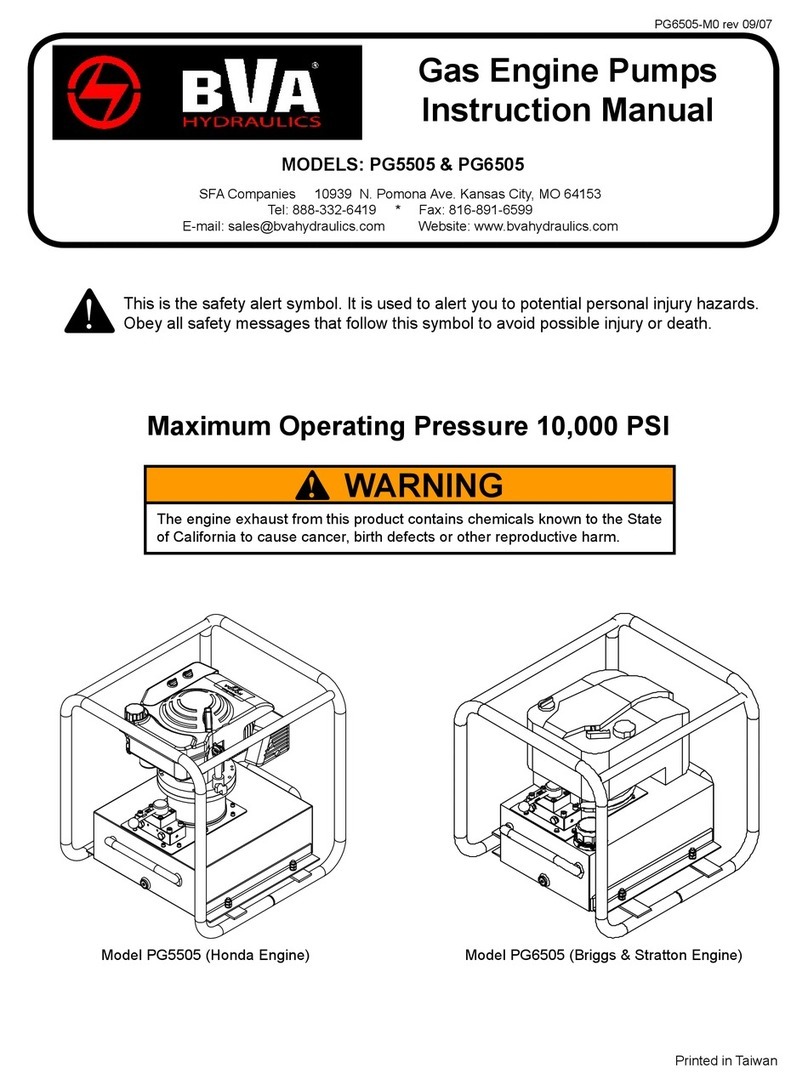

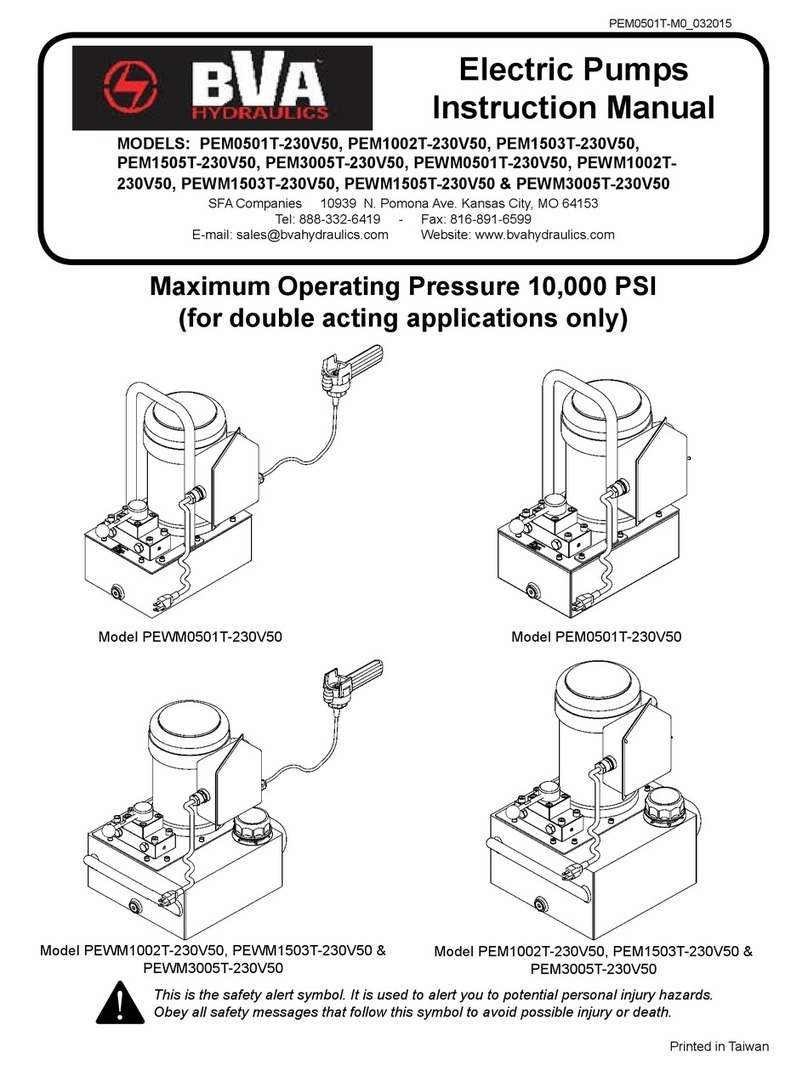

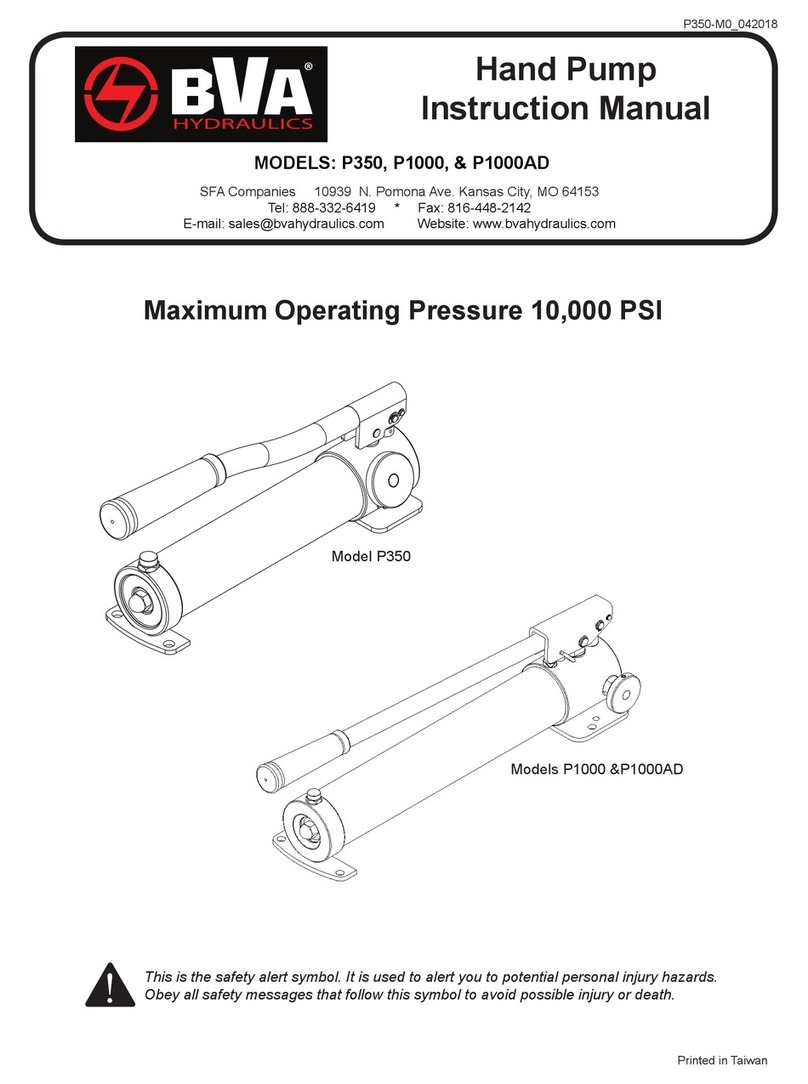

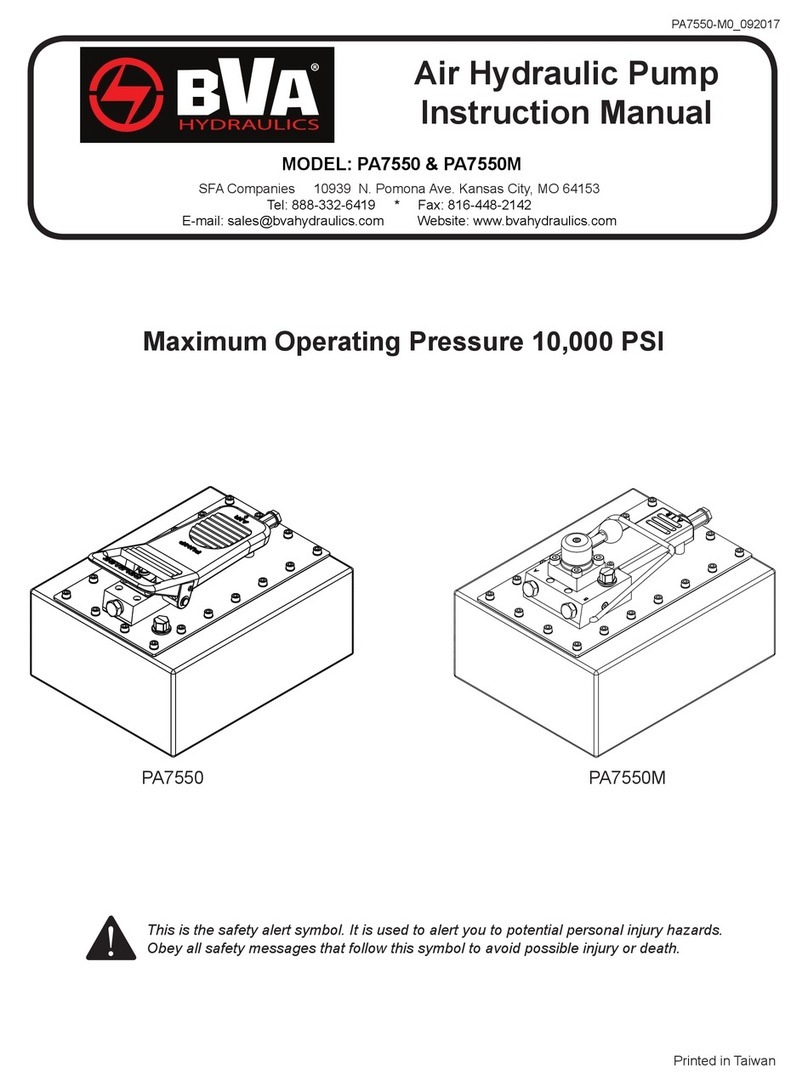

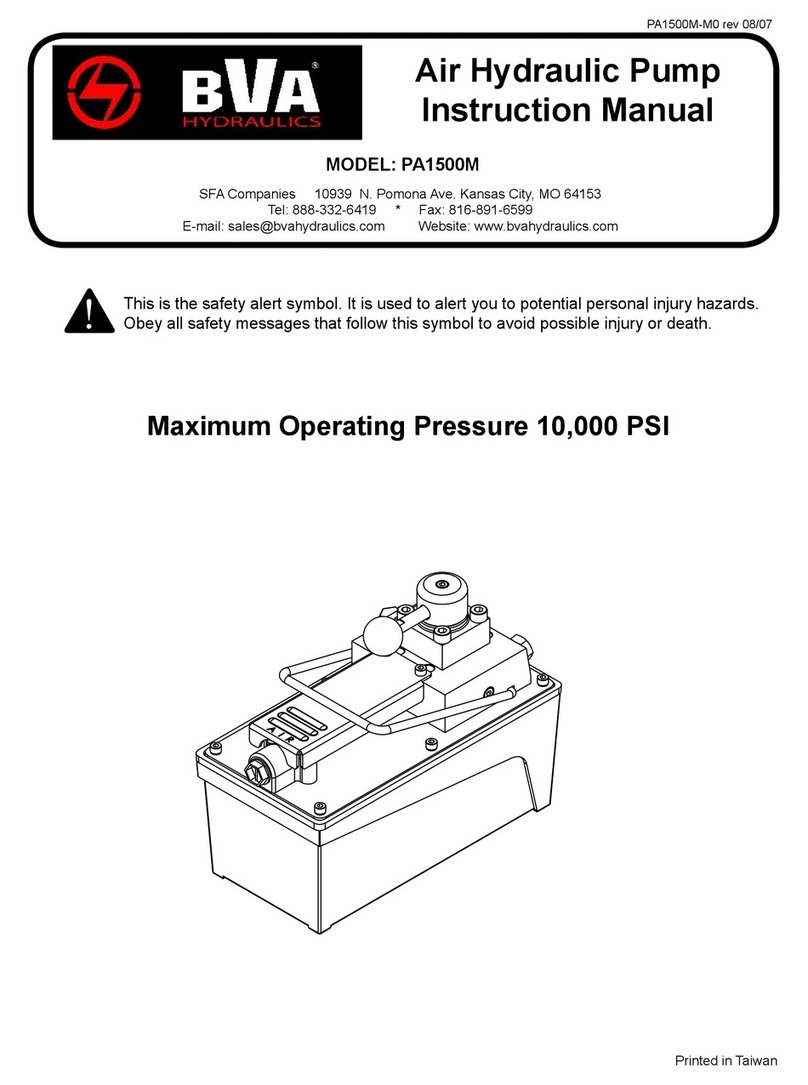

IMPORTANT: The pump’s maximum working pressure is

10,000 PSI. Make sure that all hydraulic equipment such

as cylinders, hoses, couplers and etc. used with this pump

are rated at 10,000 PSI operating pressure or more.

1. Depressurize system by opening release valve counter-

clockwise, but no more than 2 full turns. Then,

carefully

remove the threaded plug on oil outlet port, connect

3/8”NPTF hydraulic connection to oil outlet port, i.e.

coupler, hydraulic hose, fitting etc. Ensure all fluid ports

and thread connections are clean before connect.

Note: Always secure threaded connections with non-

hardening pipe thread compound. Take care not to introduce

compound into port orifices. Tighten securely to prevent

accidental removal of components while in use.

2. For model P8701M: The pump comes with a 4-way

valve to use with double acting cylinder. Connect two

hoses: connect one hose from the pressure port of the

pump to the pressure port of the cylinder; connect the

other hose from the retract port of the pump to the retract

port of cylinder.

If using on single acting cylinder, the valve needs to be

changed to 3-way valve. Consult BVA Technical service

888-332-6419.

3. Install a pressure gauge in-line from the pump for better

control and safety purpose.

4. Tighten securely to prevent accidental removal of

components while in use.

5. Check for leaks in system and have repaired by qualified

personnel as needed. Depressurize the hydraulic system

before servicing.

OPERATION

ALWAYS monitor pressure, load or position using

suitable equipment. Pressure may be monitored by

means of an optional manifold and gauge (contact BVA

Hydraulics). Load may be monitored by means of a load

cell and digital indicator. Correct application position can

only be determined by the operator of the equipment.

NEVER operate pump with release valve closed and

disconnected from application. If operated in this condition,

the hose and connections become pressurized. This

increases burst hazard. Damage may occur to pump and

its components.

1. Remove the threaded plug, then connect the pump to

suitable application.

2. Ensure the oil level is within 1/4” (6mm) of the vent screw

opening and the system fittings and connections are leak

free before operating the pump.

3. For model P8701:

A. Close release valve by turning it clockwise. Finger

tight ONLY. Using tools on release valve can

damage it and cause the pump to malfunction.

B. Pump handle until desired pressure, load or

position is reached.

C. Pressure will maintain until the release valve is

opened.

D. To retract application, turn the release valve knob

slowly counter-clockwise (never more than 2 full

turns).

4. For model P8701M:

Use the control valve knob to control the direction

of hydraulic oil flow, refer to Figure 4(a) on page 5.

Pump handle until desired pressure, load or position is

reached.

! WARNING: Operate double-acting cylinder only

when both hoses are connected to the pump. If one

coupler is left unconnected, high pressure will build

behind the coupler which could cause personal injury

and/or equipment damage.

Note: To use with 3-way setting shown in Figure 4(b) for

application such as single acting cylinder, please have

an authorized service center to change the valve to 3-

way valve. Consult BVA Hydraulics Technical Service

888-332-6419.

5. Under no load or 1st stage condition, the pump operates in

high flow for rapid advance. When load is contacted, the

pump will automatically shifts to the 2nd stage for building

pressure. When pump pressure reaches approximately

290 psi, you must momentarily stop pumping and raise

the handle to shift to the high pressure stage. After the

pump shifts, pumping takes less effort.

Note: Operate pump handle at slower speed during the

high flow 1st stage to ensure the pump deliver maximum

oil volume.

!

!

!