2XT-1200 Manual

Feature Description

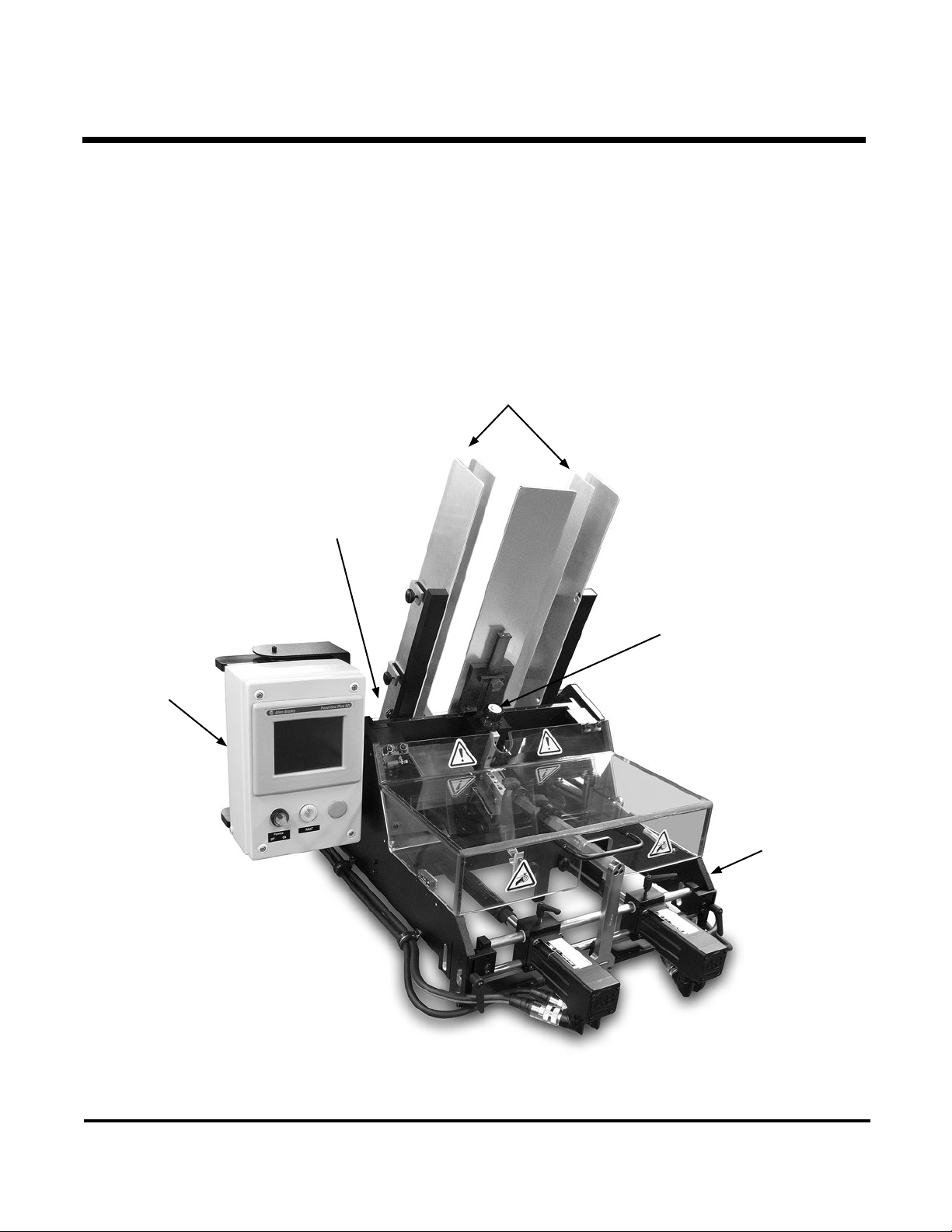

Main Assemblies Feature Descriptions

Gate assembly and adjustment Mounted on a gate plate assembly above the feed belt, this device provides a curvature to

help preshingle stacked product. When properly adjusted, a gap is created to help one piece of

product to be fed at a time.

Side guides and adjustments Holds a stack of product to be fed and helps keep it straight for proper entry through the gate

assembly area. Two adjustment knobs allows you to move each side guide together or apart for

different size product. Can be positioned equally or offset.

Back wedge assembly Lifts the product to keep it off the belt to reduce excessive contact, and helps push the product

against the curvature of the gate assembly. To achieve proper lift, an adjustment knob allows

you to slide the wedge to various positions along the feed belt.

HMI All operator functions, including Ready, Cycle Feeder, Fault Reset, Speed, Stop, Cycle,

Batch Size, and Jog are controlled at this location.

Dropper assembly Consists of two driven "star" ns (ns), the dropper assembly accumulates product, then

rotates to drop the batch and ready for the next feed cycle.

NOT SHOWN:

Hold-down assembly Used to gently force the product onto the discharge belt so it can be controlled after it exits the

gate assembly area. The proper amount of downward pressure is automatically adjusted based

on the gate setting.

Back stop and knock-down The backstop and knockdown in the dropper assembly provide the product control necessary

to manage each piece of product as it enters the dropper.

Control Panel The control panel contains all the controls to manipulate the feeder. See Feeder Control Panel

Overview page.

Stand The stand supports the feeder.

Locking Casters The locking casters provide easy mobility and the ability to lock the feeder into place next to the

printer.

O-Ring Belts The o-ring belts provide support for the edges of the product in the discharge area.