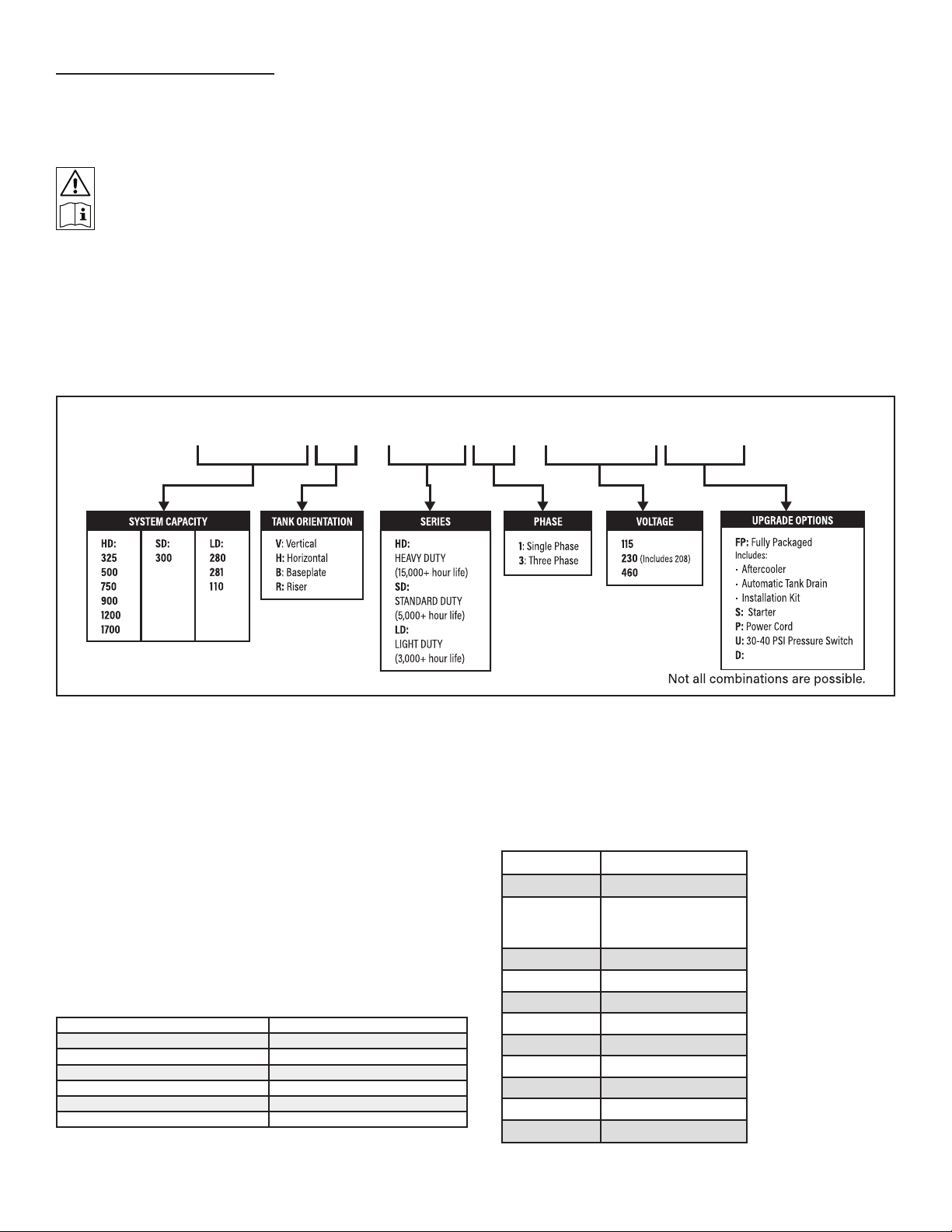

5

START UP

NOTE: There is no need to “break-in” your compressor� It has been tested and run at the factory by qualified personnel�

When operating the compressor for the first time, do the following:

1�Perform an inspection of the compressor to ensure there are no obstructions that might interfere with moving parts�

2�Release any remaining tank pressure by slowly opening the manual drain valve on the bottom of the tank (see parts identification 8)�

3�Connect the compressor to the power source (the compressor will start)�

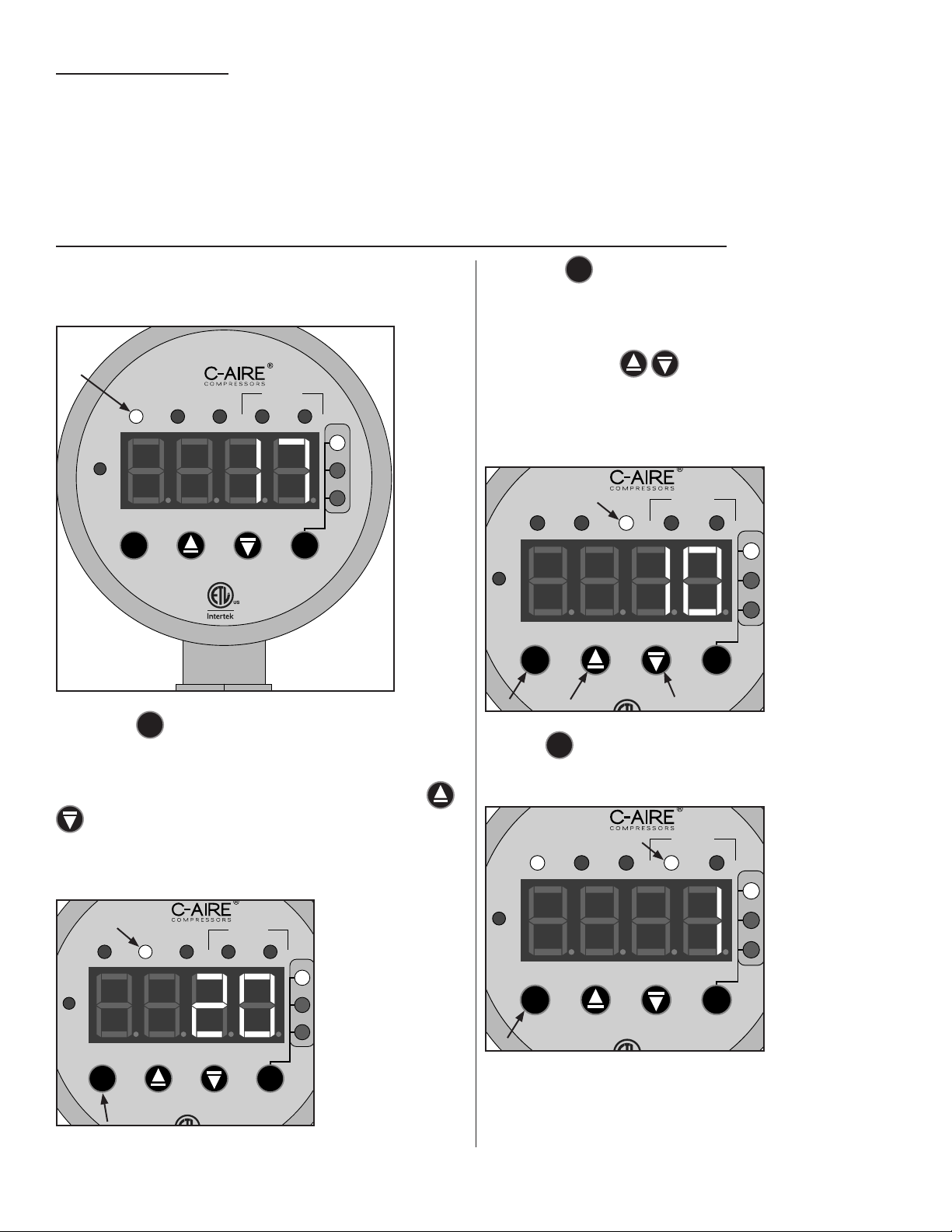

DIGITAL AMD OPERATING INSTRUCTIONS FOR S33 MODEL

This Digital AMD has 5 different modes of operation� When it is

powered on, it starts in the RUN mode and will display the current

pressure�

RUN MAX MIN

PSI

kPa

BAR

24HRS 7 DAY S

STARTS

SETTTINGS

LOCKED

C

PM

C

Pressing the

M

mode button once will switch it to the maximum

pressure setting, (or the pressure at which the compressor turns

off)� At this point you are able to adjust the maximum/turn off

pressure� When the MAX indicator is on, the arrow buttons

can perform a +1/-1 change to the set value� The

compressor will not run in this mode� If the compressor remains

in this mode for 60 seconds with no adjustments, it will

automatically revert back to the RUN mode� Range: 10-55 PSI�

RUN MAX MIN

PSI

kPa

BAR

24HRS 7 DAY S

STARTS

LOCKED

PM

Pressing the

M

mode button a second time will switch it to the

minimum pressure mode, this is the minimum pressure the

system will reach before it turns on� At this point you are able to

adjust the minimum/turn on pressure� When the MIN indicator is

on, the arrow buttons can perform a +1/-1 change to

the set value� If the compressor remains in this mode for 60

seconds with no adjustments, it will automatically revert back to

the RUN mode� Range: 5-50 PSI� Note: the upper and lower

limits have a minimum differential of 5 PSI�

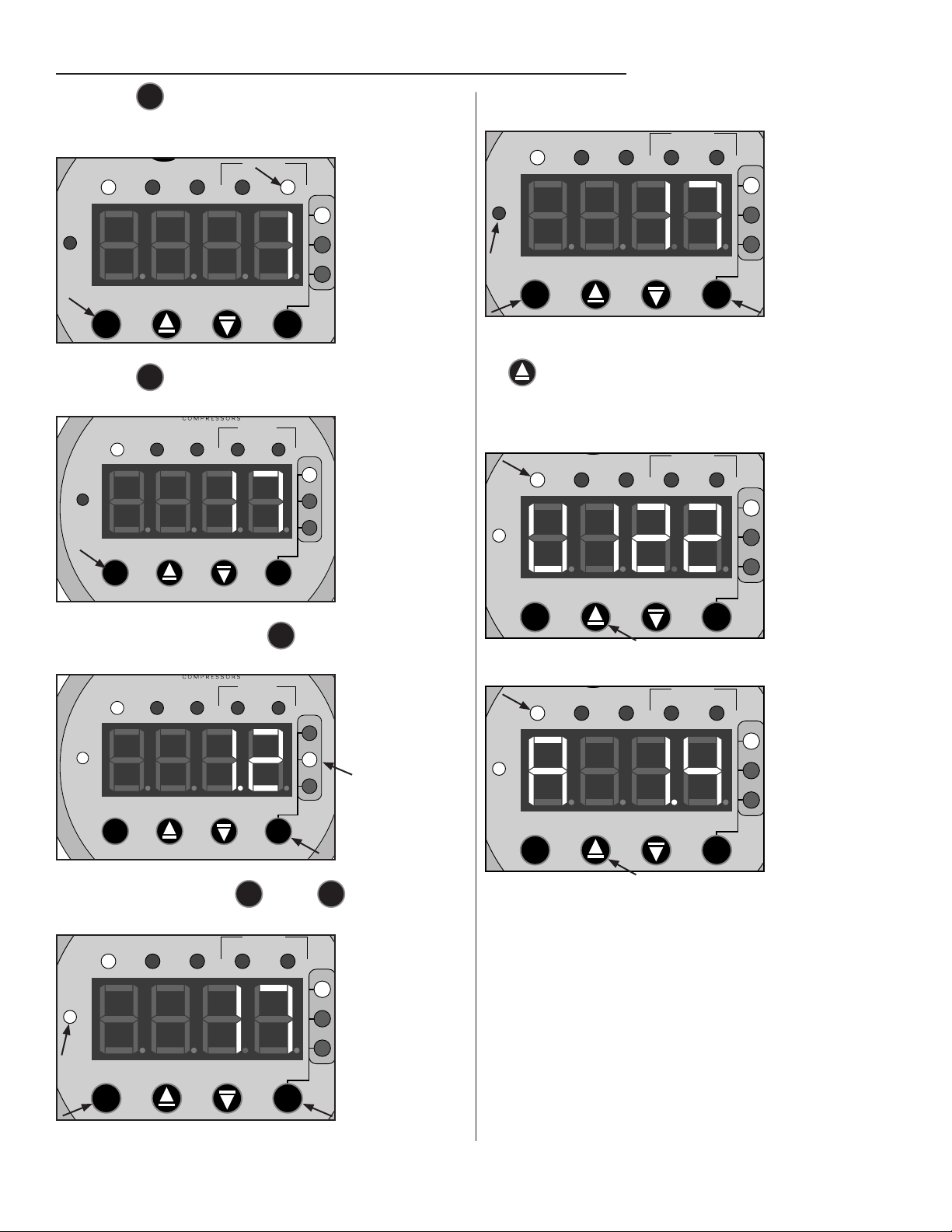

RUN MAX MIN

PSI

kPa

BAR

24HRS 7 DAY S

STARTS

LOCKED

PM

Press the

M

mode button a third time and the 24HRS indicator

will display the total number of starts in the last 24 hours (The

counter will not measure time if the unit has no power)�

RUN MAX MIN

PSI

kPa

BAR

24HRS 7 DAY S

STARTS

LOCKED

PM

(DIGITAL AMD INSTRUCTIONS CONTINUED ON NEXT PAGE)