2

SYSTEM 2316E/2316EC Installation Manual

FCC Notice

This equipment complies with FCC Rules, Part 68.

On the outside of this equipment is a label that contains, among other infor

mation, the FCC Registration Number and Ringer Equivalence Number (REN)

for this equipment. If requested, provide this information to your telephone

company.

The REN is useful to determine the quantity of devices you may connect to

your telephone line and still have all of those devices ring when your number

is called. In most, but not all areas, the sum of the RENs devices should not

exceed five (5.0). To be certain of the number of devices you may connect to

your line, as determined by the REN, you should call your local telephone

company to determine the maximum REN for your calling area.

Should you experience trouble with the telephone lines, disconnect the equip

ment from the line to determine the source of the trouble. If it is determined

that the equipment is malfunctioning, discontinue its use until the malfunc

tion has been corrected. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telephone company

Industry Canada

NOTICE: The Industry Canada label identifies certified equipment. This certi

fication means that the equipment meets telecommunications network pro

tective, operational and safety requirements as prescribed in the appropriate

Terminal Equipment Technical Requirements documents. The Department

does not guarantee the equipment will operate to the users satisfaction.

Before installing this equipment, users should ensure that it is permissible to

be connected to the facilities of the local telecommunications company. The

equipment must also be installed using an acceptable method of connection.

The customer should be aware that compliance with the above conditions

may not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative des

ignated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications

company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground con

nections of the power utility, telephone lines and internal metallic water pipe

system, if present, are connected together. This precaution may be particu

larly important in rural areas.

Caution: Users should not attempt to make such connections themselves,

but should contact the appropriate electric inspection authority, or electri

cian, as appropriate.

NOTICE: The Ringer Equivalence Number (REN) assigned to each termi

nal device provides an indication of the maximum number of terminals al

lowed to be connected to a telephone interface. The termination on an inter

face may consist of any combination of devices subject only to the require

ment that the sum of the Ringer Equivalence Numbers of all the devices does

not exceed 5.

This Class B digital apparatus meets all requirements of the Canadian Inter

ference Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

IC Certification: 1140 9153 A

Ringer Equivalence: 0.5

Table of Contents

Subject Page No.

FCC Notice 2

Industry Canada 2

Introduction 3

UL Compliance 3

Zone Programming 3

European Compliance 3

Installation 3

Mounting 3

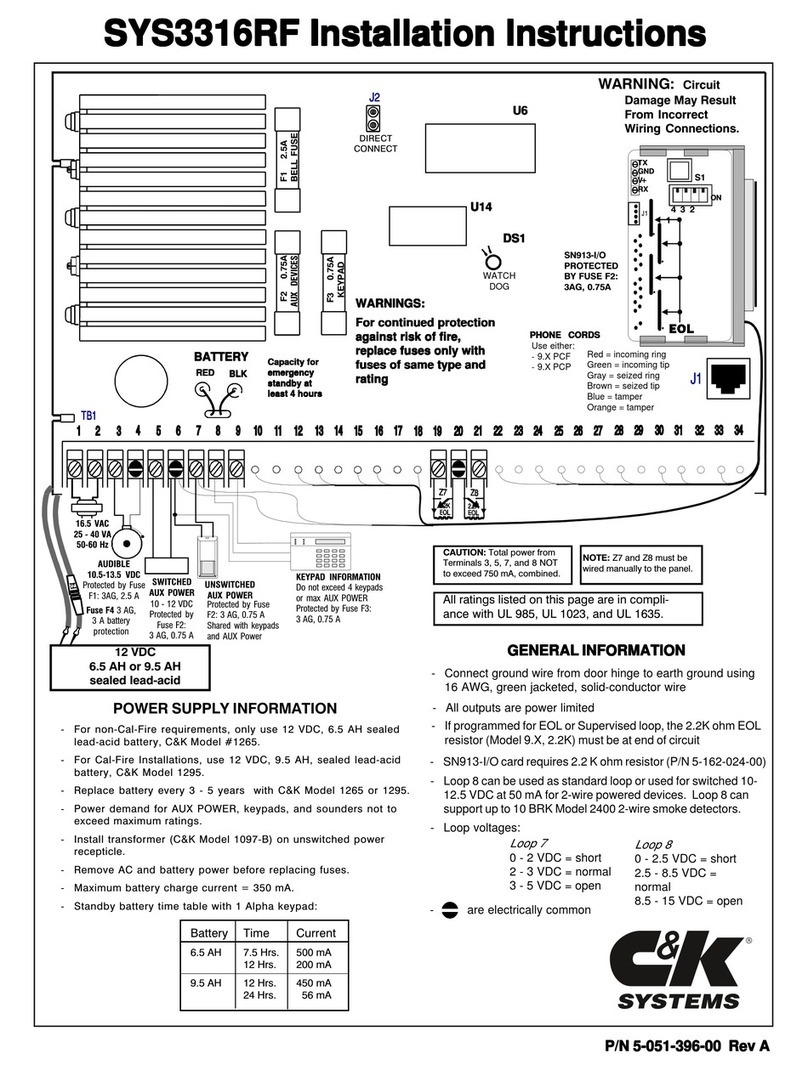

System 2316E Terminal Label 4

System 2316EC Terminal Label 5

Before You Start 6

Wiring the Panel 6

Standby Battery 6

AC Power (System 2316E) 6

AC Power (System 2316EC) 6

Audible Output 6

Setting Up the 2350 SUP 6

Auxiliary Power (Switched and Unswitched) 7

Arming Stations 7

Loop Inputs 8

Tamper Switch Installation 8

Telephone Interface 9

System Start Up 9

Standby Battery Time 9

Voltage Variations 9

Factory Settings 9

Default Program Setup 9

Programming Options (Alphabetical List) 10

Programming the Panel 10

Starting Panel Programming 10

Programming with the LED Plus Keypad 10

Programming with the Alpha Plus Keypad 11

Programming Hexadecimal Numbers 11

End of Programming Segment 11

Programming the Alpha Plus Keypad 11

Keypad Message Programming 11

Programming Options (Numerical Order) 12

End User Information 24

Testing 24

To the Installer 24

Telephone Line Problems 24

Watchdog Indicator 24

Limitations of Your Alarm System 24

Keypad Operation Command Summary 25

Survey of Most Common Questions 26

Recommendations for Reducing False Alarms 28

Programming Worksheets 30

cause to request the user to disconnect the equipment. Repairs to this equip

ment should be made by an authorized agent of C&K Systems, Inc. Contact

your local alarm installation company for service.

Should this equipment cause harm to the telephone network, the telephone

company may temporarily discontinue your service. If possible, they will pro

vide you with advance notice. Otherwise they will notify you as soon as pos

sible. The telephone company will also advise you of changes in its facilities,

equipment, operations or procedures which could affect the operation of your

equipment, allowing you the opportunity to maintain uninterrupted service.

You will also be advised of your right to file a complaint with the FCC.

This equipment must not be used on party lines or coin operated phone lines.

FCC Part 15 Notice

This equipment has been tested and found to comply with the limits for Class

B digital devices, pursuant to Part 15 of the FCC Rules. These limits are de

signed to provide reasonable protection against harmful interference in a resi

dential installation.

This equipment generates, uses, and can radiate radio frequency energy,

and if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guaran

tee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television re

ception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient the radio/television antenna;

Connect the AC transformer to a different outlet so that the equipment and

radio/television are on different branch circuits;

Relocate the equipment with respect to the radio/television;

Consult the dealer or an experienced radio/television technician for help.

FCC Registration Number: C2DCHN 25602 AL E

Ringer Equivalence: 0.67B