3

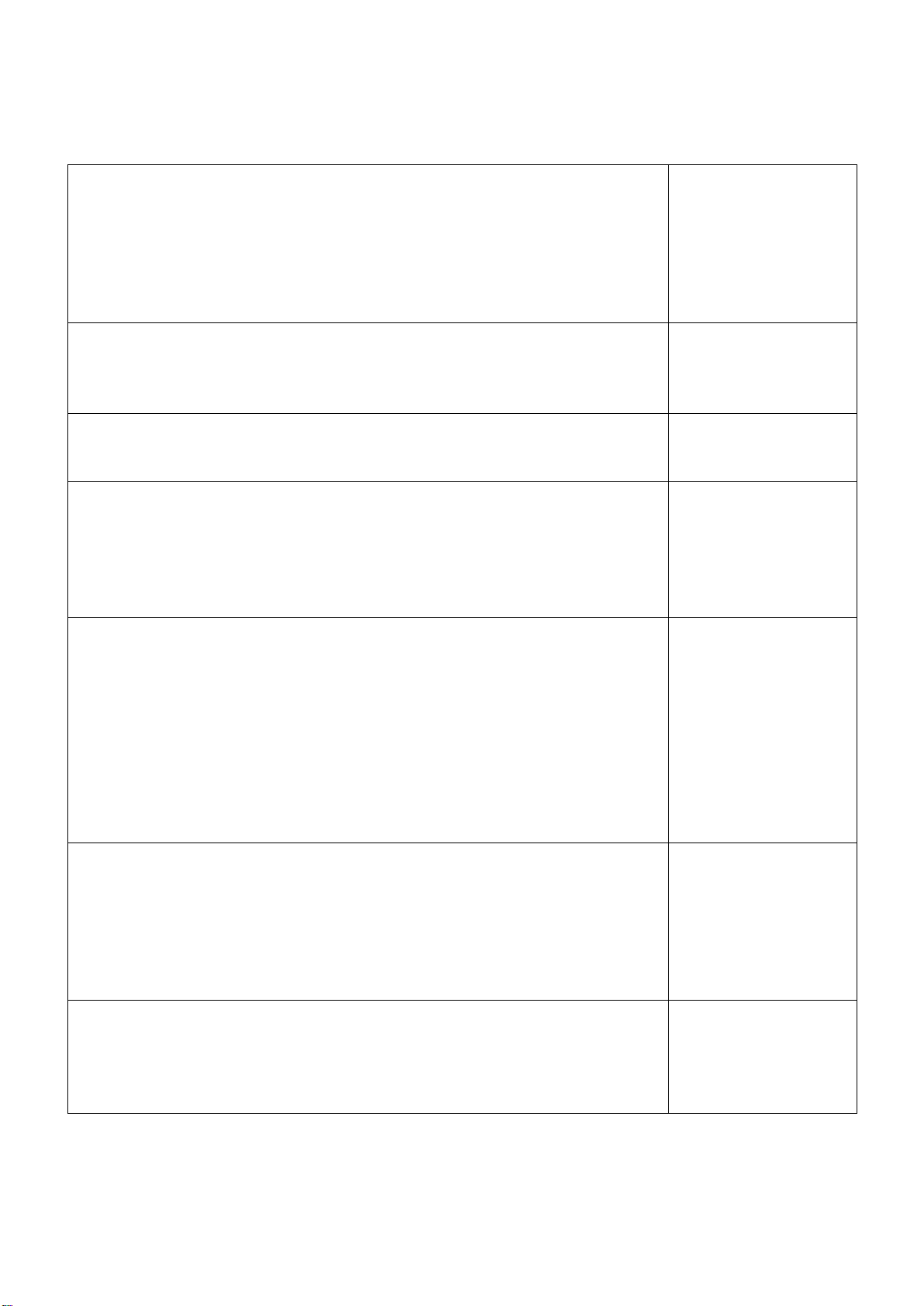

Table of Content

1. Introduction..................................................................................................... 4

2. Safety Manual.................................................................................................. 8

2.1 Installation..................................................................................................... 9

2.2 User/Operator...............................................................................................11

2.3 During process/operation...............................................................................12

2.4 Maintenance .................................................................................................15

3. Main Parts 1 ...................................................................................................16

4. Main Parts 2 ...................................................................................................17

4.2 Carriage clamp ..............................................................................18

4.3 Starting plate/Milling height adjustment ..........................................19

4.4 Milling system ...............................................................................20

4.6 Hot-melt glue tank.........................................................................22

4.7 Binding system..............................................................................25

4.8 Vacuuming unit .............................................................................27

5. How to use the machine..................................................................................28

5.1 Control Panel of the Lamibind 2000 EVA PLC...................................................29

5.1.1 Adjustment of heating zone.........................................................31

5.1.2 Adjustment of the binding time....................................................32

5.1.3 Adjustment of the carriage clamp open distance...........................33

5.1.4 Switching ON/OFF the milling system...........................................33

5.1.5 Book cycle/Job counter ...............................................................34

5.1.6 Change binding mode .................................................................34

5.1.7 Information when the machine is ready to use .............................34

5.1.8 Cover sensor ON/OFF .................................................................35

5.1.9 Book block positioning ................................................................35

5.1.10 Automatic mode .......................................................................36

5.1.11 Glue cut-off ..............................................................................36

6. Instruction manual ..........................................................................................37

6.1 Getting ready to run the job...........................................................39

7. Upkeep of the bookbinder machine ..................................................................41

8. Error codes.....................................................................................................42