EACIE Evacuation Alert Control and Indicating Equipment

Page 3 of 38 Approved Document No. DFU5030020 Rev 1 Installation and Programming Manual

7.4.1 Device Manager ....................................................................................................................................23

7.4.2 Show PSU Status ...................................................................................................................................... 25

7.4.3 Test Output Group ..................................................................................................................................25

7.4.4 Show Loop Status.................................................................................................................................... 25

7.4.5 Find Loop Break ......................................................................................................................................26

7.4.6 Change Access Level 2 (AL2) Code..................................................................................................... 26

7.4.7 Change Access Level 3 (AL3) Code..................................................................................................... 26

7.4.8 Show System Details ............................................................................................................................... 26

7.4.9 Clean Start ..............................................................................................................................................26

7.5 COMMISSIONING FUNCTIONS ..................................................................................................................27

7.5.1 Loop Learn ..............................................................................................................................................28

7.5.2 Auto Address........................................................................................................................................... 28

7.5.3 Fix Address Faults ....................................................................................................................................29

7.5.4 Verify Loop .............................................................................................................................................. 29

7.5.5 Device Manager .................................................................................................................................... 29

7.5.6 Add New Device .................................................................................................................................... 29

7.5.7 Add/Delete/Edit a Device..................................................................................................................... 29

7.5.8 Edit Zone Name ......................................................................................................................................30

7.5.9 Edit Output Group Name....................................................................................................................... 30

7.5.10 Setup Networking ................................................................................................................................... 30

7.5.11 Synchronise Network Data..................................................................................................................... 30

7.5.12 Set Loops Fitted....................................................................................................................................... 30

7.6 EVENT LOG FUNCTIONS..........................................................................................................................31

7.7 SET THE PANEL’S TIME AND DATE..........................................................................................................32

7.8 SHOW SUPERVISORY EVENTS .................................................................................................................32

8MAINTENANCE......................................................................................................................................33

APPENDIX 1 –PROTECTIVE CABINET AND EACIE PANEL DIMENSIONS ........................................34

APPENDIX 2 –EACIE PANEL PROGRAMMING MODULE ...................................................................34

APPENDIX 3 –STANDBY BATTERY CALCULATION.............................................................................35

APPENDIX 4 –FITTING THE 2-LOOP PCB (OPTIONAL).......................................................................35

APPENDIX 5 –EACIE PANEL TECHNICAL SPECIFICATION..............................................................36

APPENDIX 6 –GLOSSARY OF TERMS.......................................................................................................37

Figures

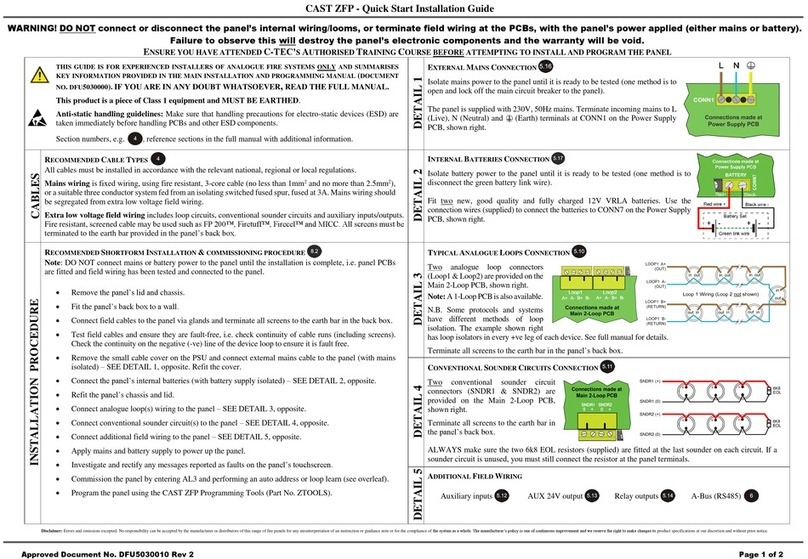

Figure 1 –Typical EACIE Panel PCB Connections...............................................................................................7

Figure 2 –Location of EACIE Panel Components.................................................................................................9

Figure 3 –Protective Cabinet and EACIE Panel Mounting Location ..................................................................10

Figure 4 –Protective Cabinet Wall Mounting and EACIE Panel Fitting .............................................................11

Figure 5 –Typical EAS Loop Overview..............................................................................................................14

Figure 6 –Analogue Addressable Loop Connections ..........................................................................................15

Figure 7 –Relay Output Detail.............................................................................................................................16

Figure 8 –PC Connection.....................................................................................................................................16

Figure 9 –5A PSU Layout and Mains Connection Details ..................................................................................17

Figure 10 –Battery Connection Details ...............................................................................................................18

Figure 11 –Access Level 3 Menu Structure.........................................................................................................21

Manufacturer: Computionics Limited (C-TEC), Challenge Way, Martland Park, Wigan, Lancashire WN5 0LD. www.c-tec.com