CONTENTS

EN54 Compliance Statement.............................................................................................................. 3

Basic Overview & Key Features ......................................................................................................... 3

Important Notes .................................................................................................................................. 4

The Fire Panel Enclosure .................................................................................................................... 5

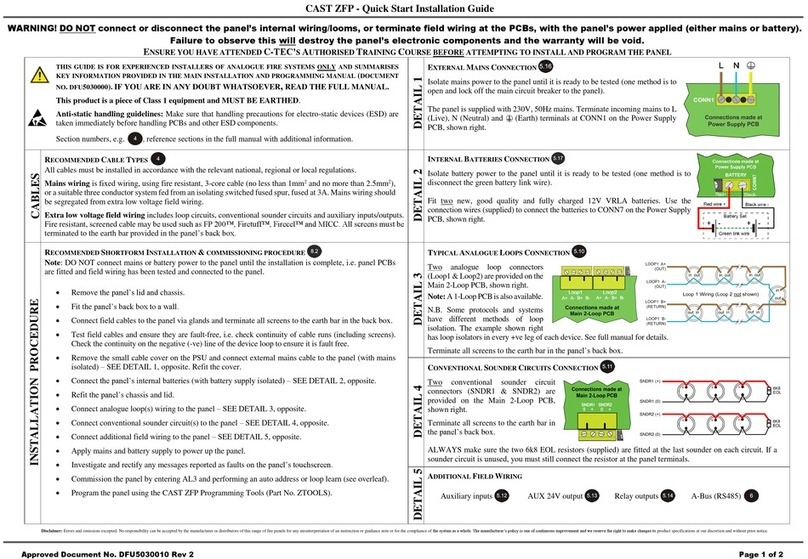

First Fix.......... .......................................................................................................................................6

Cable types and limitations............................................................................................................................. 6

Mains wiring..................................................................................................................................................... 6

Planning the cable layout in the panel.......................................................................................................... 6

Fixing the base onto a wall ............................................................................................................................ 7

AlarmSense™ zone circuit wiring .................................................................................................................. 7

Typical conventional sounder circuit wiring ................................................................................................. 8

Important sounder loading and distribution information .......................................................................... 8

Typical auxiliary input wiring ......................................................................................................................... 8

Typical auxiliary output wiring ...................................................................................................................... 9

Second Fix ......................................................................................................................................... 10

Connecting the panel .................................................................................................................................... 10

Installing the Power Supply PCB................................................................................................................... 10

Connecting the Mains.................................................................................................................................... 10

Connecting the standby batteries ................................................................................................................ 10

Installing the Main Control PCB.................................................................................................................... 12

Connecting the zone circuits and conventional sounder circuits............................................................... 13

Connecting the auxiliary inputs, auxiliary outputs and relay outputs....................................................... 13

Programming the Panel ................................................................................................................... 14

An overview of the panel’s controls ............................................................................................................ 14

Engineer functions......................................................................................................................................... 14

Accessing the engineer controls ................................................................................................................... 16

Programming coincidence, non-latching zones, delays, test, sounder status ...................................... 16-17

Fault Diagnosis ................................................................................................................................. 18

Fault indications ............................................................................................................................................ 18

Zone faults...................................................................................................................................................... 19

Power supply faults........................................................................................................................................ 19

System faults .................................................................................................................................................. 21

Repeater faults............................................................................................................................................... 22

Conventional sounder faults......................................................................................................................... 22

Remote output faults .................................................................................................................................... 22

Maintenance ..................................................................................................................................... 22

Standby Battery Calculation Guide ................................................................................................. 23

Technical Specification ...................................................................................................................... 24

INSTALLATION & MAINTENANCE MANUAL • Approved Document No. DFU7002020 Rev 4 • Page 2 of 24

LPCB APPROVED CFP ALARMSENSE 2/4/8 ZONE FIRE ALARM PANEL

Errors & Omissions Excepted. The manufacturer of this product operates a policy of continuous improvement and reserves the right to alter product

specifications at its discretion and without prior notice. All of the instructions covered in this manual have been carefully checked prior to publication.

However, no responsibility can be accepted by the manufacturer for any inaccuracies or for any misinterpretation of an instruction or guidance note.

Manufacturer: Computionics Limited (C-TEC), Challenge Way, Martland Park, Wigan, Lancashire WN5 0LD. www.c-tec.com

Niederlassung Deutschland: C-TEC Germany Limited, Virchowstr. 32, D-33332 Gϋtersloh. www.c-tec-germany.de