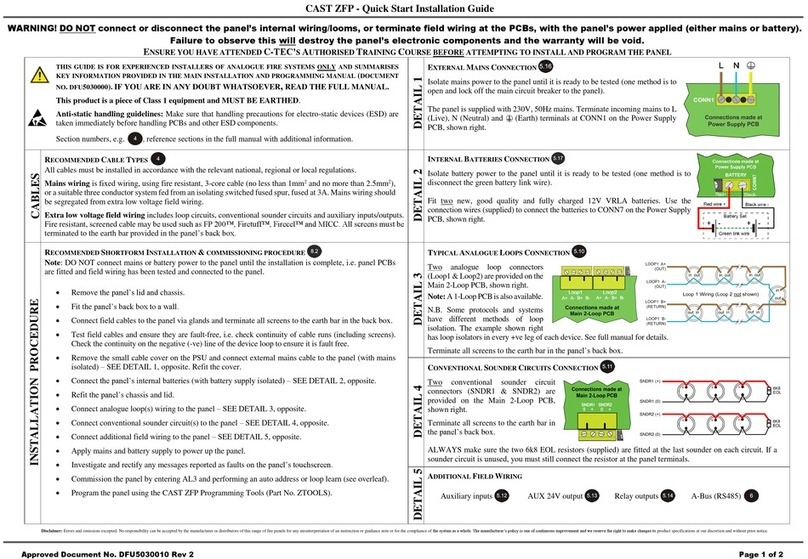

IMPORTANT NOTES

This equipment MUST only be installed and maintained by a suitably skilled and

technically competent person. Ensure you have attended C-TEC’s Authorised Training

Course before handling the panel.

This equipment is a piece of Class 1 permanently connected equipment and MUST BE EARTHED.

CAUTION: DO NOT connect or disconnect the panel’s internal wiring / looms, or terminate

field wiring at the PCBs, with the panel’s power applied (either Mains or battery). Failure to

observe this WILL destroy the panel’s electronic components and the warranty will be void.

Items supplied with this panel

• Engineering manual (Document No. DFU5010000). This manual MUST NOT be left accessible to the user.

• User Manual / Log Book (Document No. DFU5020000)

• Key for unfastening / securing the panel lid

• Electrical accessory pack containing:

6K8 0.25W EOL resistors for the two conventional sounder circuits

T 1A H 250V 20mm ceramic fuse (spare primary fuse)

1.6A F 20mm ceramic fuse (spare battery fuse)

Battery connection kit (red wire, black wire, green link wire and cable ties)

System design

Fire alarm system design is beyond the scope of this document. A basic understanding of general fire

alarm system components and their use is assumed. Contact the Fire Officer concerned with the property

at an early stage in case there are any special requirements. We strongly recommend that a suitably

qualified and competent person is consulted regarding the design of the fire alarm system and that

the system is commissioned and serviced in accordance with the laid down specification and national

standards. In the UK, we recommend you read BS 5839: “Fire Detection and Alarm Systems for Buildings

(Code of Practice for System Design, Installation, Commissioning and Maintenance)”. Other national, or

local standards of installation should be referenced where applicable.

Cable types and limitations

All system wiring should be installed to meet national standards - in the UK these are

BS 5839 Part 1 and BS 7671 (Wiring Regulations). Fire-resistant, screened cable should be used

throughout the installation. For network wiring 2-core screened, enhanced fire-resistant cable is

recommended. This not only shields the data moving through the cables from outside interference but

is essential to ensure compliance with EMC regulations. Cables such as FP200, Firetuf, Firece and MICC

may be acceptable provided they meet national standards / the system specification.

EN54 Compliance Statement

This fire alarm panel is fully compliant with the requirements of EN54 Part 2 (Fire detection and fire alarm

systems, control and indicating equipment) and EN54 Part 4 (Fire detection and fire alarm systems, power

supply equipment) and is certified as meeting these standards by the Loss Prevention Certification Board

(LPCB) - unless stated.

Note that some of the engineer functions provided on the panel go beyond the scope of EN54-2.

A caution symbol (left) is used to indicate where such a function is non-compliant with EN54-2.

DO NOT affix the LPCB approval label (supplied) to the front of the panel if it has been configured to

operate in a way that would make it non-compliant with the requirements of EN54-2.

Equipment guarantee

This equipment is NOT guaranteed unless the complete installation is installed and commissioned in

accordance with the laid down national standards (in the UK this is BS 5839: Part 1) by an approved

and competent person or organisation.

Anti-static handling guidelines

Always observe appropriate electro-static handling guidelines before handling the panel’s

PCBs, or any other static-sensitive components.

ENGINEERING MANUAL • Approved Document No. DFU5010000 Rev 4 • Page 3 of 48

CAST XFP 16 ZONE ANALOGUE ADDRESSABLE FIRE ALARM PANEL

Read these instructions thoroughly before installation and operation

General Warning Sign Danger Electrical Hazard

Symbols